Demon Hurricane P1 User manual

Page 1

Hurricane P1

Hurricane P2 & P2 Hose Reel

Hurricane P4 & P4 Hose Reel

Hurricane D1ES & D1ES Hose Reel

Hurricane P2, P4, P5 & P2 LPG Combi

Including electric start variants

Declaraon of Conformity

(E.H.S.R.)

We, Demon Internaonal Limited of Abbots Close, Lee Mill Industrial Estate,

Ivybridge, Devon, PL21 9GA, declare that this machine must be operated in

accordance with the operaon and safety instrucons as supplied with this

machine. This machine is manufactured in accordance with the following

standards and recommendaons.

HSE PVB PM29 - BS5415 Part - BS5415 Secon 2.4 1986

This instrucon manual is relevant only to the following machine and will not be kept

updated unless specically requested by the customer. However, any changes to the

operang procedure or changes which might aect the safety of this machine will be

noed to the registered owner of this machine only.

MACHINE TYPE

SERIAL NUMBER

WORKING PRESSURE

DATE OF SUPPLY

Operaons Manual

Demon Hurricane Range

Page 2

Manual Contents

Page 3 Technical Specicaons

Page 7 Preparaon & Operaon

Page 15 Fault Finder

Page 18 General Arrangement of Machines

Page 28 Combi Rotang Head Parts

Page 30 Machine Pumps

Page 36 Machine Unloaders

Page 40 Machine Gearboxes

Page 40 Machine Lance & Hoses

Page 3

Hurricane P1

Engine Honda GX120 4HP@3600rpm Air Filter HONDA0032

Pump AR RSV 3G25D + F25

Pressure 1500psi / 100

Flow 11.4lpm/ 2.5gpm

HP Nozzle 2504

Unloader Integrated

Pump oil 10W/40

Noise

Hurricane P2 & P2 Hose Reel & P2 & P2 LPG Combi

Engine Honda GX200 6.5HP @3600rpm Air Filter HONDA0031

Pump AR XT13.15

Pressure 2200psi/150Bar LPG 2000psi/135Bar

Flow 13 lpm /2.9gpm

HP Nozzle 2504

Gearbox 2:1 Reducon

Unloader Minimac4B ARMM4B/C

Pump Oil 10W/40

Gearbox oil EP90

Gearbox 2:1 reducon ARCRXT

Noise

Hurricane P4 & P4 Hose Reel & P4 Combi

Engine Honda GX340 11HP @3600rpm Air Filter HONDA001

Pump AR RK15-20H

Pressure 2900psi / 200Bar

Flow 15 lpm / 3.3gpm

HP Nozzle 2504

Gearbox 2:1 reducon ARCRXR

Unloader Gymac 3BARGM3B250

Pump oil 10W/40

Gearbox Oil EP90

Noise

Technical Specicaons

Page 4

Hurricane D1ES & D1ES Hose Reel

Engine Yanmar L100N 10HP @3600rpm Fuel Filter YAN55120

Pump ARRK15-20H Air Filter YAN114650-125901

Pressure 2900psi/200 Bar Injector YAN714650-53100

Flow 15 lpm/ 3.3gpm

HP Nozzle 2504

Gearbox 2:1 Reducon

Unloader ARGM3B250

Pump Oil 10W/40 Gearbox Oil EP90

Hurricane P5 Combi

Engine Honda IGX390

Pump ARRK 15-20H

Pressure 2900psi/200 Bar

Flow 15 lpm

HP Nozzle 2504

Gearbox 2:1 Reducon ARCRXR

Unloader ARGM3B250

Pump Oil 10W/40 Gearbox Oil EP90

Kits for Hurricane machines

Valve Piston Oil Water Support Rings

Hurricane P1 ARKIT2186 ARKIT2187 ARKIT2188 ARKIT2189 ARKIT2191

Hurricane P2 &

Combi P2 LPG ARKIT1864 ARKIT2629 ARKIT1872 ARKIT1874

Hurricane P4 & P5 ARKIT1828 ARKIT2757 ARKIT1856 ARKIT1857 ARKIT1829

Hurricane D1ES ARKIT1828 ARKIT2757 ARKIT1856 ARKIT1857 ARKIT1829

Page 5

DAILY CHECK THE FOLLOWING

a. Oil level - top up as required.

b. Fuel tank - top up as required.

c. All hose unions for leaks- replace O rings if leaking.

d. Hose condion - cuts etc.

e. If using sea water ush aer use with fresh water and spray any three way valves with

Silicone spay to lubricate valve.

EVERY 500 HOURS OR SIX MONTHS (WHICHEVER COMES FIRST)

a. Drain and replace pump oil.

b. Drain and rell fuel tank.

c. Replace fuel lter.

d. Clean water lter.

e. Replace high pressure nozzle.

EVERY 1000 HOURS OR 12 MONTHS (WHICHEVER COMES FIRST)

a. Complete 500 hour service.

b. Replace pump seals.

c. Replace oil seals.

d. Check unloading pressure and safety valve pressure and adjust.

The above service schedules are intended as a guide only, actual service mes and

replacements parts required will vary according to the area and the usage of the

machine.

Minimum Service Schedules

Page 6

P1

ARKIT2189 SEAL KIT

ARKIT2190 VALVE SEALS

AR2760400 PISTONS

ARKIT2186 H P VALVES

HONDA003 AIR FILTER

HONDA004 SPARK PLUG

2504 HP NOZZLE

DEM10115 DETERGENT PIPE

AR1981570 SEAL CARRIERS X 3

P2

ARKIT1874 SEAL KIT

ARKIT2812 VALVE SEALS

AR1271160 PISTONS

ARKIT1864 H P VALVES

AR1980200 VALVE TUBES

HONDA0031 AIR FILTER

2504 HP NOZZLE

DEM10115 DETERGENT PIPE

AR1320351 SEAL CARRIERS X 3

Service Parts

P4 & P4HR

ARKIT1857 SEAL KIT

ARKIT2611 VALVE SEALS

AR1560320 RELIEF VALVE PISTONS

AR1560051 RELIEF VALVES TUBES

ARKIT1828 HP VALVES

HONDA001 AIR FILTER

HONDA004 SPARK PLUG

2504 HP NOZZLE

DEM10115 DETERGENT PIPE

AR1380090 SEAL CARRIERS X 3

D1ES&D1ESHR

ARKIT1857 SEAL KIT

ARKIT2611 RELIEF VALVE SEALS

AR1560320 RELIEF VALVE PISTONS

AR1080831 RELIEF VALVES TUBES

ARKIT1828 HP VALVES

YAN114650-125901 AIR FILTER

YAN55120 FUEL FILTER

2504 HP NOZZLE

DEM10115 DETERGENT PIPE

AR1380090 SEAL CARRIERS X 3

Page 7

SAFETY

IWater at high pressure is dangerous and can cause serious injury. This machine is to be

used with great cauon.

II Petrol is extremely ammable and explosive under certain condions.

EXHAUST FUMES CONTAIN CARBON MONOXIDE – Inhalaon of such fumes can KILL.

III Diesel is ammable and harmful if swallowed.

AAlways refuel in an area which is adequately venlated.

BDO NOT smoke when refueling.

CAvoid overlling.

DShould fuel be spilt, wipe o any fuel spilt on machine or engine.

EMove the equipment away from the area where fuel has been spilt.

FDO NOT refuel when the engine is running.

GDO NOT run the engine in an area which has a hazardous or explosive atmosphere.

HAlways ensure that the fuel cap is secure aer refueling.

IKeep the engine at least 3 metres or more away from any other equipment or

Building.

JTake care not to get fuel on your clothing. If this happens – CHANGE your clothing

IMMEDIATELY.

DO NOT start an engine when clothing has been contaminated with fuel.

Operang Instrucons

Page 8

LAlways ensure that there is a suitable type re exnguisher available and is within easy

access.

MDO NOT leave an engine running unaended, ALWAYS STOP it before leaving the area as

thermal shock may occur if le on by-pass .

NNEVER point the high pressure spray jet at any person, animal, glass or other

Material which may shaer.

O PREVENT any over spray from injuring other people or damaging property.

PDO NOT even try to use a pressure washer on machinery or electrical equipment that is

connected in any way to the mains supply ( ALL switches in the OFF posion, pull out plugs,

if possible remove fuses). Cover or seal electric motors and ngs to prevent entry of

water. Before reconnecng electric mains supply check for water penetraon.

QDO ALL you can to keep plugs and sockets in a dry place or covered to prevent entry of

water.

RALWAYS when using this machine:-

• wear safety goggles and helmet or helmet with a visor.

•Wear waterproof clothing and gloves.

• Take parcular care with detergents and chemicals.

SNEVER aempt to disconnect any hose with pressure in it or allow the hose to be aened

or kinked.

TDO NOT use a high pressure hose from a ladder. Use a plaorm tower or proper

scaolding.

UShould the equipment fail to operate, DO NOT aempt to recfy or repair, but contact the

nearest Service Centre for advice.

V Always rinse your pump out aer using sea water.

WLeaving the pressure washer on by-pass for prolonged periods without operang the lance

will cause the water in the pump to heat up. This heat build up may damage the seals and

valves in the pump.

Page 9

LPG START

A. Connect gas regulator to gas bole.

B. Turn on gas.

C. Purge gas valve once on top of the engine.

D. Turn engine switch to on.

E. Pull re-coil to start.

LPG STOP

A. Turn o water.

B. Switch engine to stop.

C. Close gas valve on bole.

D. Release pressure by operang trigger.

Operang Instrucons for P2 LPG

Page 10

Water Supply:

AEnsure there is an adequate water supply either from the mains or a reservoir.

BAach water supply hoses to suitable tap or immerse the sucon hose with approved suc-

on lter into the reservoir.

NOTE: ONLY CLEAN WATER SHOULD BE USED. THE PUMP MAY BE DAMAGED IF DIRTY OR

CONTAMINATED WATER IS ALLOWED TO PASS THROUGH THE PUMP.

Hoses: Low pressure inlet.

For models up to 13 litres per minute use ½ “ bore sucon hose or feed pipe.

For models from 13 litres to 24 litres per minute use ¾” bore sucon hose or feed pipe.

Hoses:High pressure outlet.

For all models use 3/8” RIT or 3/8” R2T hoses.

ACheck the condion of the “O” rings in the ends of the hose.

BAatch the high pressure hose to the pump connecon.

CAatch the spray gun to opposite ends of the high pressure hose.

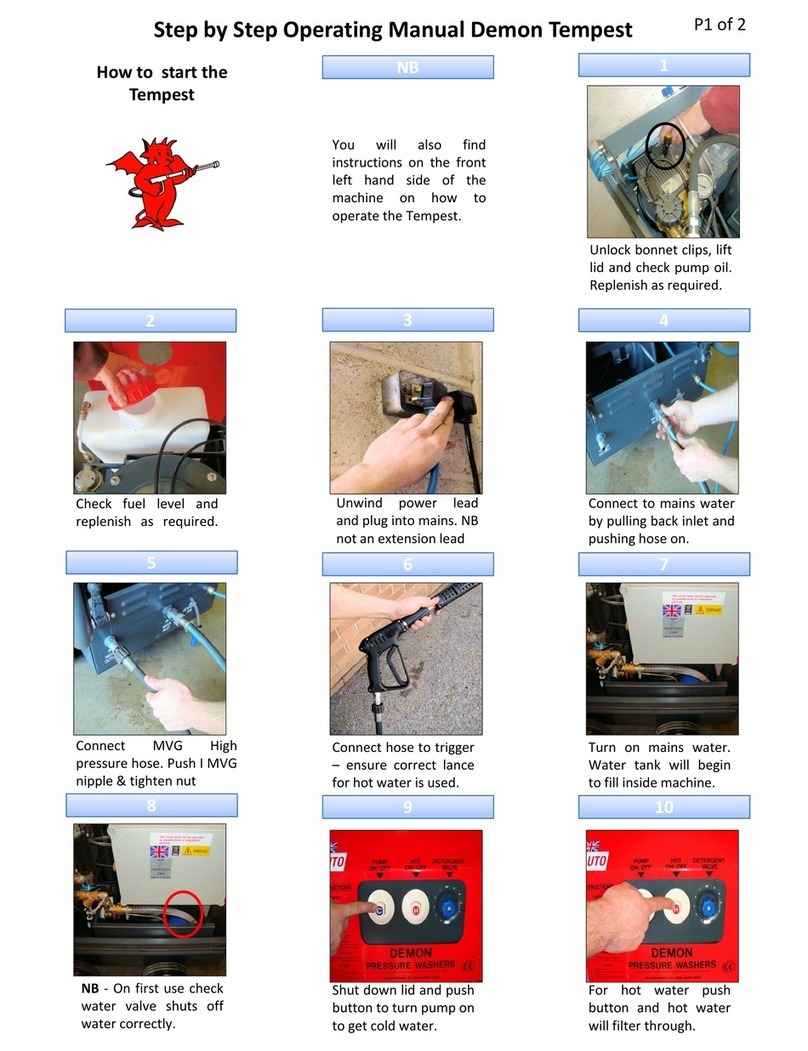

OPERATION

ATurn on the water supply.

BStart the engine

CDirect lance on to surface to be cleaned. Press the lance trigger.

Preparaon

Page 11

DAdjust pressure regulator as required to obtain working pressure if required.

ENOTE;:The high pressure water will cause the gun to “kick”. Make sure you have a rm grip

of gun and lance.

FOn compleon of operaon stop the engine.

g. Operate lance trigger

h. Turn “ OFF” water supply

i. Release residual pressure in gun and lance by operang trigger.

When using Cleaning Agents:

A. Set machine up as for water.

B. Connect detergent hose to machine and place lter end into detergent.

C. On compleon of work, ush through hose and gun with clean water to remove any residu-

al detergent.

NOTE: CHEMICAL PICKUP ONLY OPERATES AT PRESSURES BELOW 250PSI.

OPEN LANCE VALVE FULLY TO OBTAIN THIS PRESSURE.

Page 12

Page 13

Model Max Operang

Pressure

Operang Range Nozzle

P1 1500 PSI 100—1500 PSI 045

P2 2200 PSI 1500—2200 PSI 045

P4 2900 PSI 2200—2900 PSI 045

Page 14

Model Max Operang Pressure Operang Range Nozzle

D1 2900 PSI 2200—2900 PSI 2405

Page 15

FAULT CAUSE REMEDY

Machine stops suddenly

Or will not start.

P1/P2/P4—low oil

D1—at baery/fuse

P2 Combi LPG

• check and top up oil

• Check/replace baery, re-

place fuse

• Out of gas

Sudden pressure loss. Water supply failed.

No chemical

Check water supply.

Check chemical drum, close

valve

Low pressure

HP nozzle worn or un-

loader set

Incorrectly.

Replace HP nozzle. Set unloader

to correct seng.

Low pressure with noise and

vibraon.

Valves worn or

blocked. Piston seals

worn.

Pump sucking air.

Clean/replace as required.

Replace.

Check water supply pipe and un-

ions.

Pump will not by-pass. Non return valve dirty

or jammed. Clean or replace.

Water drips from pump box. Pump seals worn. Replace.

Oil drips from pump boom. Oil seal worn. Replace.

Oil is milky in colour. Water ingress through

oil lter plug. Rinse pump out and replace oil.

IF IN DOUBT ASK—OUR ADVICE IS FREE AND CAN SAVE YOU MONEY

Fault Finder

Page 16

I can’t get the pressure to where it used to be —

where do I start?

Page 17

Black knob & bolt replacement -

DEM102255

Wheel -WHEEL400

Wheel Cap -WHEEL25Pressure Gauge -

DEM20620

Hurricane Handle -

DEM10228

Sub base plate MET00193

LAB250

LAB270

LAB230/40

Rubber Mounts DEM10370

LAB291

LAB200

Hurricane Petrol & Diesel General Arrangement

Frame: P2 FRA001

P4 MET01210

D1 FRA002

Sub Base Plate: P2 MET00100

P4 MET00193

Page 18

Hose Reel

MTM20018

Unloader

Pump to Hose Reel Hose

(Black HR) HH0020

Pump to Hose Reel Hose

(Red HR) HH00213

Hurricane Petrol & Diesel with Hose Reel General

Arrangement

30m Hose (Black HR) 15M Hose (Black HR)

HH00100MVGHR HH00050MVGHR

30M Hose (Red HR) 15M Hose (Red HR)

HH00100R HH00051

Wheel

Wheel400

Brass swivel (Black HR) MTM20060

Brass Swivel (Red HR) MTM200591

Page 19

Manual Hose Reels

Page 20

Manual Hose Reels

This manual suits for next models

5

Other Demon Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Electro-Magic

Electro-Magic Grime Fighter 3000-5 GED owner's manual

Martha Stewart

Martha Stewart MTS-2030PW Operator's manual

Briggs & Stratton

Briggs & Stratton SpeedClean 2200 PSI owner's manual

Craftsman

Craftsman 919.76902 owner's manual

GreenWorks

GreenWorks GPW2100 Operator's manual

Ferm

Ferm GRM1024 Original instructions