I-145 Pg. 2 of 3

Rev. A0600

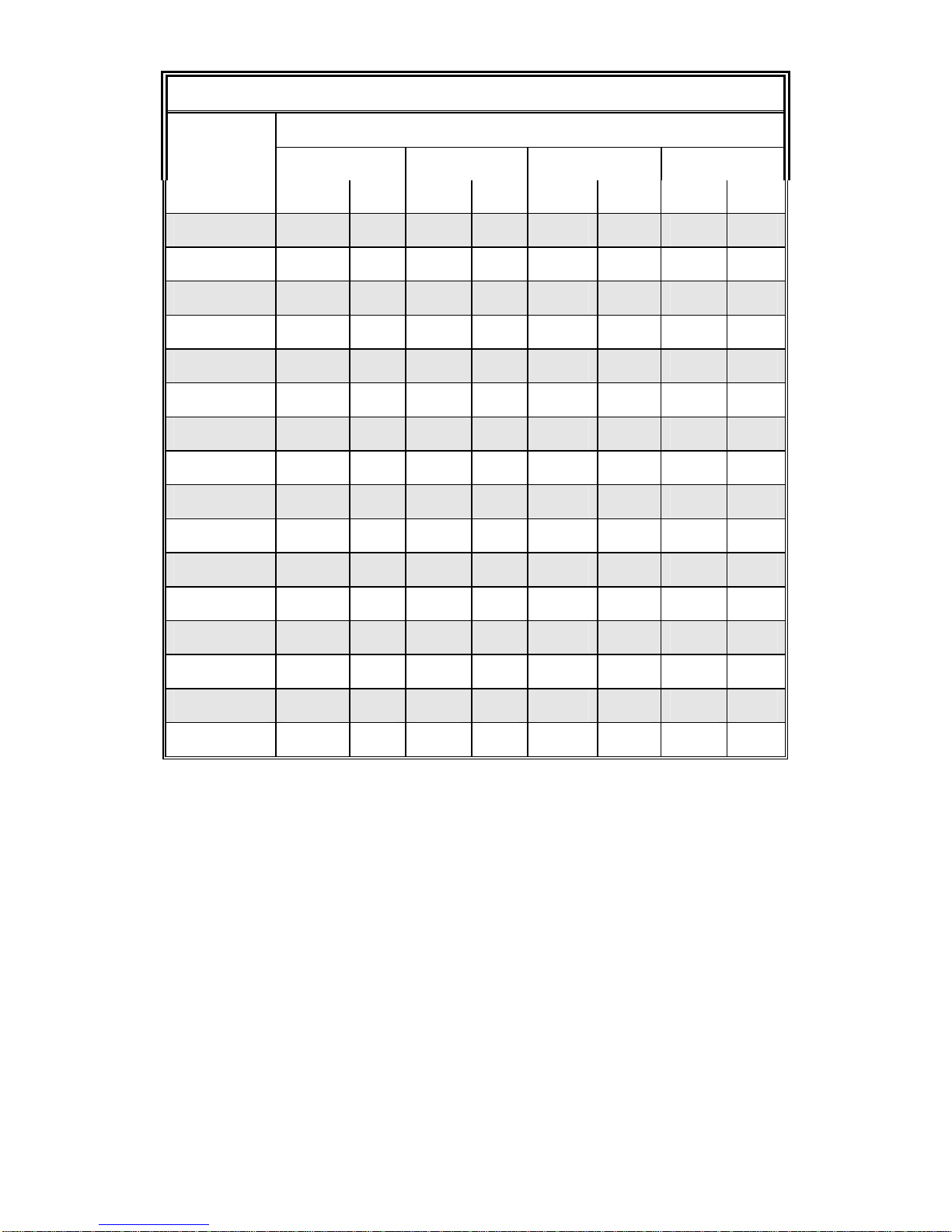

Table 4

Induction Rates for Viscosities Shown

1 cps 75 cps 200 cps 500 cps

Metering Tip

Color

Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio

Clear 0.84 152-1 0.65 197-1 0.45 284-1 0.30 427-1

Purple 1.35 95-1 1.10 116-1 0.90 142-1 0.60 213-1

Yellow 2.40 53-1 2.00 64-1 1.50 85-1 1.10 116-1

Green 4.20 30-1 3.40 38-1 2.65 48-1 2.10 61-1

Pink 5.25 24-1 4.50 28-1 3.45 37-1 2.60 49-1

Turquoise 9.40 14-1 7.25 18-1 5.45 23-1 3.70 35-1

Black 11.75 11-1 8.80 15-1 6.35 20-1 4.20 30-1

Gray 14.50 9-1 10.80 12-1 7.75 17-1 4.75 27-1

Red 18.00 7-1 13.20 10-1 8.30 15-1 5.00 26-1

Blue 20.60 6-1 14.70 9-1 8.65 14.8-1 5.20 25-1

Brown 24.10 5-1 16.15 8-1 9.30 14-1 5.50 23-1

White 27.50 4.7-1 17.80 7-1 9.70 13-1 5.70 22-1

Orange 30.00 4.3-1 18.50 6.9-1 10.10 12.7-1 5.85 21.9-1

Lt. Blue 32.00 4-1 18.90 6.8-1 10.20 12.5-1 6.00 21-1

Tan 32.50 3.9-1 19.25 6.6-1 10.40 12.3-1 6.25 20.5-1

None 34.25 3.7-1 20.45 6-1 10.60 12-1 6.50 20-1

All induction rates are based on 40 psi water pressure and 40 psi air pressure.

RETURNS: NO MERCHANDISE MAY BE RETURNED FOR CREDIT WITHOUT DEMA’S WRITTEN PERMISSION.

RETURN MERCHANDISE AUTHORIZATION NUMBER REQUIRED IN ADVANCE OF RETURN.

WARRANTY: DEMA products are warrantedagainstdefective material and workmanship under normal use andservice for oneyear fromthe

date of manufacture. This limited warranty does not apply to any products which have a normal life shorter than one year or

failure and damage caused bychemicals, corrosion, improper voltage supply, physical abuse, or misapplication. Rubber and

synthetic rubber parts such as “o”- rings, diaphragms, squeeze tubing and gaskets are consideredexpendableandarenotcovered

under warranty. This warranty is extended only to the original buyer of DEMA products. If products are altered or repaired

without prior approval of DEMA, this warranty will be void.

Defective units or parts should be returned to the factorywith transportation prepaid. If inspection shows them to be defective,

theywill be repaired or replaced withoutcharge, F.O.B. factory. DEMA assumes no liabilityfor damages. Returnmerchandise

authorization number, to return units for repair or replacement, must be granted in advance of return.