Bike Sport Developments Blip Box-Pro User manual

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

1

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Yamaha R1 –2015 onwards

Clutch-Free shifting……Perfected

Fitted in under an hour

No ECU re-flash

Can be used in all power modes and adjusts the BLIP response automatically.

All existing bike systems, and sensors are retained

Integrates with the bike CAN bus.

No error codes on the dash when plugged in.

A single high quality load cell replaces the existing up-shift switch for use with shift and blip

functions with fully programmable load set points.

Supplied with a BLIP-Map for your bike but also fully re-programmable to suit different rider,

tracks, gear ratios, and foot rest hardware

System may be re-programmed or adjusted by the additional USB interface and the WinBLIP

software. Sold as a separate part.

Machined aluminium housing with fully sealed electronics and high specification ‘plug n play’

wiring, no wiring modifications needed.

Designed and made in the UK by Bike Sport Developments Ltd

How it works –The Yamaha R1uses a Ride By Wire system with sensors to read the twist grip % telling

the ECU what the rider wants, and electric motors on the throttles carry this out. Between these 2 devices

sits the ECU with maps and control strategies to make the bike safe and easier to ride in a wide range of

conditions.

Blip-Box reads signals from the twist grip sensors and data from the CAN bus and at the appropriate foot

pressure from the rider it creates a BLIP on the throttle which releases the pressure on the gearbox

allowing a perfect smooth back shift. Like a quick shifter, but in reverse.

Download the software, drivers and PDF manuals at

www.bikesportdevelopments.co.uk/blipbox

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

2

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Important rider notes

Must be read and understood by all riders…

Blip will be activated under these conditions:

oRPM is higher than 3000

oRear wheel speed is higher than 30kmh

oThrottle grip is closed (less than 3%, engine slowing down)

oClutch is OUT (disabled when rider pulls in the clutch)

oThe time since the last blip must have been exceeded (0.35seconds)

oThere are no Blip Box diagnostics active (flashing LED)

oFoot pressure is applied by the rider

The BLIP disengages the gearbox very much like a quick shifter in reverse, but your foot pressure

makes the gear shift, so make a positive movement just like you would when using the clutch.

For riders who use the slipper clutch excessively you may need to extend the primary BLIP duration to

give more time to close the clutch and make the gearbox reversal. Use WinBLIP software or consult

your dealer.

Never force the lever, the BLIP should make it smooth and easy. If you suspect the gear is not fully

engaged, pull in the clutch and check in a normal way.

Never try to make a clutch-free downshift while accelerating (like dropping a gear to overtake). In this

case the BLIP system will not work.

After each downshift blip, release the lever pressure to re-arm it for the next gear Blip change.

IMPORTANT –When first plugged in you will see the LED blinking an error code for 30 seconds. This is perfectly normal

during the installation because the CAN connector provides permanent power to the module, and at this stage the bike is not

switched ON so the module cannot read some of the inputs correctly. The module also enters a self-calibration mode which lasts

approx. 20 seconds.

When the ignition is eventually switched ON this warning will go away and will not come back unless there is a real problem (refer

to blink code diagnostic section of the manual)

IMPORTANT –During the initial power ON self-calibration the load cell Mv is automatically adjusted to 2.5v to correct for any

sensor drift. For this reason it is very important that there is no load applied by your foot or by ‘sticking’ linkages at the power On

stage. If you suspect that the load cell is out of calibration, turn OFF the ignition switch and wait 1 minute for a complete power

shutdown, then turn back on to re-start the self-calibration.

IMPORTANT –Follow the wire routing exactly as described in the manual to avoid problems with signal interference.

Preparation

1. Turn off the ignition switch

2. Remove the seat.

3. Remove the battery cover plate

4. Remove the fuel tank

5. Remove the air box upper and lower sections to expose the throttle bodies

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

3

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Load cell fitting

1. Remove the standard shifter switch and disconnect it from the bike wiring loom.

2. Measure the total length of the standard shift rod (between centres), this will allow you to re-make the new shift rod

assembly to the same length and give you the same shift lever height –Standard ‘centre to centre’distance is 258mm

3. Remove both the upper and lower rod ends and the rubber shrouds from the standard shifter assembly.

a. The Lower rod end and nut are left hand thread, this is re-used at the TOP on the new load cell

b. The upper rod end and nut are right hand thread, this is re-used

at the BOTTOM end of the new 150mm extension rod.

4. The extension rod is 150mm in length and suits a standard foot rest

system.

5. Adjust the new load cell shift rod to be the same length as the original

via the upper or lower rod end adjusters making sure that there is always

10mm of thread used.

6. During assembly NEVER apply spanner force to both sides of the shift

load cell when tightening lock nuts. This will cause twisting and damage

to the load cell that is not covered by warranty.

7. Use Loctite 243 (or similar thread retainer) to ensure lock nuts do not

come loose during use.

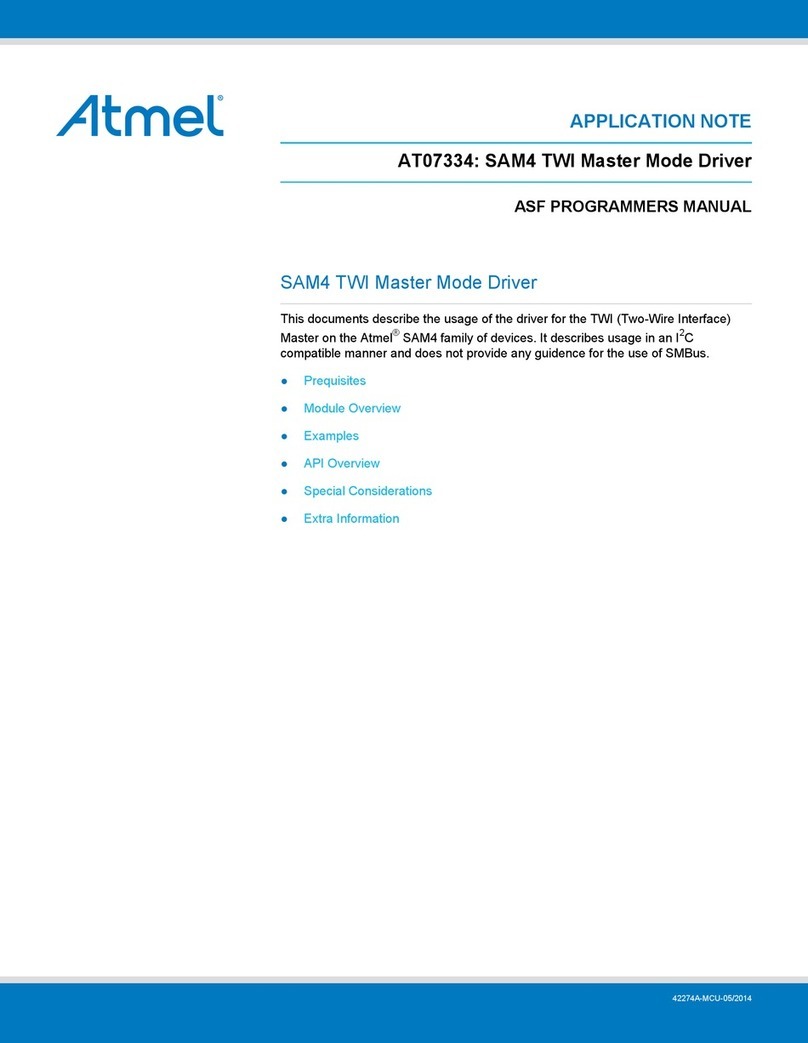

Standard gear Lever arm –pointing forwards

The lever layout shown in this image is standard for road-shift with the

lever pointing forwards.

Without any load on the sensor the voltage should be 2.5v. Note that

even if the real voltage drifts over time the system self-calibrates at

power ON to shift this back to 2.5v internally even if a multi-meter shows

an error.

The system has a maximum self-calibration of +/- 0.5v, beyond this the

sensor is considered to be permanently damaged.

Stretching (PULL) the load cell (up-shift) has a typical set point of 2100

mV, a change of 0.4v.

Compressing (PUSH) the load cell creates a higher voltage with the

default BLIP threshold at 2850Mv , a change of 0.35v

Your system is normally supplied with the load cell direction set to suit your bike, but if not, it can be changed in the Win Blip

software as described below, or by simply loading one of the Blip maps with ‘REV’ in the map name for Reverse direction.

Connect all systems and wiring as normal and turn on the bike, wait for 20 seconds for start-up auto-calibration LED to

stop flashing on the module.

Connect WinBlip and use the View Data (live data) screen to see the Mv of the load cell (it should be 2500 at rest)

Pull UP on the lever (upshift) until you feel the gear selector start to move and note the Mv at this point.

Push down up on the lever (downshift) until you feel the gear selector start to move and note the Mv at this point.

Open a normal Blip map for your bike and edit the Mv thresholds for the UP and DOWN shifts, then SEND to the bike

Re-check these new thresholds using the Led on the box and the icons within the live data screen to check the direction

is correct.

The load cell components are all supplied loose enabling custom length installation to be made with ease. The load cell should be

fitted with A at the top so the cable points upwards.

A = Left hand thread

B = Right hand thread

C = Right hand thread

The shift rod length is set to suit a bike with standard linkage arrangement. If you need a longer or shorter rod the standard

150mm rod may be replaced or modified before it is fitted to the load cell. Both ends of this standard rod Care M6x1 with right

hand threads.

150mm

Fit with Loctite 243

A

B

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

4

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Shift linkages explained.

The standard linkage is

shown to the left

In this layout the sensor will

PULL to create an up-shift

In the race pattern shift

layout shown on the right

the sensor will PUSH to

create an upshift.

Typical values for standard

shift pattern

Up shift –2100Mv

Blip shift –2850Mv

Typical values for race shift

pattern

Up shift –2900Mv

Blip shift –2150Mv

UP -Shift

DOWN-Shift

PULL =UP shift (reducing voltage)

PUSH= Down shift (rising voltage)

A

B

UP -Shift

DOWN-Shift

PULL =Down shift (reducing voltage)

PUSH= Up shift (rising voltage)

A

B

STANDARDSHIFT RACE SHIFT

Note that the Mv values seen in these examples may be different to the maps you have been given, all maps are under constant

development.

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

5

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Wiring layout and installation

A –Main blip box 12 way connector (rear of bike)

B –3 way white connector for the load cell (blue band)

C –2 way white connector for up-shift output to the bike loom (left side near the front sprocket)

D –4 way black connector (socket contacts) for the throttle twist grip signals of the throttle body (under air box)

E –4 way black connector (pin contacts) for the twist grip output signals feeding into the bike loom (under air box)

F –4 way white connector (pin contacts) for linking to the CAN bus diagnostic port under the seat (under seat)

G –4 way white connector (socket contacts) as a continuation of the CAN bus for use with the Blip Box programming cable or

any other CAN device such as a data logger (under seat)

Important note –Connector F will be live as soon as it is connected, so connect this last.

blue band

Yellowband

12

34

1 2

3 4

PINS

SOCKETS

1 2

4 3 2 1

BDW1608_01

SOCKETS

PINS

A

B

C

D

E

F

G

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

6

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

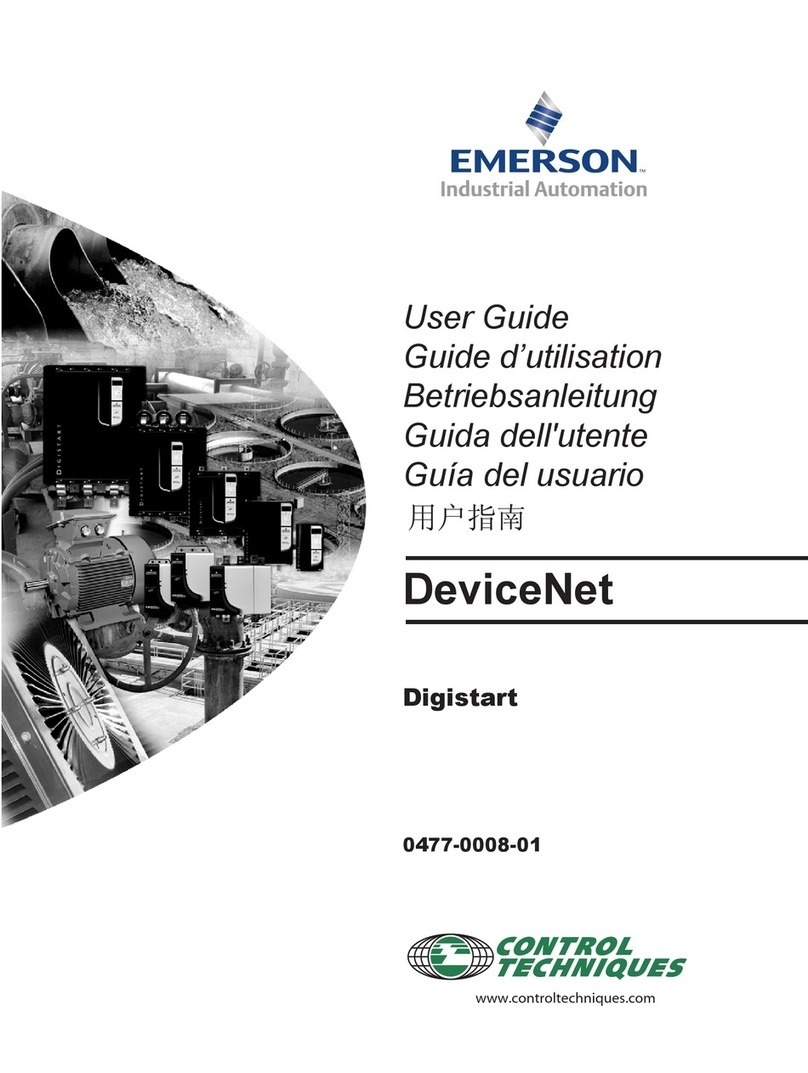

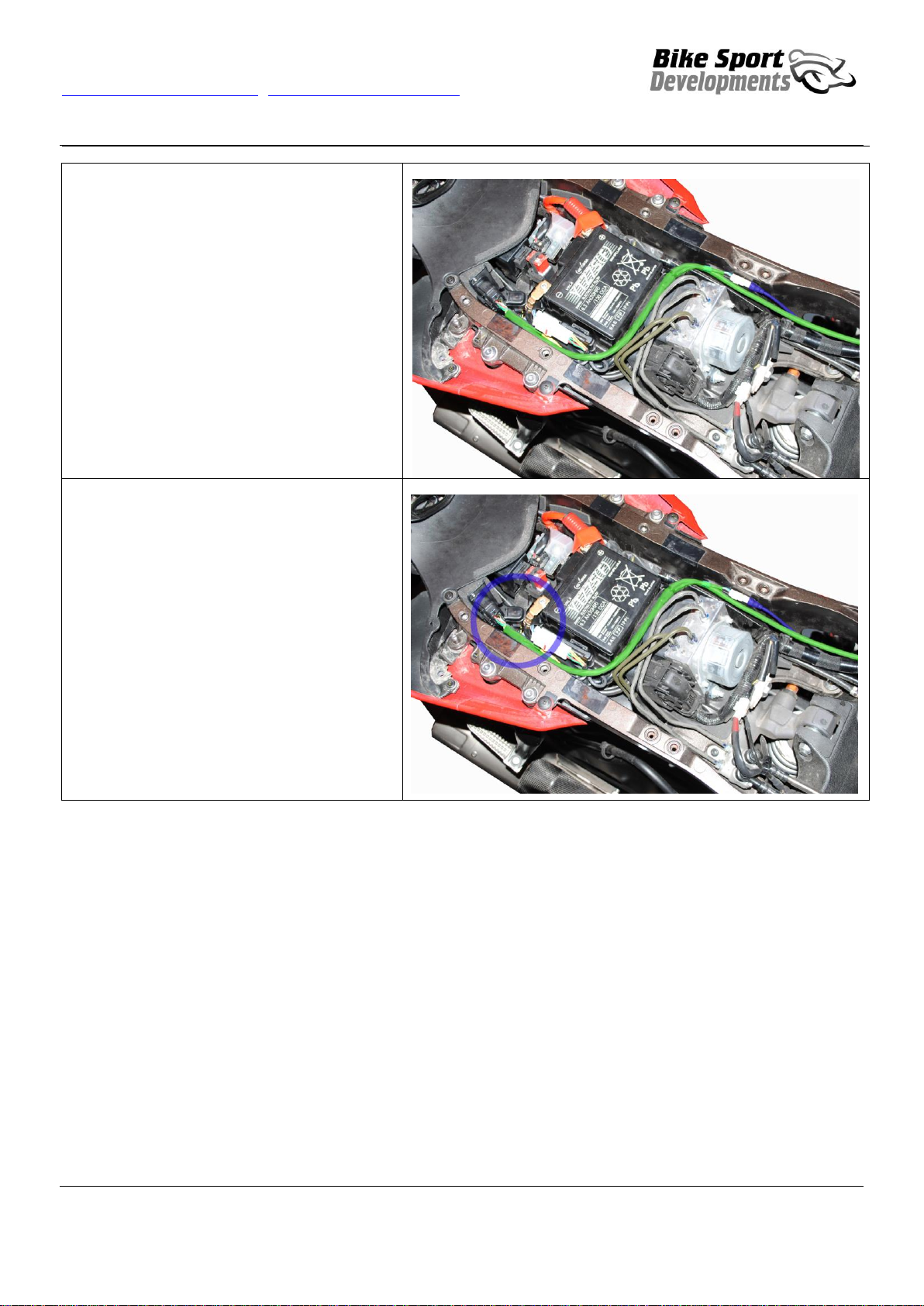

After the air-box has been removed you

will see the throttle body assembly as

shown in the photo.

Disconnect the throttle grip sensor ringed

in blue and use connectors Dand Eto

bridge between the loom and sensor. See

note -2 below

Secure the wires using a cable tie so they

cannot become tangled in the throttle

cables.

The wire routing is highlighted in green and

runs under the air pressure sensor along

the left side of the bike. Note that it helps to

temporarily disconnect the air pressure

sensor and throttle motor when routing the

Blip Box wiring.

Use cable ties as necessary to retain the

wiring.

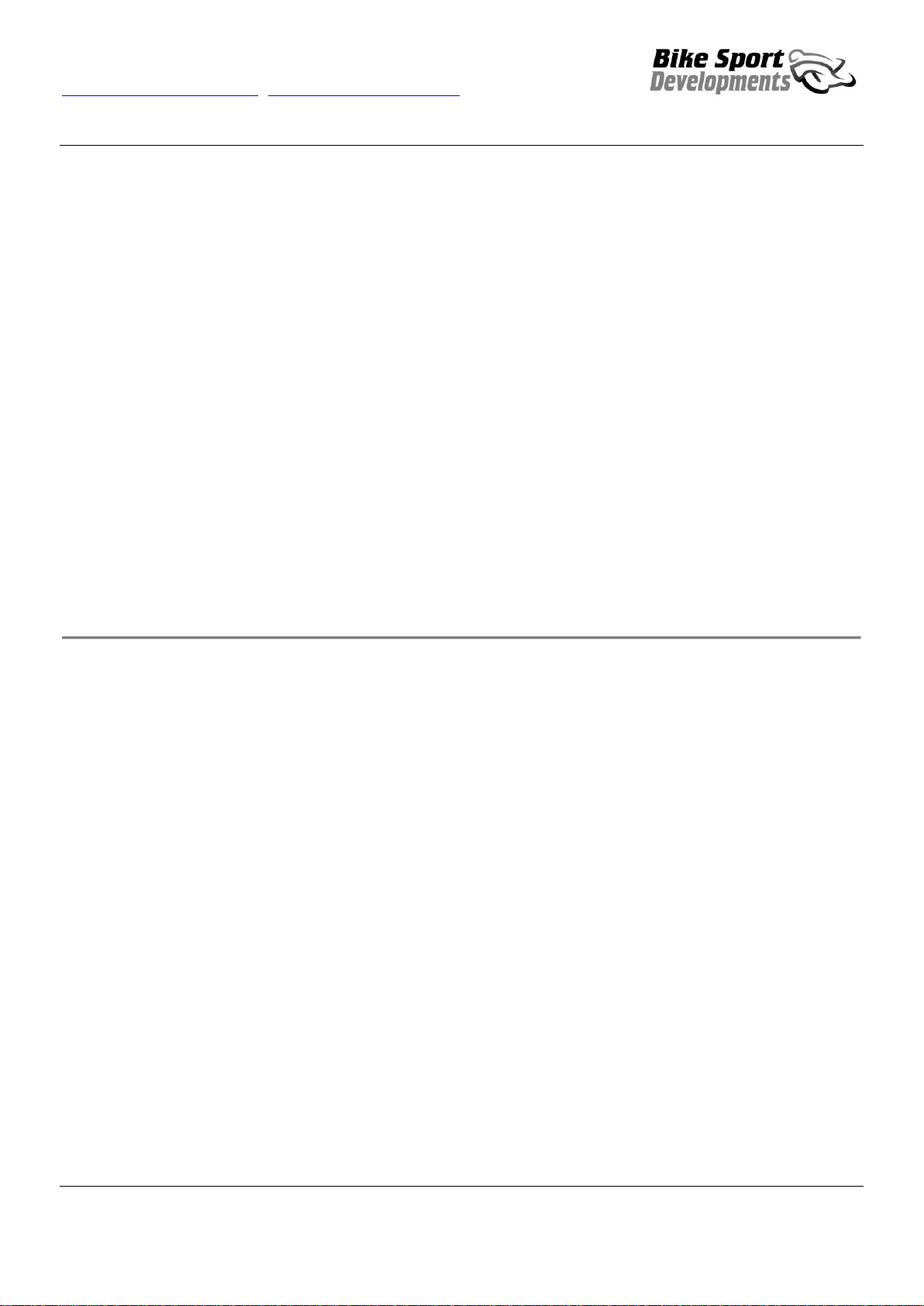

Note –2

IMPORTANT –Connector E is 3D printed

and due to production tolerances on the

latch it should be secured with a cable-tie

across the 2 connectors to ensure it cannot

come apart. –See image 2 at right inside

the blue ring.

You can now re-fit the airbox.

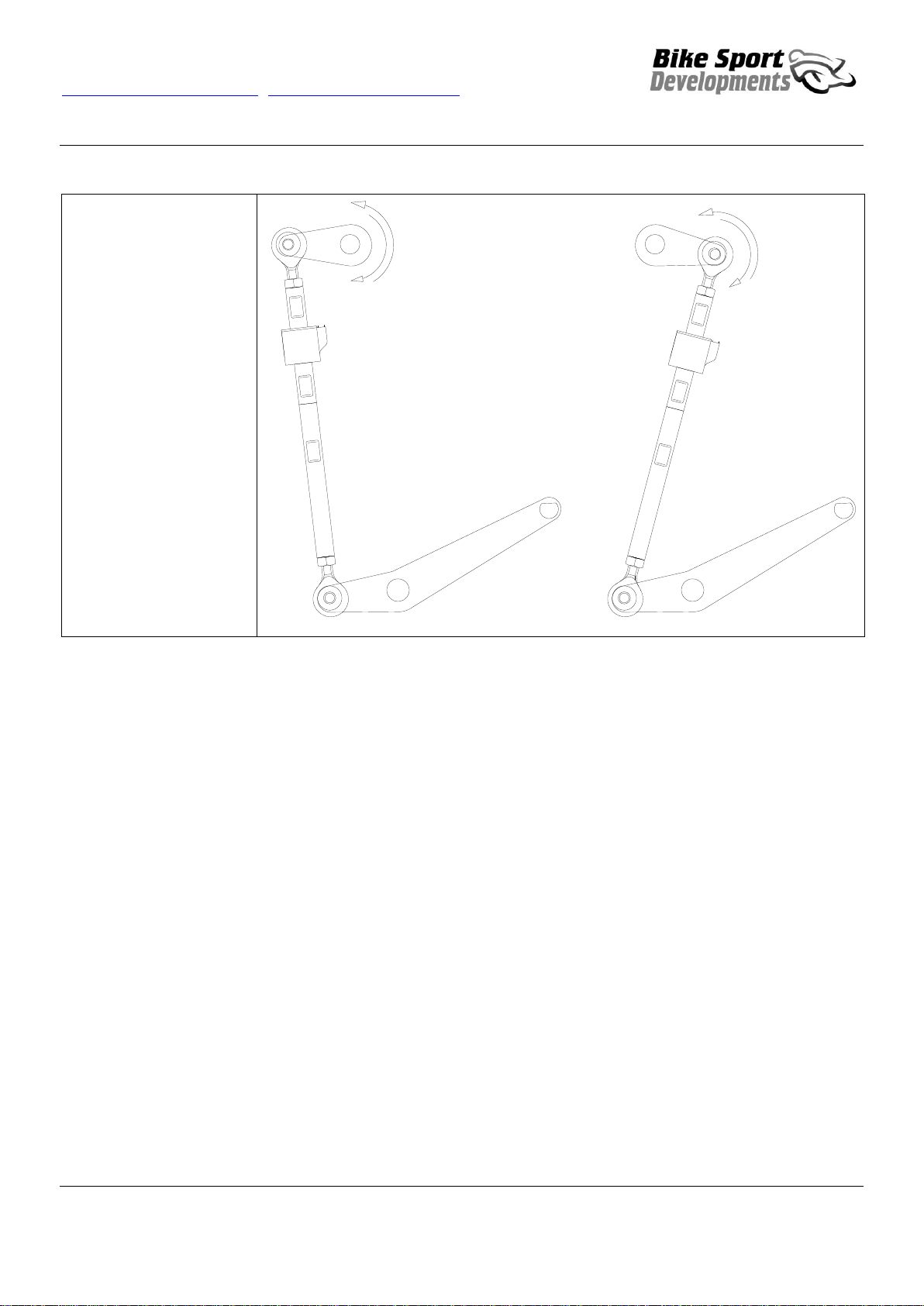

Use the main wiring as a guide and route

the Blip Box loom along the left hand side.

The Up-Shift output connector Cheads

downwards and mates up with the

standard bike loom shifter connector.

This connector is located in a large rubber

shroud.

This image also shows the routing of the

load cell sensor wire in blue as it runs

alongside the main wiring loom. But this

will be fitted later.

When the final wiring installation is

complete take your time to secure any

loose cables with cable ties.

Note cable

tie to hold

loose wires

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

7

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

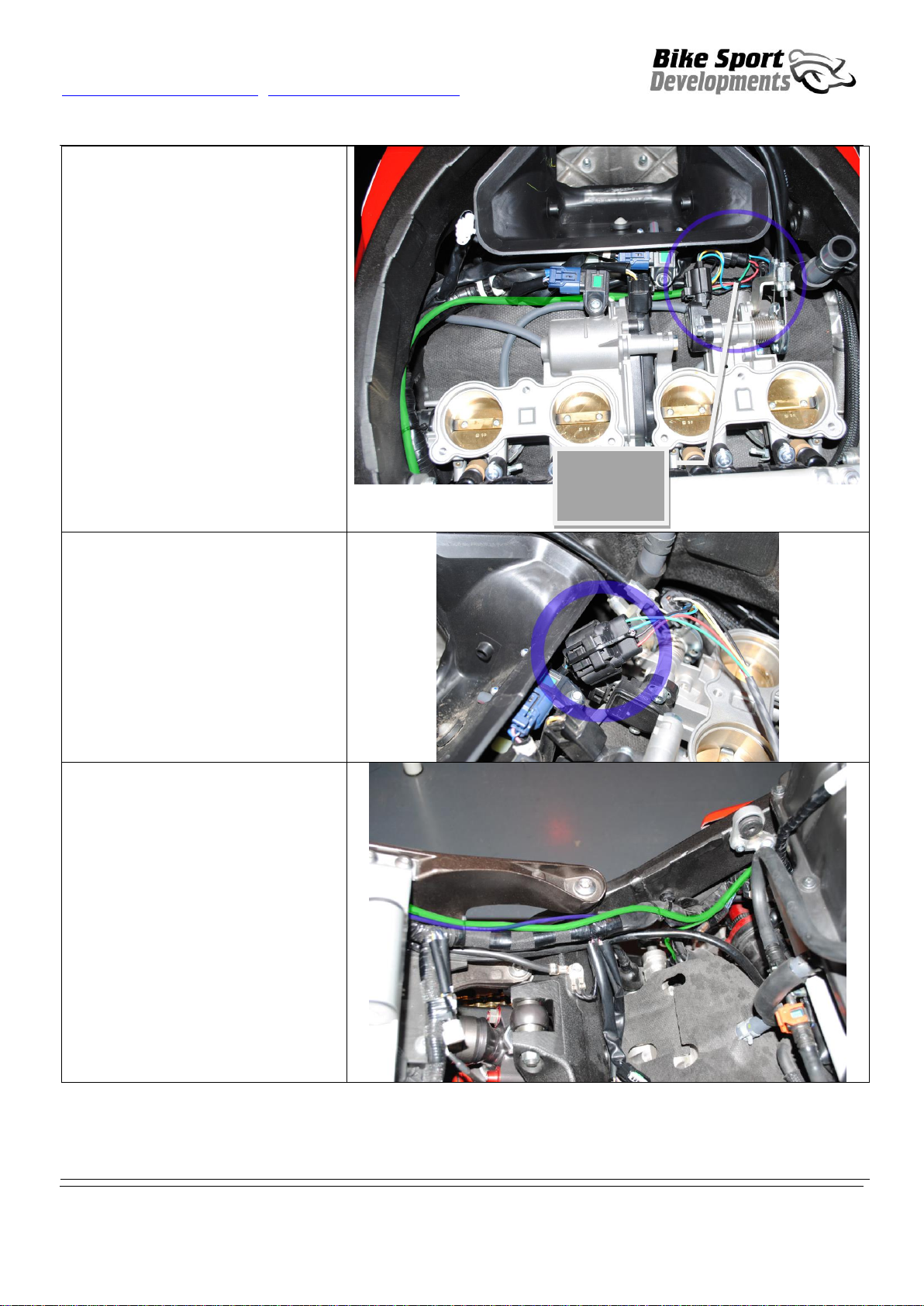

Continue along the left side and cross over to the

right side in front of the battery as seen by the green

trace line.

The connection for the load cell is from the blue

trace and sits alongside the ABD pump.

For clarity the fuel tank support has been removed.

The Blip Box module rests inside the rear of the sub

frame alongside the exhaust valve motor. The kit

contains strips of foam rubber to isolate from

vibration, but mainly to hold the component in place.

Remove the rubber shroud from the CAN bus

connector (ringed in blue) and re-fit this to connector

G of the Blip Box loom.

Not re-fit connector G to the original mounting post.

This just leaves the final connection to ‘power up’

the system when you connect F to the bike CAN

connector.

At this stage you will see the red LED switch on and

start to blink a ‘2 x blink’code for 30 seconds and is

perfectly normal even with the ignition switch off.

See notes in the next section to learn more about

the LED functions.

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

8

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

System ‘power up’ and first use.

IMPORTANT –When first plugged in (ignition switch OFF) you will see this sequence of LED events because the Blip Box

module is getting power from the rear CAN connector but all bike systems such as the ECU are OFF.

1. LED is solid ON for 2 seconds to indicate power up

2. LED blinks twice to indicate a diagnostic state relating to the throttle grip. This is because the ECU is still OFF and the

signals the Blip Box reads are invalid.

3. During this time the Blip Box is looking for CAN data from the ECU.

4. After 30 seconds of no CAN activity the Blip Box will automatically turn itself off and all LED activity will cease.

5. The system is now waiting for you to turn on the ignition in a normal way.

Normal Power on sequence if the bike has been switched OFF for at least 30 seconds. When you turn ON the ignition:

1. LED is solid ON for 2 seconds to indicate power up

2. LED blinks twice to indicate the start of self-calibration.

3. LED blinks 3 times for approximately 6-7 seconds (3 events of triple blink) , module is self-calibrating and is perfectly

normal

4. LED turns off and will now only activate when the load cell threshold is reached for UP or DOWN shift, or there is a

problem.

Normal Power on sequence if the bike has been switched OFF for less than 30 seconds. When you turn ON the ignition.

1. In this case the Blip Box module never actually turned off so there are no LED indicators or self-calibration

Normal ignition OFF sequence

1. First you will hear the main bike relay click off.

2. Blip Box will display a 2 x blink error code as the throttle grip signals go out of range when the ECU turns off.

3. The CAN data from the ECU also stops when you turn off the ignition so Blip Box goes to sleep after 30 seconds of no

CAN activity.

4. At this point the LED diagnostic activity also stops.

Summary of activation conditions for the Blip and shift system to work normally.

System not to be in a diagnostic state / bypass mode

Load cell to have exceeded threashold Mv

The inhibit time must have been exceeded since previous shift –Default is 0.35seconds

The load cell must have returned to it’s resting Mv before another blip can occur, remember to take your foot off the

lever between shifts.

Engine must be above minimum RPM –Default is 3000rpm

Throttle grip must be lower than threshold (therefore closed) –Default is 3%

Rear wheel speed must be above minimum –Default is 30kmh

Clutch switch must be out (clutch not pulled in). Note that the system is designed not to BLIP if the clutch is pulled in but

due to the delay in Blip Box getting the clutch signal over the CAN bus it is very likely that users with a fast ‘clutch / shift’

action can beat the system and still get a blip even when using the clucth.

Summary of activation conditions : Up-Shift output

System not to be in a diagnostic state / bypass mode

Load cell to have exceeded the Mv threashold

The load cell must have returned to it’s resting Mv before another blip can occur, remember to take your foot off the

lever between shifts.

The inhibit time must have been exceeded –for up-shift

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

9

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

System diagnostics - The red LED is also used as a ‘blink code’ to indicate potential problems with the system, wiring or

sensors.

No LED at ignition switch ON

Check CAN connection at rear of the bike

Inspect wiring

Disconnect other non-standard CAN devices and try again

LED on for 2 seconds at ignition switch ON,

then light off

Normal operation

1 blink > short gap

Internal error –contact manufacturer

2 blinks > short gap

Throttle grip input(s) out of normal range:

Grip signal IN 1 range is 0.72 > 4.11v

Grip signal IN 2 range is 4.32 > 0.92v

Check grip connector

Check wiring

If wiring is all OK we suggest you plug the grip directly into the bike

look and see if the same diagnostics are shown on the bike.

Potentially a twist grip failure.

See power up notes on previous page.

3 blinks > short gap

Throttle grip output is out of range

Grip signal OUT 1 or 2 range is 0.4 > 4.5v

Check grip connector

Check wiring

If wiring is OK and there is no diagnostic for the Grip Inputs signals

it suggest a damaged sensor

Note –This diagnostic is also used for the self-calibration at power

ON and lasts approximately 20 seconds.

4 blinks > short gap

Battery voltage out of range

8.5v to 16.5v

5 blinks > short gap

Load cell error - If less than 1.5v or greater than 3.5v for longer than 1.2

seconds

In this diagnostic condition the Blip and Upshift is disabled until the

sensor is back in range

Pin 1 is the 5v power from pin 7 of the Blip box

Check the signal (pin 2) is at 2.5v unloaded.

Pin 3 is ground from pin 11 of the Blip box

If all wiring checks out OK, replace the sensor

6 blinks > short gap

Load cell is out of normal range at power on. The normal value is 2.5v

without any load and this diagnostic will trigger if the sensor is less than 2.0v

or greater than 3.0v (at power on)

Pin 1 is the 5v power from pin 7 of the Blip box

Check the signal (pin 2) is at 2.5v unloaded.

Pin 3 is ground from pin 11 of the Blip box

If all wiring checks out OK, replace the sensor

7 blinks > short gap

More than 5% difference between IN and OUT voltages for input 1

Possible twist grip damage

Possible 5v sensor supply problem

Possible module damage

8 blinks > short gap

More than 5% difference between IN and OUT voltages for input 2

Possible twist grip damage

Possible 5v sensor supply problem

Possible module damage

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

10

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Download the software, drivers and PDF manuals at

www.bikesportdevelopments.co.uk/blipbox

WinBLIP software –Installation

Download the Win Blip software at www.bikesportdevelopments.co.uk/Blipbox

1. Double click your download selection and look at the lower left of your screen to see when the download is complete.

You may have a waring then ‘some downloads may harm your computer’ just change this to Keep,

not Discard.

2. Double click this Blip Box setup.exe at the lower left to start the installation process.

3. You can choose to keep the default install folder or change to one you prefer.

4. When complete you will have a new folder on your PC containing the software, blip map library and

the USB drivers for the PC cable BB-UCIF. There will also be Blip Box icon on your desktop.

5. From time to time there will be re-releases of the Blip map library, these can be downloaded

separately from the web page given above.

When you first run the software it will look like this:

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

11

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

USB –PC interface device BB-UCIF

1. PC operating systems from Windows 7 to Windows 10 are OK

to use. If you have an older PC with XP then please Email us

for specific drivers.

2. Download and install the latest USB drivers at

www.bikesportdevelopments.co.uk/blipbox , even if your PC is

news and the COM port says it is working correctly, it may not

be fully updated.

a. The download is a zip file that you should copy to

any location on your C drive.

b. Now look in that folder and un-zip the new drivers to

leave you with an exe file

c. Double click the exe file to run the new driver

installation.

d. Re-start your PC.

3. Now plug in the USB adapter and wait for up to a minute

(sometimes 2) for the drivers to install correctly.

4. Open the Control Panel , then look for the System icon , then

Device Manager to view this window:

This icon shows that the USB adapter is installed and working but it is

still worth checking that the drivers have updated. Simply ‘right click’

this COM line and select ‘update driver’

Let the PC search automatically and if no updates are found then all is OK.

Look at the COM number that has been allocated and make a note of this as it will be used in the WinBLIP software. In this

example it is COM6

Note also that you may get a different COM number if using different USB ports on your PC, so try to use the same one each

time.

Open WinBLIP and go to Setup / COM settings from the upper menu

It should look like this with the Baud Rate at 38400 and the COM line set to the

one you noted in the Device manager.

If it does not, then use the pull down arrows to change things.

Then press OK

You should now have communication.

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

12

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

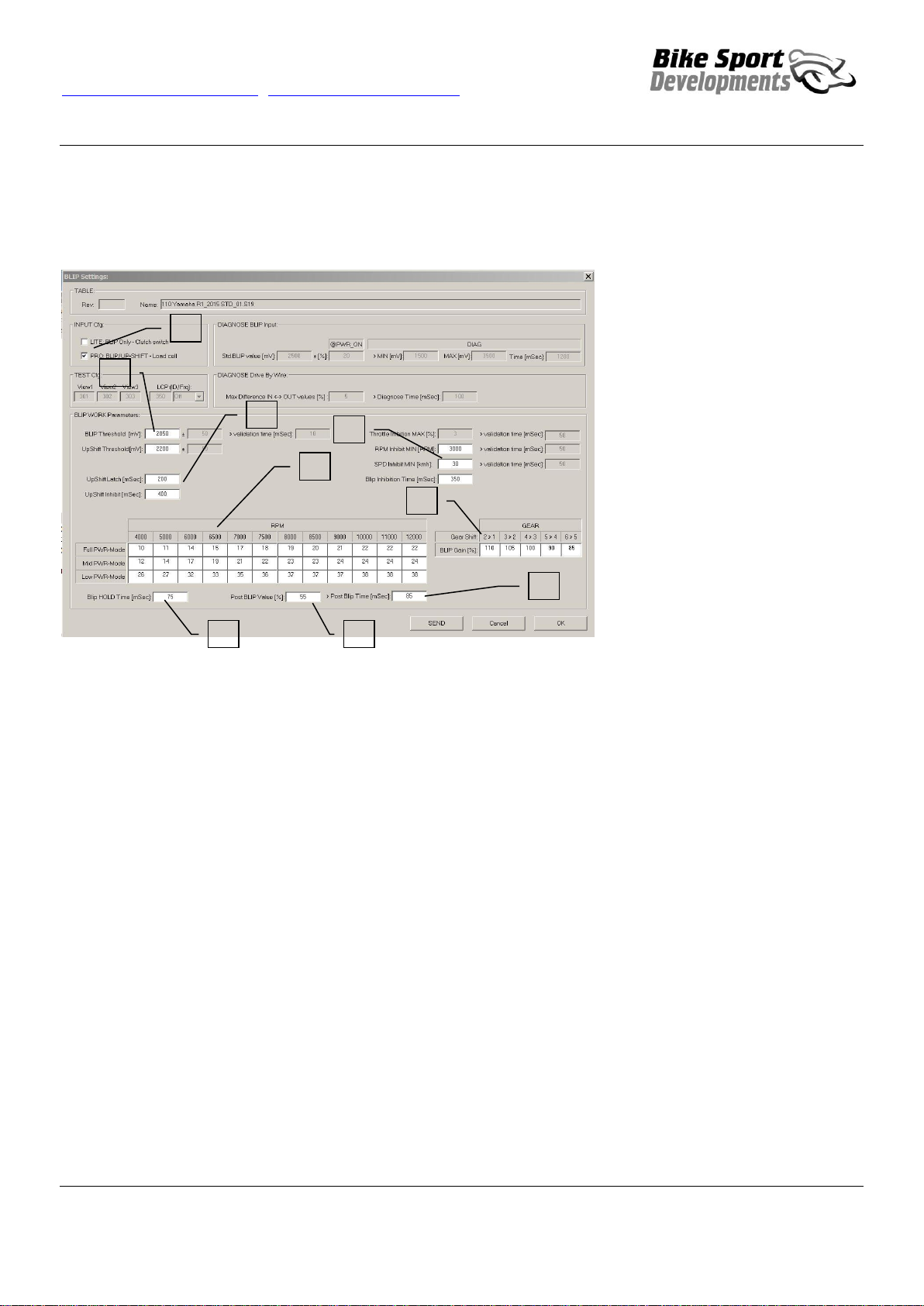

WinBLIP - Files

The system is supplied with multiple base files that are split into folders specific to each bike and also the direction of the load

cell.

From the File / Open menu locate the Blip maps folder and select the appropriate base file.

.

1. This function is used to swap the load cell input over to a ‘switch’ input from the clutch for users who prefer not to use

the load cell. It will however be necessary to change both the wiring and blip targets.

2. These values control the activation threshold for the Load Cell

a. Blip threshold Mv –above this the blip is triggered. Note the 50Mv hysteresis so it would be 2850 ON and 2800

OFF. (example values only)

b. Up shift threshold Mv –below this the blip is triggered. Note the 50Mv hysteresis so it would be 2200 ON and

2250 OFF (example values only)

c. The signals must also be above the threshold for longer than the 10mSec validation time.

3. The Blip Box generates a ‘switch output’ signal to replicate the original shifter switch on the R1, this is routed back into

the ECU via the original shifter connector.

a. Most of the shifter controls are still maintained within the ECU as before but to avoid signal errors the Blip Box

will generate a perfect signal lasting at least the latch time (default 200mSec) and avoid any other signals from

the load cell for (default 400 mSec). Both of these can be adjusted but it is not normally necessary.

4. These parameters inhibit the Blip function

a. The throttle grip must be lower than 3%, this is fixed to avoid incorrect use.

b. RPM must be above 3000

c. Rear wheel speed must be above 30kmh

d. There is a minimum time since the last blip request (from foot pressure) , default is 0.35 seconds

e. There is also these hidden inhibits:

i. Clutch pulled in removes blip. If this sensor is bypassed and shorted together you will not get a blip.

ii. Bike is already in 1st gear or Neutral

iii. Blip box has an active diagnostic (blinking LED)

iv. Foot pressure has not been removed since the last blip

1

2

3

4

4

6

5

6

7

8

9

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

13

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

5. Blip settings. The BLIP values are in % of twist grip (not engine throttle) and as the relationship between the twist grip

and the engine changes depending on which power mode and gear you are in, the settings are equally adjustable.

a. There are 3 rows of BLIP values with the first column covering all RPMs up to 4000, the next up to 5000 etc.

b. In the base map we supply the Blip % targets have been created to match these power modes

i. Row 1 is applied when you select Power 1

ii. Row 2 is applied when you select Power 2

iii. Row 3 is applied when you select Power 3 or Power 4, but the values in the map are designed for use

with Power 4

c. If you ride in power mode 3 then you may need to adjust these values to suit.

6. The ‘Gear Shift BLIP gain’ is a multiplier applied to the base BLIP values, This enables a higher blip value in lower

gears. Example a Gain of 110 would multiple the BLIP value by 1.10 (10% extra)

7. BLIP Hold –This is the primary BLIP duration and will be of a height equal to the BLIP value from the table x the BLIP

GEAR Gain (explained in 6 above)

a. The primary blip is short and fast to rapidly raise the engine RPM and disengage the gearbox pressure from

braking to accelerating.

b. There is then a ‘post blip’ with a height of x

% (parameter 8) of the primary blip and

continuing on for xmSec (parameter 9). This

keeps the RPM sufficiently high after the blip

to match the RPM of the next gear selected.

c. The image at the right shows the 2 stages of

BLIP and the perfectly matched RPM values.

d. You can also see the 2 stages of the blip in

the middle data trace called GRIP_ECU

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

14

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

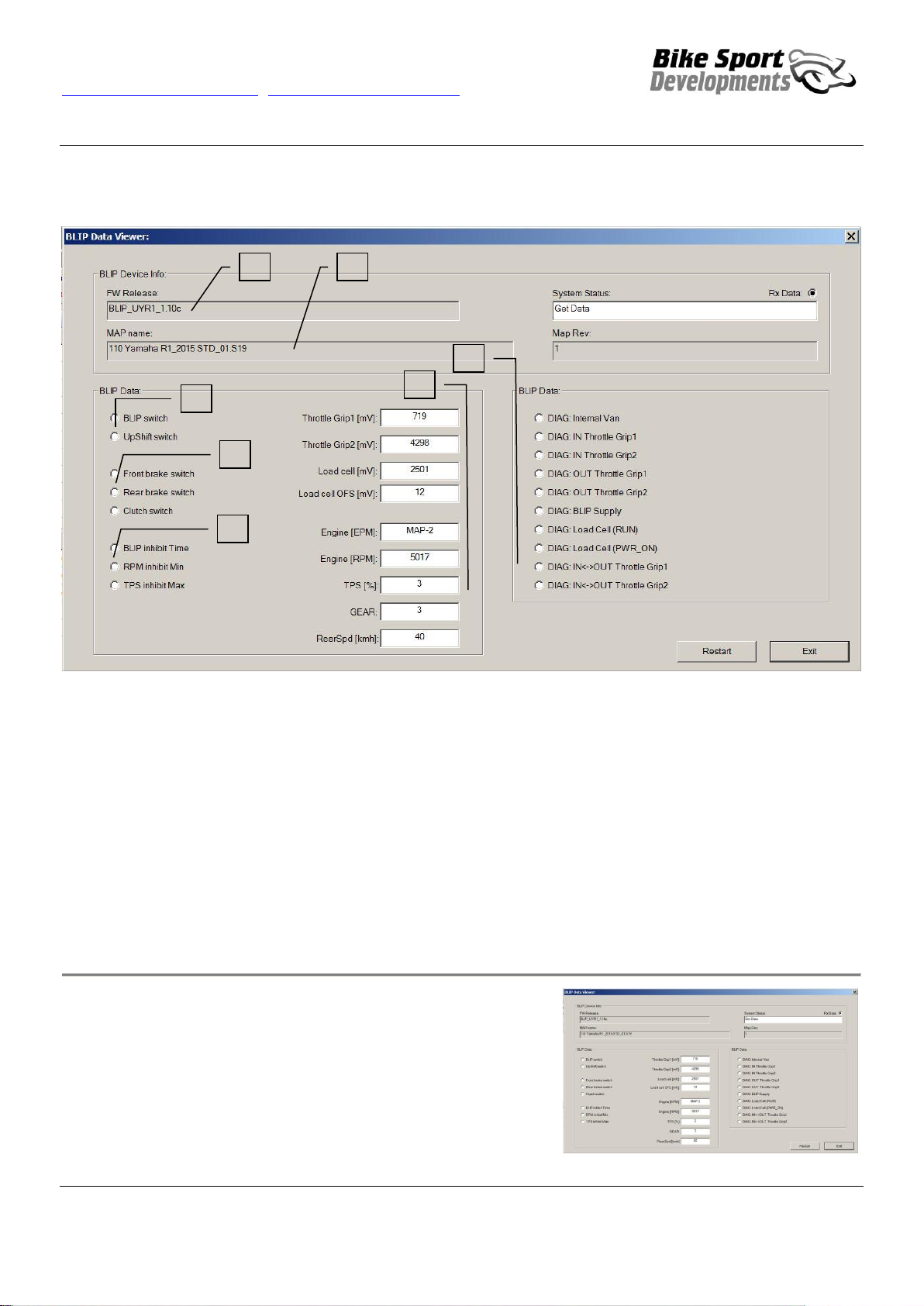

WinBLIP - View Data

From the upper menu select BLIP / View data to get the following live data screen.

1. Firmware version of the Blip Box module

2. File name currently loaded into the module

3. These icons will light up when the voltage thresholds are exceeded for UP and DOWN shift

4. These icons will light up if either the front or rear brake is applied, or the clutch (note that clutch icon will be active also if

the bike is in neutral)

5. These icons will light up if the BLIP is currently inhibited by one or more reasons

6. Live data:

a. Throttle grip 1 –Input Mv

b. Throttle grip 2 –Input Mv

c. Load cell –Mv

d. Load cell offset (self calibration adjustment after power ON)

e. Engine power mode 1 > 4

f. Engine RPM

g. TPS (Throttle grip %)

h. GEAR (0 is neutral)

i. Rear wheel speed in kmh

7. These icons will light up if one of the diagnostic (flashing LED) is active.

8. Restart –system re-start, not normally needed by the user. Used in case of power sleep mode and bench testing.

WinBLIP - Send new configuration to the module

1. First ensure you have loaded the correct file for your bike and

hardware installation.

2. From the upper menu, select BLIP, Edit Cfg to show the BLIP

Settings window see here.

3. Make sure the bike ignition is switched ON

4. Press the SEND button.

5. The BLIP Settings window will close and the main screen will show

the status of the transmission and a bar graph at the lower edge.

6. You will get an OK message when finished (about 5 seconds to

transmit)

1

2

3

4

5

6

7

3

4

5

6

7

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

15

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

WinBLIP - Firmware update

Should it ever be necessary to update the module internal firmware. First turn on the bike ignition, then from the upper menu

select Codeload / Run sequence and browse for the CodeLoadMCB.cmd file. Double click this file and the load procedure will

begin.

Remember to load the BLIP map file after any module re-flash.

This system is intended for off-highway performance use only. It is not certified for use ‘on the road’

Application : Yamaha R1 2015 onwards

Components

Part No.

Qty

Blip Box control module (version C onwards)

BBM-C

1

Main wiring loom

BDW1607_03

1

Shift load cell –520mm cable / 1000Nm (female) threads

BD-PO-78-07B

1

M6 x 35mm RH thread stud

8103

1

Shift rod extension –150mm (RH threads)

BDD1611_01

1

200mm x 3mm thin cable tie for throttle grip connector

1113

3

Foam rubber strip –100mm (in 2 pieces)

1114

2

Miscellaneous Components

Qty

Printed manual

1

Blip Box stickers

4

BB –UCIF_YAM

Ordered separately

Bike Sport Developments Ltd

Tel 0044 (0)1327 263942 –

mail@bikesportdevelopments.co.uk / www.bikesportdevelopments.co.uk

Manual revision 09, 07/11/2015

16

Bike Sport Developments Ltd

Unit 3D Manor Business park, Grants Hill way, Woodford Halse, Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

Copyright –Bike Sport Developments Ltd - 2015

Bike Sport Developments Ltd

Unit 3D Manor Business Park,

Grants Hill way, Woodford Halse,

Northants, NN11 3UB - UK

Tel: 0044 (0)1327 263942

www.bikesportdevelopments.co.uk

Download the software, drivers and PDF manuals at

www.bikesportdevelopments.co.uk/blipbox

This manual suits for next models

1

Popular Control Unit manuals by other brands

Coleman

Coleman REVOLUTION REVCOGL Assembly manual

aguilera

aguilera AE/SA-M Technical manual

Velocity

Velocity VDOT-SCM-SCI instruction manual

Tektronix

Tektronix TM 5006 instruction manual

NASSAU

NASSAU ED520 Functional description

Vestamatic

Vestamatic Rolltec Plus 500 Installation and operating instructions