I-148 Pg. 1 of 3

Rev. A0500

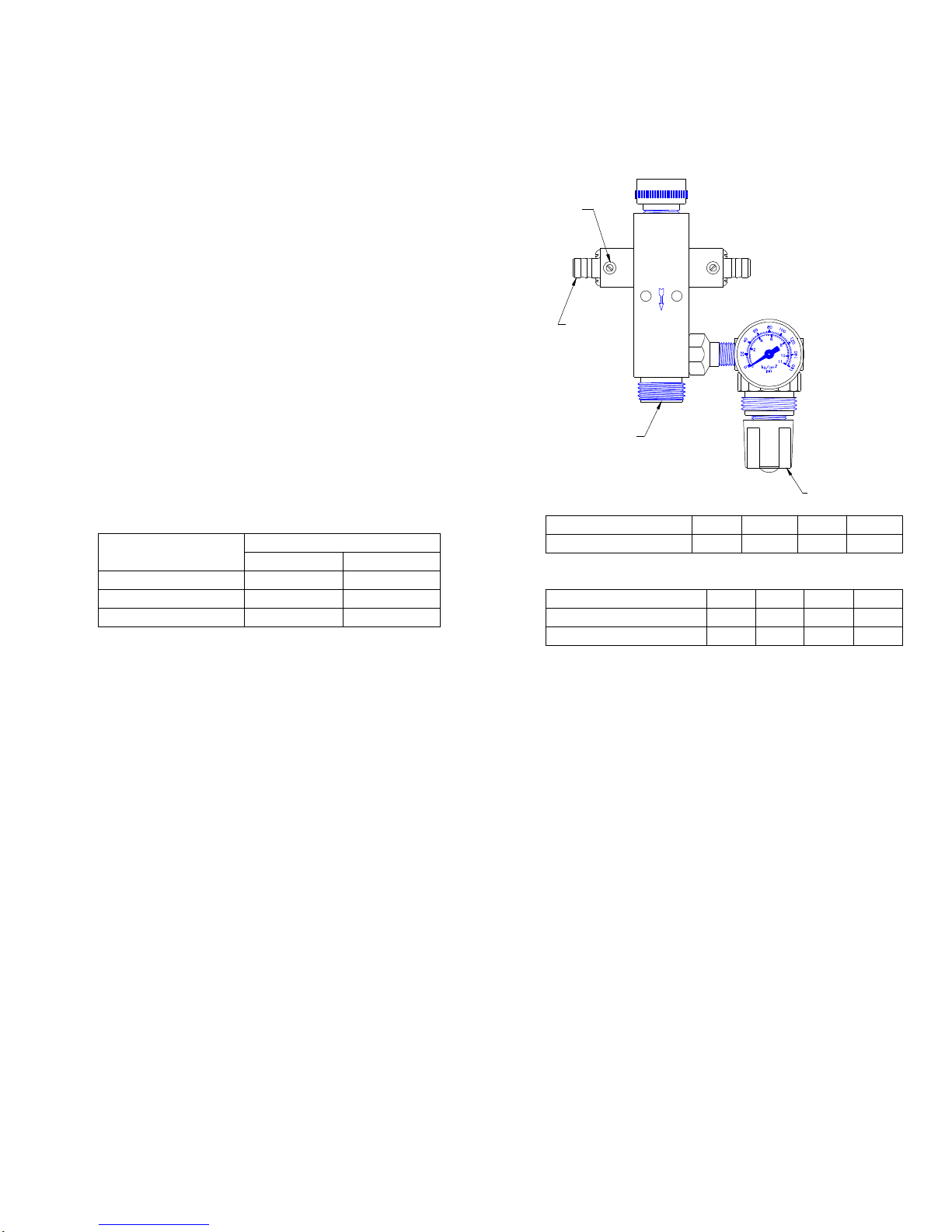

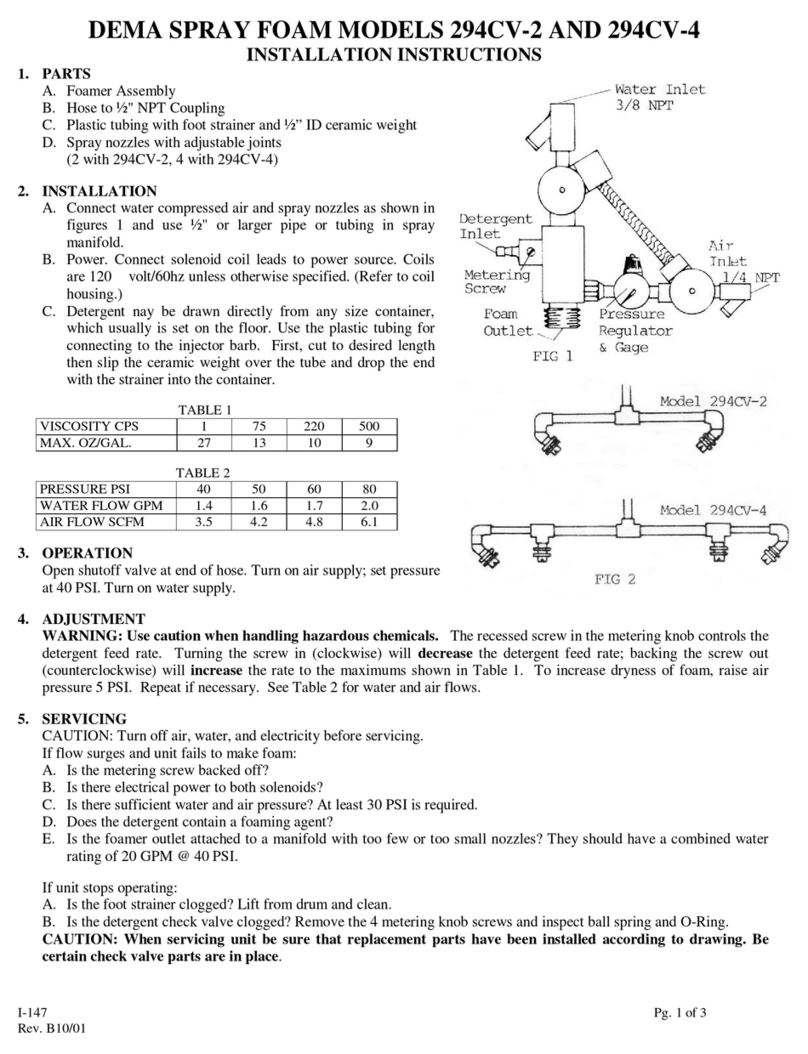

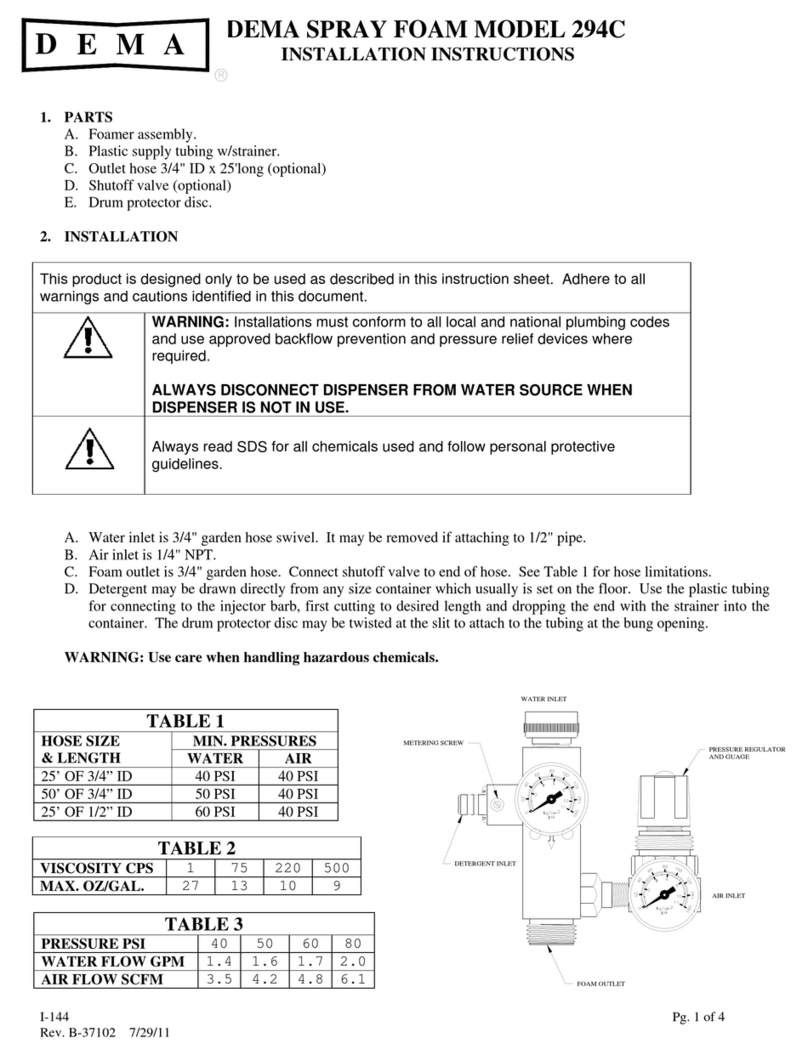

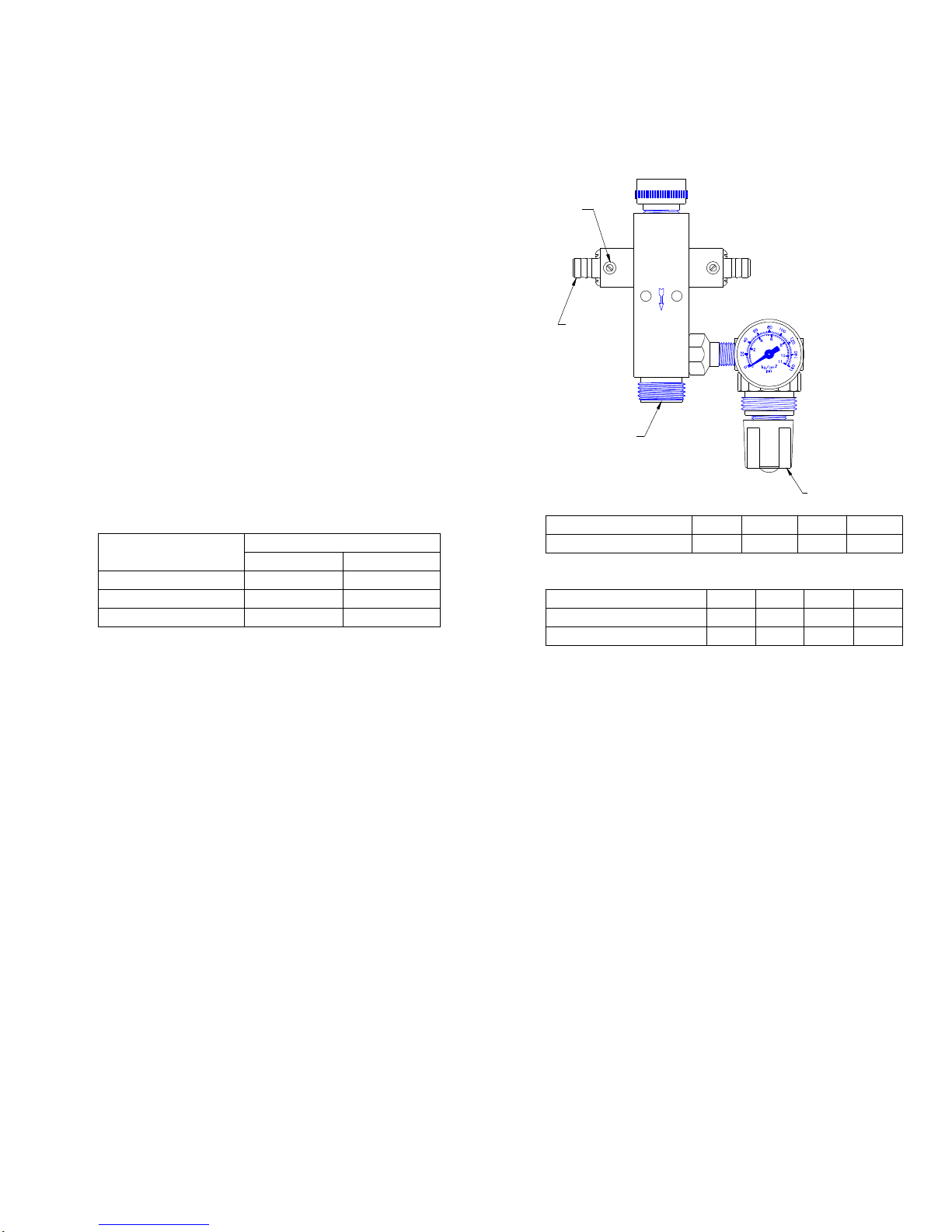

FOAM OUTLET

FIGURE 1

DETERGENT INLET

METERING SCREW

WATER INLET

PRESSURE REGULATOR

AND GUAGE

AIR INLET

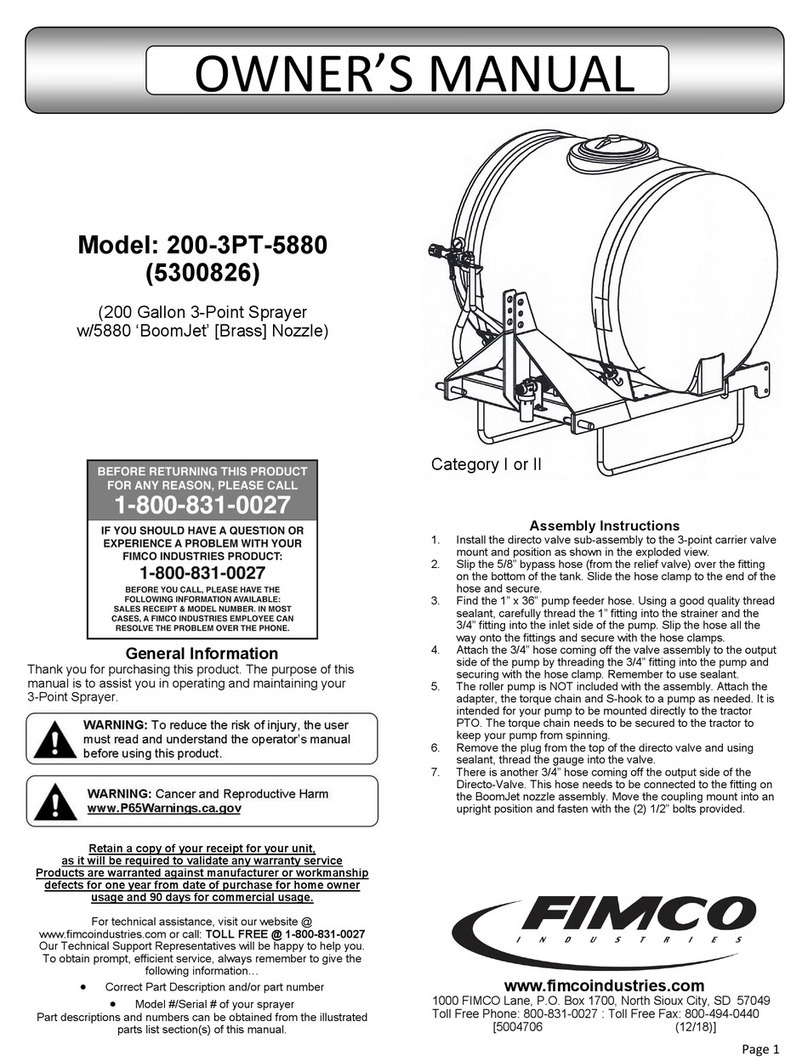

DEMA SPRAY FOAM MODEL 294CDF

(DUAL FEED, LINE PRESSURES)

INSTALLATION INSTRUCTIONS

1. PARTS

A. Foamer assembly

B. 2 pcs. plastic supply tubing with strainer

*C. Outlet hose ¾” ID x 25’ lg.

*D. Shutoff valve

*Optional

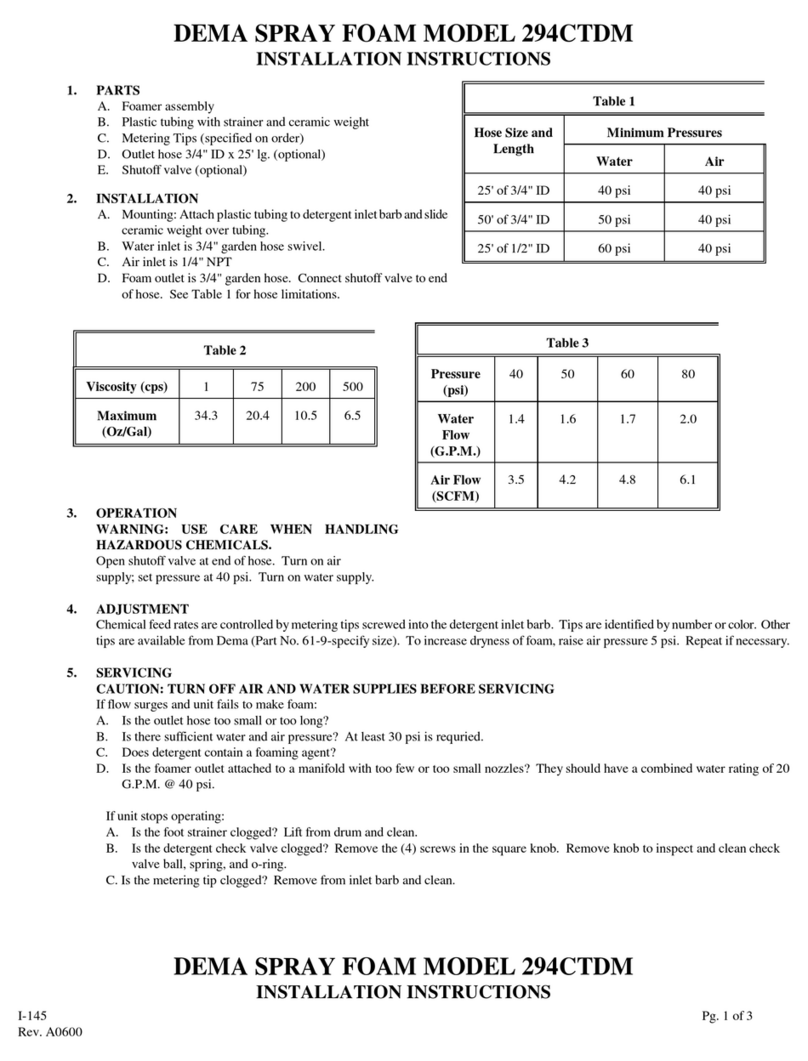

2. INSTALLATION

A. Water inlet is ¾” garden hose swivel. It may be removed if

attaching to ½” pipe.

B. Air Inlet is ¼” NPT female pipe.

C. Foam outlet is ¾” garden hose. See Table 1 for hose

limitations.

D. Detergent may be drawn directly from any size container

which is usually set on the floor. Use the plastic tubing for

connecting to the injector barbs. First cut to desired length

and then drop the end with the strainer into the container.

MIN. PRESSURES

HOSE SIZE AND

LENGTH WATER AIR

25' of 3/4" ID 40 PSI 40 PSI

50' of 3/4" ID 50 PSI 40 PSI

25' of 1/2" ID 60 PSI 40 PSI

TABLE 1

VISCOSITY CPS 1 75 220 500

MAX. OZ/GAL. 33 31 28 24

TABLE 2

PRESSURE PSI 40 50 60 80

WATER FLOW GPM 1.4 1.6 1.7 2.0

AIR FLOW SCFM 3.5 4.2 4.8 6.1

TABLE 3

3. OPERATION

Open shutoff valve at end of hose. Turn on air supply. Set pressure at 40 PSI. Turn on water supply.

4. ADJUSTMENT

WARNING: Use care when handling hazardous chemicals. Adjust detergent feed rate by turning recessed screws in the square

knobs. Turning to the left increases the rate to the maximums shown in Table 2. To increase dryness of foam, raise air pressure 5

PSI. Repeat if necessary. See Table 3 for water and air flows.

5. SERVICING

CAUTION: Turn off air and water supplies before servicing.

If flow surges and unit falls to make foam:

A. Is the metering screw backed off?

B. Is the outlet hose too small or too long?

C. Is there sufficient water and air pressure? At least 30 PSI is required.

D. Does the detergent contain a foaming agent?

E. Is the foamer outlet attached to a manifold with too few or too small nozzles? They should have a combined water rating of

20 GPM @40 PSI.

If unit stops operating:

A. Is a foot strainer clogged? Lift from drum and clean.

B. Is a detergent check valve clogged? Remove the 4 screws in a square knob. Remove knob to inspect and clean check valve

ball, spring and o-ring.

CAUTION: When servicing unit be sure that replacement parts have been installed according to drawing. Be certain check valve

parts are in

place.