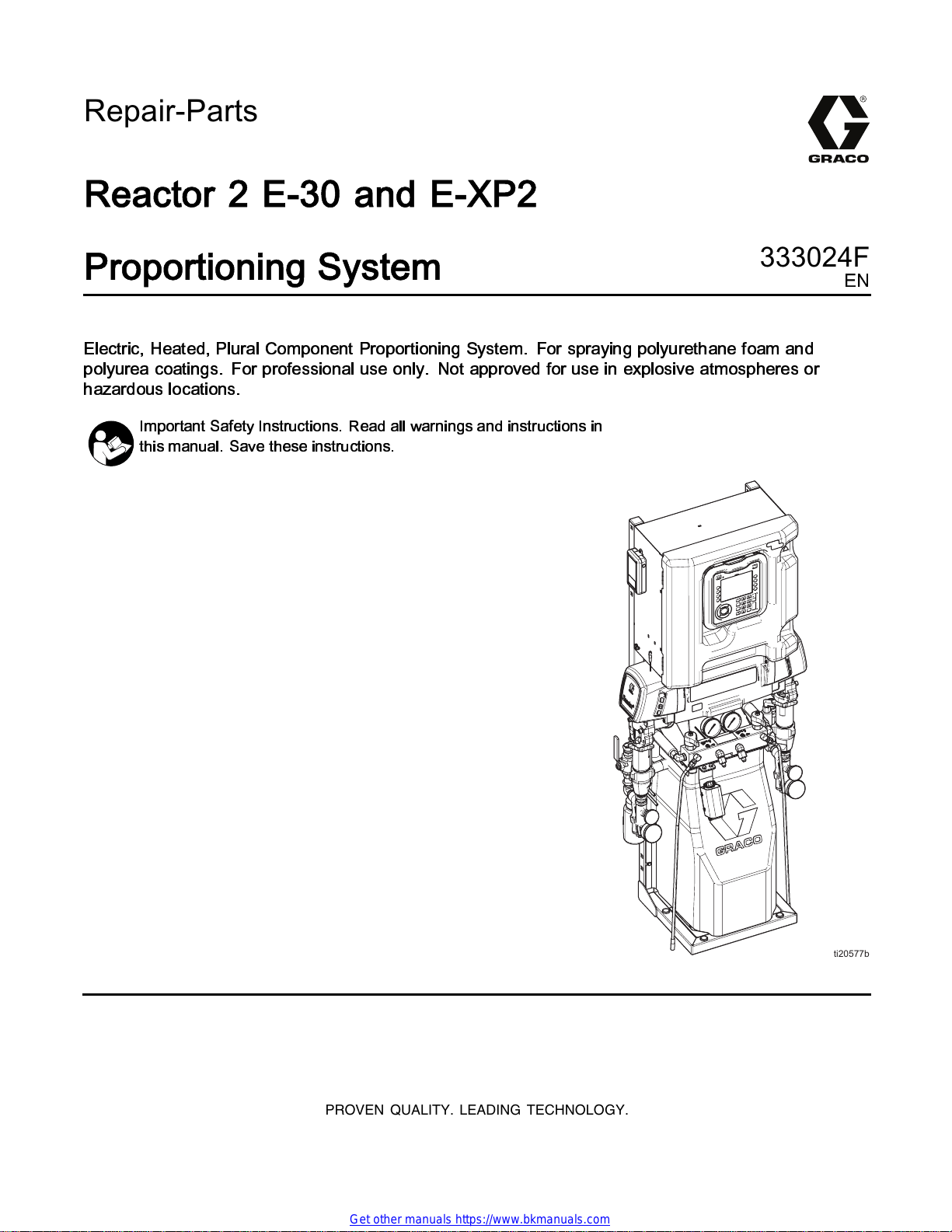

Graco Reactor 2 E-30 Use and care manual

Other Graco Paint Sprayer manuals

Graco

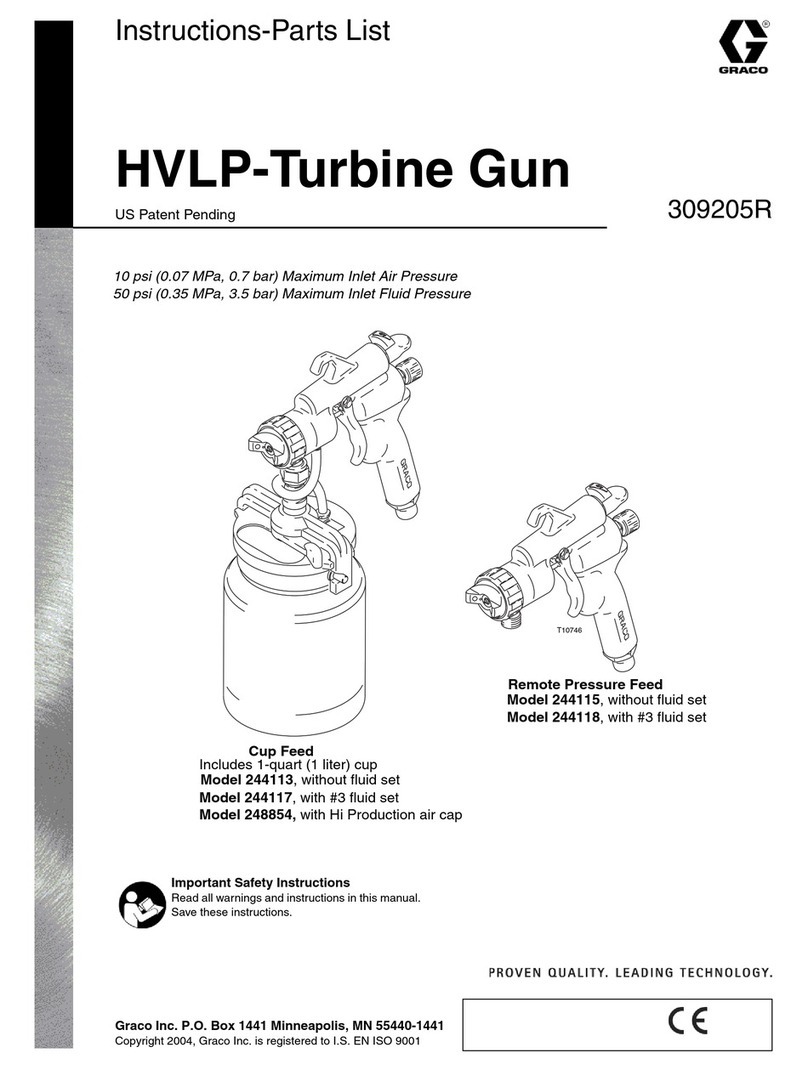

Graco HVLP-Turbine Gun Operation manual

Graco

Graco 258850 User manual

Graco

Graco 17R236 Guide

Graco

Graco 25D496 User manual

Graco

Graco 238817 User manual

Graco

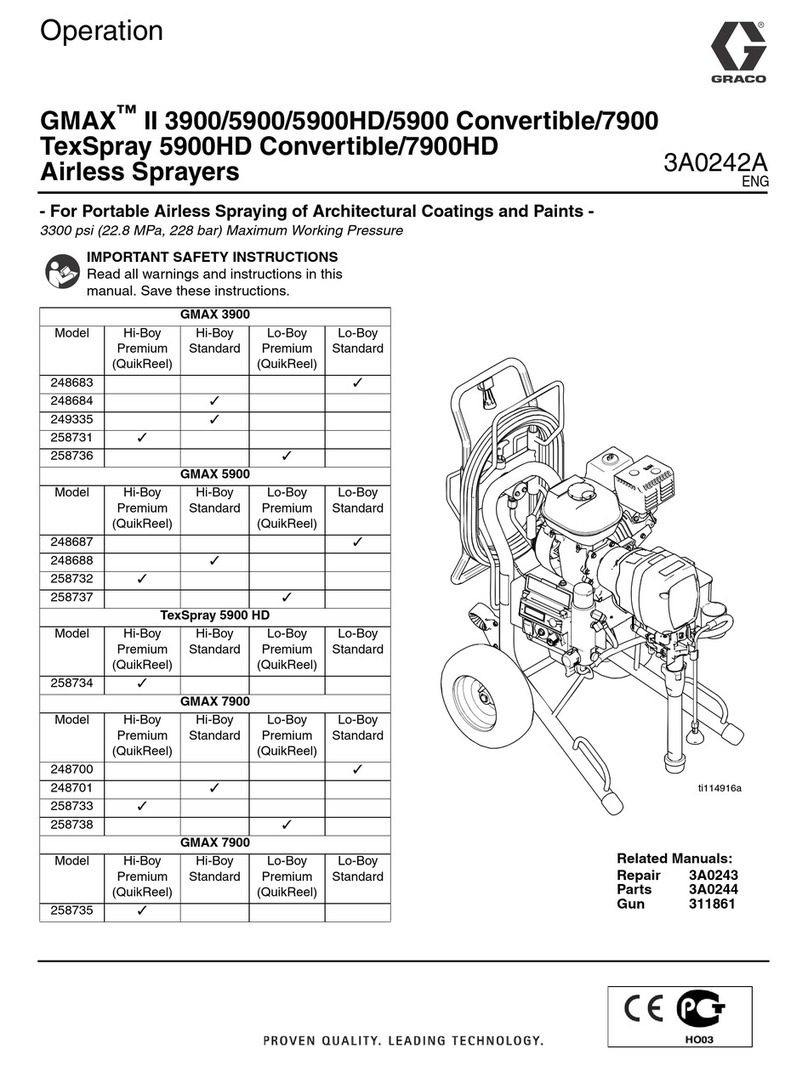

Graco GMAX 258731 User manual

Graco

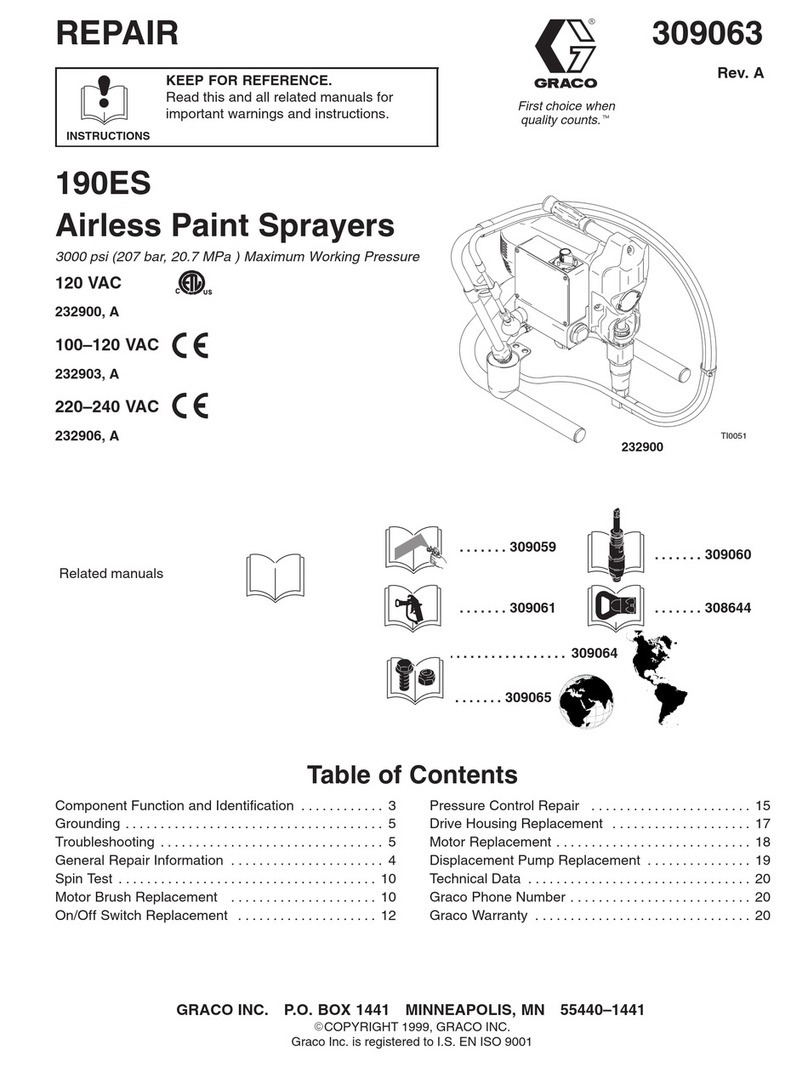

Graco 232903 Operating instructions

Graco

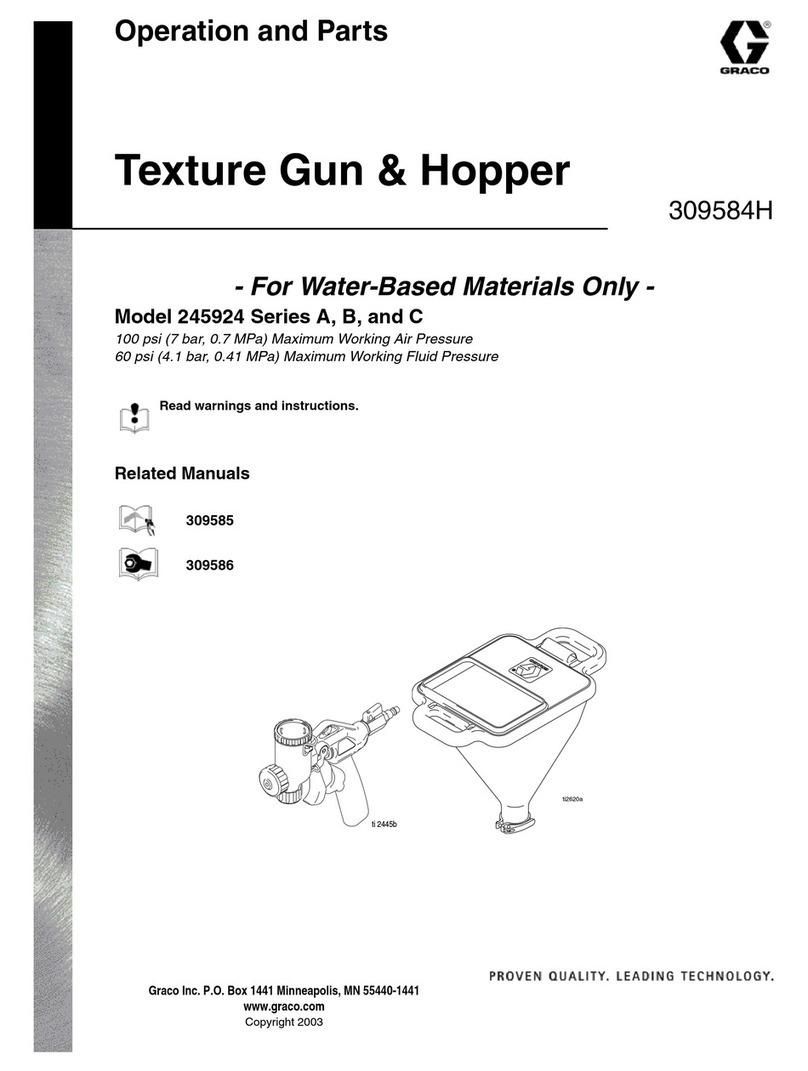

Graco 245924 A Series Guide

Graco

Graco Reactor E-10hp User manual

Graco

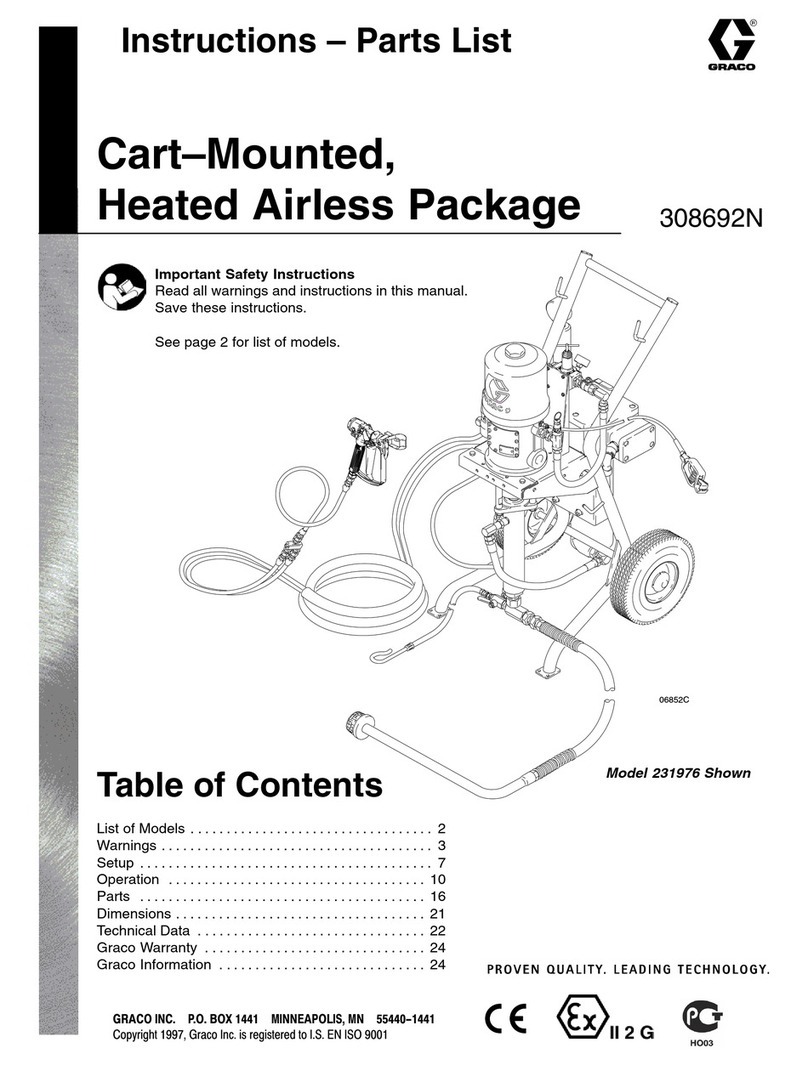

Graco 308692N User manual

Graco

Graco G40 User manual

Graco

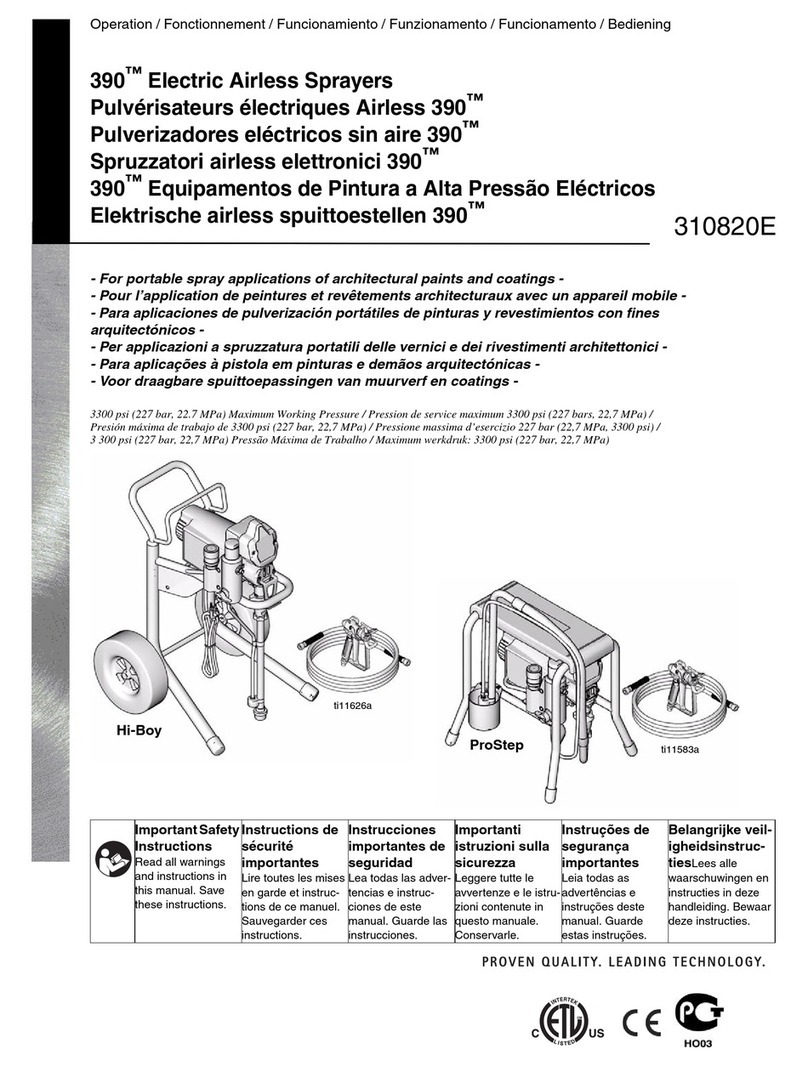

Graco 310820E User manual

Graco

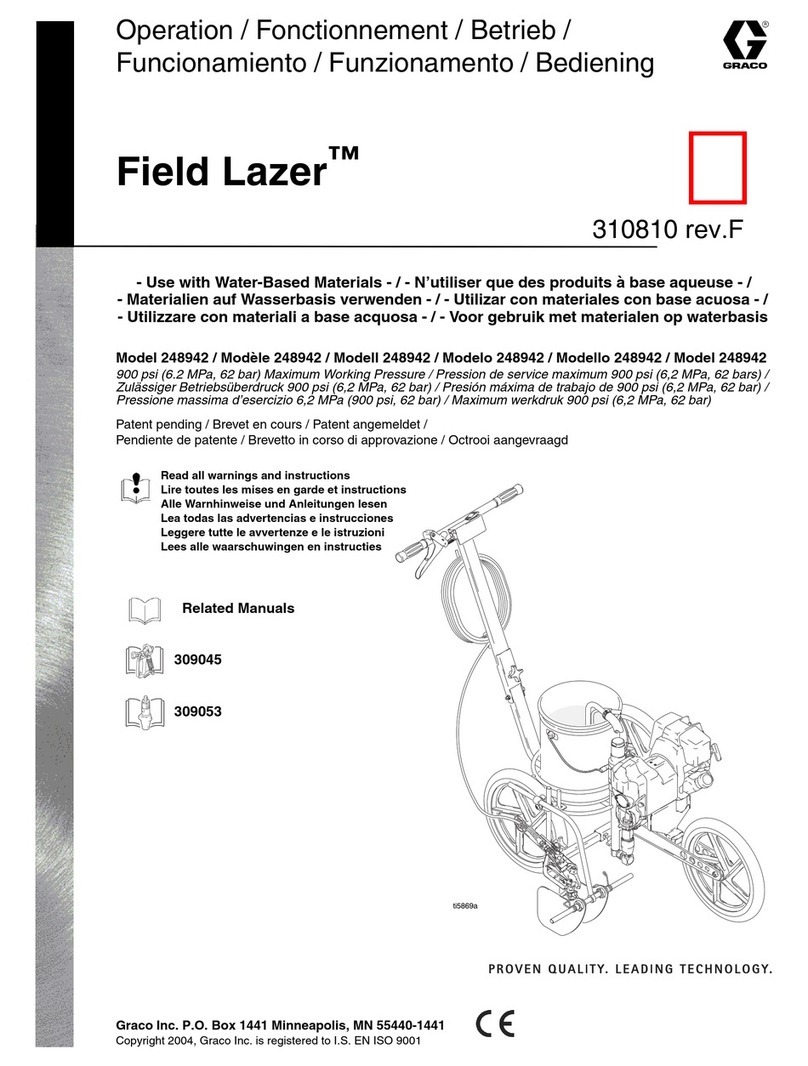

Graco Field Lazer 248942 Instruction Manual

Graco

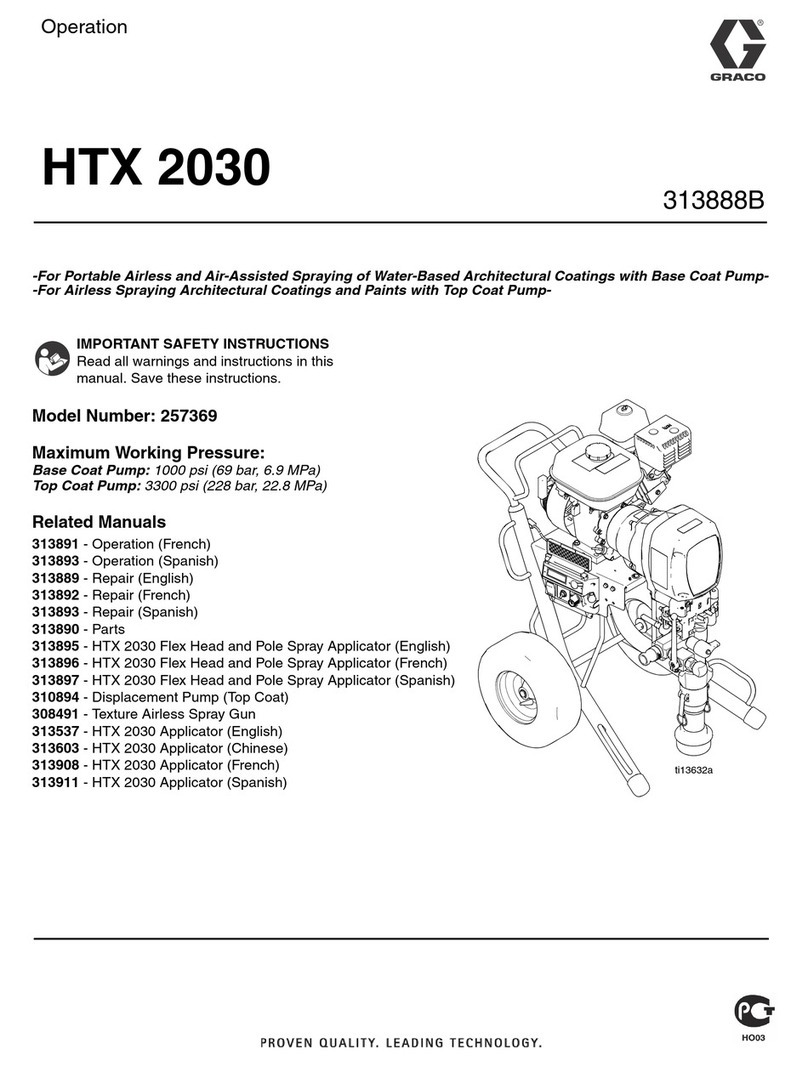

Graco HTX 313888B User manual

Graco

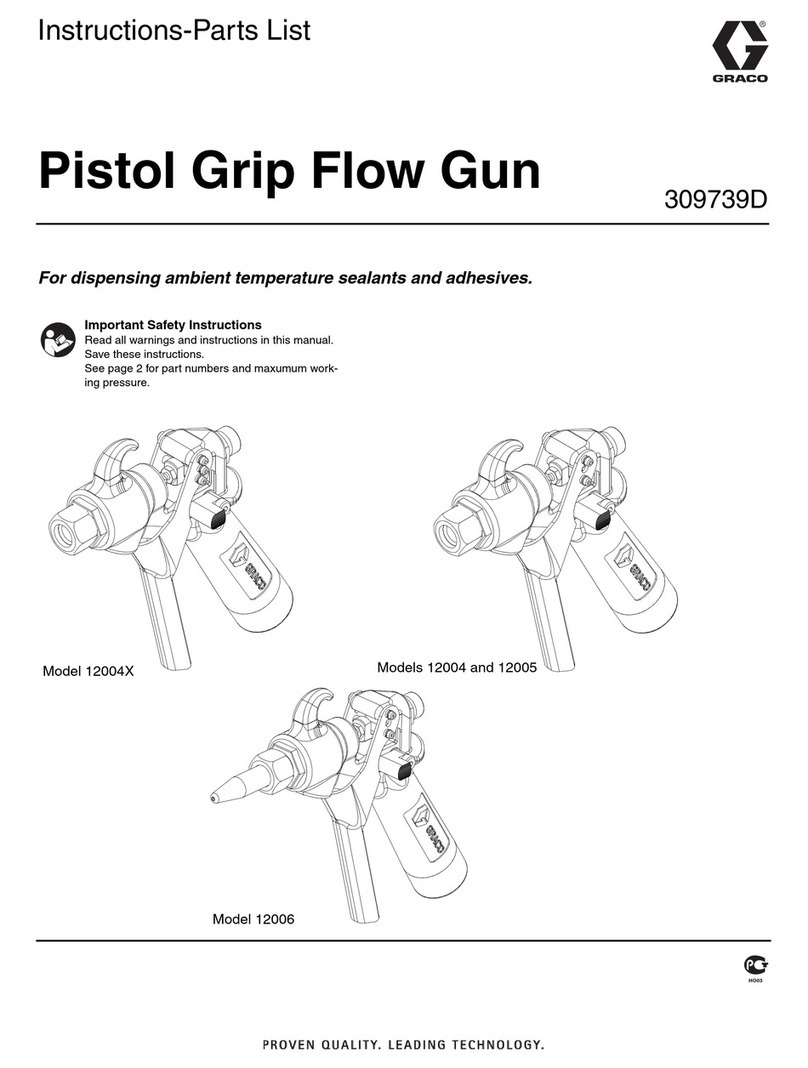

Graco 12004 Operation manual

Graco

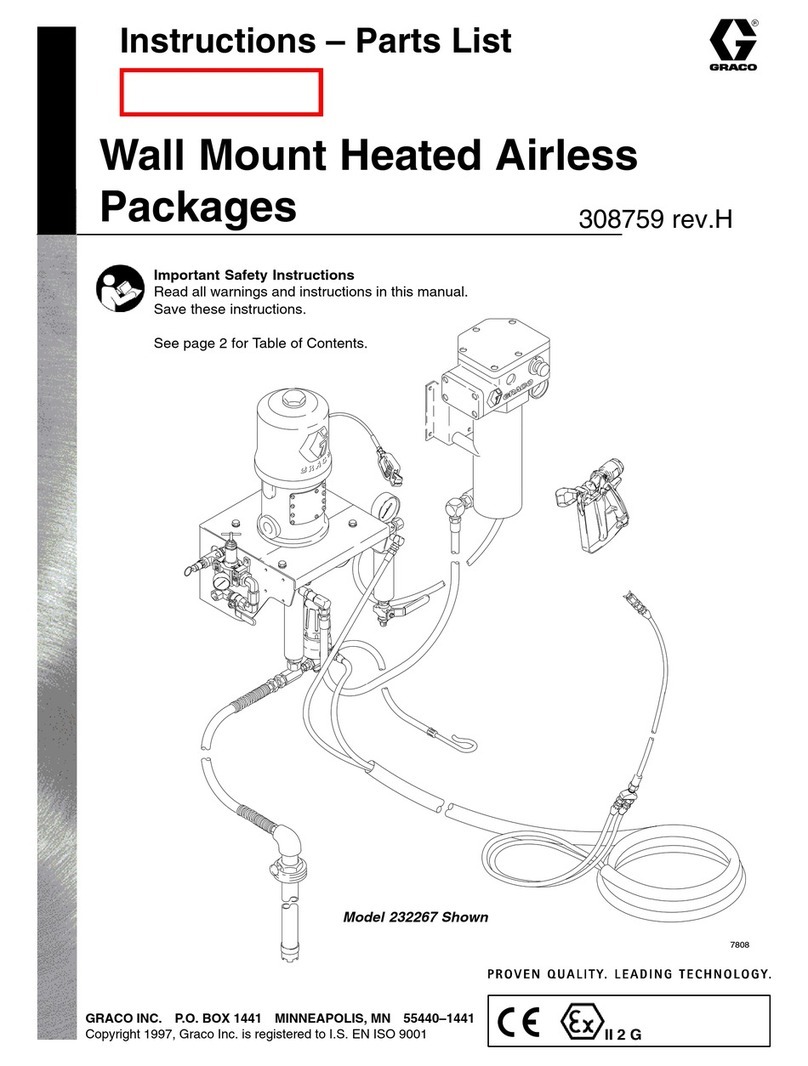

Graco 232267 Operation manual

Graco

Graco Series B Operation manual

Graco

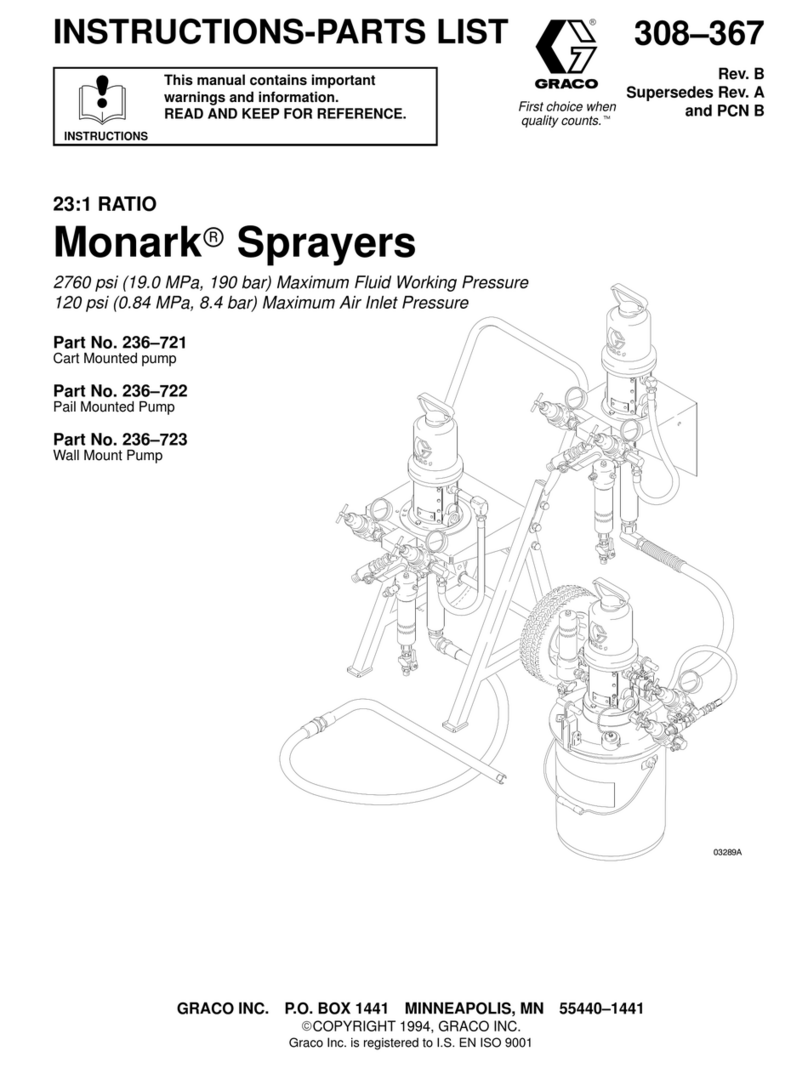

Graco Monark 03289A User manual

Graco

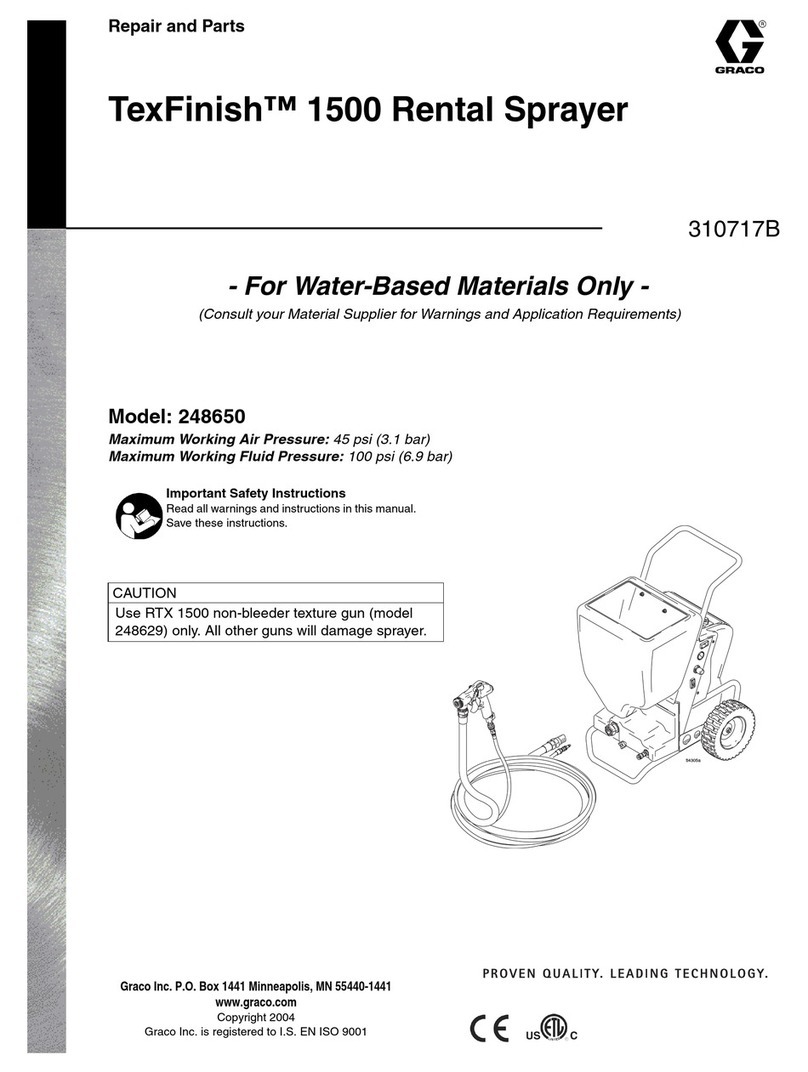

Graco TexFinish 1500 Use and care manual

Graco

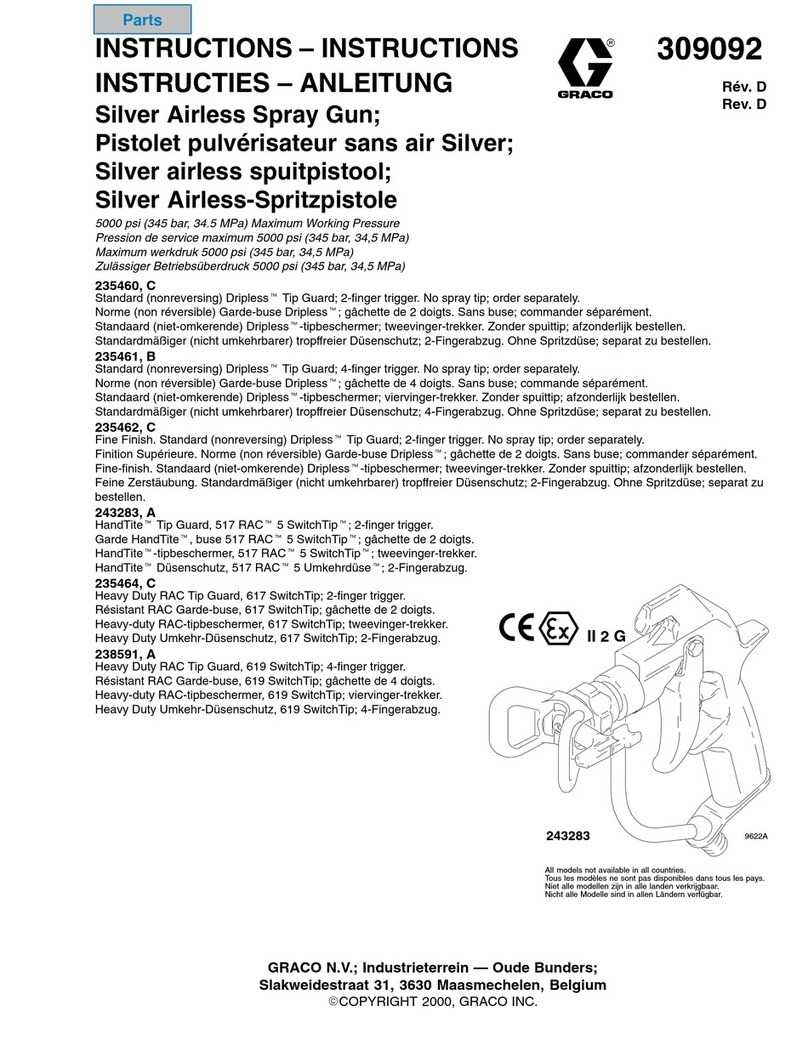

Graco 309092 User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual