Demon Storm Series User manual

STORM 1

STORM 2

Storm 1 with Hose Reel

Storm 2 with Hose reel

Storm Wall Mounted 1

Storm Wall Mounted 4

Storm Twin Cabinet 1

Storm Twin Cabinet 4

Declaraon of Conformity

(E.H.S.R)

We, Demon Internaonal Limited of Abbots Close, Lee Mill Industrial Estate, Ivybridge,

Devon, PL21 9GA Declare this machine must be operated in accordance with the

operaon and safety instrucons as supplied with this machine. This machine is

manufactured in accordance with the following standards.

HSE PVB PM - BS415 Part 1 - BS5415 Secon 2.4 1986

This instrucon manual is relevant only to the following machine and will not be kept

updated unless specically requested by the customer. However any changes to the

operang procedure or changes which might aect the safety of this machine will be

noed to the registered owner of this machine only.

Machine Type

Serial Number

Voltage

Working Pressure

Date of Supply

Operaons Manual

Demon Storm Range

Storm 1

Pump ARXT 11.14 Motor MTR00100

Pump pressure 100 bar 1500psi Motor output P1 2.2KW

Flow rate 11 lpm 2.45gpm Motor input P2 3.0KW

Max by pass seng 120 bar 1750psi Max current 12.5 amps

H.P Nozzle 2504 Voltage 230V + or - 10V

Pump oil 10W40 Insulaon Class F

Unloader valve ARMM4B/C Duty cycle 100%

Noise Protecon IP54

Storm 2

Pump XT 11.14 Motor MTR00301

Pump pressure 100 bar 1200psi Motor output P1 2.2KW

Flow rate 11 lpm 2.45gpm Motor input P2 3.0KW

Max by pass seng 120 bar 1750psi Max current 24 amps

H.P Nozzle 2504 Voltage 110v + or - 5V

Pump oil 10W40 Insulaon Class F

Unloader valve ARMM4B/C Duty cycle 100%

Noise Protecon IP54

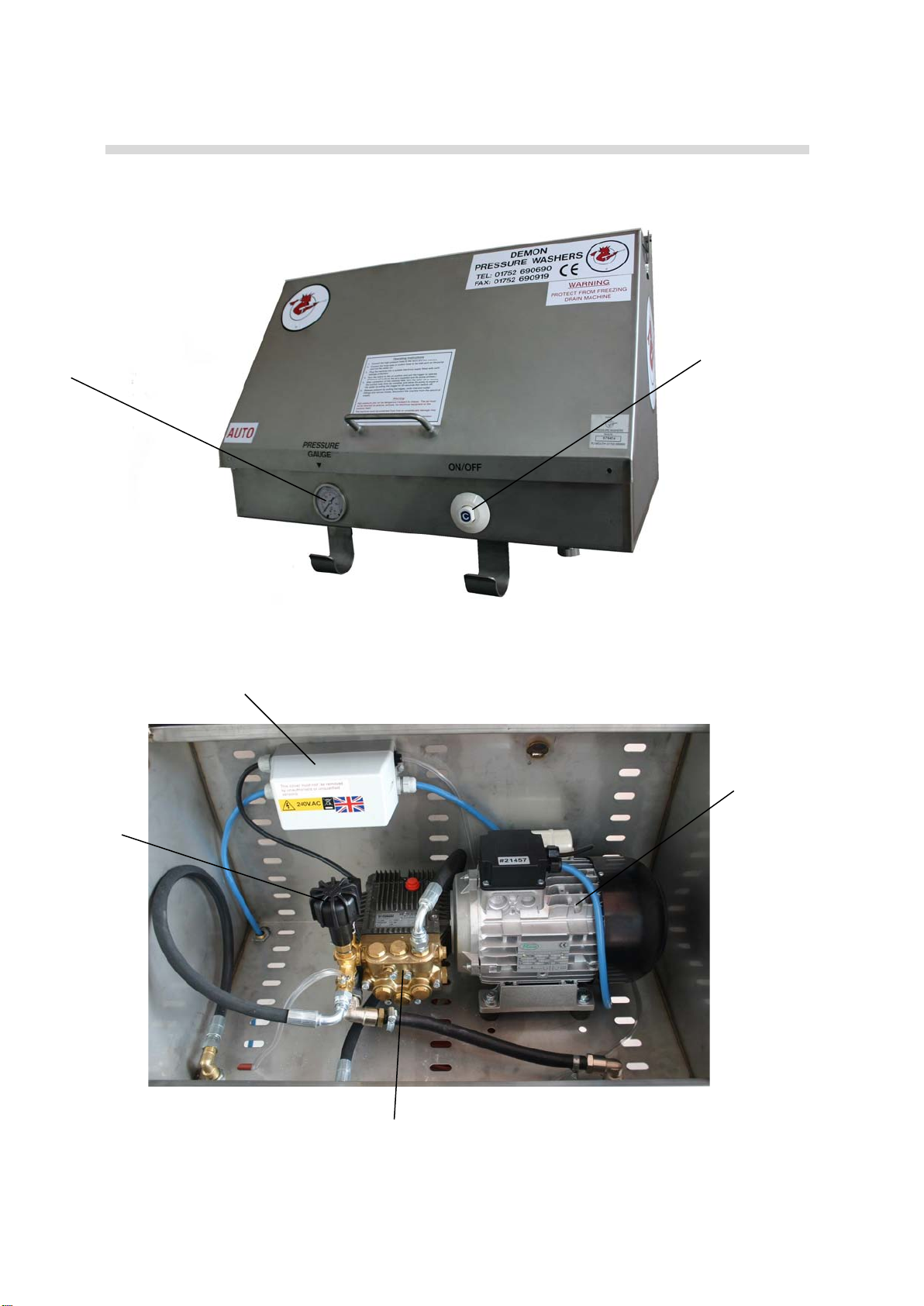

Storm Wall Mounted 1

Pump XT 11.14 Motor MTR00100

Pump pressure 100bar 1500psi Motor Output P1 2.2W

Flow rate 11 1pm 2.45gpm Motor Input P2 3.0KW

Max by pass seng 120 bar Max current 12.5amps

H.P. Nozzle 2504 Voltage 230V + or - 10V

Pump Oil 10W/40 Insulaon Class F

Unloader valve ARGM3 Duty Cycle 100%

Noise Protecon IP54

Storm Wall Mounted 4

Pump RK15.20 Motor MTR00220

Pump pressure 200bar 2900psi Motor Output P1 5.5W

Flow rate 15 lpm 3.3gpm Motor Input P2 6.6KW

Max by pass seng 210 bar Max current 12.6 amps phase

H.P. Nozzle 2504 Voltage 415V + or - 10V

Pump Oil 10W/40 Insulaon Class F

Old Unloader valve ARMM4B/TSS

New Unloader valve ARGM3 Duty Cycle 100%

Noise Protecon IP54

Technical Specicaons

Storm Twin Cabinet 1

Pump ARXT 11.14 Motor MTR00100

Pump pressure 100 bar 1500psi Motor output P1 2.2KW

Flow rate 11 lpm 2.45gpm Motor input P2 3.0KW

Max by pass seng 120 bar 1750psi Max current 12.5 amps

H.P Nozzle 2504 Voltage 230V + or - 10V

Pump oil 10W40 Insulaon Class F

Unloader valve ARGM3 Duty cycle 100%

Noise Protecon IP54

Storm Twin Cabinet 4

Pump RK15.20 Motor MTR00220

Pump pressure 200bar 2900psi Motor Output P1 5.5W

Flow rate 15 lpm 3.3gpm Motor Input P2 6.6KW

Max by pass seng 210 bar Max current 12.6 amps phase

H.P. Nozzle 2504 Voltage 415V + or - 10V

Pump Oil 10W/40 Insulaon Class F

New Unloader valve ARGM3 Duty Cycle 100%

Noise Protecon IP54

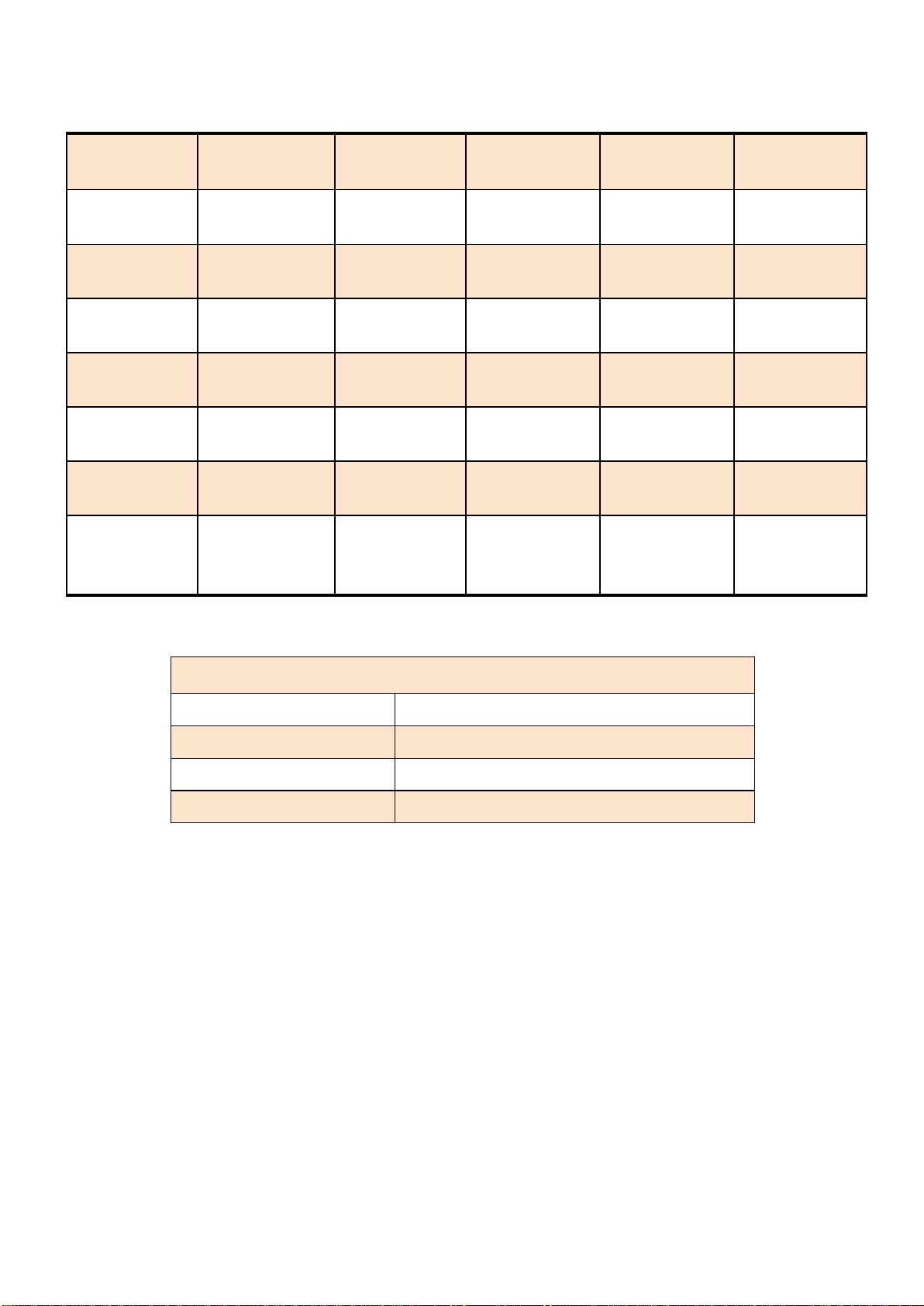

Valve Kit Piston Kit Oil Seal Kit Water Seal Kit MINIMATIC

REPAIR KIT

STORM 1

1864 2629 1872 1874 2812

STORM 2 1864 2629 1872 1874 2812

WM 1 1864 2629 1872 1857 2223

WM4 1828 2757 1856 1857 2223

FS 1 1864 2629 1872 1857 2223

FS 4 1828 2757 1856 1857 2223

Storm Twin

Cabinet

Washer

1864 2629 1872 1874 2223

Common Part Numbers

Chemical Filter MTM86010

Inlet QR Coupling MTM73001 (To Tap) 3/4 Female (Nito)

Inlet QR Coupling MTM73020 (To Tap) 3/4 Male (Nito)

Electrical Box on Storm DEM101111

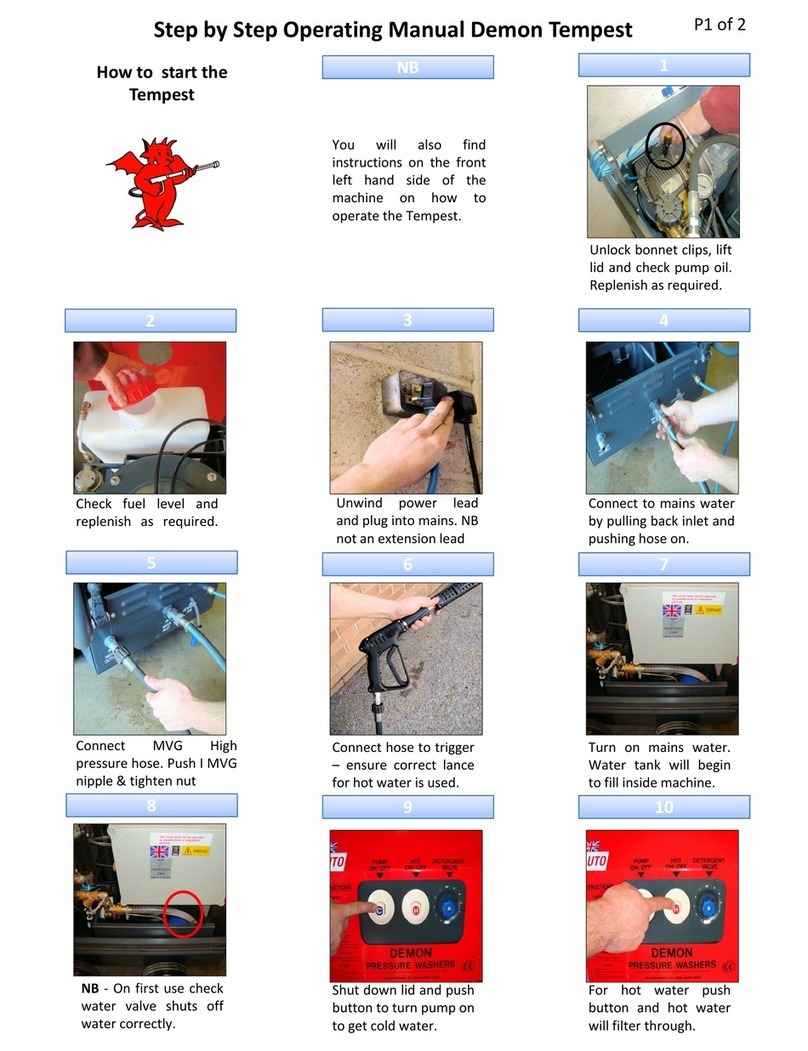

Preparaon

Water Supply:

a. Ensure there is an adequate water supply either from the mains or a reservoir.

NOTE: ONLY CLEAN FILTERED WATER SHOULD BE USED.

Hoses:

a. Aach the high pressure hose to the pump connecon.

b. Aach the spray gun to opposite end of the high pressure hose.

c. Ensure that the regulator nozzle on the end of the spray lance is CLOSED.

OPERATION

(Check that electric motor is switched ‘OFF’)

a. Plug into a suitable electrical source. (Not an extension lead)

b. Turn on water supply.

c. Ensure that the trigger is ‘OPEN’ to vent air from the pump.

d.Switch ‘ON’ electric motor.

e. Open regulator nozzle slightly and direct lance on surface to be cleaned. Press

operang trigger.

f. Adjust pressure regulator as required to obtain working pressure.

g. NOTE: The high pressure water will cause the gun to ‘kick’. Make sure you have a

rm grip of the gun and lance.

h. On compleon of the operaon switch ‘OFF’ electric motor and unplug from power

supply.

i. Turn ‘OFF’ water supply.

j. Release residual pressure in gun and lance by operang trigger.

OPERATING HINTS

a. During very cold weather it is most important to protect the machine against freezing. DO

NOT operate machine should it become frozen. Move it to a warm area and allow to thaw

naturally.

b. Check all hoses and couplings for leaks, ghten where necessary.

WHEN USING CLEANING AGENTS

a. Set machine up for water only.

b. Connect detergent hose to machine and place lter end into detergent reservoir. Unscrew the

adjustable nozzle on the end of the lance to reduce the pressure to 500psi. The chemical will

now be automacally injected into the water.

c. On compleon of work, ush through hose and gun with clean water to remove any residual

detergent.

SERVICING

The Storm range require lile maintenance apart from checking the oil level at least every week and

changing the oil should it turn white or it is six mouths old. If the oil turns white it is due only to water

entering the pump via the dipsck, which has a breather hole drilled through. The design of the pump

does not allow water from the pump to gain access to the gearbox drive.

Should the performance be reduced to a level where the jet is ineecve contact the service depart-

ment to ascertain the correct remedial repair work.

If using sea water ush aer use with fresh water and spray any 3 way valves with silicone spray to

lubricate valve.

WARNING

Leaving the pressure washer on by-pass for prolonged periods without operang the lance will cause

the water in the pump to heat up. This heat build up may damage the seals and valves in the pump.

OPERATING INSTRUCTIONS

SAFETY

i. A Residual Current Device (R.C.D.) or Earth Leakage Trip must be used with this machine.

ii. Water at high pressure is dangerous and can cause serious injury. This machine is to be used

with great cauon.

a. NEVER point the high pressure spray jet at any person, animal, glass or any other material which

may shaer.

b. PREVENT any over-spray from injuring other people or damaging property.

c. DO NOT even try to use a pressure washer on machinery or electrical equipment that is

connected in any way to the mains supply. (all switches in the o posion, pull out all plugs and if

possible remove fuses). Cover or seal electric motors and ngs to prevent entry of water.

d. ALWAYS when using machine:-

- wear safety goggles and helmet or helmet with a visor.

- wear waterproof clothing and gloves.

- take parcular care with detergents and chemicals.

e. NEVER aempt to disconnect any hose with pressure in it or allow the hose to be aened or

f. DO NOT use a high pressure hose from a ladder. Use a plaorm tower or proper scaolding.

g. CHECK that your supply voltage agrees with that shown on the machine.

h. Demon do not recommend the use of an extension lead using an extension lead will result in

switch failure or motor damage. Demon strongly recommend the use of extension hoses as

opposed to extension leads. Warranty claims for damaged switches and motors used on extension

leads will not be allowed. Ask the service department if in doubt.

I. DO ALL you can to keep plugs and sockets in a dry place or covered to prevent entry of water.

j. Where a cable is found to be damaged, the power must be switched o and the plug removed

before aempng to remove the equipment.

FAULT CAUSE REMEDY

Machine stops suddenly

Or will not start. Blown fuse.

Check mains power supply, re-

place fuse. Wait unl unit cools

down before reseng switch.

Sudden pressure loss. Water supply failed. Check water supply.

Low pressure

HP nozzle worn or

unloader set

Incorrectly.

Replace HP nozzle. Set unloader

to correct seng.

Low pressure with noise and

vibraon.

Valves worn or

blocked. Piston seals

worn.

Pump sucking air.

Clean/replace as required.

Replace.

Check water supply pipe and un-

ions.

Pump will not by-pass. Non return valve

dirty or jammed. Clean or replace.

Water drips from pump box. Pump seals worn. Replace.

Oil drips from pump boom. Oil seal worn. Replace.

Oil is milky in colour.

Water ingress

through oil lter

plug.

Rinse pump out and replace oil.

IF IN DOUBT ASK—OUR ADVICE IS FREE AND CAN SAVE YOU MONEY

Fault Finder

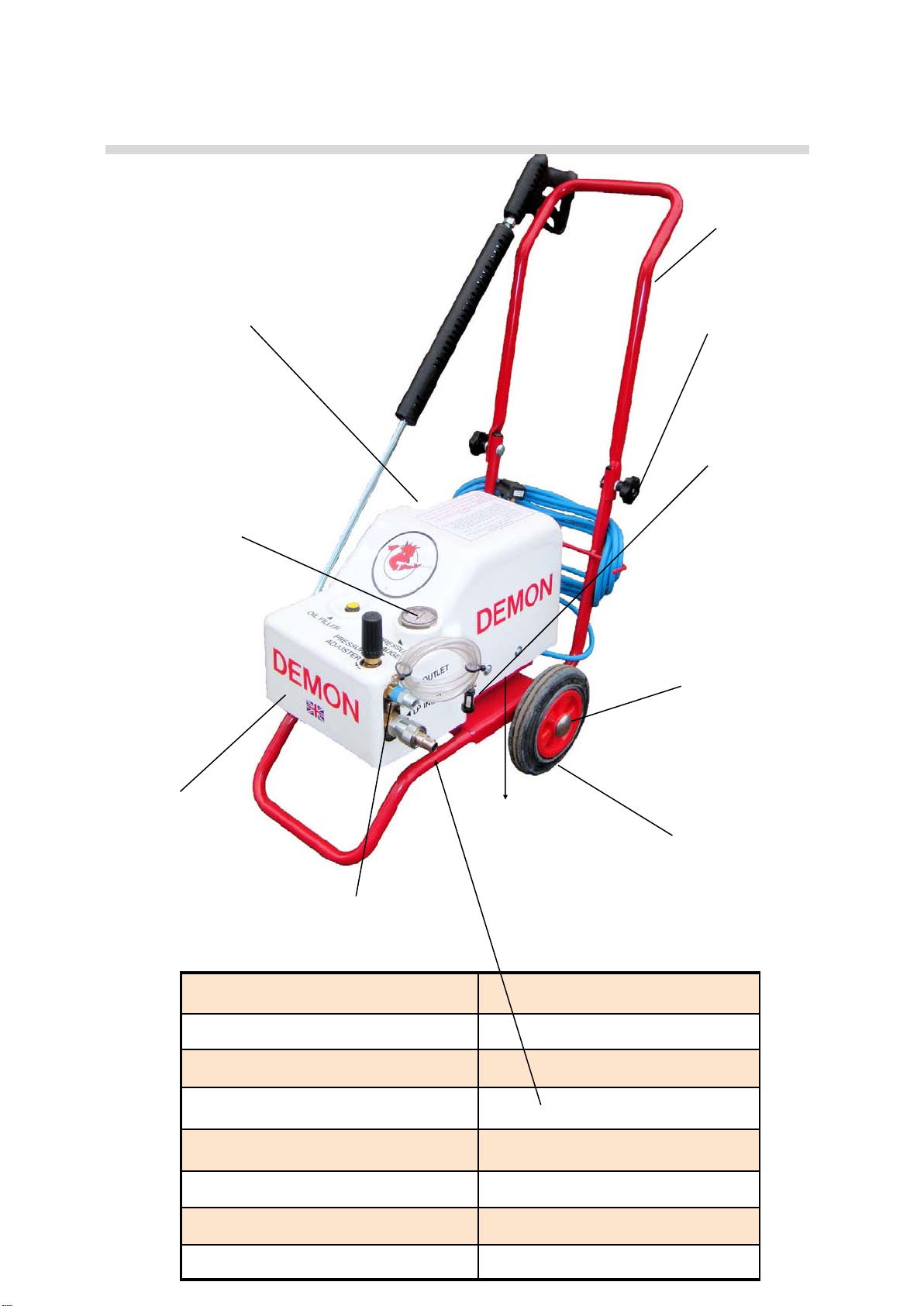

Storm Cold Water Range General Arrangement

Wheel Cap

Wheel25

13.5amp switch DEM10176

Switch cover & seal DEM10174

Protecon Cover DEM10173

Storm switch Bracket DEM101741

Wheel

WHEEL200

On Storm hose reel

machines WHEEL300

Pressure Gauge DEM20621

Cover

DEM20181

Handle Frame

DEM10226

Detergent Pipe DEM10115

Plug 13amp DEM10180

Contactor 30amp 110V DEM10111

Mini Contactor 16amp 240V DEM10125

L/P Inlet MTM73001 Female Stepped Nipple

L/P Inlet MTM73020 Male Nito

Capacitor 65mf DEM10139

Easy Start to water Inlet Pipe DEM10321

Chemical Filter

MTM86010

Outlet

MTM70013 Female 3/8

MTM70012 male 3/8

Knob Kit

DEM102255

Rubber Mounts

Blead o Part 1 MTM00100

Blead o Part 2 MTM00101

Easy Start Valve

MTM39001

Storm Easy Start to Water Inlet Pipe

DEM10321

1/8 Hose Barb x 5/16 (9mm)

DEM20401

Storm 1 Easy Start Valve

Pressure Gauge

DEM20620

Cold Water Buon

H6442B

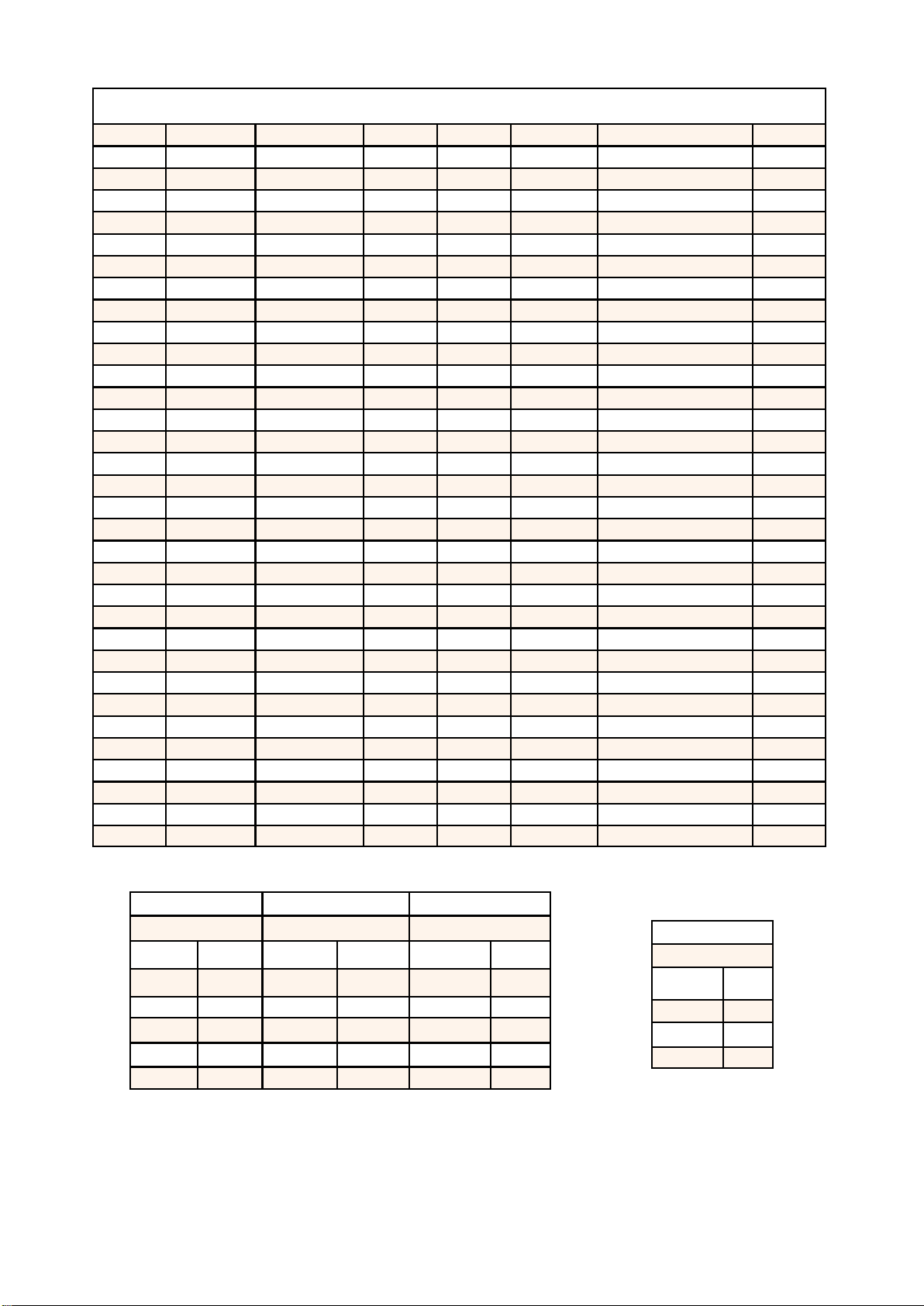

Electrics Box DEM101111

Electric Motor

MTR00100 (WM1)

MTR00200 (WM4)

Unloader Valve

ARGM3

Pump

ARXT11-14 (WM1)

ARXR15-20H (WM4)

Storm Wall Mounted General Arrangement

Demon Storm Twin Cabinet Washer

Demon Storm Twin Cabinet Washer

H Float

Low water sensor

TSS Unloader

Valve Supply

Motor

Supply

240V Mini

Contactor

Mains Supply

Hi Float Low

Water Sensor

13 Amp MCB

LED’S

ON/OFF

SWITCH

LED To indicate pow-

er in the machine

N.B. If there is no water in the machine a light will sll indicate

power but will not be operaonal. CHECK WATER

Rotary Switch

Warranty

This warranty covers the cost of all replacement parts and labour charges

incurred. It does not cover the cost of transport or carriage. It is the owners

responsibility to return the machine to a service depot or pay the travelling

expenses of a service engineer to aend. Demon Internaonal’s decision in

warranty maers is nal and binding.

Demon Internaonal Ltd undertake to repair or replace, any component which may fail due to a

manufacturing fault within a period of 12 months from the date of purchase, provided that any fault

or damage was not sustained by;

A. Lack of regular and proper maintenance, user negligence, misuse, or damage caused by ice and

frost.

B. The eects of contaminated fuel or water, the use of non-approved chemicals or an insucient

or unsuitable electrical supply.

C. The eects of un-authorised modicaon and use.

D. Compression damage to high pressure hose.(HOSES WARRANTED FOR 1 MONTH ONLY)

Parts which may or may not wear out during the rst year and which are considered

service items which will need replacing from me to me: High pressure nozzle, lance, trigger, hoses,

fuel nozzle, fuel lter, piston seals, valves, unloader seats and seals, water lter, non-return valve,

chemical barbs, chemical pipes and pump oil seals.

It is the owners responsibility to ensure the Pressure Washer is kept in a safe and suitable environ-

ment and any faults reported by operaves to be reced at the earliest possible date.

It is the operators responsibility to check the Pressure Washer for any faults and report them imme-

diately. The Pressure Washer must be used in accordance with the manufacturers specicaons and

guidelines.

Demon Internaonal Ltd undertake to use the highest quality components available during manufac-

ture, but cannot be held responsible for any undue consequence arising from the use of there Pres-

sure Washer.

This warranty is given to the original purchaser only and is not transferable without the fully

authorised and wrien consent of Demon Internaonal Ltd.

Warranty Procedure

End Users

If your machine develops a problem:

1. Phone Demon for advice with the model and serial number to hand.

2. Describe fully the problem as best you can.

3. If the problem cannot be resolved over the phone then the machine can be booked in for

repair and if the faults are covered by the warranty the repair will be carried out free of charge.

4. If you cannot bring the machine in for repair then we will despatch an engineer. If the fault

is covered by the warranty then we will not charge for labour or spares used, however the

transport charge will be payable weather or not the repair is warranty.

Hire Centres and Dealers

If your machine develops a problem:

1. Phone Demon for advice with the model and serial number to hand.

2. Describe fully the problem.

3. We will advise you on the best course of acon, however if parts are required you must raise

a purchase order number to cover the parts. When the parts are ed they must be returned

for examinaon before a credit note is issued.

4. If you are unable to repair the machine then we will despatch an engineer to carry out the

repair. We will need a purchase order to cover the cost of transport to and from the site and for

parts and labour if the repair is not covered under the warranty.

5. If required Demon will arrange for a carrier to collect a damaged machine, if the warranty

claim is valid we will pay this cost, if not it will be charged to the customer.

For parts warranty ring Demon and request a warranty claim form faxed to you. This form must

accompany any returned parts.

Notes:

You will not invalidate the warranty by invesgang faults and repairing them yourself providing

you follow our advice. Hire Centres and Dealers are expected to carry out all repairs themselves

with Demon creding faulty parts upon receipt and inspecon.

Spare parts ed to machines are guaranteed for 1 month only or the remainder of the war-

ranty period whichever is longer.

I can’t get the pressure to where it used to be —

where do I start?

XT 1450

Pos Code No Descripon Qty Pos Code No Descripon Qty

1AR680570 Screw 640 AR1320020 Pump Head 1

2AR620301 Plug 141 AR180101 O Ring 1

7AR1260162 Plug 642 AR820361 Plug 1

8AR960160 O Ring 643 AR1260200 Cranksha 1

9AR1269050 Complete Valve 643 AR1320260 Cranksha 1

10 AR880830 O Ring 644 AR1380520 Key 1

11 AR1320340 Support Ring 345 AR1320370 Bearing 1

12 AR1260220 Gasket 346 AR1260750 Seal 1

13 AR1320351 Piston Guide 347 AR1260470 Screw 4

14 AR1260420 O Ring 348 AR1263890 Base 2

15 AR1260450 Gasket 383 AR1260790 Circlip 1

16 AR1260460 Seal 385 AR1381550 Washer 6

19 AR1260790 Circlip 188 AR1269222 Pump Head pre-ass 1

20 AR1320370 Bearing 189 AR1266740 Cap 1

21 AR1320330 Bushing 1

22 AR1320010 Pump Housing 1

23 AR880130 Oil Plug 1

24 AR1260110 Nut 3

25 AR1260100 Washer 3

26 AR1260210 Piston 3

27 AR480480 O Ring 3

28 AR1260091 Spacer 3

29 AR1260070 Guiding Piston 3

30 AR1260080 Piston Pin 3

31 AR1260760 Screw 6

32 AR1269101 Complete Cover 1

32 AR1320910 Complete Cover 1

36 AR1260060 Con Road 3

36 AR1320140 Con Road 3

37 AR1260040 Gasket 1

38 AR740290 O Ring 2

39 AR1980740 Plug 2

ARKIT1864 ARKIT2629 ARKIT1872

Valve Kit Piston Kit Oil Seal Kit

Pos Qty Pos Qty Pos Qty

9624 316 3

10 625 337 1

26 346 1

27 389 1

28 3

ARKIT1874

Water Seals

11 3

12 3

14 3

15 3

This manual suits for next models

8

Table of contents

Other Demon Pressure Washer manuals