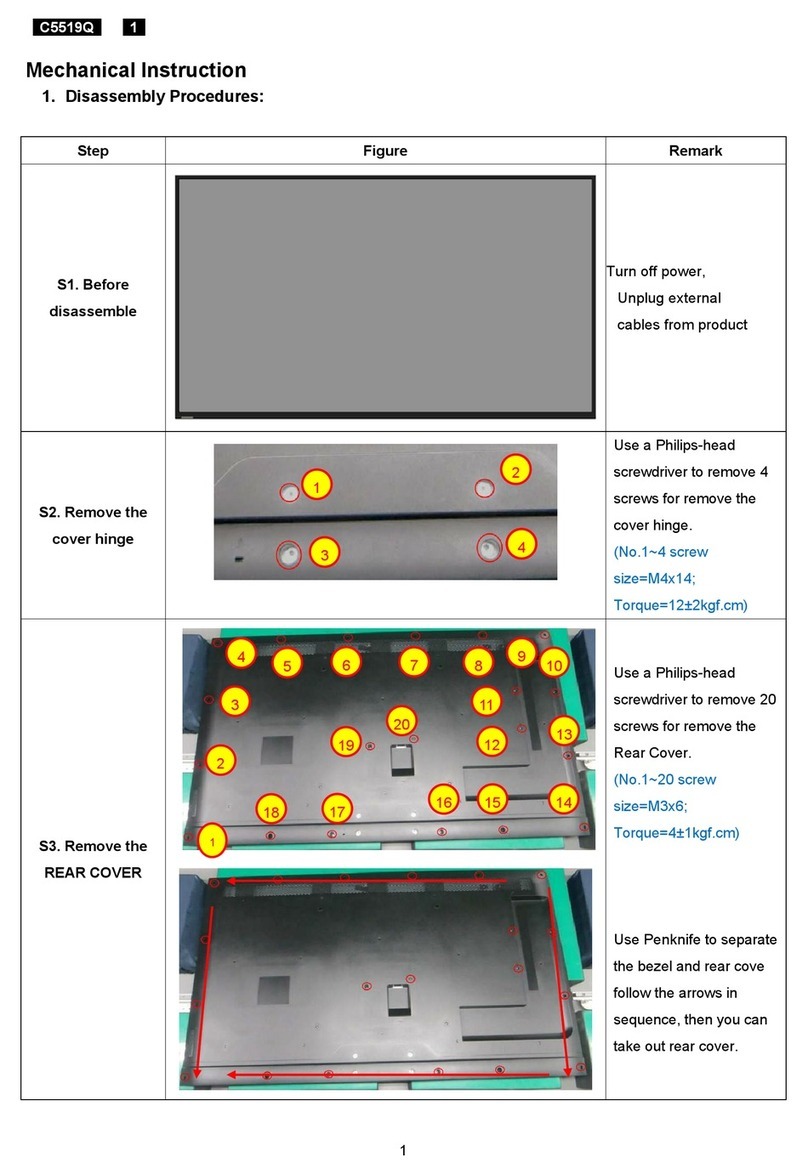

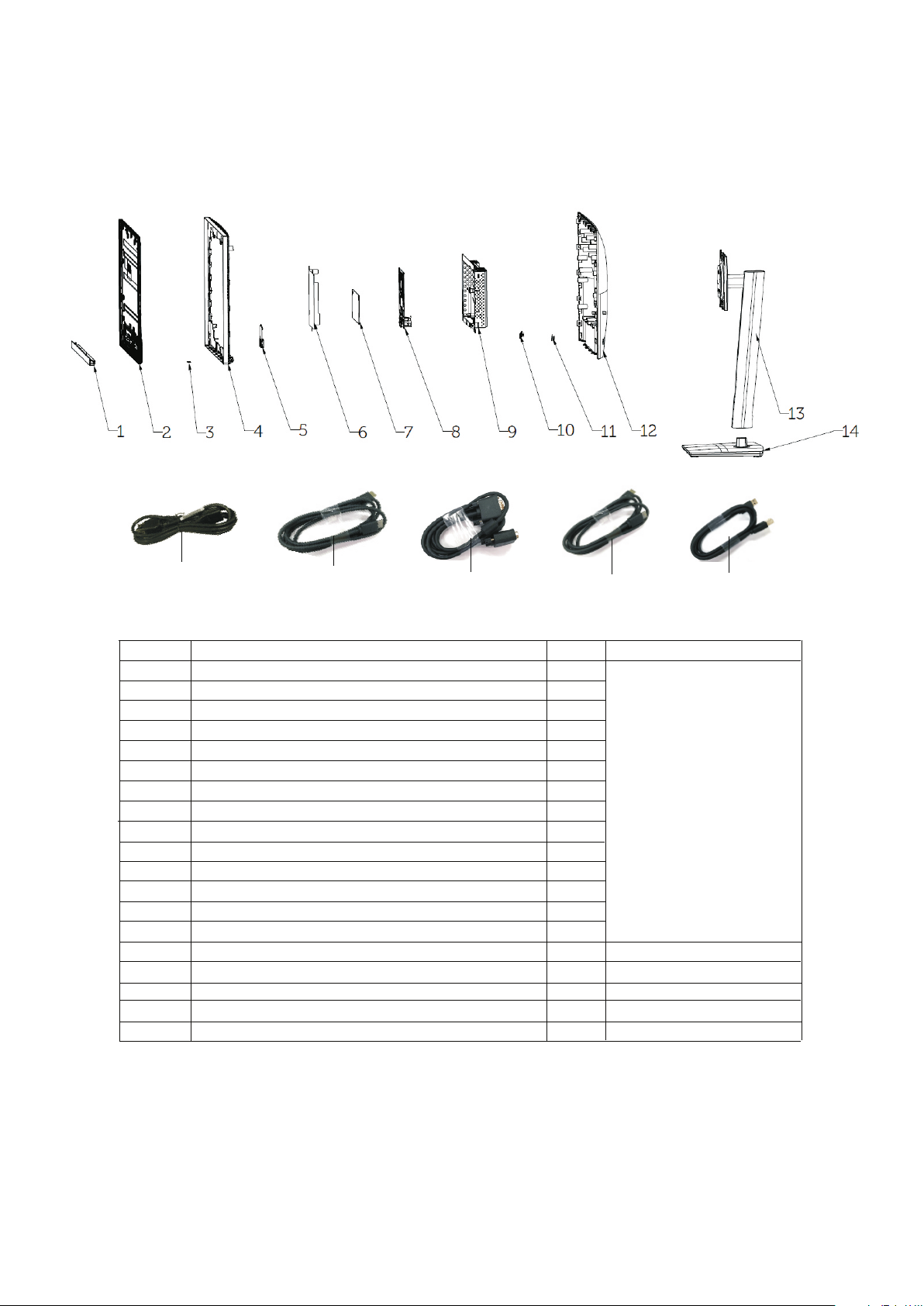

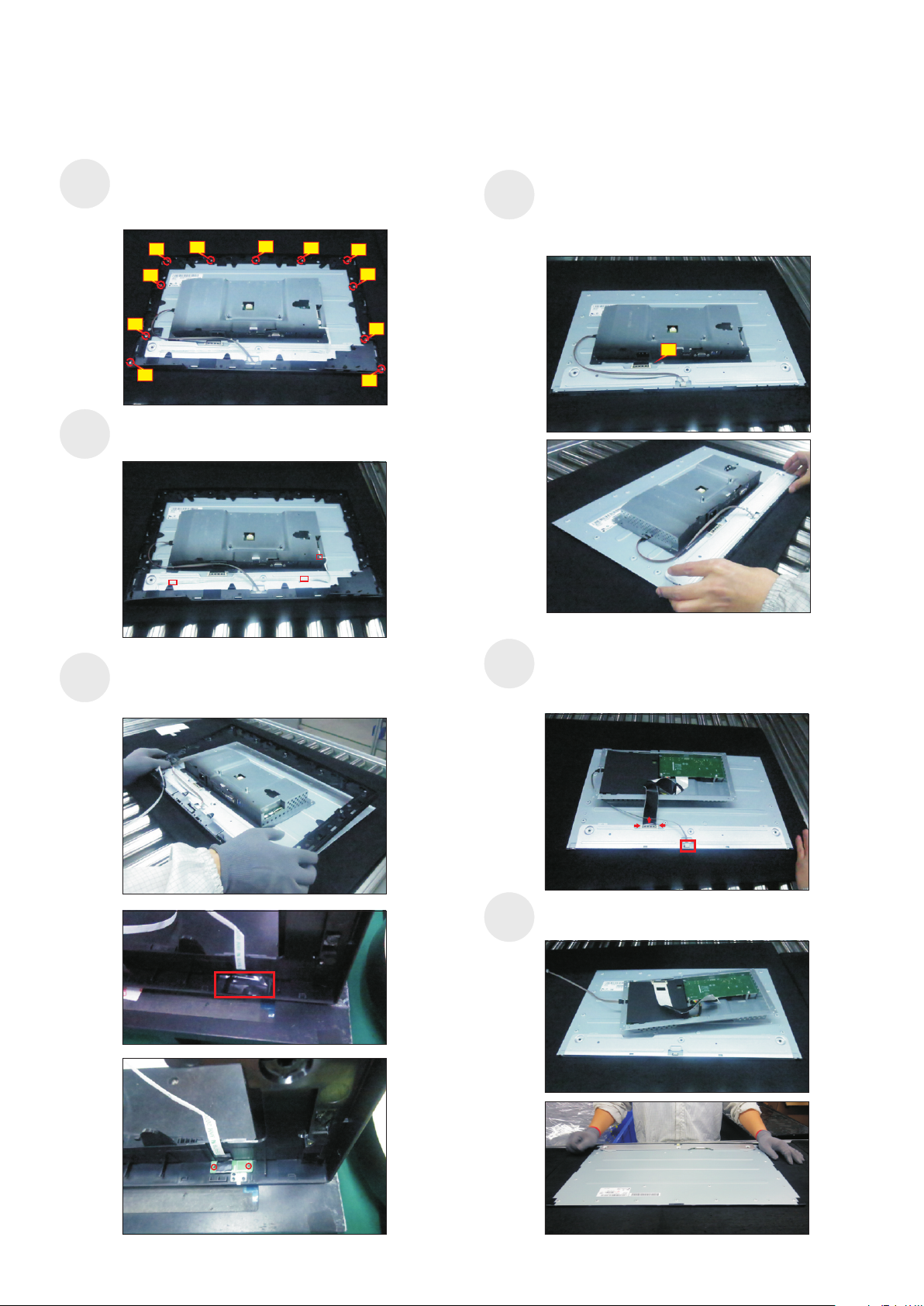

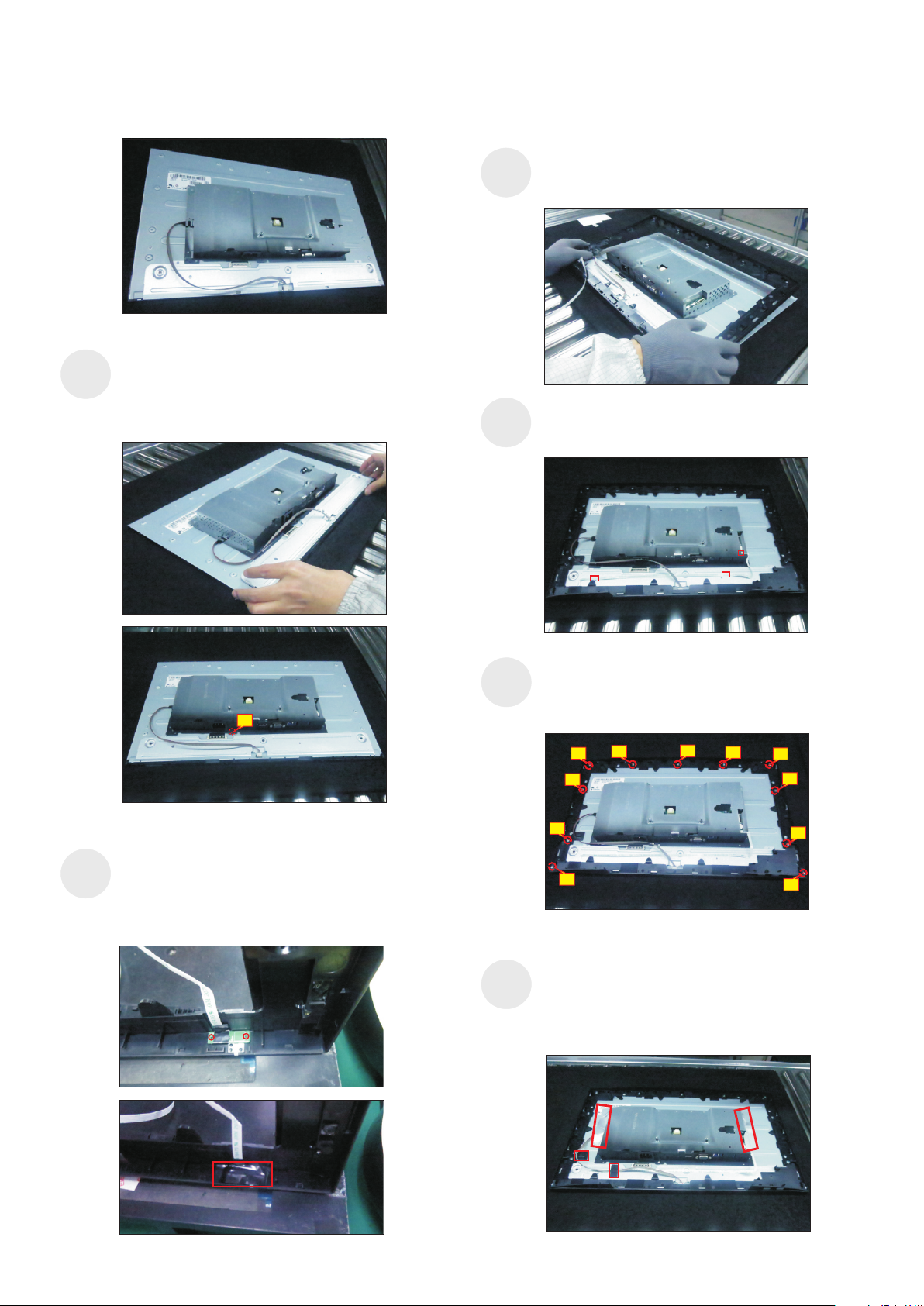

5. Disassembly and Assembly Procedures

5.1 Disassembly Procedures:

Tool Required:

List the type and size of the tools that would typically can be

used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Description:

- Screwdriver(Phillip head) #1

- Screwdriver(Phillip head) #2

- Penknife

- Soldering iron and absorber

NOTE:

This “Disassembly and Assembly Procedures” is for EMEA only,

not for other regions. Please note that Dell will deem warranty void

if any disassembly is done on the monitors.

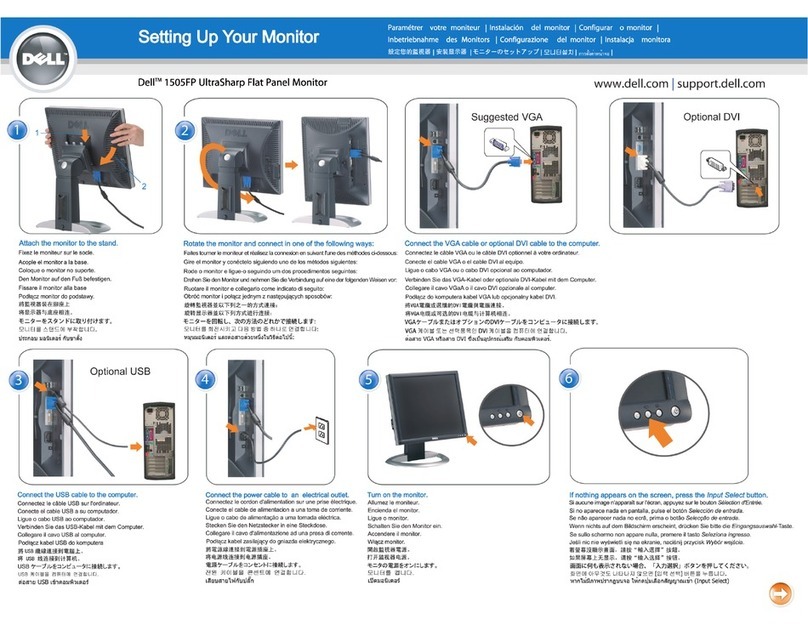

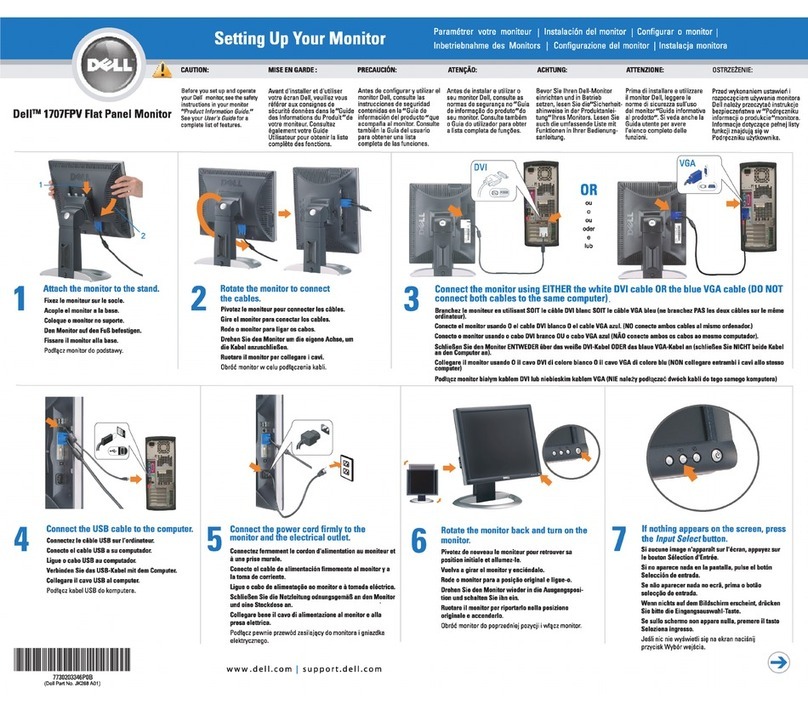

Wedge your fingers between the rear cover and the

middle bezel on the corners of the top side of the

monitor to release the rear cover, then use one hand

to press the middle bezel, the other hand to pull up

carefully the rear cover in order of arrow preference

for unlocking mechanisms of rear cover..

Use a Philips-head screwdriver to remove four

screws for unlocking mechanisms.

(No.1~4 screw size=M4x10; Torque=12±0.5kgfxcm)

S3

S2

S1

23

41

1

3

22

S1

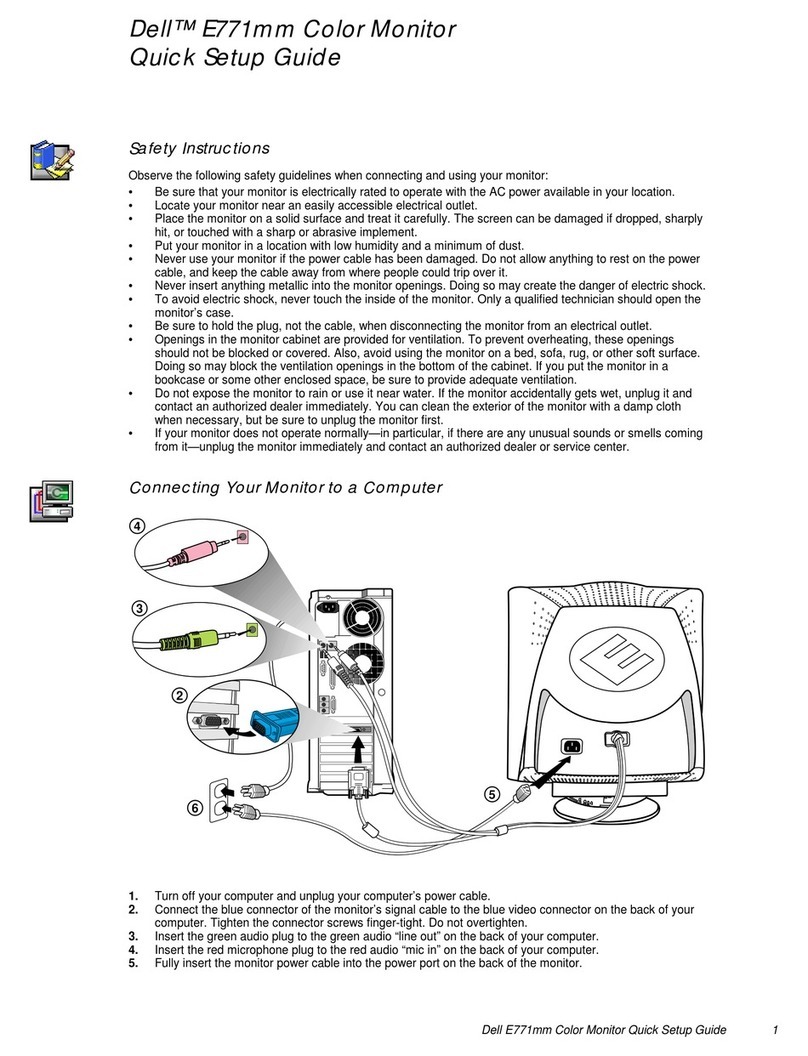

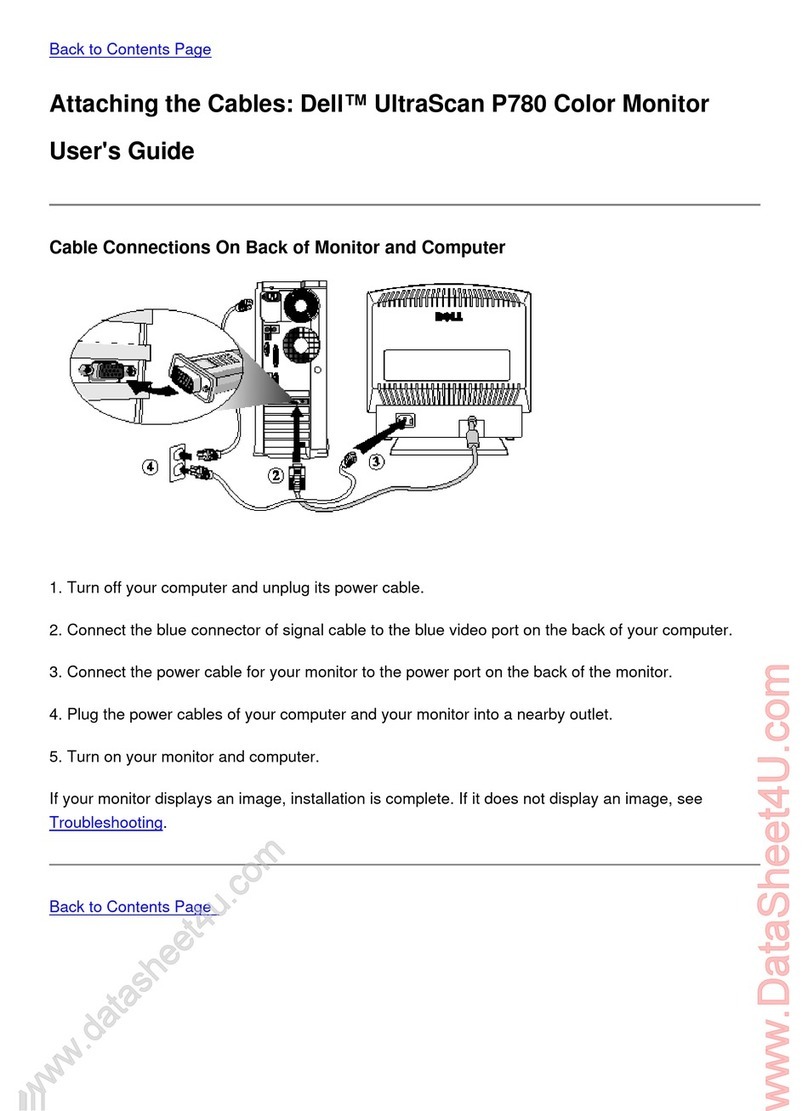

Remove the monitor stand base:

1. Place the monitor on a soft cloth or cushion.

2. Press and hold the stand-release button.

3. Lift the stand up and away from the monitor.

Lift the rear cover up carefully. Disconnect the key

cable and USB FFC cable from the connectors of

the interface board, and then remove the rear cover.

S4

Tear off 2pcs aluminium foils for unfixing the bracket

Tear off 1pcs acetate tape, and then release the

panel lamp cable from the hook of the middle bezel.

.

S7

Use a Philips-head screwdriver to remove 2pcs

screws for unlocking the joystick key board unit, then

tear off the tapes and release the USB board.

(No.1~2 screw size=M2x3.3,Torque=1±0.2kgfxcm)

S5

Use a Philips-head screwdriver to remove one screw

for unlocking the USB board unit, then release the

USB board unit and put it aside.

(No.1 screw size=M3x6, Torque=4±0.5kgfxcm)

12

1

aluminum foil

conductive tape

S6