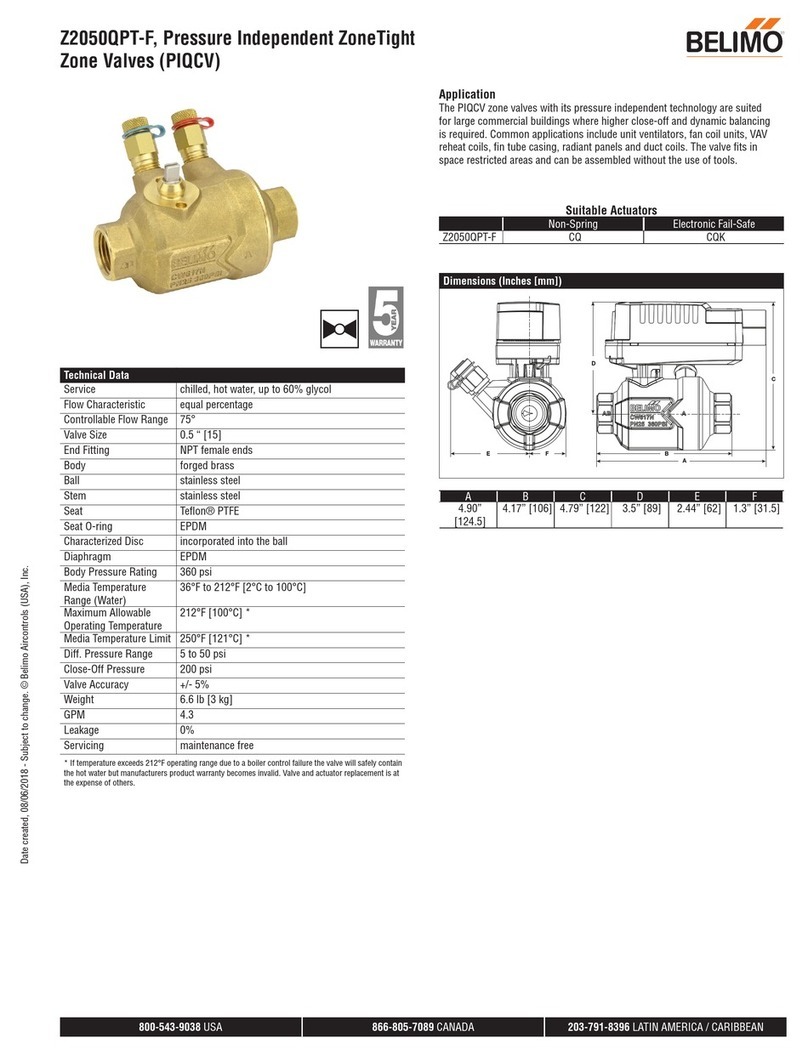

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA / CARIBBEAN

11

50904 - 02/12 -

ubject to change.

Belimo Aircontrols

U

A

, Inc.

Valve Desi

1. The SHP Series High Performance Butterfly Valve features a double

ffset

or, double eccentric

shaft design to minimize seat abrasion

and lower torque. This double offset design allows the disc to lift

ff and “cam” away from the seat as it rotates open

. The SHP valve always rotates clockwise to close (when viewed from

above) and counterclockwise to open.

. The valve bod

has an Overtravel Stop which prevents

the disc from over rotatin

into the wron

quadrant. This stop is

ot to be used as a disc position stop; if the disc contacts the

Overtravel Stop, this means it has rotated be

ond the seat.

4. The SHP valve is bidirectional, but the

referred installation

osition

is with the seat in the upstream position

SUS

. Note the arrow on

the metal tag attached to the valve body.

Safet

Precaution

1.

e sure the line is de

ressurized and drained.

. Be sure of the

i

eline media. Pro

er care should be taken for

protection against toxic and/or

lammable

luids

. Never install the valve without an Operator (Manual or Automatic)

already attached to the valve sha

t.

4. Never remove the Operator from the valve while the valve is in the

pipeline under pressure.

. Alwa

s be sure that the disc is in the full-closed position before

installin

the valve

. Take care in handling the valve; i

ou treat it like a machine, it will

perate like a machine…i

ou treat it like a piece o

pipe, it ma

work like a

iece of

i

e

Flange Compatibilit

he SHP valve is desi

ned to fit between flan

es as follows:

AN

I

lass 150 2” to 24

M

P-44

lass 150 30” to 48

AN

I B16.47

lass 150 A Flanges

ANSI Class 300 2” to 24

MSS SP-44 Class 300 30

ANSI B16.47 Class 200 A Flan

es

Gasket Compatibilit

he

HP valve is designed to accommodate the use of standard fiber

askets (such as non-asbestos,

lexible graphite, asbestos or

quivalent gasket materials) o

1/16” or less, meeting the dimensional

requirements of AN

I B16.21-1978. Thick elastomeric gaskets are not

recommended. Metallic wound (Flexitallic) gaskets may also be used

Pipe

chedule

ompatibilit

The SHP valve is designed to allow the disc edge to rotate into the

o

en

osition without interference with the

i

eline I.D. in the

following pipe schedules:

SIZE ANSI 150 ANSI 300

” - 12” SCH 80

CH 80

-

H 40

H 80

0” SCH 30

CH 80

6” - 42” STD WT

8” X

Product Identificatio

1. Every

HP valve has a metal identification tag attached to the valve

body. Information includes the Figure Number, the

ize and

Pressure Class, the Materials of Construction, and the Operating

Pressures and Temperatures

2. Ever

SHP valve is h

drostaticall

tested before it is shipped. The

metal ta

also includes a Serial Number; this number, unique for

each valve, is recorded b

the Belimo Qualit

Control Department

alon

with the test results and material certification data, for

individual traceabilit

and verification of ever

valve produced.

HP series

valves have a

preferred flow

direction.

re

erredFlowrate

UNPACKING AND STORAGE INSTRUCTIONS

1. Check the packing list against the valve received to verif

that the

uantities, sizes and materials are correct.

2. Check to make sure that the valve and operator were not dama

ed

urin

shipment.

. If the valve is to be stored before bein

installed, it should be

rotected from harsh environmental conditions.

.

tore the valve with the disc in the closed position to protect the

ealing edge and the seat

. Keep the valve in a clean location, away from dirt, debris and

corro

ive material

.

6. Keep the valve in a dry area with the flange protectors attached

7. Keep the valve in a cool location if possible, out of direct sunlight

8. If not in use, exercise the butterfly valve (full open and close) at

lea

t once a month.

n

t

t

n

mm

n

t

n

HP

eries Butter

Valves