Contents

Safety.......................................................................4

Safety-AlertSymbol............................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

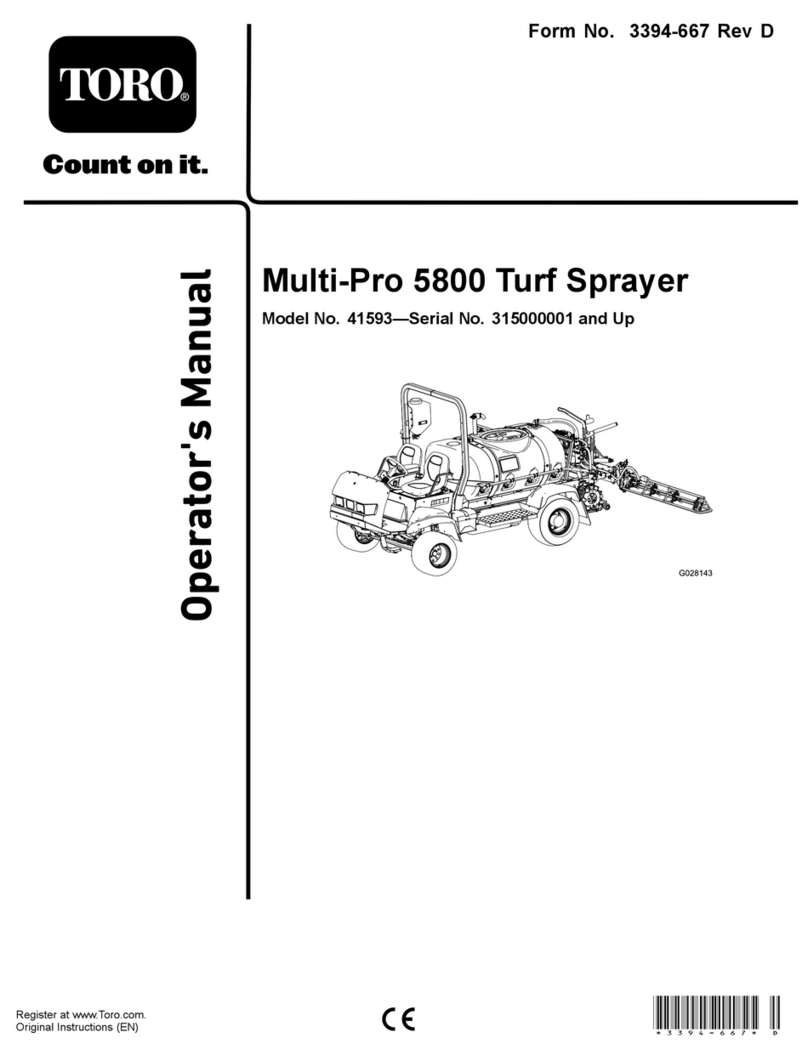

ProductOverview....................................................11

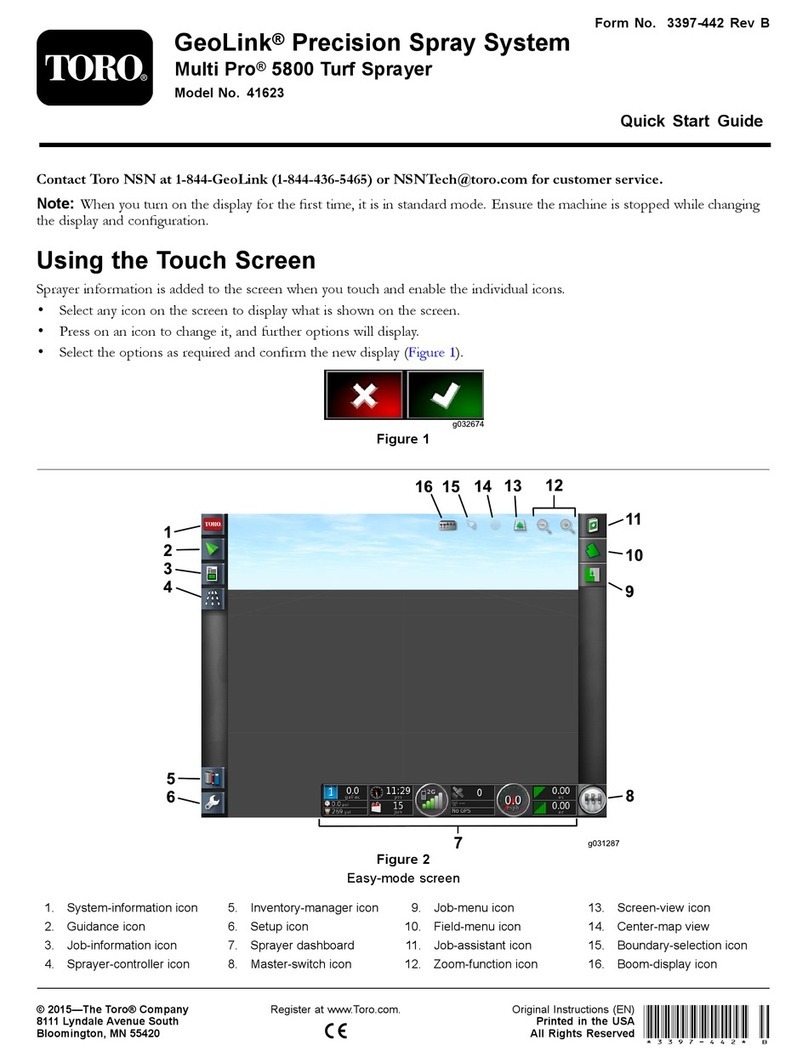

Controls............................................................11

Specications..................................................17

BeforeOperation.................................................18

BeforeOperationSafety...................................18

FuelSpecication.............................................20

DuringOperation.................................................20

DuringOperationSafety...................................20

OperatingtheMachine.....................................23

OperatingtheSpreader....................................25

OperatingtheSprayer......................................33

AfterOperation....................................................39

AfterOperationSafety......................................39

TransportingtheMachine.................................39

Maintenance...........................................................41

MaintenanceSafety..........................................41

RecommendedMaintenanceSchedule(s)...........42

NotationforAreasofConcern...........................43

Lubrication..........................................................44

LubricateGreaseFittings..................................44

EngineMaintenance...........................................44

ServiceAirCleaner...........................................44

CheckEngineOilLevel.....................................44

ChangeEngineOil...........................................44

FuelSystemMaintenance...................................45

CheckFuelFilterandT ank...............................45

ElectricalSystemMaintenance...........................46

CheckBatteryCharge......................................46

RecommendedJumpStarting

Procedure.....................................................46

DriveSystemMaintenance..................................48

CheckTirePressures.......................................48

WheelMountScrewTorque

Specication.................................................48

BeltMaintenance................................................48

CheckConditionofBelt....................................48

ControlsSystemMaintenance.............................49

AdjustingtheParkingBrake..............................49

MotionControlLinkageAdjustment..................49

MotionControlTrackingAdjustment.................50

HydraulicSystemMaintenance...........................51

CheckHydraulicOilandTankLevel..................51

ChangeHydraulicSystemFilterand

Fluid..............................................................51

HydraulicSystemAirPurge..............................51

MaintainingtheChassis.......................................52

CheckforLooseHardware...............................52

MaintainingtheSprayerandSpreader

Systems........................................................53

CheckSpreaderSystem...................................53

CheckSprayerSystem.....................................53

CheckIn-lineFilter............................................53

Cleaning..............................................................53

CleaningandStoringSafety.............................53

CleanEngineandExhaustSystem

Area..............................................................53

RemoveEngineShroudsandCleanCooling

Fins...............................................................53

CleanDebrisFromMachine.............................54

WasteDisposal.................................................54

Storage...................................................................55

ExtendedorWinterStorage..............................55

Troubleshooting......................................................56

Schematics.............................................................59

3