delta-mobrey CS Series Guide

Page 1 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

Installation, Operation &

Maintenance Instructions

CS Series

Models CS2, CS4 (Pressure Switches)

CONTENTS

Foreword

• Allowed over range

• Ambient temperature

• Process temperature

• Tools to be used for checking and adjusting set point

Operating principle

Marking

List of standards to which the product conforms

Special conditions of use

Installation

• Mounting

• Electrical connections

• Wiring

• Earthing connections

Safety Integrity Level (SIL) instrument installation

requirements

Commissioning

Inspection and maintenance

• Periodical visual inspection

• Periodical functional verification

Replacement parts

Warranty

Decommissioning

Disposal

Model code

SAFETY INSTRUCTIONS

Information ...points out useful tips,

recommendations and information

for efficient and trouble-free

operation.

CAUTION! ...indicates a potentially dangerous

situation that can result in light

injuries or damage to equipment or

the environment, if not avoided.

WARNING! ...indicates a potentially dangerous

situation that can result in serious

injury or death, if not avoided.

WARNING!...identifies hazards caused by

electric power. Should the safety

instructions not be observed, there

is a risk of serious or fatal injury.

WARNING! ...indicates a potentially dangerous

situation that can result in burns,

caused by hot surfaces or liquids, if

not avoided.

WARNING! ...indicates a potentially dangerous

situation in the hazardous area that

can result in serious injury or death,

if not avoided.

Ex applications…special instructions for Ex

applications.

Foreword

The unit is manufactured, checked and supplied in

accordance with our published specification, and when

installed and used in normal or prescribed applications,

with the lid in place and within the parameters set for

mechanical and electrical performance, will not cause

danger or hazard to life or limb.

Warning: Units must be selected and installed by

suitably trained and qualified personnel in

accordance with appropriate codes of practice so

that the possibility of failure resulting in injury or

damage caused by misuse or misapplication is

avoided.

Warning: Before installation check that the

instrument characteristics comply with process

and plant requirements

Warning: The user should ensure the equipment is

suitable for use in the application with aggressive

substances.

Warning: The users attention is drawn to the fact

that, when the unit is ‘live’ with respect to electrical

or pressure supplies, a hazard may exist if the unit

is opened or dismantled.

Warning: Where any special condition of the

product has been required as identified by the last

4 digits of the part number, follow the necessary

safety instruction for a correct installation.

Allowed over range

Pressure exceeding the adjustable range can be allowed

up to the max pressure stated on the nameplate.

Transitory electrical over ranges can have a destructive

effect on the microswitch.

Ambient temperature

The surface temperature of the instrument is influenced by

the process temperature, electrical working conditions,

installation and environmental. Special attention must be

taken to avoid exceeding the limits specified on table

below (i.e. remote mounting, valves, siphons, diaphragm

seals. See Mounting).

Process temperature

The following tables are applicable:

Temperature

Class

Ambient

temperature range

Max process

temperature at

process

Max electrical

loads

(resistive loads)

T6 .. T5 From –40 to +60°C 60°C Up to 5 A (see

nameplate)

T4 … T1 From –40 to +85°C 85 °C

Temperature

Class

Ambient

temperature range

Max process

temperature at

process

Max electrical

loads

(resistive loads)

T6 .. T5 From –40 to +45°C 45°C Up to 11 A (see

nameplate)

T4 … T1 From –40 to +85°C 85 °C

Page 2 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

Operating principles

Pressure Switch models CS2 & CS4 are diaphragm

operated switches.

These diaphragms generate a force proportional to the

applied pressure and are balanced by a user adjustable

control spring. When the force exceeds that created by the

control spring, the diaphragm moves causing a push rod to

actuate a snap-acting microswitch.

Tools to be used for checking and

adjusting set point

The following calibration circuit is to be used to proceed

with the calibration of the set point or periodical functional

verification.

The test gauge should have a range similar to the

instrument under verification with an accuracy consistent

with the accuracy required to calibrate the set point.

Product Standards List

This product complies with the following standards:

IECEx ATEX UKEx

IEC 60079-0: Ed.7 EN 60079-0:2018 BS EN IEC 60079-

IEC 60079-1: Ed 7 EN 60079-1:2014 BS EN 60079-1:2014

IEC 60079-31: Ed.2 IEC 60079-31:2014 BS EN 60079-31:2014

IEC 60079-11: Ed 6 EN 60079-11:2012 BS EN 60079-11:2012

Marking

Flameproof models carry the following label markings:

Intrinsically safe models carry the following label

markings:

Input limitations for intrinsic safety:

Ui = 30V, Ii = 300mA, Ci = 1 nF; Li = 6.3 mH

Fig. 1 - Calibration Circuit

Special conditions of use

Warning: The instrument is not capable of

withstanding the 500V rms insulation test, this must

be taken into account when installing the

equipment

Warning: The equipment wire should be protected

from mechanical damage by the use of metal

conduit or an equivalent method, to prevent the

wiring from being subjected to tension or torque.

Warning: If the instrument is to be terminated

within a potentially explosive atmosphere, a

suitably certified junction box must be used.

Warning: The corrosive environmental conditions

may adversely affect the life and the type of

protection of the instrument. It is the responsibility

of the user to take suitable precautions that prevent

it, verify the compatibility of the environmental with

stainless steel and polymeric material.

Fig. 3 - Intrinsic Safety nameplate

Fig. 2 - Flameproof nameplate

Page 3 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

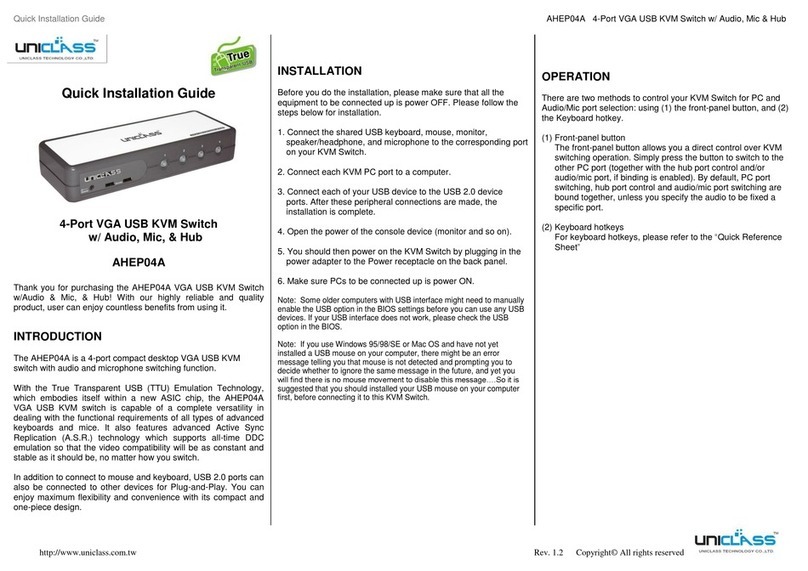

INSTALLATION

Mounting (All models)

The instruments are designed to be mounted vertically

with the process connection underneath. However,

mounting up to 45° from the vertical in any plane is

acceptable, although a small calibration shift may occur.

They can be mounted direct to the process. Select the

mounting point to avoid stresses, excessive shock,

vibration or temperature fluctuation being imparted to the

switch during the operation.

If sudden changes of pressure (pulsations) are likely then

we recommend that snubbers are fitted between the

process line and instrument.

Instruments should be mounted to avoid excessive heat

transfer from the process lines or adjacent plant.

With process fluid applications, that could crystallise/

solidify, we suggest the use of adequate chemical seals

and capillary.

Caution: Always hold a wrench on the pressure

entry hex when making a pressure connection to

the switch. Do not tighten by turning the electrical

entry; the microswitch assembly with factory sealed

leads has been carefully positioned at the factory.

Any disturbance may render this unit inoperative.

The following figures show the minimal installation tips

(Fig 4,5 and 6).

Caution: Check the connection thread size and

specification on the unit to avoid mismatching with

the process connection adaptor. See digit 11 of

product code.

Wiring

The instrument is equipped with wire with a cross section

of 0,75 mm2 (18 AWG). Individual cores of cable can be

coloured or numbered as show in fig.7.

The instrument may be equipped with micro switches

SPDT or DPDT.

Warning: Intrinsically safe instruments; where two

microswitches are fitted, the two switches must be

part of the same intrinsically safe circuit.

The entry parameters relevant for intrinsic safety

are listed on the nameplate of the instrument.

Electrical Connections

The instrument is provided with one electrical

entry. The thread type and size is marked on the

enclosure, just below the connection.

Warning: The leads are factory sealed. However,

the leads must be suitably protected against

mechanical damage and terminated in a suitable

junction box in accordance with local and national

codes.

Warning: Fittings/adaptor/plugs/terminal box used

for the electrical connection of the flameproof

instruments shall be certified according to IEC or

EN standards and shall guarantee the instrument a

level of protection to IP66

Warning: In order to guarantee the IP66 level of

protection and the non-loosening of fittings/

adaptor/plugs/terminal, we recommend sealing the

threads of connection with the same anaerobic

sealant. For instance, a sealant like Loctite ® 542

can be applied on the thread, before screwing

them.

Warning: The corrosive environmental conditions

may adversely affect the life and the type of

protection of the instrument. It is the responsibility

of the user to take suitable precautions that prevent

it, verify the compatibility of the environmental with

stainless steel and polymeric material.

Earthing connections

Warning: The instrument is to be grounded

according to applicable electrical codes. Make

use of the internal green wire and, if the cable is

not protected by metal tubing, make sure that the

equipment on which the instrument is installed is

suitably earthed.

2614

53

Fig. 7 - Wire Circuit

Fig. 4 - Remote installation

Fig. 5 - Direct Installation Fig. 6 - Installation on

Junction Box

Page 4 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

Operation Adjustments

Pressure switches are supplied and adjusted

at midscale falling, unless otherwise specified.

If the instrument has been ordered with

specific calibration values the adhesive label

shows the set point values.

It is a good rule to check the calibration values

marked on the relevant adhesive label, prior to

installation.

Calibration

Please follow the suggested steps below to

calibrate the set point of the instrument:

Connect the instrument to the pneumatic tools

in the normal installation position (see Fig.1).

If the instrument is supplied with a Junction

box, slacken the lid lock screw and unscrew

the lid. Connect the warning lamp according

the desired function.

Caution: Do not attempt to set the switch

outside the scale limits.

Though the unit may be set anywhere within

its range, for optimum performance, it is good

practice to have a set point value between

25% and 75% of span.

Connection C-NO terminal

- The circuit is open at the normal operating

pressure, the switch closes the circuit as the

pressure increases when the desired value is

reached

- The circuit is closed at the normal operating

pressure, the switch opens the circuit as the

pressure decreases when the desired value

is reached

Connection C-NC terminal

- The circuit is closed at the normal operating

pressure, the switch opens the circuit as the

pressure increases when the desired value is

reached

- The circuit is open at the normal operating

pressure, the switch closes the circuit as the

pressure decreases when the desired value

is reached

Pressurise the circuit and slowly increase the

pressure up to the set point.

Slide the cover upwards.

Using a screwdriver, rotate the range adjuster

right to left to increase the set point and left to

right to decrease the set point until the relative

lamp is turned ON, or OFF.

As a guide, one complete revolution of the

adjuster will alter the set point by

approximately 15% of the range.

Go to the normal operating pressure and

increase (or decrease) the pressure until the

relative lamp turn ON or OFF. Read the

pressure on the test gauge. Gradually adjust

the range adjuster and recheck again using

the lamp until the set point is achieved with the

required accuracy.

Slide the cover downwards.

Write the set point on the adhesive label

Periodical calibration checks

Connect the instrument to the pneumatic tools

in the normal installation position (see Fig.1).

Connect the warning lamp according to the

desired function.

Set point calibrated with increasing

pressure

From atmospheric pressure, pressurise the

circuit and increase the pressure up slowly to

the set point (the warning lamp is shown as

ON).

Record the pressure read on the test gauge.

Return to atmospheric pressure.

Repeat the above operation twice.

Set point calibrated with decreasing

pressure

From atmospheric pressure, pressurise the

circuit up to upper range value.

Decrease the pressure down slowly to the

set point (the warning lamp switches ON).

Record the pressure read it on the test

gauge.

Return to the upper range pressure value.

Repeat the above operation twice.

Evaluation of set point value and

repeatability

With all the above values detected, calculate:

- Average set point value

- Repeatability correspondent to the max

difference of the detected set point values.

If the average set point is different from the

expected, the instrument must be recalibrated.

If the repeatability is higher than the value in

the product Technical Data Sheet replace the

instrument with a new one and contact the

factory.

End of verification

Fig. 7 - Set point adjusting

Page 5 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

Replacement parts

IMPORTANT NOTE: Operations involving

the replacement of essential components

must be carried out at our workshop,

especially for instruments with a flameproof

certificate; this is to guarantee the complete

and correct restoration of the products

original characteristics.

Warning: The equipment contains no user-

replaceable parts and is not intended to be

repaired by the user.

Warranty

See Standard Conditions of Sale.

Periodical visual inspection

Isolate the unit from process and power.

Warning: The flameproof instruments

installed in explosive atmospheres of the

combustible dust, must be periodically

cleaned externally in order to remove any

accumulation of dust.

Verify the integrity of the electrical unit using

IEC 60079-17 as a guide.

Verify there is no external leakage of the

process media.

Should the diaphragm fail, the process will

vent to the atmosphere via a control orifice

without pressurising the switch enclosure.

Periodically ensure the vent area does not

become blocked and vent plug has not

degraded. Ensure that the vent area is not

obstructed.

Safety Integrity Level (SIL)

instrument and installation

requirements

Refer to Functional Safety Manual CS Series.

Commissioning

The instrument starts operating as soon as it

is energised and the root valve is opened.

Inspections and maintenance

The instrument is maintenance-free but it is

good practice to have periodical inspections

(visual and functional).

Inspections should be carried out at least once

a year depending upon operating,

environmental conditions and customer plan.

Caution: It is recommended that instruments

used to provide an alarm or a shutdown safety

related are operated periodically to ensure

they are functioning correctly.

If further maintenance is required seek advice

from Delta Mobrey before attempting repair or

replacement of parts.

Periodical functional verification

The verification consists of a check of the set

point. This verification is done, usually by

removing the instrument from the plant and

performing the verification in a test room (see

periodical /calibration check paragraph).

Warning: Flameproof instruments. Before

removing the lid or the cable gland check that

the electrical supply is not energised and that

no explosive atmosphere is present.

If the verification is done on site, the preferred

procedure is the verification of the entire loop

without removing the lid or the cable gland.

Warning: The flameproof instruments maybe

checked on site only if the apparatus suitable

for explosive atmospheres is used.

Warning: Verify that the loop is in a safe

configuration before acting on the valves and

instrument. Do not dispose of the process fluid

into the environment if this causes pollution or

personal injury.

Decommissioning

Warning: Verify that the loop is in a safe

state before working on the valves and

instrument. Power off the instrument and

verify, especially for a flameproof product, the

absence of an explosive atmosphere. Do not

dispose of the process fluid into the

environment if this causes pollution or

personal injury.

- Isolate the instrument from the process and

depressurise utilising the valves

- Disconnect all the live terminals and insulate

the cables

- Disconnect the grounding

- Remove the cable gland

- Disconnect the instrument from the process

connection.

Warning: The process fluid can be hot and or

corrosive.

Disposal

The instrument is mainly made of aluminium

and stainless steel. Remove the microswitch

and clean the wetted parts before scrapping

the instrument.

Page 6 of 6 www.delta-mobrey.com

IOM-CS-F: AUG 2022

Model code

Enclosure

Model

Electrical Entry

Material of Wetted Part

Range

Switch

Process Connection

Options & Treatments

Special Engineering

DIMENSIONS

Enclosures Styles

www.delta-mobrey.com

This manual suits for next models

2

Other delta-mobrey Switch manuals

Popular Switch manuals by other brands

Cisco

Cisco Catalyst 2960-S Series Started guide

Hubbell

Hubbell Circuit-Lock installation instructions

Uniclass

Uniclass AHEP04A Quick installation guide

3Com

3Com Switch 7700 Configuration guide

United Electric Controls

United Electric Controls ONE Series Installation and maintenance instructions

SMC Networks

SMC Networks ZSE40A Operation manual