BEAMEX POC4 User manual

Instruction Manual for

AUTOMATIC PRESSURE

OUTPUT MODULE POC4

Dear user,

We have made every effort to ensure the accuracy of the

contents of this manual. Should any errors be detected, we

would greatly appreciate to receive suggestions to improve the

quality of the contents of this manual.

The above not withstanding, we can assume no responsibility

for any errors in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without

any further notice.

For more detailed technical data about POC4, please contact

the manufacturer.

© Copyright 1997, 2006

OY BEAMEX AB

Ristisuonraitti 10

68600Pietarsaari

FINLAND

Tel +358 - 10 - 5505000

Fax +358 - 10 - 5505404

E-mail: [email protected]

Internet: http://www.beamex.com

8889700 / UEPOC4S / 000886

Operation panel (front panel)

Connection panel (rear panel)

ANALOGUE

OUTPUT OPTIONAL

INTERFACE RS232 IEEE488 CALIBRATION

MODE

VENT SOURCE OUTLET

SUPPLY INPUT

G1/8

0 1

STACKING

0 1

Type: POC4

Serial number: 250

REFERENCE

M5

ELECTRICALSAFETY

INSTRUMENT MUST BE CONNECTED TO

PROTECTIVE EARTH/GROUND CONDUCTOR.

PNEUMATIC SAFETY

SOURCE PRESSURE MAY LEAK TO THE OUTPUT PORT UNDER

FAULT CONDITION. ENSURE PNEUMATIC SUPPLY IS

ISOLATED AND VENTED WHEN NOT IN USE.

MAXIMUM SOURCE PRESSURE = 125% FULL SCALE

88 to 264 V

50/60 Hz

60 VA MAX

FUSES T2.0 A

CONTENTS

PART A GENERAL

1 GENERAL OVERVIEW ...........................................................................................................A - 1

1.1 Unpacking and Inspection..................................................................................................A - 2

1.2 Safety..................................................................................................................................A - 3

2 FUNCTIONAL DESCRIPTION................................................................................................A - 4

2.1 General...............................................................................................................................A - 4

2.2 Instrument Electronics........................................................................................................A - 4

2.2.1 Digital Electronics.........................................................................................................A - 4

2.2.2 Analogue Circuit Operation..........................................................................................A - 5

3 INSTALLATION .......................................................................................................................A - 7

3.1 Safety Instruction................................................................................................................A - 7

3.1.1 Input/Output Connections.............................................................................................A - 7

3.2 Electrical Connections........................................................................................................A - 8

3.2.1 Electrical Safety Instructions........................................................................................A - 8

3.2.2 Power Supply Connections..........................................................................................A - 8

3.3 Communications Interface Connections............................................................................A - 9

3.4 Pressure Connections......................................................................................................A - 10

3.4.1 Pressure Safety Instructions ......................................................................................A - 10

3.4.2 Connection..................................................................................................................A - 10

4 CALIBRATION.......................................................................................................................A - 12

PART B OPERATION

1 GENERAL ............................................................................................................................... B - 1

2 USING POC4 TOGETHER WITH BEAMEX PRESSURE CALIBRATORS......................... B - 2

2.1 Serial communication.........................................................................................................B - 3

2.1.1 Beamex pressure calibrator settings............................................................................B - 3

2.1.2 POC4 settings ..............................................................................................................B - 4

3 TROUBLESHOOTING............................................................................................................ B - 5

PART C CONFIGURATION

1 GENERAL ............................................................................................................................... C - 1

2 BASIC SETUP MENU............................................................................................................. C - 3

2.1 Power Up........................................................................................................................... C - 3

2.2 Keyboard ........................................................................................................................... C - 4

2.3 Recalling/Replacing Default Settings................................................................................ C - 4

2.4 Controller Setup (Stability, Autospeed and Automax)...................................................... C - 5

2.4.1 Stability........................................................................................................................ C - 6

2.4.2 Autospeed.................................................................................................................... C - 7

2.4.3 Automax....................................................................................................................... C - 7

2.5 Setting a P.I.N. protection ................................................................................................. C - 8

2.6 Displaying the Software Version....................................................................................... C - 8

2.7 Self Test: Electronic .......................................................................................................... C - 9

2.8 Self Test: Pneumatic....................................................................................................... C - 10

2.9 Basic Setup Menu Flowsheet.......................................................................................... C - 11

3 COMMUNICATIONS SETUP ............................................................................................... C - 12

3.1 RS232 Setup................................................................................................................... C - 12

4 MORE SETTINGS................................................................................................................. C - 16

4.1 Scale................................................................................................................................ C - 16

4.2 Setup Zero....................................................................................................................... C - 17

4.2.1 Manual Zero............................................................................................................... C - 17

4.2.2 Timed Zero ................................................................................................................ C - 17

4.2.3 Auto Zero................................................................................................................... C - 17

4.3 Setpoint............................................................................................................................ C - 18

4.3.1 Value.......................................................................................................................... C - 18

4.3.2 Ratio and Preset........................................................................................................ C - 19

4.4 Rate ................................................................................................................................. C - 19

PART D MAINTENANCE

1 MAINTENANCE...................................................................................................................... D - 1

1.1 Safety Instructions............................................................................................................. D - 1

1.2 Fuse Replacement............................................................................................................ D - 2

1.3 Replace Vent, Source and Outlet Manifold Filters............................................................ D - 3

1.4 Cleaning............................................................................................................................. D - 3

1.5 Fault Finding...................................................................................................................... D - 3

1.5.1 Error Codes ................................................................................................................. D - 4

1.6 Approved Service Agents.................................................................................................. D - 5

APPENDIXES

1 INSTRUMENT SPECIFICATION.............................................................................................X - 1

A - GENERAL

POC4 - General A- 1

1 GENERAL OVERVIEW

POC4 is a automatic pressure output module intended for applications in

automatic pressure testing and calibration.

POC4 is used together with Beamex pressure calibrators PC104, PC106 and

PC106P. Instructions on how to use POC4 and Beamex pressure calibrators can

be found in Section B in this manual and in the user manual of the calibrator.

A rugged piezo resistive transducer measures pressure and is compensated to

standard or enhanced accuracy as required.

Dual loop control provides extremely accurate and repeatable setting of pressure

output.

The pneumatic control actuator achieves this level of control whilst also providing

fast response and very low gas supply consumption.

Only 2U of 19 inch rack is required to house the unit which is controlled remotely

by a host computer for fully automatic applications.

Pressure demands from a Beamex pressure calibrator via an RS232 interface are

converted by POC4 into a regulated pressure supplied from a line or bottle

source.

Option B provides negative pressure calibration.

POC4's RS232 interface also communicates with any computer equipped with a

suitable software for serial communication. The use of this additional feature is

described in a separate manual that is available from Beamex when requested.

NOTE!

Using POC4 together with Beamex pressure calibrators does not require any

knowledge of serial communication. All the necessary information for applications

with Beamex calibrators are included in this manual.

A- 2POC4 - General

1.1 Unpacking and Inspection

At the factory each new POC4 passes a careful inspection. It should be free of

scrapes and scratches and in proper operation order upon receipt. The receiver

should, however, inspect the unit for any damage that may have occurred during

transit. If there are signs of obvious mechanical damage, package contents are

incomplete, or the instrument does not operate according to specifications,

contact the purchasing sales office as soon as possible.

The standard accessories are as follows:

• POC4 Instruction manual

• Calibration Certificates

• Power Supply Lead

If you have to return the instrument to the factory for any reason, use the original

packing whenever possible. Include a detailed description of the reason for the

return.

POC4 - General A- 3

1.2 Safety

The Manufacturer has designed this product to be entirely safe when operated

correctly.

lPlease pay close attention to the Safety Instructions outlined on this page and

elsewhere in this manual. They have been designed to protect the user from

personal injury and the equipment from damage.

lPotentially hazardous operations are indicated in the text

by means of a hazard warning triangle. Specific warnings

relating to each section of the manual are given at the

beginning of that section. On the instrument, this symbol

indicates that the user should refer to the User Manual.

lPlease observe the installation advice and any operational limits given in this

manual.

lThis equipment must only be used for the purpose for which it was designed

Pressure Safety

Do not permit pressures greater than the Safe Working Pressure to be applied to

the instrument. The specified Safe Working Pressure for the instrument is stated

in the Specification section of this manual.

Electrical Safety

The instrument is designed to be completely safe when used with Options and

Accessories supplied by the manufacturer for use with the instrument.

Toxic Materials

During normal operation it is not possible for the user to come into contact with

any hazardous substance which might be employed in the construction of the

instrument. The use of hazardous materials in the construction of this instrument

has been minimized.

Repair and Maintenance

This publication contains information and warnings which must be followed for

safe operation and to maintain the equipment in a safe condition. Use qualified*

personnel and good engineering practice for all procedures in this publication.

The operator must not use this equipment for any other purpose than that stated.

Do not apply a pressure greater than the maximum pressure stated.

*A qualified person must have attended a product training course given by the

manufacturer or appointed agent and successfully completed the training

course on this equipment.

A- 4POC4 - General

2 FUNCTIONAL DESCRIPTION

2.1 General

The POC4 instrument is a single channel automatic pressure output module,

designed to be programmed from an external computer system. No user controls

are provided on the instrument, its local keyboard being used only for Set-up,

Calibration and Maintenance operations. The use of these functions are

described in Sections C, D and E respectively.

Digital programming of the instrument is effected via a RS232 serial interface.

When using POC4 together with Beamex pressure calibrators, no programming

or specific commands are required. The calibrator supervises the use of POC4.

POC4 can be configured in a number of different ways as detailed in Section C.

This section also details the installation procedures.

2.2 Instrument Electronics

2.2.1 Digital Electronics

The instrument draws its power supplies from an internal power supply unit which

is, in turn, powered from an external AC source.

An internal microprocessor system controls the RS232 communications channel.

One RS232 port is provided and one optional IEEE 488 channel (not applicable

with Beamex calibrators). The RS232 port has three inputs: one is used for the

communications channel. The other optional RS232 inputs two are not required

when using POC4 together with Beamex pressure calibrators. The use of the

optional IEEE488 channel and the optional RS232 ports are not discussed in this

manual.

The microprocessor system also controls the flow of data to the instrument’s

display. The display is a two line (20 characters/line) liquid crystal dot matrix type.

Operationally, it is used to display pressures, functions and messages.

A keyboard, linked to the microprocessor, provides a user interface for Setup and

Calibration purposes only. It is not used for normal operation, all operational

commands being sent from the connected pressure calibrator.

POC4 - General A- 5

Control of the Analogue to Digital (A-D) Converters used in the analogue and

valve control circuits is effected via the microprocessor system’s bi-directional

control bus. A simplified description of the analogue control channel follows.

OPTIONAL

INTERFACE

IEEE 488

INTERFACE

OPTIONAL

INTERFACE

OPTIONAL

INTERFACE

BEAMEX

PRESSURE

CALIBRATOR

BI-DIRECTIONAL

CONTROL BUS

TO ANALOGUE

CIRCUITS

IEEE 488 BUS

RS232

INPUT

OPTIONAL

INTERFACE

(REAR)

OPTIONAL

INTERFACE

(FRONT)

DAISY

CHAIN

SWITCHING

NETWORK

POWER

SUPPLY

UNIT

MICROCONTROLLER

SYSTEM

DISPLAY

KEYBOARD

POWER TO

ANALOGUE & DIGITAL

CIRCUITS

AC POWER

2.2.2 Analogue Circuit Operation

Output pressure control is effected by means two solenoid operated valves. One

of these valves, the Apply valve, controls the application of a source pressure to

the output manifold. The other valve, the Release valve, releases the output

pressure. The output pressure is controlled by modulating the drive to each of

these valves, controlling their relative on/off times. An Isolation valve, also

controlled by the microprocessor, is used to isolate POC4 from the external

pneumatic system. The output pressure of POC4 (external system pressure when

the isolation valve is open), is measured by a suitably scaled, internally mounted,

pressure transducer.

Pressure demands to POC4 are sent via the RS232 communications interface

and decoded by the microprocessor. The decoded demand is sent to the Setpoint

A-D converter, processed (with other loop control terms) and applied to an error

amplifier. The other input to the error amplifier is the transducer output signal,

(representing the actual pressure at the output).

The error amplifier produces a bipolar error signal proportional to the magnitude

and direction of the error between the Setpoint demand and the actual output of

POC4. This error is first processed by an Error Signal Processing circuit, under

the control of the microprocessor, to drive a pulse width modulator. The output of

the pulse width modulator drives the Apply and Release valves to change the

output pressure in an appropriate direction to correct the error i.e. to equalize the

setpoint demand and pressure feedback signals. A temperature feedback signal

A- 6POC4 - General

from the output manifold, modifies the drive to the output valves should they

become overheated.

An analogue signal, proportional to the output pressure, is derived from the output

of the pressure sensing transducer. The output of the pressure transducer is

scaled by an amplifier/buffer and filtered before outputting from the instrument as

a DC signal. The gain of the output amplifier is set during manufacture to provide

the scale range.

When POC4 is used together with Beamex pressure calibrators POC4 performs

continuous pressure control only while it is reaching for the target pressure. As

the desired pressure is reached the pressure calibrator shuts POC4 off. This is

done in order to have as few disturbing variables as possible while measuring the

calibration point.

POC4 - General A- 7

3 INSTALLATION

Usually POC4 is already installed in a MCS100 Bench or Table Top system or

separately in a 19" rack. Also all the necessary connections are already done.

These following chapters are only necessary during uninstallation and

reinstallation of POC4.

3.1 Safety Instruction

IT IS ESSENTIAL THAT THE INSTALLATION OF

ELECTRICAL AND PNEUMATIC SUPPLIES BE

UNDERTAKEN BY A COMPETENT PERSON.

THE INSTRUMENT IS DESIGNED TO BE RACK

MOUNTED IN A STANDARD 19" RACK OR SUB-RACK

AND OCCUPIES 2U OF SPACE.

3.1.1 Input/Output Connections

All connections to the instrument, with the exception of an optional User Interface

connection, located on the front panel, are made to the rear panel of the

instrument. The following picture shows a diagram of a rear panel layout, together

with the electrical and pressure connections.

A- 8POC4 - General

3.2 Electrical Connections

3.2.1 Electrical Safety Instructions

IT IS IMPORTANT TO USE THE CORRECT SUPPLY

SETTINGS. OPERATING VOLTAGE RANGES ARE MARKED

ON THE REAR PANEL OF THE INSTRUMENT AND ARE

GIVEN IN SECTION 1, SPECIFICATION.

It is essential that the Earth lead (colored green/yellow) is connected to the

AC Supply Protective Safety Earth.

Before making any electrical connections to the rear panel, isolate the incoming

power supply.

Before removing any covers, isolate the instrument from all its supplies.

3.2.2 Power Supply Connections

The instrument is powered from AC mains. The supply voltage should be within

88 to 264 V and the supply frequency 47 to 65 Hz. The power consumption is

60 VA

The AC power supply socket assembly (IEC 320 connector) is located on the rear

panel as shown on the left picture below.

A fuse is also contained within the power socket assembly, details of the fuse

fitting being shown in the rightmost of the previous pictures. Both Line (L) and

Neutral (N) are individually fused.

POC4 - General A- 9

If the AC power supply need to be connected, proceed as follows (the numbers

inside brackets refer to the pictures on the previous page).

mInsert the molded I.E.C. connector (1) into the power supply socket (2)

and connect to a suitable AC power source. See previous text for

specifications.

mSwitch on the AC power source.

mCheck that the display is on.

mIf the instrument display does not come on, isolate the external power

supply and remove the IEC connector (1) from the power socket (2).

mRemove the fuse carrier (3), insert one or two new fuses (4) as required

and replace the fuse carrier. Fuses are Type T2A, rated at 250V, 2

Amps.

mReplace the IEC connector (1) and switch on the power supply and the

instrument. The display should now come on.

mSwitch off the power supply to the instrument.

3.3 Communications Interface Connections

Only the RS232 connector in the rear panel of POC4 is used when connecting a

Beamex pressure calibrator to POC4. Use the RS4 cable supplied with POC4.

Also remember to set the switch labeled STACKING on the rear panel to the 0

position.

0 1

STACKING

A- 10 POC4 - General

3.4 Pressure Connections

3.4.1 Pressure Safety Instructions

ALWAYS CHECK FOR TRAPPED PRESSURE BEFORE

CONNECTION OR DISCONNECTION OF PRESSURE

COUPLINGS.

ENSURE THAT CORRECTLY RATED PIPES AND FITTINGS

ARE USED.

3.4.2 Connection

To connect up to a pneumatic port, proceed as follows. Note that all pressure and

electrical connections must be extended from the rack so leave enough slack

cable and piping to allow the complete withdrawal of the instrument from the rack.

Source Pressure Port

SOURCE PRESSURE CAN LEAK TO THE OUTLET PORT

UNDER FAULT CONDITIONS, EVEN WITH ELECTRICAL

POWER REMOVED. MAKE SURE THAT THE USER

SYSTEMS ARE ISOLATED AND VENTED.

For a given instrument, the Source pressure must not exceed the full scale

pressure value by more than 1.25 x rated pressure.When connecting a number

of instruments of differing ranges to a common Source pressure, to ensure that

the source pressure for each instrument does not exceed the maximum level for

that instrument, appropriate external pressure regulators must be provided.

SUPPLY SOURCE 1

POC4 #1

OUTPUT 1

REGULATOR

SOURCE 2

POC4 #2

SOURCE 3

POC4 #3

OUTPUT 2

OUTPUT 3

REGULATOR

POC4 - General A- 11

mEnsure that the source pressure supply is isolated from the supply line. It

is recommended that a 40 Micron filter, regulator and an isolation valve

be fitted between the pressure source and the instrument as follows

(e.g.).

SUPPLY

REGULATORISOLATOR FILTER

INTRUMENT

SUPPLY

mFit the source pressure supply line to the Source connection port as

shown in the following picture, fitting a bonded seal between the

pressure union and the measuring port. Note the Source port has a G1/8

thread. Ensure that the coupling is tight.

Output Pressure Port

Depending on the application, the Output ports of instruments with differing full

scale outputs can be either be connected separately or connected together (in

parallel). The connection method is as follows.

mEnsure that the external system is at zero pressure.

mFit the output pressure supply line to the Output connection port as

shown in the picture above, fitting a bonded seal between the pressure

union and the measuring port. Note that the Output port has a G1/8

thread fitting. Ensure that the coupling is tight.

A- 12 POC4 - General

Vent Port

During venting of the system, gas flows from the system out of the Vent port of

the active controller. Initially, this port can be at the full working pressure of the

system. Any equipment connected to the vent port (e.g.) pipes, fittings and

vacuum pump, must be capable of handling the flow/pressure safely. On gauge

pressure instruments, a vent silencer/diffuser must be fitted.

mFit the vent line to the Vent port, fitting a bonded seal between the

pressure union and the measuring port. Note that the Vent port uses a

G1/8 thread fitting. Ensure that the coupling is tight.

For negative gauge pressure applications, a vacuum pump should be

connected to the Vent port. For gauge instruments, connection of a

vacuum supply will assist in the controlling of low pressures around zero.

Refer to specification for details of Vent pressure range.

Reference Port

The reference port is used on gauge instruments. Ambient pressures acting on

the reference port of low pressure instruments can have significant effects on the

pressure reading. A restrictor screwed into the port can reduce ambient pressure

variations. To connect the reference line, proceed as follows.

CAUTION: The REFERENCE port pressure must NOT exceed two times the

full scale pressure range or 2 bar whichever is the smaller or the

internal pipes and integral transducer could be damaged.

mFit the reference line to the Reference port, fitting a bonded seal

between the pressure union and the measuring port. Note that reference

port has an M5 thread fitting. Ensure that the coupling is tight.

4 CALIBRATION

The instrument is delivered by the manufacturer/supplier, complete with

calibration certificate(s). The re-calibration interval will depend on the total

measurement uncertainty which is acceptable for a particular application.

Note: POC4 measures the output pressure only for its own needs. When the

requested pressure level is reached, according to POC4, the pressure

calibrator measures the actual pressure and this value is used when the

calibration point is stored. Therefore any drift in POC4's own

measurement does not affect the calibration.

If there is an unacceptable drift in POC4's measurement, please contact

the manufacturer/supplier for information concerning the re-calibration of

POC4.

Beamex offers a comprehensive accredited calibration service.

B - OPERATION

POC4 - Operation B- 1

1 GENERAL

POC4 may be controlled with any computer with a suitable software for serial

communication installed. This manual includes only the simplest way of utilizing

POC4: in connection with Beamex pressure calibrators.

No special skills are needed when using POC4 the aforementioned way; just

make the necessary connections described in the next chapter and perform the

calibration using the calibrator at hand. The calibrator controls POC4 and the user

only need to concentrate in giving orders to the calibrator.

By using the on-line utility of a Beamex calibration software the calibration be-

comes even more easier. The software takes care of the tedious part and the user

only has to supervise the calibration sequence.

B- 2POC4 - Operation

2 USING POC4 TOGETHER WITH

BEAMEX PRESSURE CALIBRATORS

ANALOGUE

OUTPUT OPTIONAL

INTERFACE RS232 IEEE488 CALIBRATION

MODE

VENT SOURCE OUTLET

SUPPLY INPUT

G1/8

POC4 REAR PANEL

0 1

STACKING

0 1

BEAMEX

PRESSURE CALIBRATOR

OPTIONS

INSTRUMENT

TO BE

CALIBRATED

INPUT OUTPUT

SUPPLY

PRESSURE

PRESSURE TUBING RS4 CABLE

PRESSURE

SECTION ELECTRICAL

SECTION

VACCUUM

CONNECTION

(IF APPLICABLE)

Type: POC4

Serial number: 250

The supply pressure for POC4 should be 105 to 115 % of full scale.

Connect the outlet pressure to the input of the instrument to be calibrated and to

a suitable pressure section input on the Beamex pressure calibrator. If your POC4

is panel mounted, the outlet pressure connector is usually located on the front

panel.

Connect the output signal of the instrument to be calibrated to a suitable input

in the Beamex pressure calibrator (if applicable). If the instrument to be calibrated

is a pressure indicator you’ll have to enter the output value manually. If you need

in detail information on how to connect and calibrate your instrument, refer to your

pressure calibrator manual.

POC4 and the pressure calibrator are connected together with an RS4 cable. The

location of the options connector depends on the type of calibrator in use. Usually

it is on the rear panel. On POC4 it’s a 9-pin RS232 connector and on the pressure

calibrator it is a 25-pin RS232 connector marked options or RS232.

Note: When POC4 is used together with Beamex pressure calibrators

POC4 acts as a “pressure controller” only while it is reaching for the

target pressure. As the desired pressure is reached the pressure

calibrator shuts POC4 off. This is done in order to minimize the

amount of disturbing variables when measuring the calibration point.

POC4 cannot be used as a compensator for leaking hoses or con-

nectors.

Table of contents

Popular Control Unit manuals by other brands

Eaton

Eaton S611 Installation leaflet

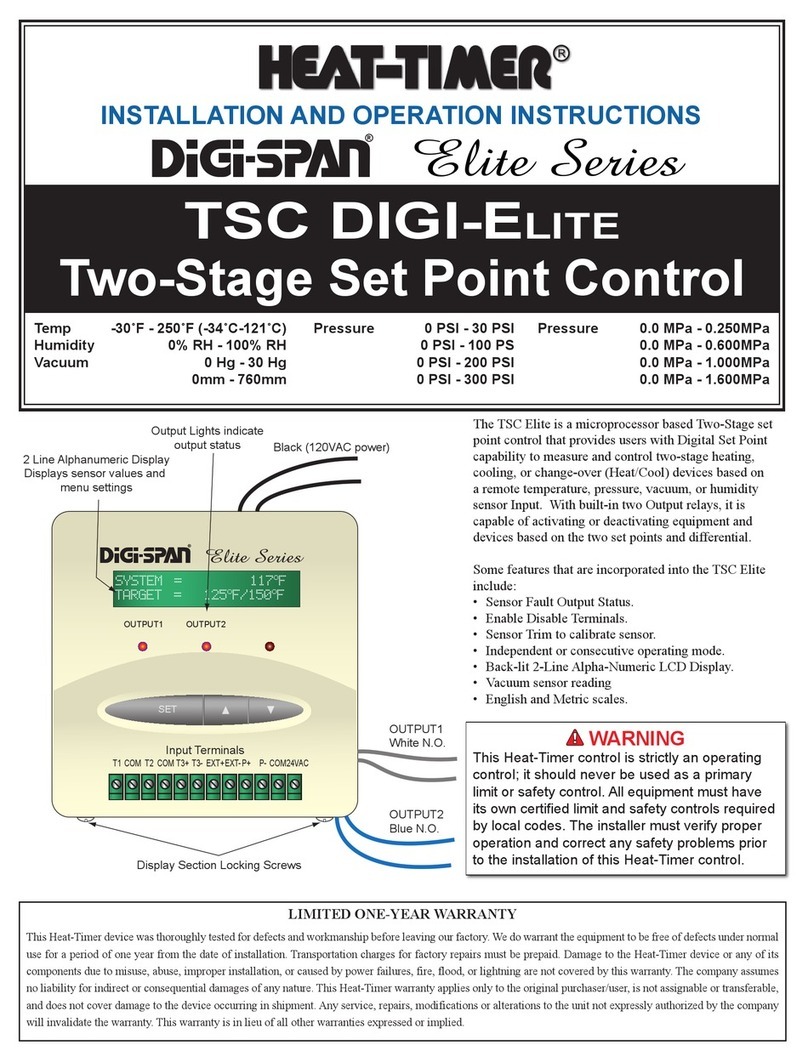

heat-timer

heat-timer DiGi-SPAN Elite Series Installation and operation instructions

EOS

EOS ECON 45A2 Assembly and operating instruction

GEM

GEM 673 Installation, Operating and Maintenance Instruction

ETC

ETC P-TS18 Setup and Connect Guide

TemperZone

TemperZone 6 Operation and installation