Toro 41228 User manual

Other Toro Paint Sprayer manuals

Toro

Toro 41593 User manual

Toro

Toro Multi Pro 41240 User manual

Toro

Toro Spray Master User manual

Toro

Toro Multi Pro WM 41240 User manual

Toro

Toro 34215 User manual

Toro

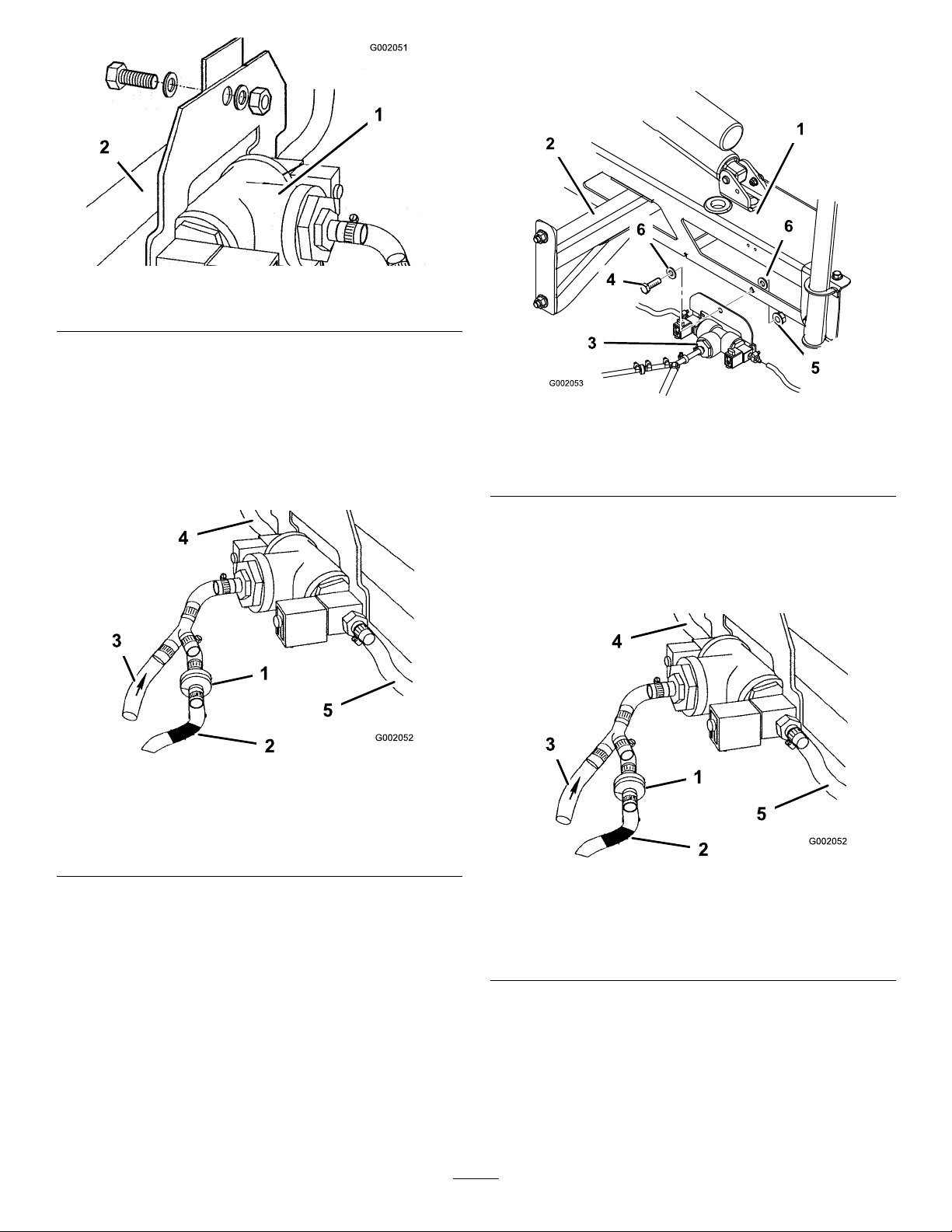

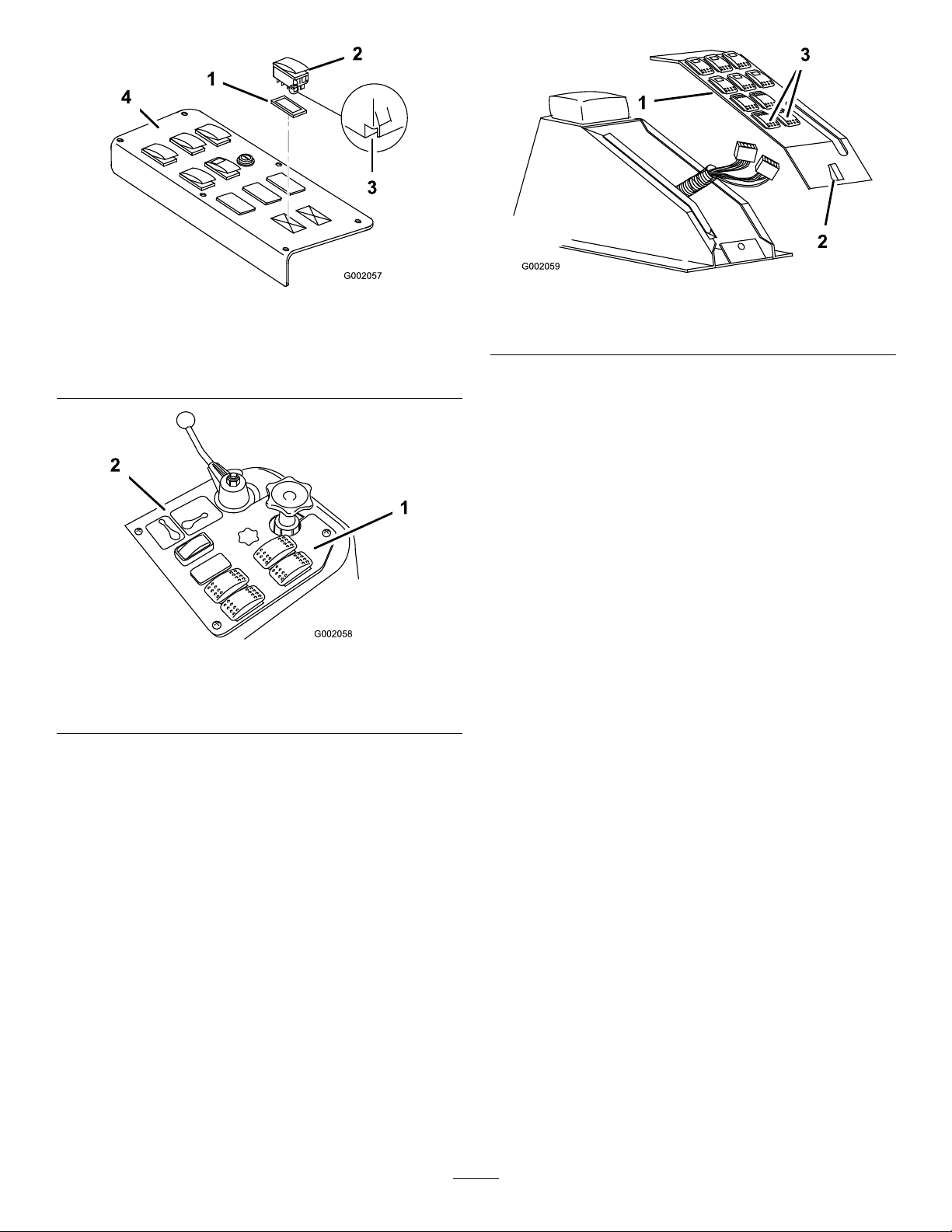

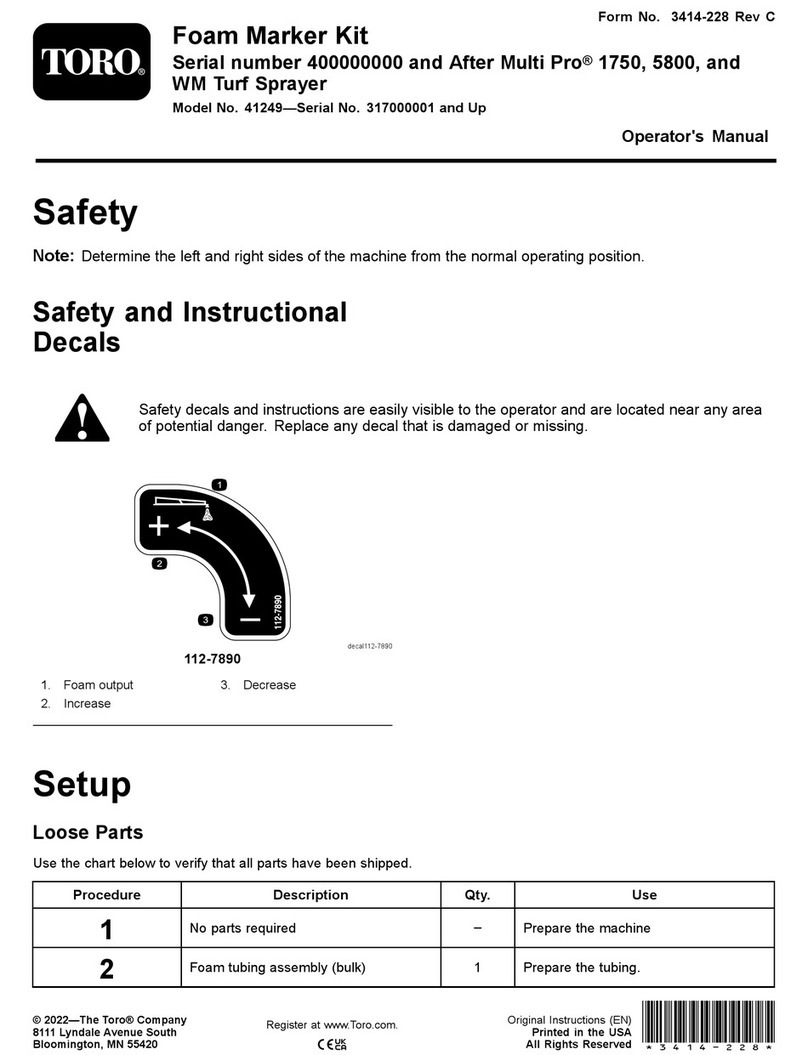

Toro 41249 User manual

Toro

Toro Pro Control XP User manual

Toro

Toro GeoLink 41624 User manual

Toro

Toro Multi-Pro 5800 User manual

Toro

Toro Multi Pro 1750 User manual

Toro

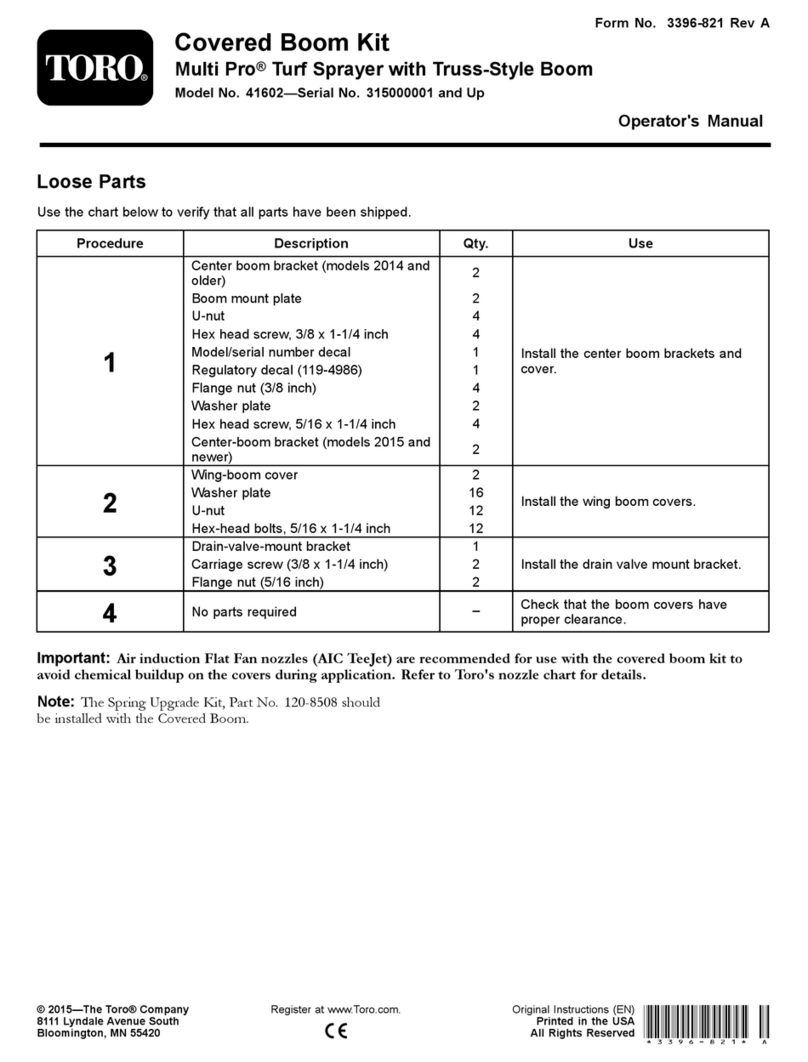

Toro Multi Pro 41602 User manual

Toro

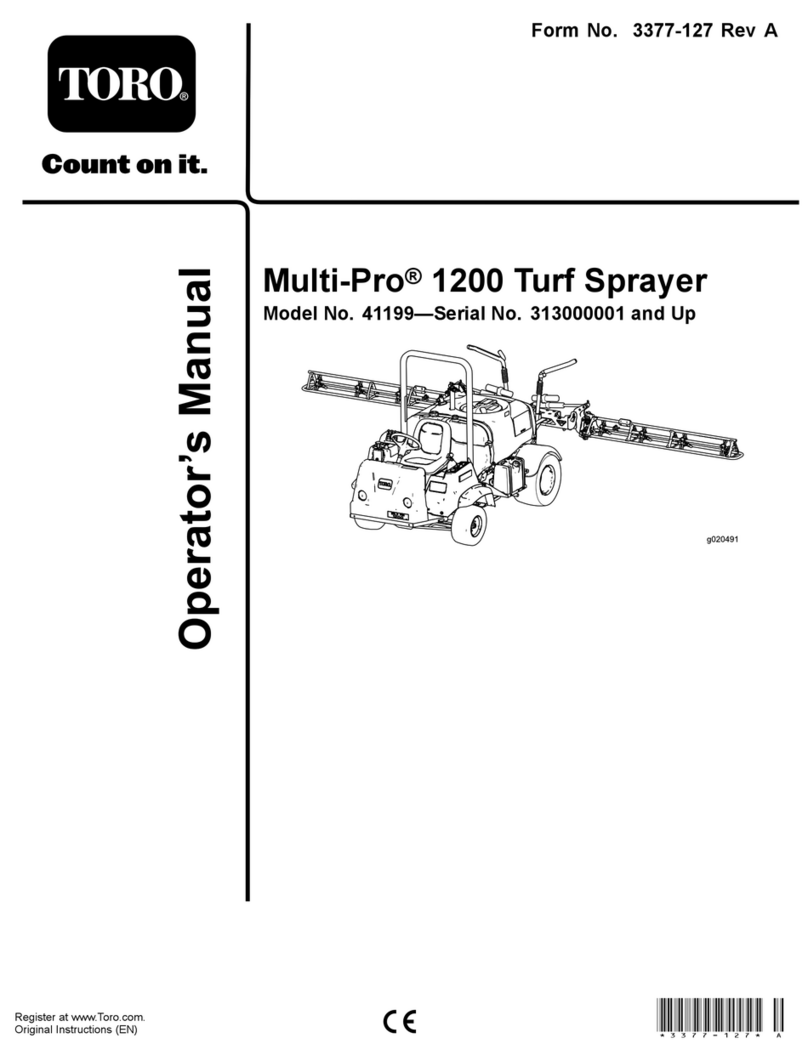

Toro 41199 User manual

Toro

Toro Multi Pro 5800 User manual

Toro

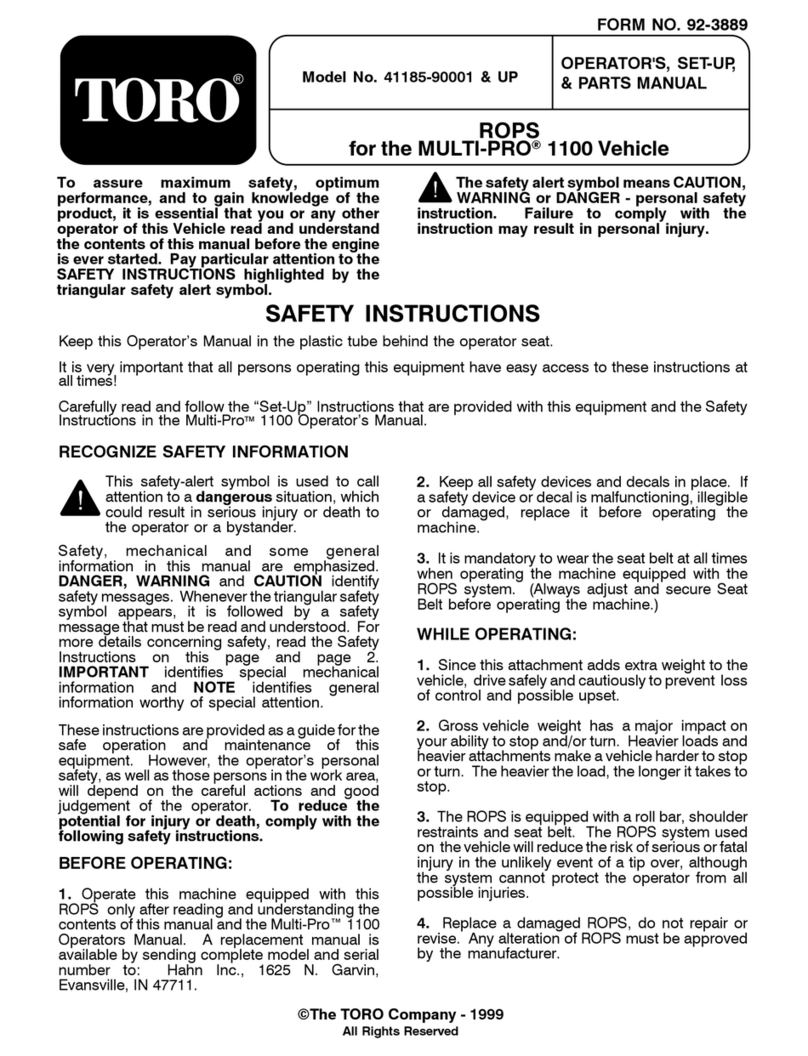

Toro MULTI-PRO 1100 User manual

Toro

Toro 136-0457 User manual

Toro

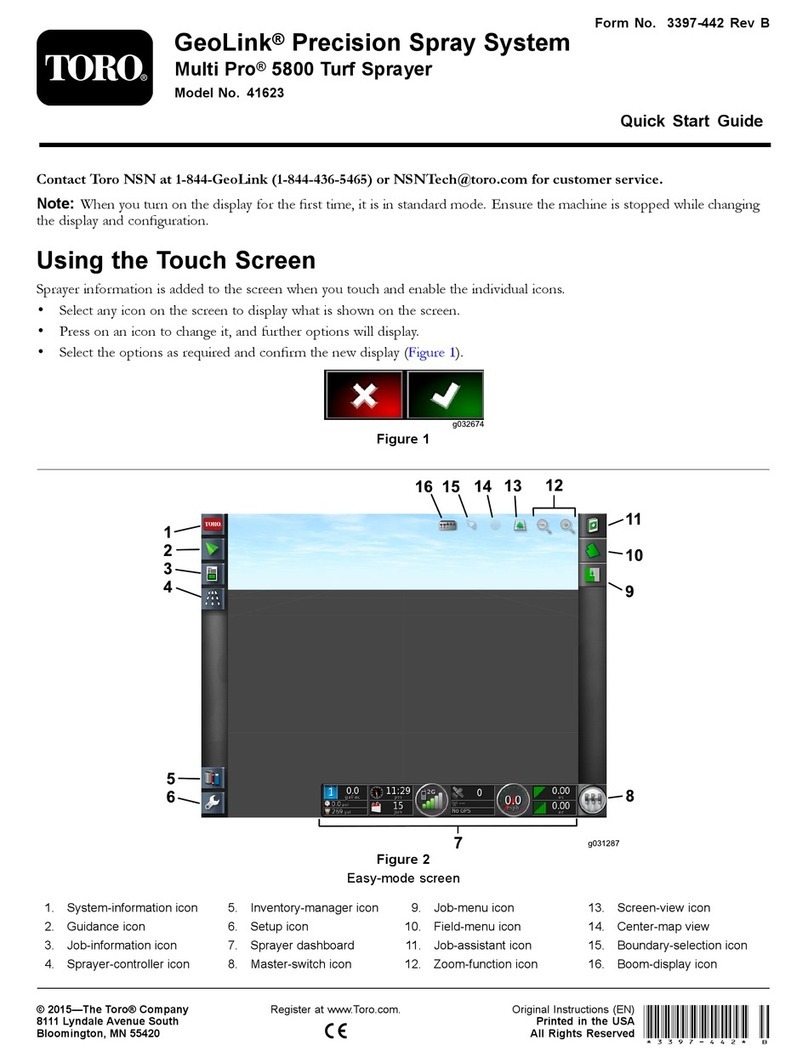

Toro GeoLink 41623 User manual

Toro

Toro 41188 User manual

Toro

Toro 41621 User manual

Toro

Toro 34215 User manual

Toro

Toro Multi-Pro 1250 User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual