demi 10368-144CK User manual

/Kits/10368-144CK_RevG.doc 1 Rev. G 5/9/2023

DEM Part Number 10368-144CK and 10368-144LPCK

10 GHz. Transverter, Low power Transverter, Kit and Complete Kit

Specifications

Frequency:

10368.000 = 144.000 standard

Noise Figure and Gain

< 1.2 dB NF, > 25 dBG

LP: < 3.5 dB NF, >17 dBG

Power Out

> 2.9 Watts.

LP: >10 mw

DC Power

11-16 VDC @ 3 A

LP: < 750 mA

IF Power Input (144 MHz)

1 mW min. - 10Watt max. Adjustable

Options:

Switchable IF frequency control

Preliminary:

This kit and requires knowledge of assembling and testing microwave frequency circuits.

This document refers to some pictures for ease of assembly. A full color PDF picture addendum

document is found on line at: http://01895fa.netsolhost.com/PDF/Manuals/10368-

144CK_RevG_Pics.pdf. This on-line addendum contains extra pictures and details that may help

answer some assembly issues. Within the text of this document, after a description of a procedure,

there may be a number in brackets e.g. [53]. This will refer to a picture on the addendum file on

line.

The 10368-144CK and 10368 -144LPCK is a complete kit version of the 10368-144 High

Power transverter and the 10368-144LP Low Power transverter [1]. In our Complete Kit version,

you receive all three circuit board kits, the 10368K (transverter PCB kit) [2]; the TC [3] and the

DIGILO Synthesizer [4] with a prepped extruded aluminum enclosure, mounting plate and all

necessary hardware and connectors to get you on the air [5]. When completed, you will only need

to supply a TR switch, (SMA relay) [6] Antenna, and a 2-meter transceiver. Originally, the 10368K

PC board kit was designed by W1GHZ and Down East Microwave Inc. but has seen many design

revisions since the original was published by W1GHZ in the 1999 Microwave Update proceedings.

DEMI has refined the design and produced a basic PCB Kit (low power) and two Complete Kits, a

low power and a 3 watt version with all of the interfacing required. This latest Revision includes the

latest LNA designed by W5LUA as the RX input stage in the high power version transverter only.

In this kit, the DEM TC is the interface circuit board that allows the use of up to a 10 watt

144 MHz transceiver. It contains TX and RX level adjustments. It provides all of the DC and RF

switching functions for the transverter actuated by it’s keying circuit that is either PTT-L (to ground)

or PTT-H (+ voltage) on transmit. It also supplies all internal biasing of the transverter and external

switching functions for TR switches, PAs and LNAs. Along with a +9 Volt 1.5 amp regulator to

supply regulated DC power to the transverter and the supporting circuit for the DIGILO that

indicates the external / internal 10 MHz source activation.

The DIGILO synthesizer (the base Local Oscillator) provides a nominal +0 dBm output at

3408.000 MHz for 144 MHz IF operation. The transverter PCB accepts the LO input and multiplies

it to 10224.000 MHz. A test port for tune-up and testing the LO before the signal is injected into

the mixers is available on the transverter board. After mixing, the 10368 MHz signals are tested

through two separate SMA connectors, TX and RX. The TX and RX connectors are spaced

correctly to allow the direct connection of common SMA relay to complete the system and allow the

use of a common antenna connection.

/Kits/10368-144CK_RevG.doc 2 Rev. G 5/9/2023

Kit Building Success Requirements:

This assembly manual assumes that the complete kit version (10368-144CK or 10368-

144LPCK) is being assembled but is also used for the 10368K, the PC board kit version. Use what

is required from this document for the different assembly types. All kits include the PCB, all of its

components, pipe caps, connectors, required hardware, and a CNC machined circuit board

mounting plate [7]. This plate is the key to the success and reliability of the transverter. The plate

is used as a fixture to attach the pipe cap filters to the circuit board. It aligns the pipe caps in the

correct position and then prevents scorching of the PCB while sweating the pipe caps to the PCB.

After assembly of the pipe caps, the mounting plate provides support to the circuit board to prevent

cracking of components, and damaging ground vias. After assembly, the plate provides easy

attachment of standard SMA connectors used for tune-up and final use. There are 2 main

requirements for the completion of this kit. You will need to “Sweat” the pipe caps in place on the

circuit board. This requires a propane torch or a very hot, Hot Air gun! A standard soldering iron

will not work! Second, you will need a way to detect RF power at 3 cm (10 GHz) frequencies to

aid in tune-up. This can be done with a detector diode, a microwave milli-watt power meter or a

spectrum analyzer. The filters need to be tuned after assembly! There are seven of them in

the low power version and nine in the 3 Watt unit. Both transverters will not work without correct

alignment of the filters!

Options:

There are no assembly options for the 10368 transverters detailed in this manual. You are

limited by the transverter’s PCB and supplied components of what version you can assemble. The

manual will describe one way of assembly that will produce a state of the art 10368 MHz

transverter of power level choice. If you wish to experiment with different gain stages and add-on

filters and amplifiers, do so with caution. Modifications should not be attempted without test

equipment that will provide accurate power levels and a spectrum analysis. DEMI will be more

than happy to consult you with any of your modifications, but will only assume full responsibility for

this design if you use the supplied components and assembly procedure. If you decide to stray

from the original design, or assemble the 10368 PCB with your own components, you will assume

the responsibility of the results. We will answer any questions you may have but a repair and/or

alignment by DEMI will only occur if the transverter kit is in stock form! (or at least close!) If

you have any questions about this policy please consult us first before proceeding with your own

design or modification.

Pre-Assembly:

Basic tools that are required besides hand tools such as a #1 Philips head screw driver,

cutting pliers, tweezers, and a minimum of a 25 watt solder iron with a fine wire solder are a

suitable heating device to "Sweat" the pipe cap filters to the transverter's circuit board and a hot

plate to warm the pallet assembly. The aluminum pallet provides excellent structural support of the

PCB but will "heat sink" just about any general consumer's solder iron not allowing clean smooth

solder joints on the surface mount components. Warming the pallet on a hot plate while soldering

the components is the best way.

The TC board which has most of the surface mount work completed requires stuffing the

board with the leaded components and general soldering. It should be assembled per its assembly

document. Some general assembly options may be implemented to it depending on your

requirements. The DEM TC has provisions for an extra RXIF gain stage but only should be utilized

if you require more than 30 dB of system RX gain. The TC allows 1 mW to 10W common or

separate IF input/output that requires the proper configuration during assembly. It’s your choice.

/Kits/10368-144CK_RevG.doc 3 Rev. G 5/9/2023

The regulated or unregulated voltage is switched to supply any additional stages such as a LNA or

power amplifier and the PTT circuit may be mirrored or inverted. The standard document of the TC

has many more details concerning its various options of operation. Please follow it for assembly

and for the completion of the complete kit version of the 10368-144 or 10368-144LP.

The DIGILO can be experimented with before the main transverter assembly is started but

is not required since they are pretested assemblies. You may set the frequency required for your

transverter's conversion scheme and according to the DigiLO's document. It can then be tested for

frequency, output power and spurious if desired with the correct voltage applied and coaxial

connection. Do not operate it without a 50 ohm load on its output. The complete manual is found

on line at our website here: http://01895fa.netsolhost.com/PDF/Manuals/digilor18_9_1.pdf

and includes extra pictorials to illustrate that may help in assembly. Please take time to review

When configuring your system, please note that DEMI can supply a few external options for

the" Low Power" version transverter. If you require a “State of the Art“ noise figure, a 3 cm PHEMT

preamp designed by DEMI and W5LUA can be purchased. It is part number L3-2LNAK (board kit)

or a complete kit version is L3-2LNACK. This is the same circuit design used in the High Power

version transverter. If you decide to increase the output power of your Low Power version

transverter, the 3-3PACK and 3-3PAP 3 watt amplifier is available if you don't have access to the

surplus market of TWTs and other solid-state amplifiers. DEMI also stocks a basic sequencer, and

other accessories that will enable you to complete your 10368 MHz high performance system.

Assembly:

1. Now is the time to get familiar with the kit and verify it is complete. This will also ensure that

you have the correct tools and supplies required to complete the project. It is also time to make

the last minute decision on building the kit or not. A full exchange towards an assembled version

will be provided if you do not go past this step. We want you to be on the band and operating not

struggling to assemble this kit because you were not aware of what it takes to assemble this

microwave transverter. ------ Last chance? OK!

Start by inventorying the parts list. Every part in this kit is important and should be

identified. There are extra chip components packed in the kit, so no need to count them. The

hardware should be sorted and identified. There are some extras there too. However, remember,

No substitutions! Review the schematic and the component placement diagram. Read all of the

assembly steps, 1 - 14, identifying every component used. Some instructions will specify the Low

power (LP), version or the standard High Power (HP) version transverter.

2. Now, let's assemble what we believe is “The most bang for a buck” 10 GHz kit on the

market! Start by examining the circuit board for irregularities. Do not remove the copper foil that is

attached to the backside of the board. This is to provide additional grounding for the 3 watt power

MMIC. During the drilling and plating process, plating or debris may fill the filter probe holes and

prevent the silver pins from being inserted. It is simple enough to use one of the silver pins (extras

provided) and push it through all of the filter probe holes and wiggle it around a bit to be sure it

clears 14 holes total for the LP and 18 for the HP board [8]. Use the component placement

document to identify the filter pin holes. Do not make the holes larger or drill out! Just be sure

the pin fits in all of the holes and they are clear. Also, look very closely for shorts from the ground

plane side and be sure to clear on the top side.

3. Install the PCB to the mounting plate [9]. Place the ground plane side on the pallet and line

up the holes. It only fits one way. Use the 4-40 x 3/16” screws but do not tighten the screws. The

clearance holes in the PCB are purposely made larger so the board can move around slightly on

the mounting plate to allow proper alignment of the SMA connectors and filters. Tighten a few

/Kits/10368-144CK_RevG.doc 4 Rev. G 5/9/2023

random circuit board screws around the pallet and check for alignment with a visual inspection of

the clearance holes in the pallet. They are for the wire and Coax connections on the circuit board.

Adjust the board to center the via pads in the pallet holes then tighten all screws. Now install the

two 4-40 x 9/16” screws, the 1/8” spacers and two 4-40 nuts in the clearance holes on the back

corners of the circuit board[10]. The head of the screw belongs on the pallet. The screw head is

on the pallet, the spacer is between the PCB and the nut. Tighten them and recheck all circuit

board screws.

Then cut the excess material off the board edges with a sharp knife [11]. If you find yourself

cutting too much of the metal of the board, the board is not centered on the pallet. You may use

the pallet as a guide. It is possible that some excess solder from the foil to board attachment is in

the way. If so, remove with the knife or soldering iron tip. When complete, the board edge to pallet

edge will now act as the alignment if the circuit board is ever removed from the pallet. Then clean

up the connector panel edge. Be careful not to cut the copper foil in installed. Again, use the

pallet as a guide.

4. It is now time to prep the pipe caps. All off the pipe caps have been drilled, tapped and

surfaced. Check for remaining burs inside and outside of the caps [12] and then with an abrasive

cloth, (sandpaper, Scotch-Brite) buff-up the open end of the pipe cap, both inside and outside.

The shinier the better the solder will flow [13]. The pallet will hold them in position during

soldering.

5. If you do not wish to solder the pipe caps to the PCB, we can do it for you. Return the pallet

with the PCB mounted and aligned with the pipe caps without the pipe cap hardware. Include

your payment or payment information of $45 USD, which will also cover standard return shipping.

Your pallet will be ready for assembly when returned!

To solder the pipe caps requires a propane gas torch or a very hot "Hot Air System". A

standard solder iron will not do the job! Electronic grade flux (liquid or paste) and electronic grade

solder is also required. Do not use a Acid base flux or solder! Even if you clean the acid flux off

the outside when finished, you cannot clean the inside of the cap and the acid will destroy the

board from the inside out.

6. Starting with any pipe cap, flux the area within the pallet [14] and flux the open end of the

cap and place it into a pallet hole [15]. We prefer to use "No Clean Flux" for the reason stated in

step #5. Do all of the pipe caps. Now heat any cap with the torch being careful not to allow the

flame to come in contact with any bare circuit board [16]. Remove the flame and flow the solder

into the corners of the pallet hole around the pipe cap joint. Re-heat if necessary. Repeat this

process on the rest of the pipe caps until finished. After a few are complete, the soldering becomes

faster because the pallet is now pre-heated.

Do not install the screws in the cap before soldering. The heated gasses inside of the cap

need to escape. Do not apply pressure to the pipe cap while cooling. It will push the PCB away

from the pallet. Then the excess solder will flow between the board and the pallet causing a

“Bump” in the board. Although this is not a disaster, it will cause a problem when soldering the

components to the circuit board. Allow it to cool completely before touching.

7. At the factory, we use “No-Clean” solder exclusively. It disappears with heat with minimal

smoke. We never use any cleaning solution on our assembled products. The concern we have for

kit builders is that after assembly of the pipe caps, excess flux and residue has migrated between

the PCB and the pallet. Depending on the corrosiveness of the flux, this may be a potential

problem. If so we suggest removing the PCB mounting screws and cleaning everything completely

/Kits/10368-144CK_RevG.doc 5 Rev. G 5/9/2023

if you feel that there could be a flux invasion problem but understand it is not an easy task. Only

do this if you absolutely need to. Be careful not to flex the circuit board excessively. Also, do not

trim any excess solder or re-flow a filter when it is not mounted to the pallet. It will cause a

misalignment and the PCB will not fit flush to the pallet when re-assembled. If you find a bad joint,

re-assemble the PCB to the pallet being sure that the PCB is mounted flat to the pallet before

tightening the screws and re-flow the pipe cap. Then, remove the PCB assembly, inspect and

clean.

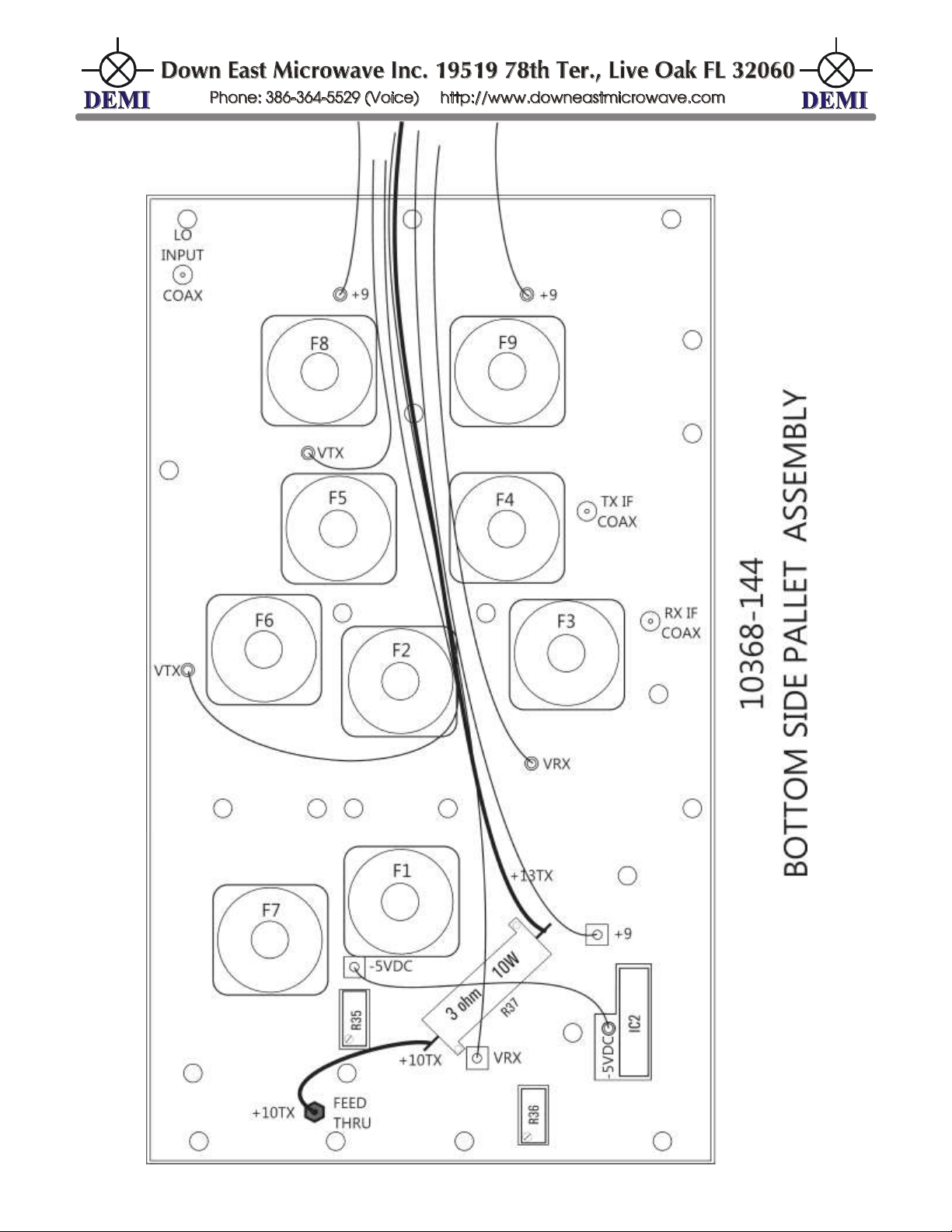

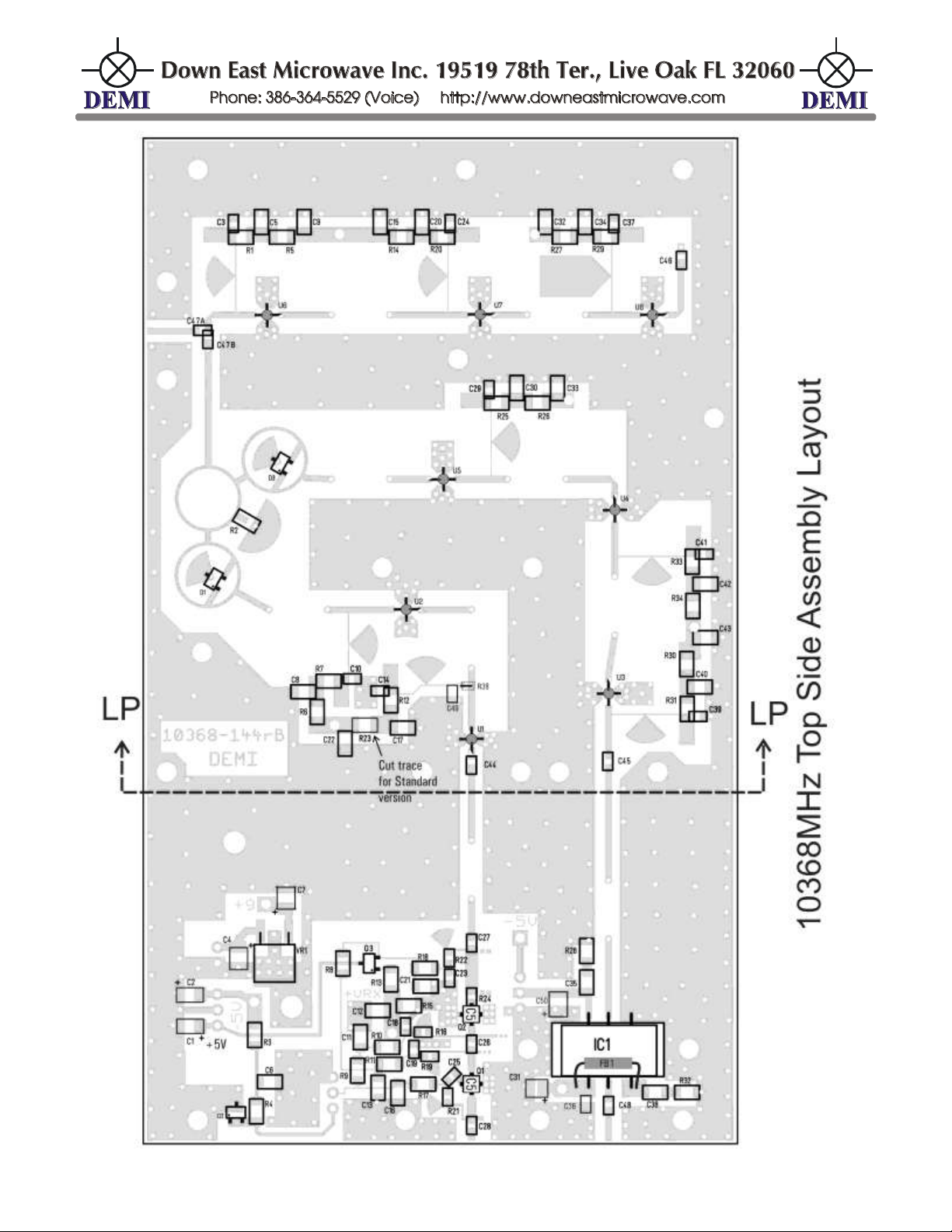

8. Referring to the component placement diagram, it depicts the standard version transverter

but the LP version is indicated on the placement. Use the component list to determine what

components are installed. For the actual assembly, start by installing the MMIC’s U1 - U8. You

will need a large solder iron to flow the solder on the ground leads. We use 40-watt irons with 700-

degree tips in the Factory. We also preheat the pallet to about 120 degrees F on a hot plate. You

may do the same with whatever means of pre-heating you have including the torch you used for

the pipe caps. If you can still handle the pallet after pre-heating, it could be hotter! The aluminum

pallet will hold the heat for a while but re-heating may be required, depending on your soldering

speed, to keep the solder flowing smooth. Be sure of the MMIC’s alignment. Consult the

component placement diagram with every installation. The MMIC’s are very difficult to remove if

installed incorrectly.

INPUT

FET N6 MMIC and MGA86576

U1 is different in the low power transverter. It will solder flat to the circuit in the Low power

(MGA86576) and the N6 in that position will be raised up in the HP unit. Be sure to install the

MMIC’s as flat and square to the pin alignment as possible [17]. U2-U8 may be installed the same

way centered above the holes in the board but he bodies of U2- U8 will fit squarely in the PCB

holes if flipped upside down. If you decide to do that, bend all four legs down before soldering. Be

sure to flow the solder on all of the ground leads up to the body of the MMICs. These leads need

to be a short as possible to ground. If you can see the ground lead, it’s not soldered correctly.

Use minimum amounts of solder on the input and output leads but solder them as close to the

body as possible.

After all of the 8 MMICs have been installed, use an Ohmmeter to check for shorts on the

input and output leads to ground. If you did a good job in prepping the PCB in step #2, you should

have no problems. If you do find a short, try wicking some of the solder from the shorted lead with

Solder Wick. If still shorted, try lifting the problem lead and re-wicking. Be careful not to break

the lead. A close inspection should reveal a short. Use the knife and re-move, then re solder and

re-test again.

If you have the HP version transverter, Install Q1, Q2 and VR1 paying attention to the

component document alignment. Use the same technique for Q1 and Q2 as U8 [18]. It is

important to get a good source lead to ground connection on the FET's and a ground connection

/Kits/10368-144CK_RevG.doc 6 Rev. G 5/9/2023

on the VR1 regulator so it may require some pallet heating. You could remove the mounting

screw near VR1 before soldering the ground tab.

8. Using the pictorial below as a guide for proper SMD soldering install all of the other surface

mount components in any order with the noted exceptions: [19]

Circuit board

Correct

Incorrect

Solder Fillet

Incorrect Component

Placement

Proper SMD Assembly.

Do not install R8, R18, D1 and D3

R38 is installed in the LP version and shorted in the standard version.

R23 is installed in the standard version only after cutting the trace for installation.

Verify the correct value for R12 depending on version of transverter.

It is easier to install all of the resistors in the low power section of the transverter first.

Install C47 in the "A" position.

You will need to remove the 4-40 screws to install C16 and VR1. Replace when soldered.

R3, R8 and R9 are just jumpers

If you have the HP version transverter, do not install IC1 and the jumper.

9. Install all of the filter probes (the silver pins) after cutting to the correct size [20].The length

indicated is the total length including the head. Cut 10 pins at 1/4” or 0.210 - 0.230”. Insert them

into F1- F3, F8 and F9, then solder [21] [22]. Cut the rest of the needed filter pins for F4 - F7

(there are extras!) to a total length of 3/16” or approximately 0.180” - 0.190” (F1 and F7 not

required for LP version). Insert pins in the remaining filter holes. Solder them in place using a

minimum amount of solder. You do not want the solder to “Icicle down” and extend the pin length

and thickness or short to the ground plane. Also, be sure that the pinhead is flat to the surface to

ensure that the probe is straight.

Install the 4-40 feed thru connector as shown on the bottom side pallet drawing (the filter

side off the pallet). The pin will come through the board near C31. Solder it to the pad and with an

ohm meter, verify it is not shorted to ground. Now, take the time to clean any excess flux off the

complete assembly with any cleaner you desire. It doesn't need to be "Spotless" just not coated

with excess flux.

10. With the clean pallet assembly, clear the foil in the mounting holes of IC1. Then, review the

FMM 5061LV pictorial for pin numbers and apply a very thin light of thermal compound to IC1

being careful not to smear any on the circuit board. Install with 3-48 screws. Be sure of the

alignment, tighten the screws and then solder the leads. The Copper foil will stretch enough and

conform to the installation. Now Fabricate the Ferrite bead jumper and install between both Drain

pins (4 and 6) keeping it as short as possible as shown on the component placement document

[23].

/Kits/10368-144CK_RevG.doc 7 Rev. G 5/9/2023

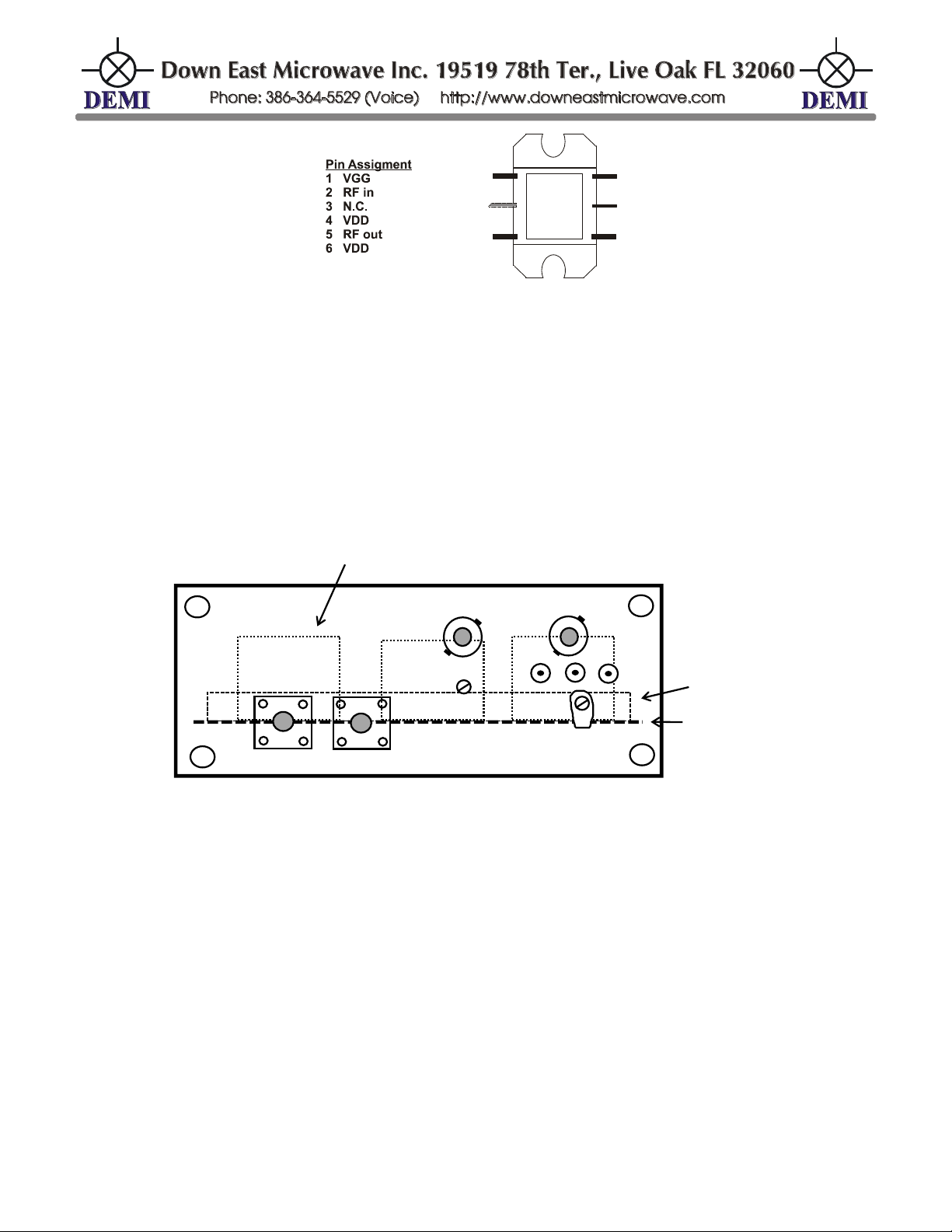

FMM 5061LV

11. Install the rear panel to the PCB by first prepping two SMA connectors so that the Teflon will

not interfere with the circuit board [24]. Insert the SMA connectors through the connector panel

and using the panel as a guide, trim the excess Teflon with a sharp knife flush with the panel.

Make a clean, square cut. Now trim the center pins to 1/16" extending from the Teflon. Attach the

SMA connectors to the panel with four of the #3-48 x 3/16” screws. Then attach the panel to the

pallet with five 3-48 x 3/8” screws. Look for any gaps or bulges between the pallet and the panel.

If so, remove panel and re-trim excess circuit board without cutting into the foil. Tighten the 5

screws evenly and be sure the cut center pins do not interfere with the circuit board. If needed,

dis-assemble and re-trim the Teflon on the connectors or the PCB and try again to obtain a perfect

fit. A complete flush connection of the pallet to the panel is the most important part of this kit.

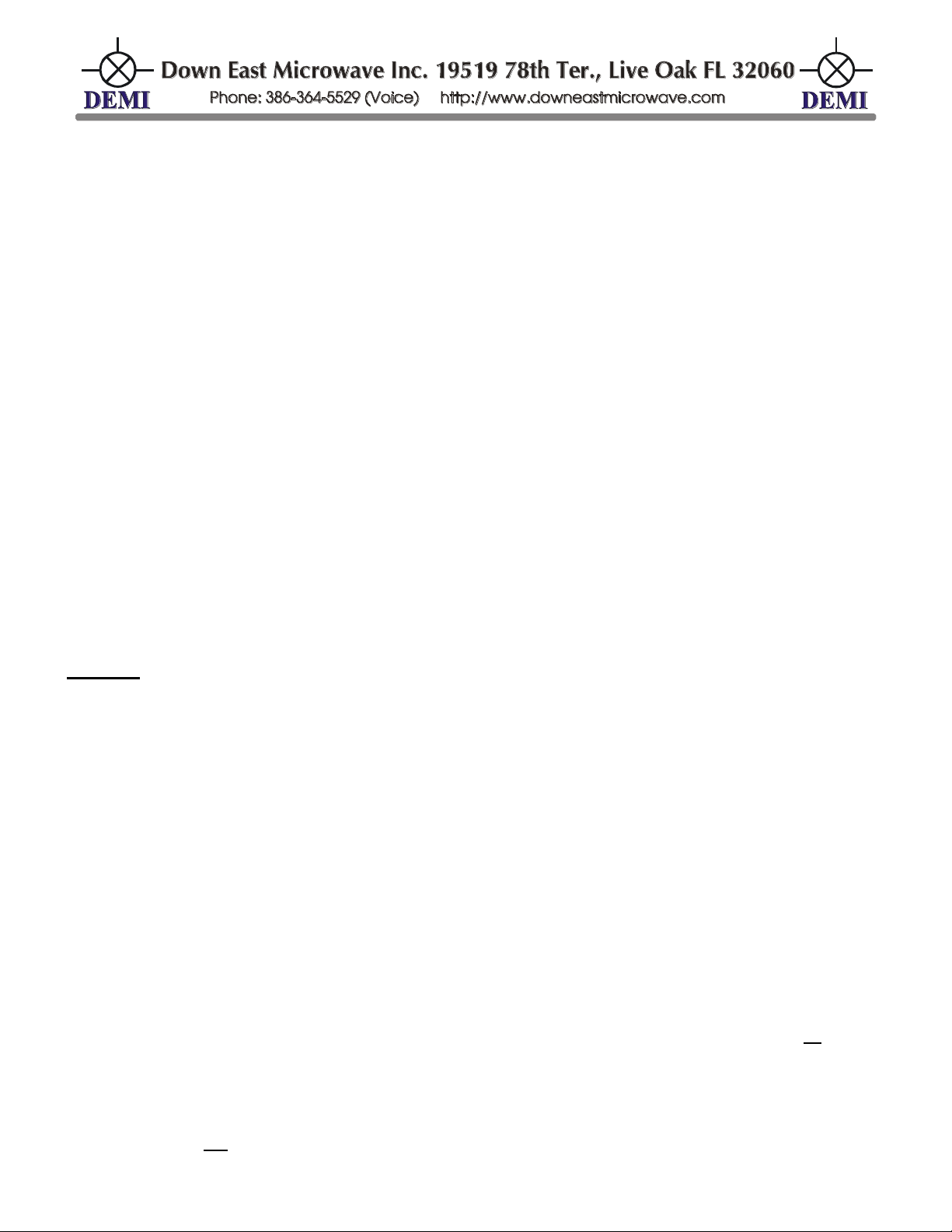

TX

RX

PTT +13.8VDC AUX

GND

IF

PCB

Aluminum

Plate

Pipe Caps

10 MHz

Insert all of the 8-32 feed thru caps with a #8 ground lug on each by bending them in a right

angle for latter attachment. Then install two BNC connectors. Be sure to install the lock washer/

ground lug on the BNC connectors with the lugs positioned towards the RF connectors [25]. Then

Solder the SMA center pins.

12. All of the coax connections need to be made next. Start by cutting two 7” pieces (RXIF and

TXIF) and one 4" piece (LOIN). The best way of making this coax assembly will result in

something that looks like the next diagram. Start by removing approximately ¾” of the outside

jacket. Tin solder the entire exposed shield. Place the Rivet in position and solder in place. Try to

keep the coax in the center of the rivet while the solder cools. Now with a #22 wire stripper,

remove the shield that is below the rivet. The wire striper should score the shield if it is tinned and

you will be able to “Snap” off the shield. Then with a #28 wire striper, remove the insulation off the

center conductor. Leave a small amount of insulation as shown in the diagram below. Tightly wrap

the exposed center conductor and lightly tin the end. Be sure not to let the solder expand the

diameter of the center conductor and /or wick off [26].

3

2

16

5

4

/Kits/10368-144CK_RevG.doc 8 Rev. G 5/9/2023

1/4”

3/16”

1/16”

Insulation

Conductor

Prepped Coax details.

Once the coax is prepped, do a trial fit. Insert the center conductor through the hole in the

pallet and then through the hole in the PCB (either RXIF, TXIF or LOIN). The reason in making the

center conductor so long is so you have a guide for insertion. Fit the brass rivet into the pallet

hole. If it fits to tight (solder build up), scrape or file down the rivet’s high spot and try again.

Notice the tapped hole located close to the rim of the rivet. Insert a 4-40 x 3/16” screw and tighten.

The head of the screw should compress down on the rivet rim and hold it in place. Do not over

tighten [27].Then do the same for the other coaxes. After all coax is installed, cut off the excess

center conductor and solder it to the circuit. When complete install D1 and D2 on the RXIF and

TXIF. Be very careful with the lead alignment of the diodes.

13. On the HP version only as shown on the bottom side pallet drawing, install R35, R36 and

IC2 through the pallet into the board. Cut off excess leads. Then install the 3.3 ohm 10 Watt

resistor with two 3-48 x 3/16" screws. Now using the supplied #26 Teflon wire, cut, strip and tin the

ends of a 2.5" wires and connect it to both -5VDC points. All wires come in through the back of the

pallet through the 1/8” holes [28]. They are soldered to the circuit board where indicated on the

bottom side assembly diagram. They are the via holes with an "X". They can solder to any part of

the circuit board attached to the via.

The rest of the #26 wiring is labeled VRX, VTX, and +9 on both transverters.

Pass one end of the wire through the pallet in all of the indicated holes shown on the bottom

assembly document and solder. Cut, strip, and tin as before then insert one end of it through the

hole and solder to the board. After routing the wires as shown, cut them so they extend a

minimum of 3.5" past the end of the pallet.

Connect the +10TX connection from the feed thru to the10 watt resistor with a 1” #22 wire

and connect a 9” #22 wire to the other end of the 3.3 ohm resistor.

Wire the three rear panel feed through as follows. The center is connected to a 11" of #22,

the other two are connected to a 11" of #26. All wires should be routed as shown on the bottom

assembly [41].

14. Install all of the filter hardware now. The screw heights may be pre-set for tuning.

Examine the next pictorial. Set the 4-40 brass screws and stainless locking nuts to approximately

all the same height of 0.150”. The lock nuts should be "snug" but not locked.

Nut

0.150”

/Kits/10368-144CK_RevG.doc 9 Rev. G 5/9/2023

Re-inspect all solder connections. Touch up what is questionable. Now review the test

procedure before proceeding. Using the assembled unit for a “Dry Run” may clarify some of the

testing requirements that may have been in question when first read.

DC Testing:

1. With an Ohmmeter, check all resistors and wire connections for shorts or opens. Then

check the RXIF and TXIF cables for shorts. If all testing of the MMIC leads was a “Go” in

assembly step #8 the transverter is ready for DC and RF testing.

2. The MMICs, U1 –U8, if working correctly, will draw current. This current drain will cause a

voltage drop across the resistor network. With a +9 VDC supply, the total resistance in the bias

networks of all but the U8 MMIC (U1 in the low power Transverter) should be approximately 80 -

90 Ohms. With + 9VDC applied to the network the voltage drop should be approximately 5.3 volts.

This means U1 –U8 should have +3.5 - 4.0 VDC on the output lead and +2.5 VDC on the input

lead. The input lead voltage may vary up or down as much as 0.5 VDC or more. Apply +9VDC to

each stage in order and check the voltages on the leads of the MMICs. If large discrepancies

occur, check the bias resistors for correct value. If a MMIC does not draw current, it is dead (very

Rare!) or the resistor network is open. If it drops voltage down to less than 1 VDC, its leads are

shorted. Seek the problem out and repair. Now test in the following order: The LO stage, U6-U8,

the TX stage, U3–U5, and the RX stage to U1-U2 only. Do not apply voltage to the +VRX wire

attached to LNA section in the HP version

+9VDC

+2.5VDC

36

51

+3.5VDC

Input

DC Input

U4

Resistor Network with Voltage Points

U1 in the Low power transverter is different. The output lead should measure between +6

and +7 VDC. If it is over 7.2 VDC, remove bias immediately and check the bias resistors for

proper value. If the values are correct, R19 may need to be adjusted up in value. If it is less than

+5.5 VDC, the MMIC may be oscillating which could be caused by the filter not being tuned yet.

Place your finger on the input of the MMIC to verify if the voltage changes in an upward direction.

If the voltage measured is less than +2VDC on the output lead, it may have a solder short under

either lead. Check and repair.

3. If you have the HP version transverter, the LNA/PA section should be tested by verifying the

operation of IC2 first. Apply 9 VDC to the +9 and check for –5V (and it may be as low as –.7 VDC)

/Kits/10368-144CK_RevG.doc 10 Rev. G 5/9/2023

where indicated on the PCB. If OK, verify that the -5 V is on Pin 1 of IC1. If not adjust R35 to

obtain a maximum negative voltage. If -5 V cannot be obtained, examine the circuit for defects.

Check the LNA section by verifying a negative voltage on both Q1 and Q2 gates or inputs.

The voltage is limited by D2 and R4 and will not exceed -0.8VDC (or less than negative 1 volt) but

could be Zero volts. Adjust R36 so the both voltages are around -0.350 VDC. If it will not adjust,

seek the issue. It is either a short or open somewhere.

If OK, check the +5 V where indicated. It may be as high as +7.5 VDC. If OK install R8 and

R18 then connect +9VDC to the VRX wire that connects to R13 and R15. Measure the voltage at

the flag by R22 and adjust R36 to obtain between +2.0 and +2.2 VDC. Then verify approximately

the same on the flag by R19. Remove the VRX voltage when complete. The DC testing is

complete.

LO Testing:

The testing procedure will describe operation for 10368 MHz RF frequency with a 144 MHz

IF. It assumes the DIGILO will be used as the 3408 MHz oscillator. If a 145 MHz IF is desired,

select the correct DIGILO frequency. See its Chart. If anything other than a 2M IF frequency

range is desired, you may select any DIGILO frequency that will be multiplied by 3 to produce the

correct final LO frequency including an IF in the 70 cm band. Slight adjustment other than what is

detailed in this procedure may be required and RF test equipment such as a Spectrum Analyzer

may be required.

1. Connect a trimmed SMA connector to the 10224 TEST POIT. Be sure that it is a flush

mount [29].Verify that

C47 is in the test position

(C47A on the component

diagram). Install the

DIGILO as shown right by

installing two 4-40 x 1/4"

HEX standoffs and lock

washers in the pallet with

two 4-40 x 3/16" screws

for the board. Connect

the LO input to the RF

OUT of the DIGILO by

soldering the coax. Make

this coax connection as

short as possible [40].

The 10 MHz input is not

required for testing. Set

the correct jumpers (if not

done previously) by

shoring all 6 positions

except #4 for 10368 = 144

MHz. If you desire anything different, make the selections on the DIGILO now. Make the DC

connection to the DIGILO's +V with a 3" length of #26 wire [39].

2. Position the transverter so the LO Multiplier filter adjustment screws are easily accessible.

Connect a RF power-detecting device to the 10224 test point. It is preferred that this is a milliwatt

/Kits/10368-144CK_RevG.doc 11 Rev. G 5/9/2023

power meter but a diode detector may be used for peaking. Apply +9VDC to the DIGILO and the

two +9 wires on the transverter. If the screws are pre-adjusted correctly, some output power

should be detected. Adjust F9 first for maximum power. Use very slight adjustments (1/2 turn

maximum each way to find peak) while maintaining lock nut pressure to ensure the contact of the

screw to the pipe cap. Be careful of downward pressure with adjustment tools on the filter when

adjusting. Lock the nut into position when peak is found. Then adjust F8 for maximum power

using the same technique. Lock the nut when peaked. If using a detector diode you can only peak

it and on to step 2 of the RF test procedure. If using a milliWatt power meter, power should be

between + 3 and +10 dBm. Greater than is OK, less than is not. If test is OK, remove +9VDC and

go on to step 2. If the LO power is low, check the following in this order: Low DC Voltage, High

DC voltage (over +10VDC). Incorrect bias on U6 - U8, or C47 not in the test position "A". Low

level from DIGILO (coax short on either board). Also, revaluate the coax length between the

DIGILO and transverter. It is sensitive to length. As short as possible is required. If the LO power

is still below +3dBm, a snow flaking may be required in the coax input to the transverter. A simple

probing or touching will verify this. Add if required. Then consider the filters being tuned

incorrectly (wrong starting point). Incorrect probe length, probe missing, or probe shorted to

ground. Suspect defective MMIC last if voltages are correct. Always question your construction.

When test is complete, remove the SMA test connector and reposition C47 to the "B" position.

3. Further testing of

the transverter can be

completed to verify tune

up and operation. Both

the TXIF and the RX IF

cable can be temporally

connected to the BNC [43]

connectors and the tune

up procedure that is

described in the Testing:

may be followed except

the individual TXON and

RXON voltages are

applied as in the

DC Testing:section. For

the purest, this is the best

method to tune up the RX

section. This will allow the

ability to do any trimming

or snow flaking to optimize

the performance nut---

very little can be accomplished if the transverter is assembled correctly. But if you have a Noise

figure meter, the Gain and Noise Figure can be optimized. Connect the IF coax as show and test

and tune as specified in the test section. Then when complete, follow the next steps to complete

the assembly. If you decide to test and align the TX side, do not drive the TX mixer with more than

+10dBm.

/Kits/10368-144CK_RevG.doc 12 Rev. G 5/9/2023

4. For the complete testing of the transverter unit, the complete enclosure assembly should be

finished. Start by examining the two enclosure halves. Notice that in one half, there are four taped

holes. This is the transverter side. Install the microwave absorber in the bottom of the enclosure

as shown away from the end with the tapped holes [30].

Then unbolt the DIGILO and install the pallet assembly in the housing using the two 4-40 x 9/16”

screws and 1/8 spacers that are on the pallet. Remove the nuts and insert the pallet in the

enclosure being sure not to pinch any wires. Seat the pallet in place and start the screws. Now

start the two flat head panel screws (black in color). When everything lines up and you are sure

about the spacers being in place, tighten all four screws.

5. Install two 4-40 standoffs with split lock washers in the two remaining holes that are in the

transverter side of the enclosure. Make them snug but do not over tighten. The threads are

Aluminum. Now refer to the Installation section of the TC assembly document (pre assembled

earlier) and proceed with the installation. Be sure of your IF configuration and continue to the next

step below after completion [31].

6. If you are assembling the standard unit, the wire from the 3 ohm, 10-watt resistor should be

connected to the +13TX via on the TC board. Re-check all connections and verify that there are

no lose wires, if so identify and connect if needed. Check all mounting hardware and connectors

to be sure nothing is lose.

Testing:

1. Start by getting the same equipment ready that was used for the LO testing. Preset the IF

pots on the TC board by turning the TXIF counter clockwise and the RXIF clockwise. Connect

13.8VDC to the transverter and switch the power on. The green LED should light. If you connect

an external 10 MHz source, the Loc light should change to Green. If not it should be Red [32].

Check voltages on the TC board. There should be +9VDC on the VRX and the +9 points. There

should also be +13.8VDC where indicated on the TC. Now toggle the TC board by activating the

PTT circuit. The relay will click and the TX LED will light. VRX drops to zero volts and the VTX will

now be +9VDC and the +13TX will measure the transverter's input voltage.

2. Even though the fixed attenuator has been predetermined, for initial testing, the TXIF pot

should be adjusted to the maximum attenuation position (full counter clockwise). If you don’t,

excessive drive may produce spurious signals and make aligning the TX chain more difficult.

Connect a RF power detector to the TXRF port of the transverter after verifying the correct

attenuation for the version of transverter you have. Position the transverter so the filter

adjustments are accessible [33]. Key the PTT circuit and apply the 144 MHz TX signal to the

transverter. If the adjustment screws of the filters were pre-set, monitor the power detector and

adjust F4, F5, F6 and F7 if you have the standard version in order. Start by turning them IN, 1/8 of

a turn at a time maintaining lock nut pressure. Power should be detected eventually. When power

is detected, remove the 144 MHz IF signal to verify that the detected signal vanishes. You may

also want to adjust the TXIF pot on the TC board to verify operation. If the power doesn’t change,

you have tuned the filters to the LO frequency. If so, continue adjusting the screws 1/8 turn at a

time in the same IN direction until the next power peak is detected. Verify that it is the desired

signal by removing the 144 MHz IF signal. When you are sure you have the desired signal, peak

/Kits/10368-144CK_RevG.doc 13 Rev. G 5/9/2023

all filters one at a time starting with F5. After each filter is peaked, remove the 144 MHz IF signal

and re-verify that the detected signal vanishes. Final output power should be the limit of the

version transverter you have at the desired IF drive level. Toggle the PTT with the IF drive off and

check for oscillations. If none are detected, proceed to the RX testing.

If output power is less than specified, check the following in this order: Low or High voltage.

Verify that the DIGILO is connected to +9VDC. Check C47 to verify it is installed in the "B" position

(need to remove pallet to check this). IF drive power level either too low or too high or wrong

configuration on the TC. Is the IF coax cable short or open? Is C45 (LP) or C48 (standard)

damaged from the connector installation? Filter Probes (length, shorted, missing?). D3 blown

from excessive drive. Suspect defective MMIC last if their voltage is correct. Always Question

Construction! AND the 3 watt MMIC is never bad unless installed backwards!!

3. To test the 10368 RX, a signal source at the desired receive frequency is required. This

may be a signal generator, a harmonic from a transmitted signal source, or a on the air signal

transmitted from a 10.368 GHz transmitter. The IF port should be connected to a 144 MHz

receiver with an “S” meter, though a low level power meter, spectrum analyzer, noise figure meter

or service monitor may be used. The transmitted signal from the transverter should not be used

because of the use of the same IF frequency. It would be very difficult to determine what was the

desired signal versus the radiated 144 MHz signal being detected in the IF receiver, no matter

what level it was. At the factory, a 10368 MHz signal generator set for -30 dBm for the LP and

–50dBm for the standard version and is injected directly into the RXRF port of the transverter then

adjusted for maximum gain into a 144 MHz receiver. Then we test and optimize it with a noise

figure meter [34].

Your actual testing and alignment starts with generating a 10368 MHz signal and detecting

it on a 144 MHz receiver through the RXIF connector on the transverter. Be sure that the 10368

RX port is terminated with a 50 ohm device while adjusting the filters. If connecting a signal

generator directly to the RX port, do not exceed -30 dBm. A signal source higher than that will

compress all of the gain stages, possibly generate harmonics, and make alignment difficult. With

the DC power applied to the transverter, adjust F2 and F3 filters (and F1 if you have the standard

transverter) by turning the screws IN to maximize the IF level signal strength. Adjust 1/8 of a turn

at a time while maintaining lock nut pressure. Keep adjusting until peaked. When complete, lock

the nuts. The LNA bias adjustment should not be adjusted unless you are testing the transverter

with a noise figure meter and then in conjunction with additional filter tuning.

If RX gain is less than expected, check the following in this order: Low or High voltage.

Verify if the RXIF gain control is at minimum or the RXIF gain stage on the TC board, if installed, is

working correctly. Verify the input signal level. If it is too high, it could cause harmonics in the

Q1/Q2 stage allowing the misalignment of the filters. Is Q1/Q2 oscillating? Is the IF coax cable

short or open? Is C44 (LP) or C28 (standard) damaged from the connector installation? Filter

Probes (length, shorted, missing?) Is D1 blown from excessive drive during the TX test while not

keying the PTT line? This would also cause damage to the RXIF Gain stage but suspect defective

MMIC on the Transverter board last if the voltages are correct. Always Question Construction!

Completion:

When you become satisfied with the RF operation of the 10368-144, you need to install the

External 10 MHz. coax to the DIGILO and wire it's LOC detect line to the "IN" via on the TC board

located next to the ON/OFF switch. Then test by connecting a external 10 MHz source and verify

that the LOC led changes from RED to GREEN.

Now, you may want to bundle all of the control wires and coaxes together to make a neat

appearance (see next picture) [35]. It is not necessary, but it will contain the wires to make closing

/Kits/10368-144CK_RevG.doc 14 Rev. G 5/9/2023

the enclosure easier. Do a final check on the TX and RX IF levels and if you are satisfied, close

the enclosure and bolt it with the four remaining flat-head screws. Be sure not to pinch any wires

or coax and re-test the transverter after closing.

This completes the assembly and testing of the 10368-144. You now have enough

knowledge of how this assembly works that implementing it into a complete working system should

not be a technical problem. Remember that the unit is designed to operate from a +13.8VDC

source but any voltage between 11 and 16.5 VDC will work making it perfect for portable

operation. You may wish to test this before going portable.

The LP versions receive conversion gain is limited and may require some additional

amplification. To overcome your IF switching scheme insertion loss when interfacing the

transverter with a 144 MHz transceiver, you may want to install the MMIC in the TC board. If the

transverter is to be used in a high performance terrestrial or EME set up, a Low Noise Amplifier

should be considered [36]. If so, additional filtering and isolation may be required and/ or the use

of the RX OPT may need to be omitted. If a higher power amplifier is added, consider a additional

filter and/or isolator [37]. Also consider some attenuation if using a high gain TWT amplifier for +5

dBm may be too much driving power.

The standard version only needs a SMA TR switch to make it a top-notch portable rig mated

to a modest size antenna that will produce Hill top DX! Both units can be interfaced with any 2M

transceiver in its standard form if it doesn't exceed 10 watts. Higher output power transceivers are

not recommended unless modified or adjusted to prevent damage. Addition of external power

amplifiers and LNA’s can be accomplished with the AUX output of the transverter or by

implementing a sequencing scheme. Remote location mounting is possible with this unit in its

stock form. It would just need to be installed in a weatherproof enclosure.

Conclusion:

We hope you had fun with this kit and that you enjoy many hours of operation with your

completed transverter. Please take time to read the papers published by W1GHZ (N1BWT) for

other operation tips and suggestions including antenna designs and a similar 5760 MHz

transverter design. Good luck with the DX and have fun!

NOTICE:

This equipment is to be used solely by licensed amateur radio operators within the

specifications and guidelines governed by their licensed agreements.

/Kits/10368-144CK_RevG.doc 15 Rev. G 5/9/2023

This product should not be thrown away. Please dispose any components or equipment

properly. By reusing, returning or using proper collection points which are designated for it.

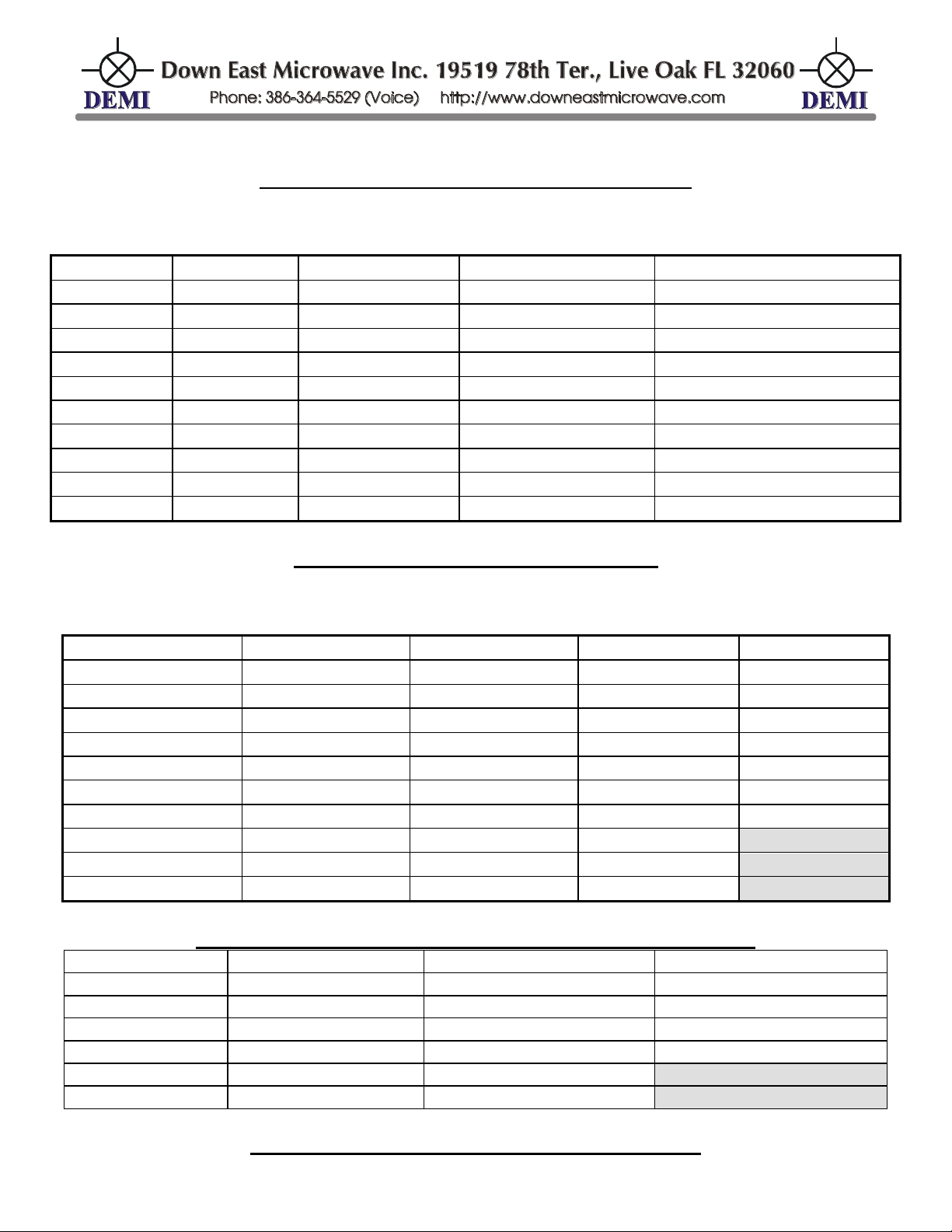

10368-144LP Transverter Board Parts List

All components are Surface Mount. All resistors are 1206 size unless indicated. All capacitors are

1206 size except for 1.0pF are 55mil ATC. All others are as indicted. Any substation of values or

types is at users own risk.

C3 1.0 pF

C29 1.0 pF

C44 1.0 pF

R12 51 or 100(LP)

R34 36

C5 0.1F

C30 0.1F

C45 1.0 pF

R14 36

R 35 100

C8 0.1F

C32 100 pF

C46 5 pF (0805)

R20 51

R38 short or 51(LP) (0805)

C9 1000 pF

C33 100 pF

C47 1.0 pF

R23 36Not in LP

U1 N6 or MGA86576 (LP)

C10 1.0 pF

C34 0.1F

D1 HSMS8202

R25 51

U2 N6

C14 1.0 pF

C37 1.0 pF

D3 HSMS8202

R26 36

U3 N6

C15 100 pF

C39 1.0 pF

R1 51

R27 75

U4 N6

C17 0.1F

C40 0.1F

R2 51 (0805)

R29 51

U5 N6

C20 0.1F

C41 1.0 pF

R5 36

R30 36

U6 N6

C22 100 pF

C42 0.1F

R6 36

R31 51

U7 N6

C24 1.0 pF

C43 100 pF

R7 51

R33 51

U8 N6

10368-144 3 watt version additions.

All chip resistors are 1206 size unless indicated. All 1.0pF capacitors are ATC 55mil. 4.7F is a

tantalum and the white band indicates positive polarity. Any substation of values or types is at

users own risk.

C1 4.7F

C21 100pF(0805)

C49 0.1F (0805)

R8 0

R22 51(0805)

C2 4.7F

C23 0.1F (0805)

C50 4.7F

R9 0

R24 15(0603)

C4 4.7F

C25 0.1F (0805)

D2 MMBD914

R10 470

R28 51(0805)

C6 0.1F(0805)

C26 1.0 pF

FB1 Ferrite Bead

R11 240

R32 51(0805)

C7 4.7F

C27 1.0 pF

IC1 FMM5061VF

R13 5.1K

R35 200Pot

C11 100pF(0805)

C28 1.0 pF

IC2 NMA0505S

R15 5.1K

R36 1KPot

C12 100pF(0805)

C31 4.7F

Q1 CE3512K2

R16 51(0805)

R37 3, 10 W

C13 100pF(0805)

C35 0.1F (0805)

Q2 CE3512K2

R17 470

VR1 78M05

C16 100pF(0805)

C36 1.0 pF

Q3 MMBT3904

R18 220

C18 0.1F (0805)

C38 0.1F (0805)

R3 0

R19 51(0805)

C19 0.1F (0805)

C48 1.0 pF

R4 5.1K

R21 51(0805)

10368-144LP board and enclosure hardware Parts List

7 1/2” Pipe Cap

8 4-40 locknuts

20 silver pins

1 machined 1/4” plate

22 4-40 x 3/16

5 3-48 x 3/8”

3’ RG-188 coax

3 SMA connector

6 3-48 x 3/16”

8 4-40 x 3/8” brass

3’ # 28 Teflon wire

2 BNC connector

2 4-40 x 3/8”

1 # 4 Ground Lug

1 SPDT switch

2 Machined End Plates

2 4-40 x 9/16

4- #4 split washers

3 8-32 feed thru

8 Flat head screws

3 4-40 x 1/4”

2- #4 x 1/8” spacer

4 1/8” x 3/16” rivets

1 Hole plug

2 4-40 nuts

41/4” threaded standoff

LNA and Power Amplifier Section Hardware

/Kits/10368-144CK_RevG.doc 16 Rev. G 5/9/2023

4- 3-48 x 3/16”

2- 4-40 lock nuts

4- silver pins

2- 4-40 x 3/8” Brass

2 - 1/2” Pipe caps

8- 4-40 x 3/16

24” #22 Teflon wire

1- 4-40 feed-thru

C45

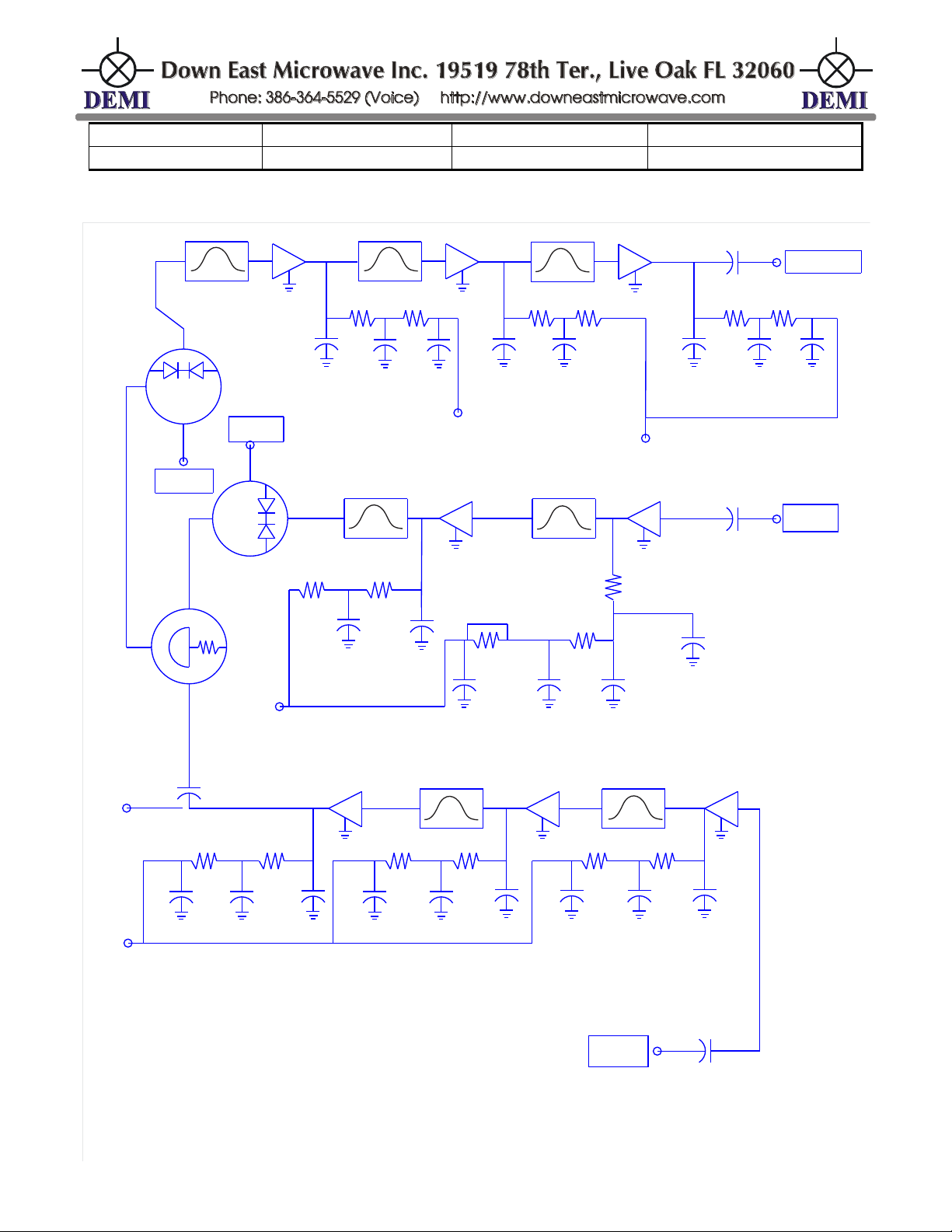

C39 C40 C43

R31 R30

U3

F6

U4

F5

U5

F4

C29 C30 C33

R25 R26

C41 C42

R33 R34

D3

D1

R2

F3

U2

F2

U1 C44

R38

(Add for Standard

Version)

R23

R7

R6

C8 C10

C22 C17 C14

C47A/B U6

F9

U7

F8

U8

C3

R1 R5 R14 R20 R27 R29

C5 C9 C15 C20 C24 C32 C34 C37

C46

LO IN

10224MHz TP

+9

VRX

RX IN

RX IF

TX IF

VTX

VTX

TX OUT

10368-144LPrC TRANSVERTER SCHEMATIC

(Short for Standard Version

51ohm (0805) for LP Version)

R12

C49

/Kits/10368-144CK_RevG.doc 17 Rev. G 5/9/2023

/Kits/10368-144CK_RevG.doc 18 Rev. G 5/9/2023

/Kits/10368-144CK_RevG.doc 19 Rev. G 5/9/2023

/Kits/10368-144CK_RevG.doc 20 Rev. G 5/9/2023

This manual suits for next models

1

Other demi Media Converter manuals

Popular Media Converter manuals by other brands

Crestron

Crestron DigitalMedia DM-NVX-350C quick start guide

Coltene

Coltene BioSonic S1 owner's guide

TR-Electronic

TR-Electronic Profibus 582 Series Assembly instructions

Baumer

Baumer HOG 9 Mounting and operating instructions

Altronix

Altronix NetWaySP8A installation guide

Sony

Sony BKSI-2020 installation manual