Delta-T T Series Operating instructions

(847) 360-9170

World Leader in Used Die Casting Machinery!

HOME

RECENT

ADDITIONS

INDUSTRY

SERVICES

JOIN OUR

MAILING LIST

SELL US

YOUR MACHINE

If we can be of any assistant or if you have any questions,

please don't hesitate to contact us at (847) 360-9170.

You may also visit our website at

https://www.diecastmachinery.com

Thank you!

Document #: EM-00002 Revision: D

Document P/N: 900-00001-00 2of 19 | P a g e

TABLE OF CONTENTS

SAFETY GUIDELINES ..................................................................................................................................................3

Safety Symbols and Descriptions..............................................................................................................................3

Warnings and Precautions ........................................................................................................................................3

GENERAL INFORMATION............................................................................................................................................5

Purpose of Instructions..............................................................................................................................................5

Equipment Description ..............................................................................................................................................5

Models Covered ........................................................................................................................................................5

Included Documents..................................................................................................................................................5

Standard Equipment Features...................................................................................................................................5

SHIPPING INFORMATION............................................................................................................................................6

Receiving and Inspection ..........................................................................................................................................6

Uncrating Your Unit...................................................................................................................................................6

INSTALLATION..............................................................................................................................................................7

Work Rules................................................................................................................................................................7

Unit Location..............................................................................................................................................................7

Rigging......................................................................................................................................................................7

Electrical Connections...............................................................................................................................................7

Piping Connections....................................................................................................................................................8

Piping Considerations ...........................................................................................................................................8

Process Connections ............................................................................................................................................8

Cooling Water Supply Connection (Cooling Option)..............................................................................................8

Filling the Tank with Oil.........................................................................................................................................9

FIRST TIME STARTUP PROCEDURE........................................................................................................................10

Preliminary Operations............................................................................................................................................10

Startup Procedures..................................................................................................................................................10

Operation.................................................................................................................................................................11

Circulation of Oil in the System................................................................................................................................11

Returning Oil to Tank...............................................................................................................................................11

Controller Operation................................................................................................................................................12

Safety Thermostat...................................................................................................................................................12

ROUTINE MANTENANCE...........................................................................................................................................13

Motor.......................................................................................................................................................................13

Pump.......................................................................................................................................................................13

Heaters....................................................................................................................................................................13

Reservoir Vent.........................................................................................................................................................13

Drain Lines ..............................................................................................................................................................13

Oil….................................................................................................................................................................... …13

Heat Exchanger.......................................................................................................................................................14

Strainers..................................................................................................................................................................14

Connection Lines.....................................................................................................................................................14

Troubleshooting Guide.................................................................................................................................................15

Document #: EM-00002 Revision: D

Document P/N: 900-00001-00 3of 19 | P a g e

SAFETY GUIDELINES

SAFETY SYMBOLS AND DESCRIPTIONS

High Voltage Hazard

The equipment is supplied with 3-phase electrical power. Components inside this equipment may

have live power. Use caution when servicing this equipment.

Hot Surface Hazard

This equipment has the ability to operate above 212°F (100°C). The surface of the equipment’s

cabinet and connected piping may reach excessive temperatures. Use caution when servicing

this equipment.

Caution

This equipment can cause a potentially hazardous situation. If caution is not taken, there is a

potential for injury and death or property damage.

WARNINGS AND PRECAUTIONS

The Delta T Systems Oil Temperature Control Unit is designed to provide safe and reliable operation when installed

and operated within design specifications, following national and local safety codes.

To avoid possible personal injury or equipment damage when installing, operating or maintaining this equipment, use

good judgment and follow these safe practices:

1. Compliance and recognition of the following precautions are the sole responsibility of

the user of this equipment.

2. Do not operate or service this equipment until you have read and understand the

manual supplied with this equipment.

3. Only qualified personnel familiar with the information within this manual should install,

use, or service this equipment.

4. Follow all Safety Codes

5. Wear safety glasses and work gloves.

6. Install and ground equipment per NEC code and local requirements before switching

on main power.

7. Operate equipment within design specifications.

8. Unrestricted flow of fluids to drain service must be provided.

9. This equipment may contain dangerously hot fluids which may cause components,

cabinets and piping to be a burn hazard. Do not come in contact with hot fluid or piping.

10. Cool equipment down to at least 125°F prior to shutting down and relieve internal

pressure from air and fluid supply before disconnecting or servicing this equipment.

11. When welding or brazing in or around this equipment be sure there is adequate

ventilation. Protect adjacent materials from flame or sparks by shielding with sheet

metal. An approved fire extinguisher should be close at hand and ready for use if

needed.

Document #: EM-00002 Revision: D

Document P/N: 900-00001-00 4of 19 | P a g e

12. Do not operate equipment without covers installed and do not jump or bypass electrical

safety controls.

13. Control power switches do not remove power to all terminals. Turn off or disconnect

main power to unit when not in use, or for service.

14. Do not restore power until all tools, test equipment, etc. have been removed and the

panels replaced.

15. Open, tag and lock all disconnects before working on equipment. It is best practice to

remove all the fuses and carry them with you.

16. Make sure the temperature control unit is properly grounded before switching power

on.

17. Disconnect and lock out input power before servicing this equipment.

18. Shut off equipment using main electrical disconnect.

19. Do not replace the breather plug on the inside of the unit or the breather on the

fill pipe on the outside of the unit with a plug or a cap. Never create conditions

which would allow the reservoir tank to be pressurized.

20. Do not operate or allow equipment to run unattended!!

Document #: EM-00002 Revision: D

Document P/N: 900-00001-00 5of 19 | P a g e

GENERAL INFORMATION

PURPOSE OF INSTRUCTIONS

These instructions are furnished to simplify and minimize your work of operating and maintaining Delta T Systems

Temperature Control Units.

Your acquaintance with the construction and characteristics of these units will help you obtain optimum performance,

reduce shutdowns and increase service life.

Some units may be modified for specific applications from those described in this bulletin and other changes may be

made without notice.

EQUIPMENT DESCRIPTION

Delta T Systems Oil Temperature Control Unit provides reliable and accurate temperatures up to 550°F (see equipment

specs). They are available in sizes up to 300KW and are self-contained, fully assembled and ready to use.

A properly installed, operated, and maintained unit will provide many years of reliable operation. To get the most

satisfaction from your new portable temperature control unit, please read and follow the instructions in this manual.

MODELS COVERED

This manual provides operation, installation and maintenanceinstructions for Delta T Systems T-series Oil Temperature

Control Units.

Model numbers can be found on the unit’s nameplate. If contacting Delta T Systems, please have your model

number and serial number available.

Model numbers containing an “X”a specially constructed custom unit, and not all information in this manual may apply.

For any custom unit shipped with additional documentation that conflicts with this manual, the unit-specific

documentation overrides.

INCLUDED DOCUMENTS

The following documents are included for the operation and maintenance, of your Delta T Systems Oil Temperature

Control Unit and internal components.

•This manual

•Electrical schematic

•Flow schematic

STANDARD EQUIPMENT FEATURES

•Microprocessor-Based PID Controller

•Over Temperature Protection

•Positive Displacement Pump

•Fused Motor Protection

•Fused Heater Protection

•Grounded Control Circuit

•Low Watt Density Heater Element

•Fused Transformer Protection on both Primary &

Secondary Sides

•Solid-State Heater Control Relays

•NEMA 1 Electrical Specifications & Wiring in

Conformance with NEC

•Bypass Valve to Insure Proper System Flow and

Velocity

•Delivery Pressure Gauge

•Pilot Lights to indicate Separate Functions of Use

SHIPPING INFORMATION

RECEIVING AND INSPECTION

Every Delta T Systems Oil Temperature Control Unit is shipped in a custom-made wood crate to ensure the integrity

of the unit when it is received at your facility.

If the crate seems to show signs of damage, thoroughly inspect the equipment for any signs of damage that may have

occurred in transit. If components are broken or damaged, refer to www.deltatparts.com or contact Delta T Systems for

potential return to the factory for recertification and repair.

UNCRATING YOUR UNIT

CAUTION: Steel banding may spring back and cause injury!

The crate and unit are heavy and should not be moved without the aid of a hand truck/fork lift.

First, remove sides and top from the base, but leave the unit banded to the base.

Then, cut steel banding to release the unit from the base.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 7of 19 | P a g e

INSTALLATION

WORK RULES

The installation, operation, and maintenance of this equipment must be conducted in accordance with all applicable

work and safety codes for the installation location. This may include, but is not limited to OSHA, NEC, CSA, and any

other local, national, and international regulations.

•Read and follow these instructions when installing, operating, and maintaining this equipment. If the instructions

become damaged or unreadable, obtain additional copies from Delta T Systems.

•Only qualified personnel familiar with this equipment should work on or with this Oil Temperature Control Unit.

•Work with approved tools and devices.

•Disconnect the electricity before maintenance or service.

UNIT LOCATION

The unit is designed for indoor installation where the temperature of the room is between 40°F and 120°F. The

equipment must be installed on a rigid surface suitable to support the full operating weight of the unit. Level all

equipment to ensure proper operation.

The unit must bein an accessiblearea. To allow forproper maintenance and servicing of the unit, consider accessibility

to all components when locating the unit. In general, whenever possible allow a minimum of 36 inches of clearance

around all sides and above the unit for maximum ease of service and maintenance. Avoid locating piping or conduit

over the unit. This ensures easy access with an overhead crane or lift to lift out heavier components when they are

replaced or serviced.

When locating the unit, it is important to consider a proper ventilation, especially in high ambient temperature conditions.

For proper ventilation and heat dissipation, allow an adequate room on both sides of the unit. Failure to do so may lead

to overheating of the motor windings and other components which can cause premature component failure.

RIGGING

The unit has a structural steel base with casters to facilitate easy movement and positioning. Follow proper rigging

methods to prevent damage to components. Avoid impact loading caused by sudden jerking when lifting or lowering

the unit. Use pads where abrasive surface contact may occur. Use the frame supporting the unit for positioning it with

a crane or forklift.

ELECTRICAL CONNECTIONS

WARNING: Electrical shock hazard

Check identification plate to make certain your electrical service conforms to unit specifications and amperage draw.

Have a qualified electrician bring properly sized power leads and ground from a fused disconnect to the unit. Make

certain the disconnect switch is sized according to the National Electrical Code recommendations.

•Electrical connections must comply with all applicable electrical codes.

•The temperature control unit must be grounded in accordance with NEC Article 250.

Before applying power: Tighten all electrical terminations or connections and inspect for damage to wires and

components, electrical connections can become loose during shipping.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 8of 19 | P a g e

PIPING CONNECTIONS

Piping Considerations

When installing the unit, all connection piping and hoses should follow these considerations:

•All external hose, valves, fittings, and piping should be rated for a minimum of 150 psi and 550°F

•All external hose, valves, fittings, and piping should be the same size or larger that the size of the connection. This

will help reduce flow restriction.

•If quick disconnects are used, be careful to minimize pressure drop. Do not use quick disconnects with check

valves unless absolutely necessary.

Process Connections

Every Delta T Systems Oil Temperature Control Unit connection is clearly labeled on the back of the unit. Make sure

you carefully select components with the minimum rating recommended in this manual.

DELIVERY –Connect this port to the Oil In port on your process

RETURN –Connect this port to the Oil Out port on your process

Connection port sizes will depend on the unit. To ensure maximum efficiency, the process oil piping circuit should be

designed to avoid excessive use of elbows and or lengths of pipe or hose. If hose is used, avoid tight bends, twists,

and curls.

Valves, filters, and strainers may be installed in the process piping circuit to aid in maintenance, provided that such

devices maintain full inside diameter of the process connection. If installed, conduct regular maintenance to guarantee

the devices are clean and not restricting flow to the process.

Cooling Water Supply Connection (Cooling Option)

Some Delta T Systems Oil Temperature Control Units come with a cooling option. The cooling option will utilize a shell

and tube heat exchanger with water or a water glycol mix as the cooling fluid. The cooling systems in Delta T Systems

Oil Temperature Control Units are designed to run with only water or a water glycol mix. The use of any other fluids is

prohibited. The connection portsize of the cooling water supply and drain will depend on the size of the heat exchanger.

WATER SUPPLY –Connect this port to your plant’s city water, well water, tower water, or chilled water supply.

WARNING: Use proper temperature and pressure rated piping and hose for external connections to

the unit.

WARNING: Using small diameter lines restricts flow and heat transfer.

Your Delta T Systems Oil Temperature Control Unit is designed to operate using most water sources available,

however, service life is greatly diminished by hard or corrosive water. These water sources cause control problems that

eventually damage your equipment.

It requires a water inlet and drain connection. The drain outlet should be unrestricted without back pressure and

should be directed away from all personnel.

It is highly recommended that you have a treated water source available for this equipment.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 9of 19 | P a g e

Filling the Tank with Oil

CAUTION: Because of the expansion of the oil during the process, be sure to not overfill the tank.

CAUTION: Do not replace the breather plug on the inside of the unit or the breather on the fill pipe

on the outside of the unit with a plug or a cap. Never create conditions which would allow the reservoir

tank to be pressurized.

The expansion tank, the internal piping, and the heater tank require an amount of oil depending on the model. Additional

oil should be added to fill the connecting lines plus the channels in the process. As the unit is operating in the heating

cycle, the oil expands.

Delta T Systems recommends Paratherm NF Heat Transfer Fluid for operating temperature from 100°F to 600°F.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 10 of 19 | P a g e

FIRST TIME STARTUP PROCEDURE

Please note before starting unit:

The controller provided with your Delta T Systems Temperature Control Unit has already been fully programmed. Any

attempts to re-set the values may cause a malfunction of the unit’s operation.

PRELIMINARY OPERATIONS

Prior to following the start up procedures, please make sure that all of the following items have been completed

1. Check to make sure the applied 3-phase voltage matches the unit nameplate within 10%.

2. Install all the process, supply, and drain connections.

3. Fill the tank to the correct level. Ensure the tank is not overfilled, as this will cause unit failure.

4. Ensure all the service panels are installed.

5. Connect the main power to the unit and follow the start up procedure.

CAUTION:

Your Delta T Systems Oil Temperature Control Unit operates with hot oil under pressure. To reduce

the risk of scalding:

•Always wear work gloves and safety glasses when operating the unit

•Never operate the unit with the cabinet panels removed

•NEVER install or use a hose or fitting that is rated less than 150 psi and 550°F

To reduce the risk of electrical shock:

•All electrical installing and repairs should be done by a qualified electrician

•Ground the unit in accordance with electrical codes

•Never attempt repairs without disconnecting and locking out main power

•Never jump or deactivate any safety devices

Venting of air and moisture from the process loop is the most important part of installing your new

Delta T Systems Oil Unit. Failure to fully vent the system of air and moisture properly prior to use can

cause severe injury or death.

STARTUP PROCEDURES

1. After electrical, oil, and water connections are made, and the tank is filled, proceed to the following steps.

2. Turn the cool/off/auto selector switch to “OFF”.

3. Close return line valve and open the vent valve.

4. Push Start/Forward button and check the fluid in the gauge glass:

•If oil goes down and the rotation matches with the arrow on motor: the motor rotation is correct

•If oil goes up and the rotation doesn’t match with the arrow on motor: the motor rotation is wrong.

To change motor rotation, follow the steps below:

I. Disconnect and lock out incoming power to the unit.

II. Reverse leads L1 and L3 on incoming supply power.

III. Do not switch leads at the motor, contactors, or starters.

IV. Recheck for proper rotation and pressure when unit is running.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 11 of 19 | P a g e

5. If positive pressure is not noticed or oil level in the sight gauge is not going down after 10-15 seconds, push Stop

button and repeat until positive pressure is observed or oil level begins to go down.

6. Push Start/Forward button. Once pressure in the pressure gauge is noticed, open the return valve slightly. If any

air is in the system, it will come out the vent valve, and air will be noticed in the gauge glass. Allow unit to run

until no air bubbles are noticed in the gauge glass. Open the return valve slightly every 5 minutes. Watch the flow

coming into the gauge glass for bubbles or erratic flow.

7. Once the unit is vented of air, turn the cool/off/auto switch to “AUTO” and input a set point of 215F.

8. Continue to vent unit until pressure gauge is holding steady and no air bubbles appear in the sight glass.

9. Completely close the vent valve.

10. Recheck the sight gauge glass for proper fluid level.

OPERATION

Push the Start/Forward button. The pump will start automatically and the power light will illuminate.

To set your desired temperature, please refer to the information in the manual concerning your temperature controller.

Switch the cool-off-auto selector to Auto.

NOTE: The energy from the pump adds heat to the oil, and the oil will warm up to a higher temperature than ambient

conditions, even when the heaters are off. If the TCU does not have a heat exchanger, the oil will always remain

above the ambient temperature while the pump is running.

CIRCULATION OF OIL IN THE SYSTEM

Upon Startup of a new or reconnected unit, the pump and motor should always be checked for proper rotation.

1. To start the pump, push the Start/Forward switch. This is a spring return momentary switch.

2. Fluid will be drawn to the pump and starts to circulate throughout the system.

3. As fluid is circulated through the system pressure will develop and will be indicated on the pressure gauge.

4. High pressures will initially be noticed until the fluid starts to heat up and then lower pressures will be noticed

depending upon operating temperatures and fluid velocity.

5. Returning fluid passes through a strainer which collects any foreign matter.

NOTE: If high pressure is constantly present, even if the return valve is open, the strainer should be checked for

blockage.

A bypass valve is installed in every Delta T Systems Oil TCU. The bypass is installed to prevent the system from

experiencing high pressure. The valve is a preset valve that connects the delivery to the return of the TCU to allow oil

to bypass the process. If there is a blockage or restriction in the process lines, the valve will open to allow flow through

the TCU.

Important: It is very important that the sight gauge glass indicates there is an ample supply of fluid contained in the

expansion tank. One or two inches visible in the sight glass is sufficient after the system is properly purged of air.

RETURNING OIL TO TANK

Do not replace the breather plug on the inside of the unit or the breather on the fill pipe on the

outside of the unit with a plug or a cap. Never create conditions which would allow the

reservoir tank to be pressurized.

Caution: The expansion tank may not have adequate volume to hold total system capacity. Ensure

the amount of fluid in the process is sufficient.

If your unit is equipped with the “pump reverse” feature, the following steps must be taken to return fluid to the tank:

•Cool the unit down until the oil is under 100°F (Push the Cool switch).

•Push Stop button (this must be done before using pump reverse).

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 12 of 19 | P a g e

•Close the return line valve.

•Open the vent valve to allow air to enter the system.

•Push the reverse button, and fluid will start to run in the reverse direction into the expansion tank.

•Watch the sight glass gauge as it fills up because it may not be large enough to hold all the fluid volume.

CONTROLLER OPERATION

See the Controller bulletin for instructions on the controller in your unit.

SAFETY THERMOSTAT

The safety thermostat is installed to prevent a runaway temperature situation. When the temperature of the oil reaches

the pre-set, non-adjustable temperature, the safety thermostat will cut power to the heater. The unit will still circulate

but will not heat the oil. To reset the safety thermostat, wait for the temperature of the oil to decrease, then click the

“rst” button directly on the safety thermostat. Once reset, the TCU should return to normal operation.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 13 of 19 | P a g e

ROUTINE MANTENANCE

Periodic inspection of the following equipment must be made to maintain optimum performance of your Delta T Systems

Oil Temperature Control Unit.

WARNING:

•Improper electrical connections can damage the unit and cause serious operator injury or death.

•Disconnect all power to the unit, let the unit cool down, relieve all water pressure, and turn off the

water prior to any servicing.

CAUTION:

•All electrical connections must be done by a qualified electrician. Never attempt to service a unit until

a qualified electrician has opened and locked out the main disconnect using proper safety

procedures.

•Internal pressure should be relieved before working on the unit. To do so shut off the water supply,

and switch to cool to empty the water left in heat exchanger and associated piping.

•Maintenance should be done by an individual familiar with all of the information in this manual

MOTOR

1. Clean out the motor air intake grill of dust and any oil accumulation

2. Make certain that the belts are in good condition and are aligned with the pump. Replace if necessary.

PUMP

1. It is best practice to keep the pump as clean as possible. This will facilitate inspection, adjustment, and repair

work and help prevent omission of lubrication to fittings covered or hidden with dirt.

2. Check bolts and nuts that hold the pump to the support

3. If your unit has a mechanical seal pump, it should not leak. Leaking on this type of pump indicates a failing seal

and the seal should be replaced.

4. Grease all bearings after 500 hours of operation or after 60 days, whichever comes first. Use #2 ball bearing

grease.

HEATERS

Heaters may need to be cleaned chemically or mechanically to remove build up on the sheath of the elements. Never

reuse an old gasket when reinstalling heaters.

RESERVOIR VENT

Do not replace the breather plug on the inside of the unit or the breather on the fill pipe on the

outside of the unit with a plug or a cap. Never create conditions which would allow the

reservoir tank to be pressurized.

DRAIN LINES

Check outlet of drain line for any obstructions or back pressure.

OIL

Be sure to replace oil according to manufacture recommendations.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 14 of 19 | P a g e

HEAT EXCHANGER

Inspect frequently for leaks.

STRAINERS

Clean out the strainers as needed depending upon usage and operating conditions.

Take off the side panel, remove the screen inside the strainer and clean it.

CONNECTION LINES

Connection lines, hose and connectors should be inspected frequently to ensure that the original service rating has not

been reduced by age, damage and/or deterioration.

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 15 of 19 | P a g e

TROUBLESHOOTING GUIDE

PREPARE FOR TROUBLESHOOTING:

•Many common performance issues are caused by air in the process loop. Verify the unit/process

is fully vented (see Step 6 in the Startup Procedures, Page 11).

•Verify all connections to the process and cooling water (if present) are correct (deliver-to-delivery,

return-to-return, water supply, water drain).

•The troubleshooting guide applies to typical Oil TCUs with no special custom functionality.

•Refer to the image below of a typical Oil TCU electrical panel to aid in identification of components

during troubleshooting.

2

3

1

HEATER PRIMARY

CONTACTOR

HEATER SAFETY

CONTACTOR

SAFETY

THERMOSTAT

4

HEATER FUSES

5

CONTROL FUSES

6

MOTOR FUSES

7

MOTOR

CONTACTOR

8

MOTOR

OVERLOAD

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 16 of 19 | P a g e

TROUBLESHOOTING GUIDE

CONTINUED NEXT PAGE…

YES

1. IS THE SUPPLY

VOLTAGE CORRECT?

CORRECT THE

SUPPLY VOLTAGE

NO

CHECK

YES

NO

2. DOES THE CONTROLLER

LIGHT UP?

PROCEED TO STEP 4

4. IS THE MOTOR

OVERLOAD TRIPPED?

RESET OVERLOAD

& VERIFY TRIP

SETTING

NO

YES

5. ARE THE MOTOR

FUSE(S) BLOWN?

REPLACE FUSE(S)

NO

IF PROBLEM STILL PERSISTS,

CALL DELTA T SERVICE

(800) 733-4204

UNIT WILL NOT

START/ RUN

ELECTRICAL

TROUBLESHOOTING

REQUIRES ACCESS

INSIDE THE ELECTRICAL

ENCLOSURE AND

SHOULD BE PERFORMED

BY, OR UNDER THE

DIRECT SUPERVISION OF

A QUALIFIED

ELECTRITIAN.

PRIOR TO SERVICING

ANY ELECTRICAL

COMPONENT, VERIFY

THE UNIT IS OFF AND ALL

SUPPLY POWER IS

DISCONNECTED.

YES

3. ARE THE CONTROL OR

PRIMARY FUSE(S)

BLOWN?

REPLACE FUSE(S)

NO

YES

5

8

6

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 17 of 19 | P a g e

TROUBLESHOOTING GUIDE

1.

CONTINUED NEXT PAGE…

TRY

ADJUSTING THE RETURN VALVE TO THROTTLE FLOW.

UN-THROTTLED FLOW IS A COMMON CAUSE OF LOW PRESSURE

NO

YES

1. IS THE PUMP/ MOTOR

RUNNING?

GO TO “UNIT WILL NOT

START/RUN”

(SEE STEP 4 ON PAGE 16)

UNIT DEVELOPS

INSUFFICIENT

PRESSURE

CHECK

TO PREVENT SERIOUS

BODILY HARM, VERIFY

UNIT IS OFF, POWER IS

DISCONNECTED, AND

ALL RESIDUAL MOTION

IS STOPPED BEFORE

SERVICING PUMP,

MOTOR, OR BELT!

YES

NO

REPLACE BELT OR

ADJUST TENSION

3. IS THE DRIVE BELT

BROKEN/SLIPPING?

(PD PUMPS ONLY)

N/A

OR

TCU SURFACES MAY BE

HOT, VERIFY UNIT HAS

COOLED BEFORE

SERVICING!

2. IS THE PUMP

ROTATION CORRECT?

(SEE STEP 4 ON PAGE 10)

REVERSE PUMP

ROTATION

(SEE STEP 4 ON PAGE 10)

YES

NO

TRY

ADJUSTING THE RETURN VALVE TO UNRESTRICT FLOW.

RESTRICTED FLOW IS A COMMON CAUSE OF HIGH PRESSURE

NO

YES

1. IS THE STRAINER

CLEAN?

CLEAN STRAINER

UNIT DEVELOPS

EXCESSIVE

PRESSURE

CHECK

YES

CLEAN PROCESS LOOP

2. IS THERE A

BLOCKAGE IN

YOUR PROCESS?

TO PREVENT SERIOUS

BODILY HARM, VERIFY

UNIT IS OFF, POWER IS

DISCONNECTED, AND

ALL RESIDUAL MOTION

IS STOPPED BEFORE

SERVICING PUMP,

MOTOR, OR BELT!

TCU SURFACES MAY BE

HOT, VERIFY UNIT HAS

COOLED BEFORE

SERVICING!

NO

IF PROBLEM STILL PERSISTS,

CALL DELTA T SERVICE

(800) 733-4204

IF PROBLEM STILL PERSISTS,

CALL DELTA T SERVICE

(800) 733-4204

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 18 of 19 | P a g e

TROUBLESHOOTING GUIDE

CONTINUED NEXT PAGE…

CHECK

2. IS THE UNIT SET TO

“AUTO”?

NO

YES

SWITCH TO “AUTO”

1. IS THE SETPOINT

GREATER THAN THE

PROCESS TEMP?

YES

NO

INCREASE SETPOINT

3. IS THE HEAT LIGHT ON?

GO TO STEP 5

NO

YES

T

4. IS RETURN PRESSURE

GREATER THAN 10PSI?

ADJUST RETURN

VALVE TO INCREASE

RETURN PRESSURE

YES

NO

5. IS THE SAFETY

THERMOSTAT TRIPPED?

HOLD DOWN “RST”

BUTTON TO RESET

NO

YES

UNIT RUNNING,

NOT HEATING

ELECTRICAL

TROUBLESHOOTING

REQUIRES ACCESS

INSIDE THE ELECTRICAL

ENCLOSURE AND

SHOULD BE PERFORMED

BY, OR UNDER THE

DIRECT SUPERVISION OF

A QUALIFIED

ELECTRITIAN.

PRIOR TO SERVICING

ANY ELECTRICAL

COMPONENT, VERIFY

THE UNIT IS OFF AND ALL

SUPPLY POWER IS

DISCONNECTED.

TO PREVENT SERIOUS

BODILY HARM, VERIFY

UNIT IS OFF, POWER IS

DISCONNECTED, AND

ALL RESIDUAL MOTION

IS STOPPED BEFORE

SERVICING PUMP,

MOTOR, OR BELT!

TCU SURFACES MAY BE

HOT, VERIFY UNIT HAS

COOLED BEFORE

SERVICING!

7. IS THE HEATER

PULLING A BALANCED

AMP LOAD ACROSS ALL

THREE LEGS?

REPLACE FUSE(S)

YES

NO

6. ARE THE HEATER

FUSE(S) BLOWN?

NO

REPLACE HEATER

YES

IF PROBLEM STILL PERSISTS,

CALL DELTA T SERVICE

(800) 733-4204

3

4

Document #: EM-S00002 Revision: B

Document P/N: 900-00001-00 19 of 19 | P a g e

TROUBLESHOOTING GUIDE

CHECK

2. IS THE UNIT SET TO

“AUTO”?

NO

YES

SWITCH TO “AUTO”

1. IS THE SETPOINT

LOWER THAN THE

PROCESS TEMP?

2.

YES

NO

DECREASE SETPOINT

3. IS THE COOL LIGHT

ON?

CALL DELTA T

SERVICE

(800) 733-4204

NO

4. IS THERE WATER

SUPPLIED TO THE

WATER SUPPLY

CONNECTION?

UNIT RUNNING,

NOT COOLING

YES

NO

CONNECT WATER

SUPPLY

YES

IF PROBLEM STILL PERSISTS,

CALL DELTA T SERVICE

(800) 733-4204

NOTE:

THE ENERGY FROM THE PUMP

ADDS HEAT TO THE OIL, AND THE

OIL WILL WARM UP TO A HIGHER

TEMPERATURE THAN AMBIENT

CONDITIONS, EVEN WHEN THE

HEATERS ARE OFF.

IF THE TCU DOES NOT HAVE A

HEAT EXCHANGER, THE OIL WILL

ALWAYS REMAIN ABOVE AMBIENT

TEMPERATURE WHILE THE PUMP

IS RUNNING.

Table of contents

Popular Control Unit manuals by other brands

Samson

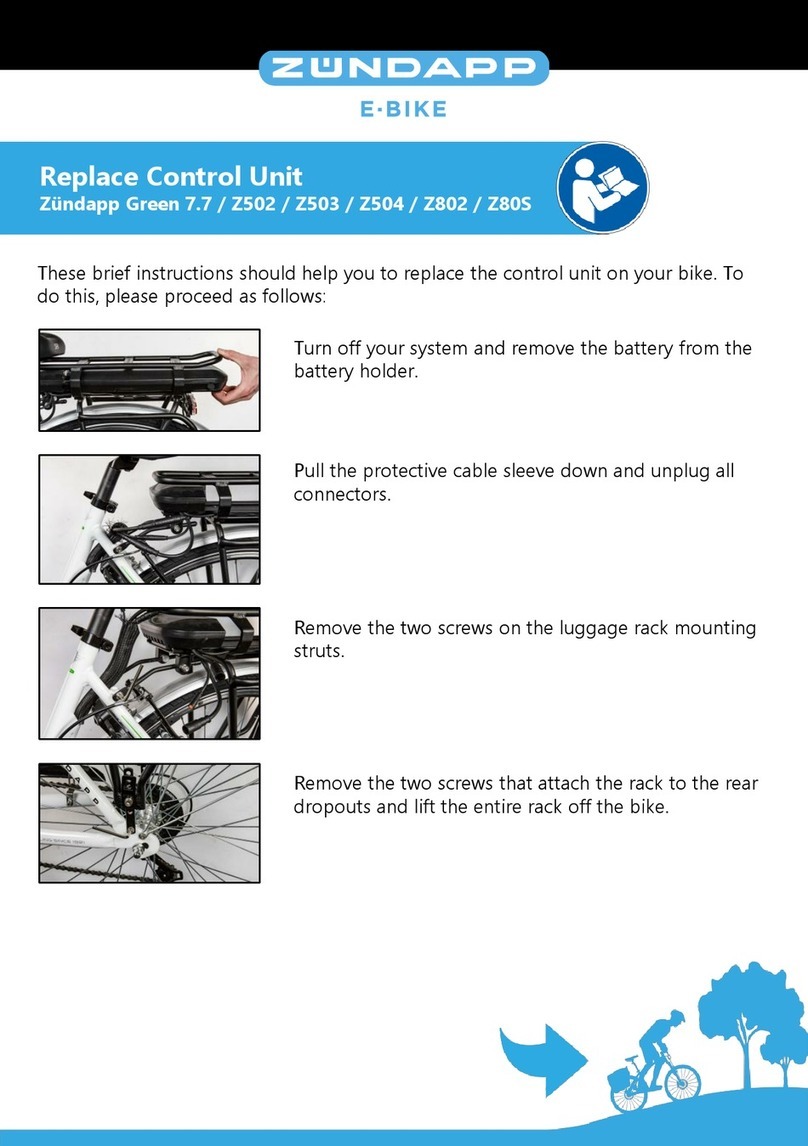

Samson 3711 Mounting and operating instructions

Jetter

Jetter JX3-COM-PND installation manual

Belimo

Belimo SHP Series Installation Recommendations

Siemens

Siemens ANT792-6MN Compact operating instructions

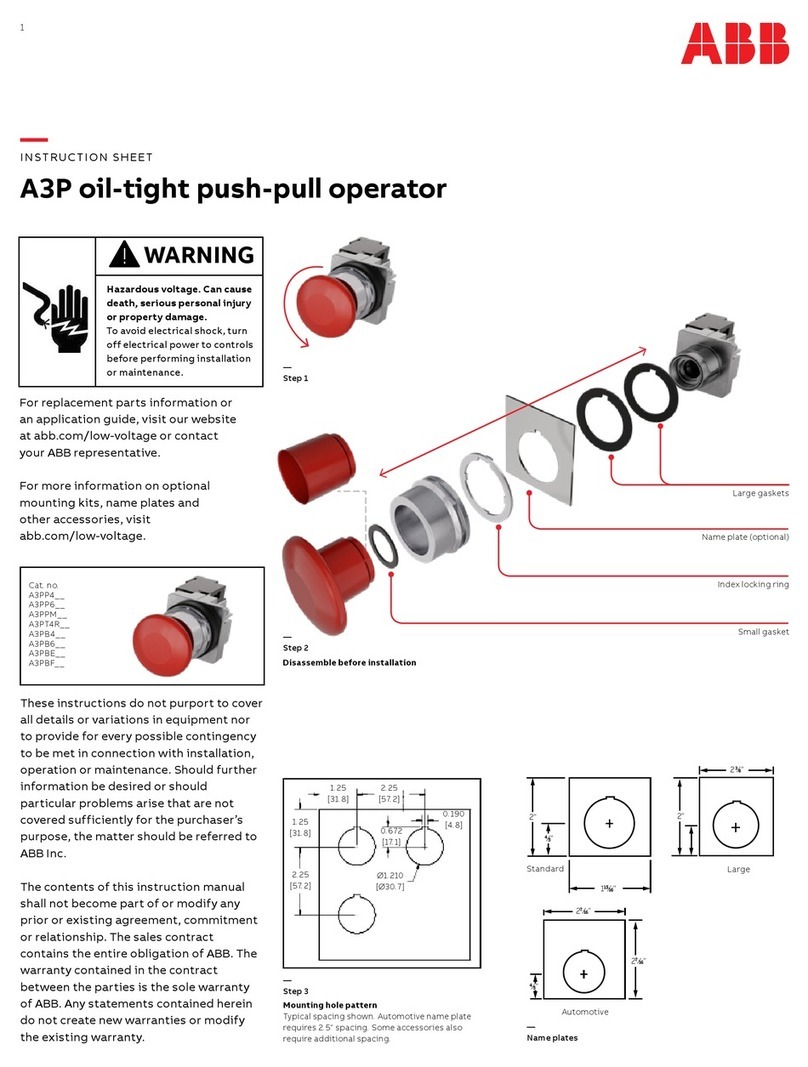

ABB

ABB A3 Series instruction sheet

Panduit

Panduit IndustrialNet IAEBHUSBAA installation instructions