Della Toffola OMNIA Series User guide

Azienda: Della Toffola S.p.A

Indirizzo: Via Feltrina, 72 – 31040 Signoressa di Trevignano (TV) (Italia)

Tel: +39 0423 6772

Web: www.dellatoffola.it

USE AND MAINTENANCE

INSTRUCTIONS MANUAL

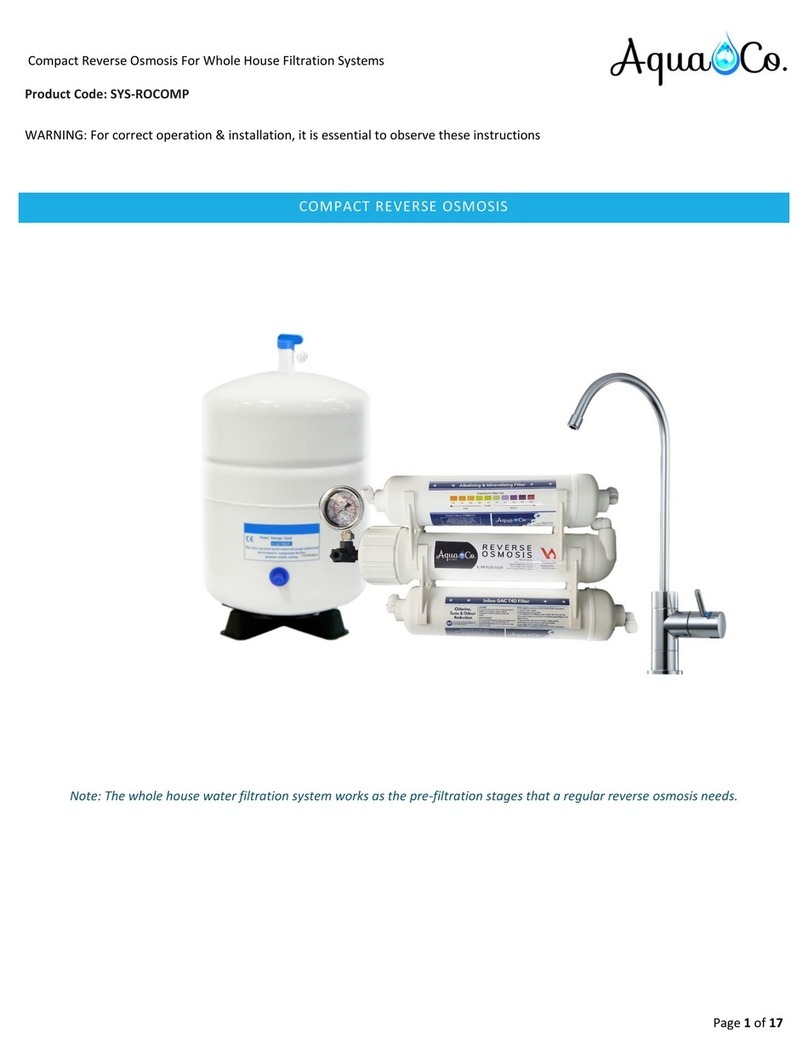

OMNIA crossflow filter

OMNIA_0314R02EN-II.docx

EN

Read all the following safety

recommendations very carefully before

undertaking any action whatsoever with your

machine.

FIRST LEARN AND THEN ALWAYS FOLLOW ALL THE SAFETY

RECOMMENDATIONS

Read these safety recommendations very carefully before installing and using the machine.

Also read all the explanatory and warning signs attached to the machine itself. Make sure that they are always easy to read, replacing any damaged

or missing signs without delay.

Read this manual carefully before using the machine to make sure that you are thoroughly familiar with how it works and all the controls.

Never postpone learning this important information until you are already working with the machine.

Never allow any unauthorized persons unfamiliar with the equipment to come into the vicinity or operate the machine.

Always keep this manual readily available so that anyone taking action on the machine can refer to it.

If the machine is sold or transferred to third parties, it is compulsory to hand over all the related technical documentation, use and maintenance

EXPLANATION OF THE SYMBOLS

Several symbols are used in this manual and on the machine itself to accompany hazard warnings and safety recommendations.

These warnings and recommendations serve primarily to ensure the safety of Installers, Technicians and Operators, but also to avoid the machine

being damaged.

THIS SYMBOL IS USED TO DRAW YOUR ATTENTION TO THE RISK OF FATAL ACCIDENTS, SEVERE INJURIES AND EXTENSIVE

DAMAGE IN THE EVENT OF THE SPECIFIED SAFETY MEASURES BEING DISREGARDED.

THIS SYMBOL DRAWS ATTENTION TO RISKS OF A GENERAL NATURE.

THIS SYMBOL IS USED TO DRAW YOUR ATTENTION TO THE RISK OF FATAL ACCIDENTS, SEVERE INJURIES AND EXTENSIVE

DAMAGE IN THE EVENT OF THE SPECIFIED SAFETY MEASURES BEING DISREGARDED.

THIS SYMBOL DRAWS ATTENTION TO RISKS DERIVING FROM THE PRESENCE AND USE OF ELECTRICITY.

IMPORTANT

This word is used to identify paragraphs in the manual containing essential information concerning the machine. Read the related information

DEFINITIONS

The following are definitions of the individual and legal entities involved in handling and using the machine.

OWNWER: In this user manual, the OWNER is the legal representative of the company or body, or the individual, that purchased the

machine. The Owner is responsible for ensuring compliance with all the safety requirements specified in the present manual

and in the current legislation in the country where the machine is installed. This last aspect is waived if the Owner appoints a

plant MANAGER, who thus takes responsibility for implementing the safety recommendations and for compliance with the

safety standards relating to the use of the machine and relations with the OPERATOR.

INSTALLER: In this user manual, the INSTALLER is the legal representative of the company appointed by the OWNER to install and connect

the machine to the hydraulic, electrical and compressed air supply networks (etc.) at the plant. The Installer is responsible for

correctly handling and installing the machine in compliance with the recommendations of this manual and with the current legal

requirements in the country where the machine is used.

OPERATOR: In this user manual, the OPERATOR is the person authorized by the OWNER or MANAGER to take all action on the machine for

its usage, adjustment, control and routine servicing, as detailed in this manual (with which Operators must strictly comply,

limiting their action to the explicitly allowable procedures).

TECHNICIAN: In this user manual, the TECHNICIAN is the person directly authorized by the Manufacturer or, failing this (and entirely under the

latter's responsibility), by the Manufacturer's Dealer in the various European Community states outside Italy, to carry out all

extraordinary servicing procedures, as well as any adjustments, tests, repairs and replacements of parts proving necessary

during the working life of the machine.

GENERAL SAFETY RECOMMENDATIONS

!In unloading the machine on arrival, lifting and positioning it at the workplace, and all other handling procedures, comply scrupulously with the

recommendations of the relevant section of this manual.

EN

Pay particular attention when handling wheel-mounted machines, which have to be moved by hand once they are on the ground.

To prevent any risk of crushing, only move the machine by pushing it, never by pulling it, so that nobody can ever come to be in the path of the

machine as it moves. Anyone handling the machine must be supervised by another person uninvolved in the procedure, who shall keep a

constant watch to ensure that no obstacles or persons get in the machine's way and no other hazardous situations occur. This supervisor must

promptly alert the person moving the machine of any hazards so that the machine can be stopped immediately.

!The surface on which the machine slides, like the surface on which it is used, must meet all the essential safety requirements: it must be perfectly

horizontal and smooth, with nothing to interfere with the machine's movements. Check in advance to ensure that the whole distance to cover with

the machine meets all the above-mentioned requirements. Make sure that the sliding and supporting surfaces have a load-bearing capacity

sufficient to withstand the weight of the machine both empty and in use. Any discontinuity in the floor, e.g. expansion joints, grids and manholes,

must meet the specified requirements.

!Never, for any reason whatsoever, lift the machine by any hoisting points other than those indicated.

!Before the machine is used, it must always be immobilized using the fixing devices provided.

!The machine must be placed in an area accessible only to the OPERATORS and TECHNICIANS; failing this, it must be protected by a barrier

situated at least 2 m away from its outer edge. OPERATORS and TECHNICIANS may access the area where the machine is used providing they

are adequately clothed and equipped with the personal protective equipment specified by law (safety shoes, gloves, helmet, etc.). The

INSTALLER's personnel, or any visitors, must always be accompanied by an OPERATOR. Unauthorized personnel must never be allowed to

remain alone in the vicinity of the machine. The place of installation must be made inaccessible to children.

!OPERATORS shall restrict themselves to taking action on the machine's controls, so they must not open any of the panels, except for the one for

accessing the controls (if any).

!The INSTALLER shall restrict himself to taking action on the connections between the plant and the machine, so he must not open any panels, or

operate any controls.

!In all handling, usage, servicing or repairs on the machine, it is compulsory to comply with all current safety standards in the country where the

machine is used. This applies both to the equipment and to the operating methods adopted.

!Always disconnect the electric power supply before taking any action to install, service, repair or move the machine. This is of fundamental

importance to prevent the risk of death, severe injury and extensive damage to the plant.

!In certain stages of normal use, some of the containers comprising the machine are under pressure (e.g. the filter vessel, plenum chamber,

erosion-type dosing units, etc.). Never open such containers or remove any components connected to them before you have completely vented

said pressure. Venting must be done through the valves provided on the machine specifically for this purpose.

!Never move the machine during normal working cycles.

!Before each new working cycle, make sure that any mobile electric connections (power cords, plugs, etc.) are sound and efficient. If they show

any signs of damage, repairs must be made only by a specialized TECHNICIAN.

!Never take any action not mentioned in this manual under your own initiative.

!Connect the machine to the mains electric power supply according to the recommendations of this manual.

!Before starting the machine, check the efficiency of the earthing for the electric circuitry and machine frame or structure.

!Never use power cords of inadequate cross-section or provisional connections, not even briefly, and certainly not in the event of an emergency.

!Start the machine only after you have made sure of its perfectly safe connection to the systems providing the energy and anything else it needs to

function properly (mains electricity and water, compressed gas supply, water drainage network, etc.).

!Keep a safe distance from any mechanical parts in motion.

!Immediately report any alarms or the tripping of any automatic machine safety devices to the TECHNICIAN.

!Never manually reset the machine after an alarm or an automatic safety device has been tripped without first identifying and dealing with the

problem that caused them.

!Never remove the guards over moving parts while the machine is in operation.

!Before starting the machine, make sure all guards are correctly installed.

!Routinely perform all the scheduled servicing operations.

!Dispose of the packaging material for the machine at a suitable landfill, taking particular care over any film and plastic bags, which can expose

children to the risk of suffocation.

!Never release the processing waste deriving from the working process directly into the environment.

REGULATIONS FOR USING THE MACHINE IN THE FOODSTUFFS

SECTOR

The following considerations apply only to machines used with foodstuffs, i.e. destined to come into contact with products for human consumption:

!The machine in your possession has been designed and built to make it suitable for contact with foodstuffs, and fluids in particular. If in doubt

about the intended uses of your machine, refer to the relevant chapter in this manual.

!For logistic reasons related to the phases prior to its use (e.g. transport to the user's premises, storage in warehouses, etc.), it is impossible to

guarantee the delivery of the machine in conditions suitable to enable its immediate use without an accurate, preliminary sanitization. This is the

responsibility of the end user, who may have to comply with any established protocols, e.g. HACCP.

DEMOLITION AND DISPOSAL OF THE MACHINE

!At the end of its working life, the machine must be demolished and disposed of.

!THE MACHINE MUST ONLY BE DEMOLISHED AND DISPOSED OF BY ADEQUATELY-TRAINED AND PROPERLY-EQUIPPED PERSONNEL IN

COMPLIANCE WITH THE FOLLOWING PROCEDURE.

!1. Divide the machine into its constituent parts, separating the materials it is made of:

!mechanical parts (reducers, pump bodies, etc.);

!metal parts (structure, piping, etc.)

!electrical parts;

!rubber parts;

!plastic and synthetic parts.

!2. All resulting materials must be treated and disposed of in accordance with the legal requirements in the country where the machine is used.

!3. All components contaminated by oil and oily residues must be considered as special waste and disposed of by authorized consortiums. The

same applies to the lubricants that periodically have to be changed.

!4. In the event of the machine being placed out of commission, even only temporarily, it must be stored in an area inaccessible to children. All

circuit breakers and isolators must be segregated and disconnected.

Make a thorough check and release any built-up residual energy, e.g. liquids or gases under pressure inside containers or piping. The

machine must also be checked from the static standpoint, to eliminate the risk of any single machine parts moving unexpectedly.

!THE MANUFACTURER ACCEPTS NO LIABILITY FOR DAMAGE TO PERSONS OR PROPERTY DUE TO THE RE-USE OF SINGLE MACHINE

PARTS FOR ANY OTHER THAN THE ORIGINAL PURPOSES OR IN OTHER ASSEMBLY CONDITIONS.

INSPECTION OF THE GOODS ON RECEIPT

When it is delivered, the machine must be checked by the Customer to identify any signs of damage that it may have suffered in transit and ensure

that the machine is complete in every part, as listed on the order form.

If there are signs of damage, make an immediate note of the anomalies detected on the transport document (delivery note or CMR), adding the

wording “RECEIVED WITH RESERVE DUE TO EVIDENT DAMAGE TO THE MACHINE”. Delivery ex works includes insurance coverage for any

damage in accordance with the Italian law 450 of 22.08.1985 "Compensation limit". In the event of complaints, the Customer must be able to

produce an adequate photographic documentation of the most obvious damage.

GUARANTEE

The Manufacturer guarantees the machine for the period indicated in the order form.

The GUARANTEE consists exclusively in the replacement or repair, free of charge, of any parts acknowledged as being defective.

The GUARANTEE does not cover electrical parts.

The GUARANTEE is valid only if all installation and usage instructions have been followed (not only those stated by the Manufacturer, but also those

suggested by current practice).

The GUARANTEE becomes null and void in the event of any servicing procedures being undertaken by personnel not authorized by the

Manufacturer. If the machine alarm sounds or one of the automatic safety devices is tripped, the machine must not be reset manually until the cause

of the shutdown has been dealt with. Repeated manual resets can be sufficient reason for the Guarantee to become null and void.

The GUARANTEE is valid providing any flaws or defects are reported within eight days of their detection; moreover, the GUARANTEE takes effect

providing the use of the machine was suspended immediately after the fault was discovered.

AFTER-SALES ASSISTANCE

When requesting any information, servicing, or other services, it is essential to specify the SERIAL NUMBER of your machine.

It is impossible to provide accurate instructions or schedule servicing measures unless this information is provided.

NOTES

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

RECOMMENDATIONS FOR PROTECTION AGAINST FREEZING

If there is a danger of the ambient temperature dropping to 0°C / 32°F, be sure to empty any liquids (water or product to treat) from all

of the machine's hydraulic circuits to prevent ice forming in the piping and damaging parts of the machine.

Crossflow filter Pag. 2/75

CONTENTS

1GENERAL INFORMATION ...................................................................................................................... 8

1.1SCOPE OF THE USE AND MAINTENANCE INSTRUCTION MANUAL .............................................................. 8

1.2HOW TO CONSULT THIS MANUAL .................................................................................................................... 9

1.2.1NUMERATION OF FIGURES ..................................................................................................................... 9

1.2.2NUMERATION OF TABLES........................................................................................................................ 9

1.3CONSERVING THIS MANUAL........................................................................................................................... 10

1.4MANUAL REVISION METHOD .......................................................................................................................... 10

1.5ADDRESSEES ................................................................................................................................................... 10

1.6PASSWORD....................................................................................................................................................... 11

1.6.1User (Level 0) – no password required ..................................................................................................... 11

1.6.2Machine operator – Client Technician (Level 1) - User “A” (password level 1).......................................... 11

1.6.3Advanced Client Technician - (Level 2) – User “B” (password level 2)...................................................... 11

1.6.4Della Toffola Technician (Level 3) – User “DT” (password level 3) ........................................................... 11

1.7GLOSSARY AND PICTOGRAMS....................................................................................................................... 12

1.7.1GLOSSARY:.............................................................................................................................................. 12

1.7.2PICTOGRAMS REGARDING OPERATOR QUALIFICATIONS................................................................ 13

1.7.3PICTOGRAMS REGARDING SAFETY..................................................................................................... 14

2GENERAL INFORMATION .................................................................................................................... 15

2.1MANUFACTURER IDENTIFICATION DATA...................................................................................................... 15

2.2MACHINE IDENTIFICATION DATA AND NAMEPLATES.................................................................................. 15

2.2.1CE nameplate............................................................................................................................................ 15

2.2.2PED inspection plate ................................................................................................................................. 16

2.3CERTIFICATION ................................................................................................................................................ 17

2.3.1EC Statement of conformity....................................................................................................................... 17

2.4WARRANTY ....................................................................................................................................................... 17

2.4.1Centro di assistenza tecnica...................................................................................................................... 17

2.5PRELIMINARY OPERATIONS AT THE USER’S RESPONSIBILITY................................................................. 18

3SAFETY .................................................................................................................................................. 19

3.1SAFETY RULES ................................................................................................................................................. 19

3.2GENERAL SAFETY RECOMMENDATIONS...................................................................................................... 19

3.2.1Control operations and inspections ........................................................................................................... 22

3.3DANGER ZONES ............................................................................................................................................... 23

3.4SAFETY DEVICES ............................................................................................................................................. 23

3.4.1Pressure-switches and safety valves ........................................................................................................ 23

3.5RESIDUAL RISKS .............................................................................................................................................. 24

3.5.1Risk of contaminating the product ............................................................................................................. 25

4INSTALLATION...................................................................................................................................... 26

4.1INSTALLATION SITE REQUIREMENTS............................................................................................................ 26

4.2OPERATOR WORK AREAS .............................................................................................................................. 27

4.3SHIPPING AND MOVING................................................................................................................................... 28

4.3.1Transport ................................................................................................................................................... 28

4.3.2Lifting and moving the machine................................................................................................................. 29

4.3.3Assembly................................................................................................................................................... 30

4.4LEVELLING ........................................................................................................................................................ 31

4.5CONNECTIONS ................................................................................................................................................. 31

4.5.1Hydraulic system connections ................................................................................................................... 31

4.5.2Pneumatic system connections ................................................................................................................. 35

4.5.3Electric system connections ...................................................................................................................... 37

4.6PRELIMINARY OPERATIONS ........................................................................................................................... 38

4.6.1Checking the phase balance ..................................................................................................................... 39

4.6.2Checking the cycle of the power supply phases........................................................................................ 39

4.7LOADLESS TESTING ........................................................................................................................................ 40

5MACHINE DESCRIPTION...................................................................................................................... 41

5.1INTENDED USE ................................................................................................................................................. 43

5.2MISUSE (uses that are not allowable) ................................................................................................................ 44

5.3RECOMMENDATIONS FOR USE...................................................................................................................... 44

5.4FLOW CHART .................................................................................................................................................... 45

5.4.1Key to components.................................................................................................................................... 45

Crossflow filter Pag. 3/75

6TECHNICAL FEATURES....................................................................................................................... 48

6.1PERFORMANCE ................................................................................................................................................ 48

6.2SERVOMECHANISMS ....................................................................................................................................... 48

6.3CONSUMPTION ................................................................................................................................................. 49

6.3.1Decalcified mains water (hardness ≤15°F) for washing............................................................................. 49

6.3.2Filtered and dry compressed air ................................................................................................................ 49

6.3.3Nitrogen..................................................................................................................................................... 50

6.3.4Chemical detergents ................................................................................................................................. 50

6.4TECHNICAL DATA ............................................................................................................................................. 50

6.5DIMENSIONS ..................................................................................................................................................... 51

6.6VIBRATION ........................................................................................................................................................ 52

6.7NOISE EMISSION .............................................................................................................................................. 52

7OPERATOR CONTROL PANEL............................................................................................................ 53

7.1OPERATOR CONTROL PANEL......................................................................................................................... 53

7.1.1Electric control panel component key........................................................................................................ 53

7.2EMERGENCY STOPPING ................................................................................................................................. 54

8OPERATION........................................................................................................................................... 54

8.1NOTIONS ON THE PROCESS........................................................................................................................... 54

8.2PRELIMINARY OPERATIONS ........................................................................................................................... 54

8.3STARTING.......................................................................................................................................................... 54

8.4INTERRUPTING THE WORK CYCLE................................................................................................................ 55

8.5MACHINE STOPPING........................................................................................................................................ 55

9WORKING STAGES .............................................................................................................................. 56

9.1FILLING .............................................................................................................................................................. 56

9.2PRESSURIZATION ............................................................................................................................................ 57

9.3FILTRATION....................................................................................................................................................... 57

9.3.1Internal recirculation/External recirculation:............................................................................................... 57

9.3.2Backwashing during filtration..................................................................................................................... 58

9.3.3Automatic discharge by the rotating screener SRB ................................................................................... 58

9.4EMPTYING PRODUCT ...................................................................................................................................... 58

9.4.1Discharge of clean product from rotating screener SRB ........................................................................... 58

9.4.2Discharge from the filter ............................................................................................................................ 58

9.5PRESSURE VENTING ....................................................................................................................................... 59

9.6WASHING........................................................................................................................................................... 59

9.6.1Cold washing............................................................................................................................................. 59

9.6.2Washing with hot water ............................................................................................................................. 59

9.6.3Chemical washing ..................................................................................................................................... 60

9.7WASHING CHECK ............................................................................................................................................. 62

10DETAILED DESCRIPTION OF THE CONTROLS................................................................................. 62

11MAINTENANCE OPERATIONS............................................................................................................. 63

FOREWORD ................................................................................................................................................................ 63

11.1.1Precautions........................................................................................................................................... 63

11.1.2General rules ........................................................................................................................................ 64

11.2PROGRAMMED MAINTENANCE ...................................................................................................................... 65

11.2.1General................................................................................................................................................. 65

11.2.2Counter-current system rubber sleeve ................................................................................................. 65

11.2.3Tank SE wash ball................................................................................................................................ 65

11.2.4Safety valves ........................................................................................................................................ 65

11.2.5Wiring and electric components............................................................................................................ 65

11.3EXTRAORDINARY MAINTENANCE .................................................................................................................. 66

11.3.1Changing the mechanical seals............................................................................................................ 66

11.3.2Changing the rotating brush ................................................................................................................. 66

12TROUBLESHOOTING ........................................................................................................................... 67

12.1MESSAGES........................................................................................................................................................ 67

12.2ALARMS ............................................................................................................................................................. 68

13PUTTING THE FILTER OUT OF OPERATION ..................................................................................... 73

14SPARE PARTS....................................................................................................................................... 73

14.1TECHNICAL ASSISTANCE................................................................................................................................ 73

14.2SPARE PARTS................................................................................................................................................... 74

Crossflow filter Pag. 4/75

15ADDITIONAL INSTRUCTIONS.............................................................................................................. 74

15.1WASTE ELIMINATION ....................................................................................................................................... 74

15.2DEMOLITION AND DISPOSAL .......................................................................................................................... 74

16FLOW CHART........................................................................................................................................ 75

Crossflow filter Pag. 5/75

Crossflow filter Pag. 6/75

This manual is the property of Della Toffola S.p.A. No part of this publication may be reproduced,

circulated, translated into any language, transmitted or copied in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise, without prior permission from Della

Toffola S.p.A.

© ALL RIGHTS RESERVED.

ENQUIRIES AND FURTHER INFORMATION:

For any enquiries or further information concerning the use of the machine or the contents of this

manual, or for any technical support, please contact the Della Toffola S.p.A. Customer Support

Service, using the following references:

Della Toffola S.p.A – Servizio Assistenza

Via Feltrina 72 - 31040, Signoressa di Trevignano (TV) (Italia)

Tel.: +39 0423 6772 Fax: +39 0423 670841

PRESERVATION:

Always keep a copy of this manual near the machine and readily available to the user, and store a

spare copy in a safe place.

If the manual is lost or damaged, contact Della Toffola S.p.A. for a replacement.

This manual reflects the state of the machine as at the time when it was developed.

Bear in mind that, in accordance with current legislation, this instructions manual forms an integral

part of the machine and must accompany the machine at all times.

DOCUMENT ID:

Title Use and maintenance instructions manual

Machine Crossflow filter

Models OMNIA 50/80/130/170

Nome file OMNIA_0314R02EN-II.docx

Machine code

Serial number

IC.

Rev. No. 02 – 01.2015

Crossflow filter Pag. 7/75

Crossflow filter Pag. 8/75

1 GENERAL INFORMATION

All the data provided in this manual regard European units of measure.

This manual regards only European standards and regulations. The client is responsible for

adapting it to the standards and regulations adopted in the nation of use.

This manual contains the instructions for the standard version of the filter and it may be that the

machine in your possession does not include certain components or optionals illustrated here at no

expense to its satisfactory operation.

1.1 SCOPE OF THE USE AND MAINTENANCE INSTRUCTION MANUAL

This manual is an integral part of the machine and has been provided to supply all the information

necessary for:

●correctly informing operators of all aspects regarding safety;

●correct machine installation;

●detailed knowledge of machine operation and limits to use;

●use of the machine correctly and in conditions of safety;

●servicing the machine correctly and safely;

●dismantling the machine in conditions of safety and in respect of the laws in force governing

the safety of the workers and the workplace.

The persons in charge of the company departments where this machine will be installed are

required by the laws in force to carefully read this manual and to ensure that the sections

pertinent to the machine’s operators and maintenance personnel are read by the same.

This manual has been prepared under the assumption that the rules in force for workplace safety

and hygiene are regularly respected at the plants for which the machine is destined.

The instructions, drawings and documents contained in this manual are of reserved technical

nature and the exclusive property of the Manufacturer, and cannot be fully or partially reproduced.

The client is also responsible for making sure that whenever it is emended by the Manufacturer,

only updated versions of the manual are rendered available for consultation wherever the machine

is used.

Crossflow filter Pag. 9/75

1.2 HOW TO CONSULT THIS MANUAL

This manual has been divided into separate chapters, each of which is dedicated to a specific type

of operator (INSTALLER, OPERATOR AND MAINTENANCE MAN) and defines the skills

necessary for such to conduct operations on the machine in conditions of safety.

The terms, abbreviations and pictograms used with the meanings indicated in par. 1.7 are intended

to make the text immediately comprehensible.

This manual is composed of a cover, a table of contents, a set of chapters, figures, diagrams, and

tables.

Page 4 provides the machine’s identification data, model, serial number, and the manual’s revision

number.

This document makes frequent use of the numbering of parts provided in the figure on page

45. For quick consultation, we recommend keeping the respective figure always in sight.

1.2.1 NUMERATION OF FIGURES

Each figure is provided with progressive numeration.

The numbers start from “1” at the start of each new chapter.

Numbers are composed as follows:

1.1

1.2.2 NUMERATION OF TABLES

Each table is provided with progressive numeration.

The numbers start from “1” at the start of each new chapter.

Numbers are composed as follows:

1-1

Chapter

Progressive numeration of

figure

Chapter

Progressive numeration of

table

Crossflow filter Pag. 10/75

1.3 CONSERVING THIS MANUAL

This Instruction Manual is certified to CE conformity and must be conserved with care and

ALWAYS accompany the machine through all its changes of ownership for its entire

working life.

Conservation must by ensured by handling it carefully with clean hands and never leaving it on

dirty surfaces

No parts of the manual must ever be removed, torn out or arbitrarily modified.

This manual must be stored in an area free from humidity and sources of heat, and in the

immediate vicinity of the machine.

Whenever requested by the user, the manufacturer can provide additional copies of this manual.

1.4 MANUAL REVISION METHOD

The Manufacturer reserves the right to modify the design and improve the machine without

notifying the client and without revising the manual previously delivered to the same

The Manufacturer is responsible only for descriptions provided in the Italian language. Given that

translations into other languages cannot be completely verified, whenever an incongruence

appears, greater attention should be given to the wording in Italian. Della Toffola can be notified in

order to make any modifications deemed necessary.

1.5 ADDRESSEES

This manual is addressed to the machine Installer, Operator, and Qualified Personnel for

maintenance.

The term “OPERATOR” means the person operating, adjusting, cleaning, and performing the

ordinary maintenance of the machine.

“QUALIFIED PERSONNEL or QUALIFIED OPERATOR” means the person or persons that have

completed training and specialization courses, etc. and have acquired experience in installing,

operating, maintaining, repairing, and moving the machine.

“DANGER ZONE”means any zone within and/or around machinery in which a person is subject

to a risk to his or her health or safety;

“EXPOSED PERSON” means any person wholly or partially in a danger zone

Crossflow filter Pag. 11/75

Qualification of addressees

The machine has been designed and constructed for industrial, and therefore professional, not

general use. For such reason, it can be entrusted for use to a qualified personnel, in particular,

those who:

●have reached adult age,

●are physically and psychologically capable of performing tasks of particular technical difficulty,

●have received adequate training in the operation and maintenance of the machine,

●have been deemed capable by the employer of performing the task(s) assigned,

●are capable of understanding and interpreting the operation manual and its safety rules,

●are familiar with the respective emergency procedures and their implementation,

●possess the ability to operate the specific type of equipment in question,

●have experience in applying the specific rules required,

●have understood the operating procedures defined by the machine Manufacturer.

1.6 PASSWORD

The 4 levels of access to the operator panel are :

1.6.1 User (Level 0) – no password required

This is the person at client premises who uses the machine in complete safety with the default

parameters. The User can start all the work phases but cannot access the machine parameters.

1.6.2 Machine operator – Client Technician (Level 1) - User “A” (password level 1)

This is the person at client premises who uses the machine in complete safety. User “A” can start

all the work phases, entering and modifying the process parameters of the various work phases

but cannot access the machine parameters.

1.6.3 Advanced Client Technician - (Level 2) – User “B” (password level 2)

This is the person at client premises who in addition to being qualified to enter and modify typical

process passwords during the various work phases can also access some of the advanced

machine parameters.

1.6.4 Della Toffola Technician (Level 3) – User “DT” (password level 3)

This is the Della Toffola Project Manager with access to all the machine setting parameters, the

various logs, and the definition and modification of the passwords.

Crossflow filter Pag. 12/75

1.7 GLOSSARY AND PICTOGRAMS

This paragraph lists the terms in this manual not commonly used and the terms used herein with

uncommon meaning.

Abbreviations and the meanings of the pictograms used to indicate the qualifications of the

operator and the status of the machine are also explained below, the use of which permits the

rapid and unequivocal presentation of all the information required for the correct use of the

machine in conditions of safety.

1.7.1 GLOSSARY:

The following terms were used in accordance with Paragraph 1.1.1 of Directive 2006/42/CE during

the design of this machine:

HAZARD: a potential source of injury or health damage;

DANGER ZONE: means any zone within and/or around machinery in which a person is subject to

a risk to his or her health or safety;

EXPOSED PERSON: means any person wholly or partially in a danger zone;

OPERATOR: means the person or persons installing, operating, adjusting, maintaining, cleaning,

repairing or moving machinery;

MAN-MACHINE INTERFACE: means any situation in which the operator must interact with the

machine in any moment or any operative phase of the working life of the same;

RISK: means a combination of the probability and the degree of an injury or damage to health that

can arise in a hazardous situation ;

SAFETY GUARD: means a part of the machinery used specifically to provide protection by means

of a physical barrier;

PROTECTIVE DEVICE: means a device (other than a guard) that reduces the risk, either alone or

in conjunction with a guard;

INTENDED USE: means the use of machinery in accordance with the information provided in the

instructions for use;

REASONABLY FORESEEABLE MISUSE: means the use of machinery in a way not intended in

the instructions for use, but which may result from readily predictable human behavior.

RESIDUAL RISKS: risks that cannot be totally eliminated or sufficiently reduced through the

design of efficacious means of protection and the complementary protection measures adopted.

Crossflow filter Pag. 13/75

1.7.2 PICTOGRAMS REGARDING OPERATOR QUALIFICATIONS

Table 1–1

Symbol Description

Unskilled laborer: operator without specific skills capable of performing only simple

tasks upon instruction by qualified technicians.

Lifting and moving equipment operator qualified for the use of lifting and moving

equipment for the materials and the machine (while scrupulously following the

Manufacturer’s instructions) in compliance with the laws in force in the nation of use.

Level 0 machine operator (User): operator without specific skills capable of

performing only simple tasks, such as the operation of the machine using the operator

panel without the use of the password.

Valve opening/closing operations and device enabling/disabling operations with safety

guards installed and enabled; this operator is not qualified to modify PROCESS

PARAMETERS for the various work phases.

Level 1 machine operator (Client technician): operator capable of performing all the

tasks of a Level 0 machine operator and qualified to modify the PROCESS

PARAMETERS for the various work phases (Password level 1).

Not qualified to modify MACHINE CONFIGURATION PARAMETERS.

Level 2 machine operator (Advanced client technician): operator capable of

performing all the tasks of a 1st level machine operator and qualified to modify

MACHINE CONFIGURATION PARAMETERS (Password level 2).

Level 3 Manufacturer’s technician: a qualified technician provided by the

Manufacturer to conduct operations of complex nature in particular situations or

whenever agreed with the user. This person may vaunt mechanical and/or electric

and/or electronic and/or software skills as required.

This person can access all MACHINE SETTING PARAMETERS protected by

Password level 3.

Mechanical maintenance man: a qualified technician capable of operating the

machine under normal conditions, with the safety guards disabled, and intervening on

the mechanical organs for the adjustment, maintenance, and repairs necessary. This

person is not usually enabled to perform operations on the electric system with

voltage connected.

Electric maintenance man: a qualified technician capable of operating the machine

under normal conditions and with the safety guards disabled, and assigned to all the

electrical operations regarding adjustment, maintenance This person is enabled to

perform operations inside the electric cabinets and cutout boxes with voltage

connected.

Crossflow filter Pag. 14/75

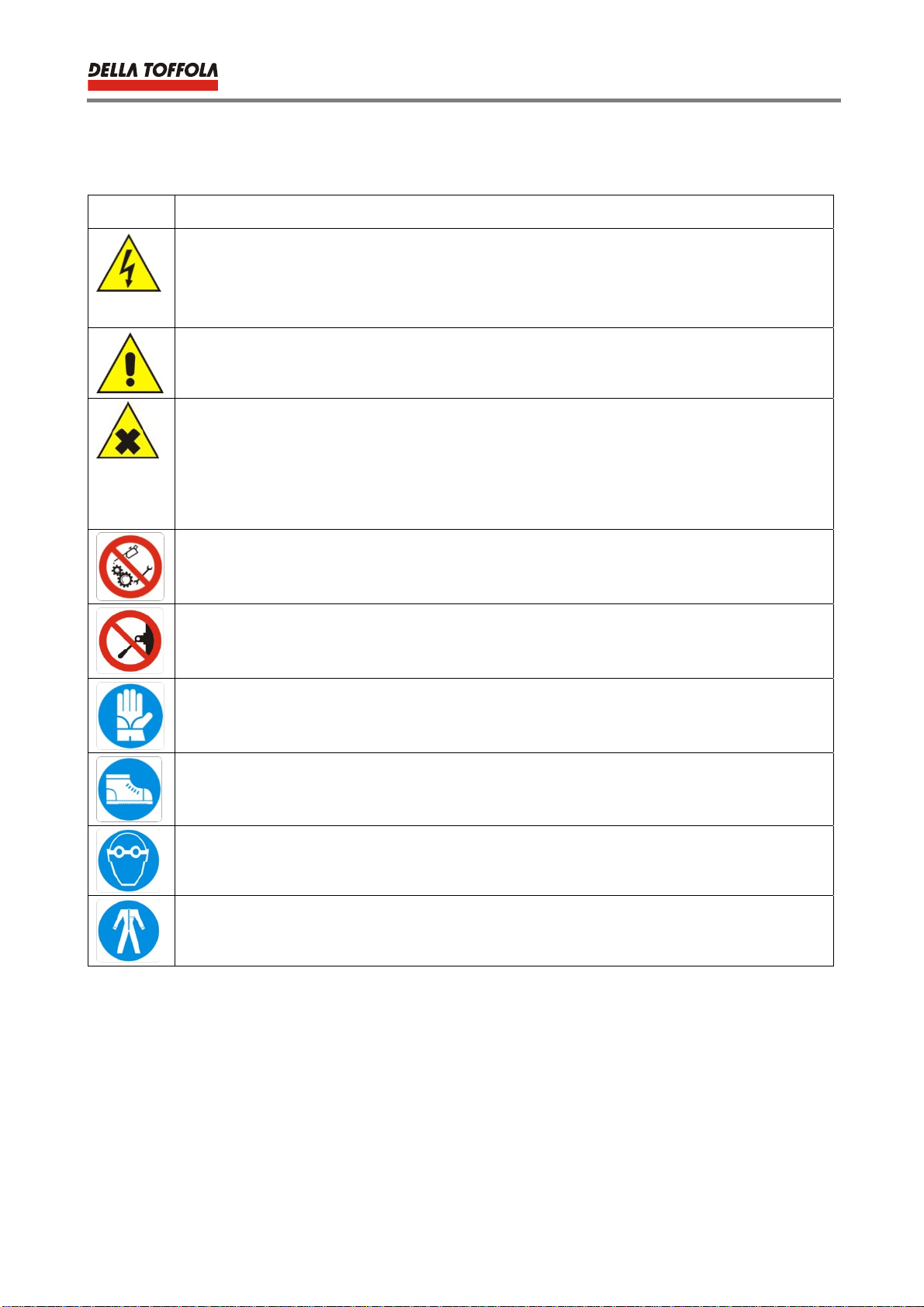

1.7.3 PICTOGRAMS REGARDING SAFETY

●Pictograms inside a triangle indicate DANGER.

●Pictograms in a circle indicate an OBLIGATION or a PROHIBITION.

Symbol Name

High voltage

The presence of this symbol is intended to draw the attention of personnel to the

possibility of serious damage and injury and even death whenever the safety

measures specified are not applied. This symbol draws attention to the risks posed

by the presence and use of electricity.

Risk

This symbol is used to highlight extremely important information/prescriptions with

particular regard to safety which if not respected can lead to injury.

Irritants/corrosive substances

The acid substances used for the chemical washing of the machine are capable of

producing toxic and corrosive reactions on human tissue in case of contact, and their

fumes can cause serious irritation to the eyes, the respiratory tract, and the mucosa.

Read the safety information provided on the label by the producer and adopt all the

measures indicated prior to using such substances.

Cleaning, repairing or setting moving parts by hand prohibited.

Performing operations before first disconnecting all voltage through the use of the

main power switch prohibited.

Safety gloves must be worn.

Safety footwear must be worn.

Goggles or facemask must be worn.

Protective clothing must be worn.

Table1–2

Crossflow filter Pag. 15/75

2 GENERAL INFORMATION

2.1 MANUFACTURER IDENTIFICATION DATA

MANUFACTURER

Della Toffola S.p.A

Via Feltrina 72

31040 Signoressa di Trevignano (TV) (Italia)

CONTACT PERSONS

Tel.: +39 0423 6772

Fax: +39 0423 670841

2.2 MACHINE IDENTIFICATION DATA AND NAMEPLATES

2.2.1 CE nameplate

The machine is identified by means of a CE nameplate on which its identification data are indelibly

printed.

Figure 2–1

The CE nameplate must be kept intact and visible because it specifies the main characteristics of

the machine, such as:

-manufacturer's name and address;

-name of the machine;

-serial number;

-year of manufacture;

-weight.

This manual suits for next models

4

Table of contents

Popular Water Filtration System manuals by other brands

Vacon

Vacon RFI-0012-5-IP54 user manual

Grunbeck

Grunbeck BOXER RX 1 1/2 Operation manual

Sterilight

Sterilight Ozone S2ROZAP Installation instructions and owner's manual

US Water Systems

US Water Systems Big Blue installation guide

Waterdrop

Waterdrop WD-PT-04-42 owner's manual

eSpring

eSpring 11-0192-CA owner's manual