Demon Tempest 1 User manual

Thanks for viewing this information PDF

There's more products, details, specification etc. on our website - CLICK THE LINKS ABOVE

Floor Cleaners Other Cleaners Hire Options Contact More Astley Hire

DEMONTEMPESTRANGE

Tempest1

Tempest3

Tempest4

CabinetWasher

ADeclarationofConformity

(E.H.S.R.)

We,DemonInternationalLimitedofAbbotsClose,LeeMillIndustrialEstate,

Ivybridge,DevonPL219GAdeclarethatthismachinemustbeoperatedin

accordancewiththeoperationandsafetyinstructionsassuppliedwiththis

machine.

Thismachineismanufacturedinaccordancewiththefollowingstandards

andrecommendations.

HSEPVBPM29–BS5415Part1–BS5415Section2.41986

HSEPVBPM29–BS5415Part1–BS5415Section2.41986

Thisinstructionmanualisrelevantonlytothefollowingmachineandwill

notbekeptupdatedunlessspecificallyrequestedbythecustomer.However,

anychangestotheoperatingprocedureorchangeswhichmightaffectthe

safetyofthismachinewillbenotifiedtotheregisteredownerofthisma‐

chineonly.

MachineType

SerialNumber

WorkingPressure

DateofSupply

TechnicalSpecifications

Tempest1/Auto/CabinetWasher240V(BlueCable)

PumpXT11.11 Boiler

Pumppressure 100bar1500psiFueltype Kerosene/gasoil/derv

Flowrate 111pm2.45gpmPressure 7bar 110psi

Maxby‐passsetting110bar1650psiNozzle 1.5USgalls

Minpressuresetting50bar750psiNozzlemake Monarch60°RorAR

Danfoss60°S

H.Pnozzle 25045 Electrodegap 6mm±1mm

Motorpower 2.2KW(MTR00100)IgnitionTransformer70Watts

Pumpoil 10W40 Fuelpump 50Watts

Unloadervalve ARMM4B/TSS Fanmotor 75Watts

NoiseFuse001 1ampsemidelay20mmglass

ValveKit ARKIT1864 OilSealKit ARKIT1872

SealKit ARKIT1874 PistonKit ARKIT2629

GeneratorSizerequired6KVA

Tempest3/Auto110V(YellowCable)

PumpXT11.11 Boiler

Pumppressure 100bar1500psiFueltype Kerosene/gasoil/derv

Flowrate 11lpm 2.45gpmPressure 7bar 100psi

Maxby‐passsetting110bar1650psiNozzle 1.5USgalls

Minpressuresetting50bar750psiNozzlemake Monarch60°RorAR

Danfoss60°S

H.Pnozzle 25045 Electrodegap 6mm±1mm

Motorpower 2.2KW(MTR00301)IgnitionTransformer70Watts

Pumpoil 10W40 Fuelpump 50Watts

Unloadervalve ARMM4B/TSS Fanmotor 75Watts

NoiseFuse002 3ampsemidelay20mmglass

ValveKit ARKIT1864 OilSealKit ARKIT1872

WaterSealKit ARKIT1874 PistonSealKit ARKIT2629

Generatorsizerequired8KVA

Tempest4/Auto/CabinetWasher415V(BlackCable)

(Fromthe03/07/12ARGM3unloader)

PumpRK15.20HBoiler

Pumppressure 200bar2900psiFuelType kerosene/gasoil/derv

Flowrate 151pm Pressure 7Bar 110psi

Maxby‐passsetting200bar2900psiNozzle 1.75USgalls

Minpressuresetting50bar750psiNozzlemake Monarch600RorAR

Danfoss600S

HPNozzle 2505Electrodegap 6mm+1mm

Motorpower 7.5KW(MTR00220)IgnitionTransformer70watts

Pumpoil 10W40 Fuelpump 50watts

OldUnloaderValveARMM4B/TSS NewUnloaderValveARGM3

fanMotor 75watts

NoiseFuse001 1ampsemidelay20mmglass‐

ValveKit ARKIT1828 WaterSealKit ARKIT1857

OilSealKit ARKIT1856 Piston ARKIT2757

TempestCabinetsfittedwithlowwaterandlowfuelcutoutsensors

Service Part Numbers for Tempest 1 & 3

ARKIT1874 Seal Kit

ARKIT2812 Seals for Unloader

ARKIT1864 Valve Kit

AR1271160 Pistons

AR1980200 Unloader Seat

DB000010 Fuel Nozzle

DB000110 Electrodes

DB00250 Fuel Filter

N26001/25045 Nozzle

DEM10115 Detergent Pipe

AR1320351 Piston Guides

ARKIT1857 Seal Kit

ARKIT2611 Valves

AR1560320 Pistons

AR1560051 Valve Tube

ARKIT1828 H P Valves

DB000015 Fuel Nozzle

DB000110 Electrodes

DB00250 Fuel Filter

N26001/2505 Nozzle

DEM10115 Detergent Pipe

AR1380090 Seal Carriers

Tempest 4 Service Kit

FAULTFINDER

FAULT

CAUSE

REMEDY

Machinestopssuddenlyorwillnot

start

BlownFuse Checkmainspower,poweroverload

13ampfuseand1or3ampcontrol

fuse.

SuddenpressurelossNowater

Lowwatersensoractivated

Nochemical

Burstdiskfailure

Checkwatersupply

Fillwithwater

Checkchemicaldrum

Closevalve

Replacedisk

LowpressureH.P.Nozzlewornorunloaderset

incorrectly.

ReplaceHPNozzle

Resetunloadervalve

Lowpressurewithnoiseandvibra‐

tion

Valveswornorblocked

Pistonsealsworn

Pumpsuckingair

Cleanandreplaceasrequired

Replace

Checkwatersupplypipeandunions

PumpwillnotBy‐passNonreturnvalvedirtyorjammed.Cleanorreplace

WaterdripsfrompumpPumpsealswornReplace

OildripsfrompumpbottomPumpsealswornReplace

BurnerwillnotigniteFueltankempty

Lowfueltanksensortrippedout

Fuelfilterblocked

Fuelnozzleblocked

Electrodesdirtyoroutofadjust‐

ment.

Flowswitchoutofadjustment

Refill

Refill

Replace

Clean,replace

Clean,replaceoradjust

Adjust

OilismilkyincolourWateringressthroughoilfilterplugReplaceoil.

IFINDOUBTASK–OURADVICEISFREEANDCANSAVEYOUMONEY

DAILYCHECKTHEFOLLOWING

a.Oillevel‐topupasrequired.

b.Fueltank‐topupasrequired.

c.Allhoseunionsforleaks‐replaceOringsifleaking.

d.Hosecondition‐cutsetc.

e.Electricalledandplug—damagedetc

EVERY500HOURSORSIXMONTHS(WHICHEVERCOMESFIRST)

a.Drainandreplacepumpoil.

b.Drainandrefillfueltank.

c.Cleanandresetelectrodes.

d.Replacefuelfilter.

e.Cleanwaterfilter.

f.Replacehighpressurenozzle.

g.Replacefuelnozzle.

h.Descalewatersystem.(hardwaterareasonly)

EVERY1000HOURSOR12MONTHS(WHICHEVERCOMESFIRST)

a.Complete500hourservice.

b.Replacepumpseals.

c.Replaceoilseals.

d.Checkfloatlevel.

e.Replacechemicalpipes.

f.Checkunloadingpressureandsafetyvalvepressureandadjust.

g.Replacefuelnozzleandsetfuelpressure.

h.Checkflowswitchandadjustifnecessary.

i.Checkelectricalconnectionsfortightness.

Theaboveserviceschedulesareintendedasaguideonly,actualservicetimes

andreplacementspartsrequiredwillvaryaccordingtotheareaandtheusage

ofthemachine.

MINIMUMSERVICESCHEDULES

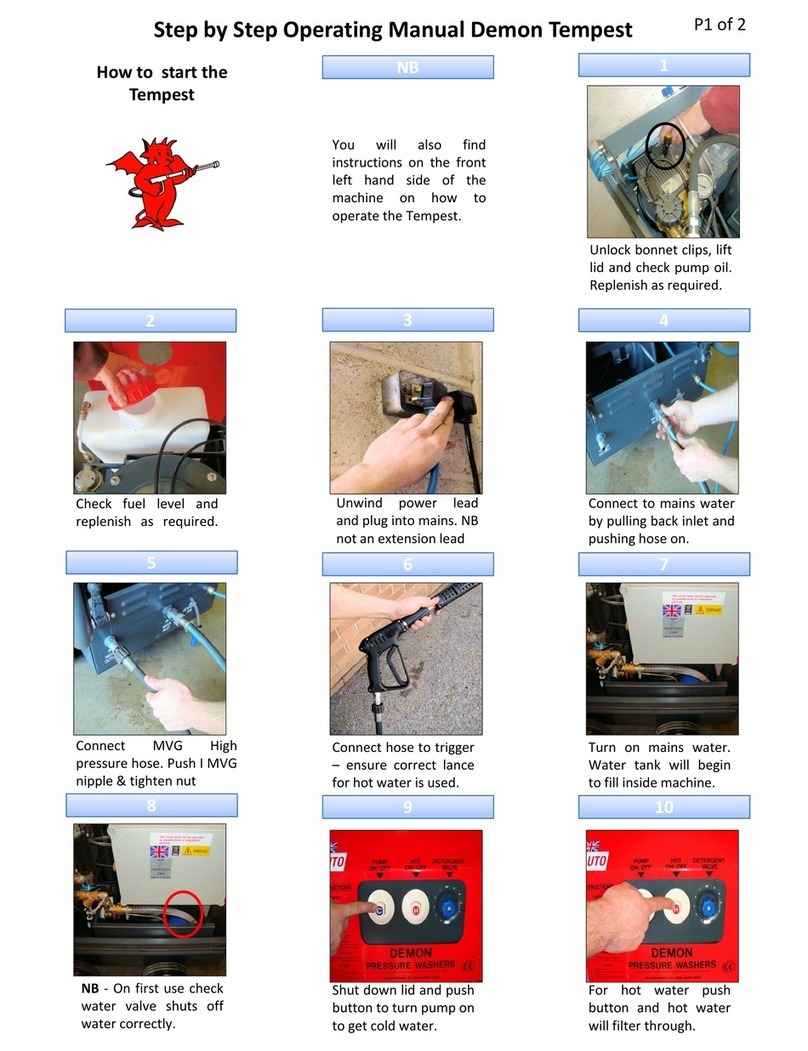

PREPARATION

a.Connecthosetowaterinletconnectorandturnon.

b.Connecthighpressurehosetoconnector.

c.Connectlancetohose.

d.ConnectplugtosuitableRCDprotectedsupplyandturnon.

e.Topupfuellevelsandcheckoillevelsinpumpandengine.

f.Ifchemicalistobeusedplacefilterindrumofchemicalandopenvalve.Ifnot

makesurevalveisclosed.

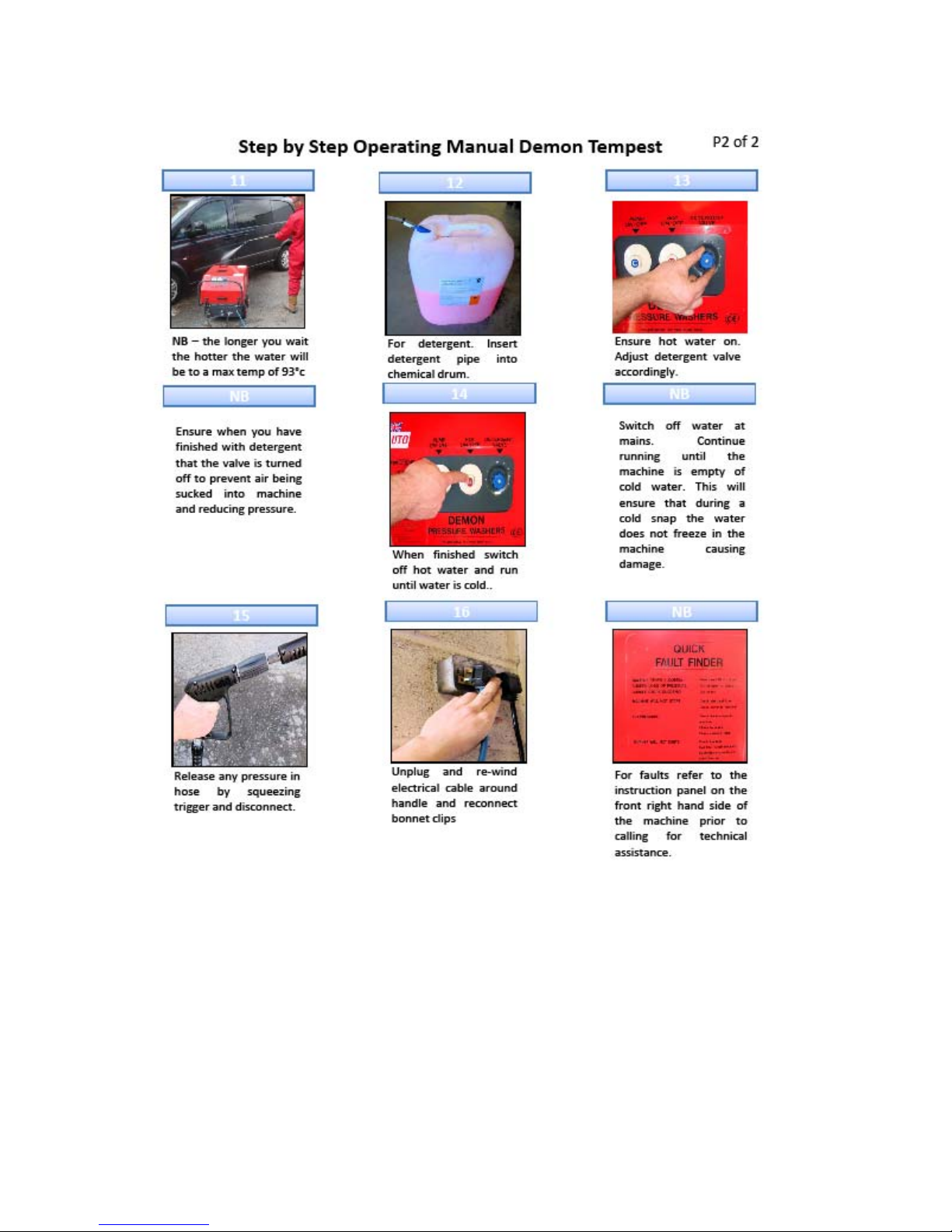

OPERATIONTOSTARTMACHINE

a.Pushblueswitchoncetostarttheengine.

b.Pulltriggeruntiloperatingpressureisreached.

c.Pushredswitchonce,burnerwillthenoperate.

d.Burnerwillthenigniteoncetriggerispulled.

OPERATIONTOSTOPMACHINE

a.Closethechemicalvalveifopened.

b.Switchtocoldbypressingredbuttononceandrunthemachineuntilthewater

turnscold.

c.Switchoffbypressingbluebuttononce.

d.Pulltriggertoreleaseexcesspressureanddisconnectfrommachine.

e.Ifthemachineistobestored,drainwatersystemandtopupthefuelandoillevels.

IFINDOUBTASK‐OURADVICEISFREE

SAFETY

I.UnderthetermsoftheHealth&SafetyatWorkActandfortheoperatorsprotectiona

ResidualCurrentDevice(R.C.D)orEarthLeakageTripMUSTbeusedwiththismachine.

iiWaterathighpressureisdangerousandcancauseseriousinjury.Thismachineistobe

usedwithgreatcaution.

a.NEVERpointthehighpressuresprayjetatanyperson,animal,glassoranyothermaterial

whichmayshatter.

b.PREVENTanyover‐sprayfrominjuringotherpeopleordamagingproperty.

c.DONOTeventrytouseapressurewasheronmachineryorelectricalequipmentthat iscon‐

nectedinanywaytothemainssupply.(allswitchesintheoffposition,pulloutallplugsand

ifpossibleremovefuses).Coverorsealelectricmotorsandfittingstoprevententryofwater.

d.ALWAYSwhenusingmachine:‐

‐wearsafetygogglesandhelmetorhelmetwithavisor.

‐wearwaterproofclothingandgloves.

‐takeparticularcarewithdetergentsandchemicals.

e.NEVERattempttodisconnectanyhosewithpressureinitorallowthehosetobeflattened

orkinked.

f.DONOTuseahighpressurehosefromaladder.Useaplatformtowerorproperscaffolding.

g.CHECKthatyoursupplyvoltageagreeswiththatshownonthemachine.

h.Extentionleadsarenotrecommendedforusewiththisequipment.Fitextentionhosesor

contacttheservicedepartment.

i.Whereacableisfoundtobedamaged,thepowermustbeswitchedoffandtheplug re‐

movedbeforeattemptingtoremovetheequipment.

j.ALWAYSdisconnectthehoseswhenthemachineisnotinoperationandprotectthemachine

fromfrostandcoldwinds.

k.ALWAYSusethemachineinawellventilatedarea.

CAUTION‐ifusingchemicalssomebrandswilladverselyaffectthebrasscomponentsfittedtothis

machine.Ifindoubtpleasetelephoneourtechnicaldepartmentforadvice.

DemonTempestHotWaterRange‐GeneralArrangement

ChemicalValve—MTM25801

Chimney

FuelFillerDEM10410

Wheel—WHEEL230

WheelCap—WHEEL25

MainsCable—DEM10390

Chassis—DEM102165

ChemicalPickup

LidDEM20170

Handle—DEM10190

RubberBonnetClips—DEM10360

WaterInlet—MTM73001FemaleCoupling

MTM73020MaleCoupling

WaterOutlet—MTM70013

AirButtons

Blue—H6442B

Red—H6442R

DemonCanopyLabelPack

DemonTempestRangeArrangementDrawing—PlanView

Pump

ARXT11.14—230v/110v

ARXRC13.17—415v

FuelTankDEM10410

CompleteFueltankDEM410

ElectricalEnclosure

DEM10323

UnloaderValve

Boiler

FlowS

w

FuelPump

240VDB002300

110VDB002305

240VMotorMTR00100

110vMotorMTR00301

415VMotorMTR00220

TripswitchDEM10175

Note:NotvisibleCapacitor

230v—1x65μcapacitor

110v—2x65μcapacitor

PressureGauge

DEM20620

OutlettoBoiler

pipeHH00021

Flowswitchto

BoilerHH00022

TheTempestCabinetwasherissimpletoinstall,therearefourholesinthefeetforboltingtoasolidsur‐

facesuchasaconcreteplinthanda10mmmasonrydrillcanbedrilledtoadepthtosuiteitherrawbolts

orsleeveanchors.Thewatersupplyisviaastandardhosepipetoatapandthereisasteppednippleto

suit13mmand19mmpipe.

Electricitysupplymustbewiredbyacompetentelectricianandwerecommendthesupplyiswiredusing

armouredcablewithanisolatornearby.Ifaseparatesupplyisrequiredforthefrostprotectionsystem

thenthismustbeinstalledupstreamoftheisolatorsotheheaterwillworkevenifthemainssupplyis

turnedoff.Afusedspurisidealforthisapplication.

230Vmodel–needsaD20MCBonyourdistributionpanel

415Vmodel–needsaD20tripleMCBonyourdistributionpanel

Bothmodels–separatefeedforfrostprotection5ampfusedspur

Prolongedperiodsofcoldweather

Inprolongedperiodsofcoldweatherweadviseturningthewateroffandrunningthemachineuntilitis

emptythendisconnectallhosesandisolatefromthemainspowerbutleavingthefrostprotectioncircuit

livetogivesomeheatinsidethecabinet.

TempestCabinetWasher‐InstallationInstructions

TempestCabinetWasher‐GeneralArrangement

Boiler

FanMotor

DB000160230V

FlowSwitch

MV00385

WaterTank

DEM10437

FlowValveAssembly

DEM10450

FuelTank

DEM10401

FrostProtection

Heater

DEM101341

FrostStat

DEM101342

Lid

DEM10420

PressureGuage

DEM20620

Pump

230vARXT11‐14

415vRK15‐20

FuelPump

DB002300

LockingHandleforCabinetDEM101361

Pleaseretainkeynumber

FlowswitchtoBoilerHoseHH000292

WARRANTY

Thiswarrantycoversthecostofallreplacementpartsandlabourchargesincurred.It

doesnotcoverthecostoftransportorcarriage.Itistheownersresponsibilityto

returnthemachinetoaservicedepotorpaythetravellingexpensesofaserviceen‐

gineertoattend.DemonInternational’sdecisioninwarrantymattersisfinaland

binding.

DemonInternationalLtdundertaketorepairorreplace,anycomponentwhichmayfailduetoa

manufacturingfaultwithinaperiodof12monthsfromthedateofpurchase,providedthatany

faultordamagewasnotsustainedby;

A.Lackofregularandpropermaintenance,usernegligence,misuse,ordamagecausedbyice

andfrost.

B.Theeffectsofcontaminatedfuelorwater,theuseofnon‐approvedchemicalsoranin

sufficientorunsuitableelectricalsupply.

C.Theeffectsofun‐authorisedmodificationanduse.

D.Compressiondamagetohighpressurehose.(HOSESWARRANTEDFOR1MONTHONLY)

E.Wornoutitemsconsideredfairwearandtear.

Partswhichmayormaynotwearoutduringthefirstyearandwhichareconsideredserviceitems

whichwillneedreplacingfromtimetotime:Highpressurenozzle,lance,trigger,hoses,fuelnoz‐

zle,fuelfilter,pistonseals,valves,unloaderseatsandseals,waterfilter,non‐returnvalve,chemi‐

calbarbs,chemicalpipesandpumpoilseals.

ItistheownersresponsibilitytoensurethePressureWasheriskeptinasafeandsuitableenviron‐

mentandanyfaultsreportedbyoperativestoberectifiedattheearliestpossibledate.

ItistheoperatorsresponsibilitytocheckthePressureWasherforanyfaultsandreportthemim‐

mediately.ThePressureWashermustbeusedinaccordancewiththemanufacturersspecifica‐

tionsandguidelines.

DemonInternationalLtdundertaketousethehighestqualitycomponentsavailableduringmanu‐

facture,butcannotbeheldresponsibleforanyundueconsequencearisingfromtheuseofthere

PressureWasher.

Thiswarrantyisgiventotheoriginalpurchaseronlyandisnottransferablewithoutthefully

authorisedandwrittenconsentofDemonInternationalLtd.

WarrantyProcedure

EndUsers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblemasbestyoucan.

3.Iftheproblemcannotberesolvedoverthephonethenthemachinecanbebookedinforrepair

andifthefaultsarecoveredbythewarrantytherepairwillbecarriedoutfreeofcharge.

Ifyoucannotbringthemachineinforrepairthenwewilldespatchanengineer.Ifthefaultiscov‐

eredbythewarrantythenwewillnotchargeforlabourorsparesused,howeverthetransport

chargewillbepayableweatherornottherepairiswarranty.

HireCentresandDealers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblem.

3.Wewilladviseyouonthebestcourseofaction,howeverifpartsarerequiredyoumustraisea

purchaseordernumbertocovertheparts.Whenthepartsarefittedtheymustbereturnedforex‐

aminationbeforeacreditnoteisissued.

4.Ifyouareunabletorepairthemachinethenwewilldespatchanengineertocarryoutthere‐

pair.Wewillneedapurchaseordertocoverthecostoftransporttoandfromthesiteandforparts

andlabouriftherepairisnotcoveredunderthewarranty.

5.IfrequiredDemonwillarrangeforacarriertocollectadamagedmachine,ifthewarrantyclaim

isvalidwewillpaythiscost,ifnotitwillbechargedtothecustomer.

6.ForpartswarrantyringDemonandrequestawarrantyclaimformfaxedtoyou.Thisformmust

accompanyanyreturnedparts.

Notes:

Youwillnotinvalidatethewarrantybyinvestigatingfaultsandrepairingthemyourselfproviding

youfollowouradvice.HireCentresandDealersareexpectedtocarryoutallrepairsthemselves

withDemoncreditingfaultypartsuponreceiptandinspection.

Sparepartsfittedtomachinesareguaranteedfor1monthonlyortheremainderofthewarranty

periodwhicheverislonger.

LanceandMachineColourCodes

Part

Number Description Storm Wall

Mounted Hurricane Tempest

Inc Cabinet Typhoon Evolution Tornado &

Mini-Bowser

DEM10031B Cold Water Lance

045 Blue

Storm

1 & 2,

FS1 WM1 P1 & P2 N/A N/A N/A P1 & P2

DEM10031R Cold Water Lance

05 Red FS4 WM4 P4 & D1 N/A N/A N/A P4 & D1

DEM10032B Hot Water Lance

045 Blue N/A N/A N/A Tempest

1, 3 &

4 (13.17 pump) N/A N/A N/A

DEM10032R Hot Water Lance

05 Red N/A N/A N/A Tempest 4

(15.20 Pump) Typhoon

1, 2 & P4 Evo1 &

Evo 2 N/A

Company/marketing/lancechartissue306/10

Other manuals for Tempest 1

1

This manual suits for next models

2

Table of contents

Other Demon Pressure Washer manuals