Demon Tornado P2 User manual

DEMONTORNADORANGE

TornadoP2

TornadoP4

TornadoD1ES

Electron

Includingelectricstartvariantsandbowserwashers

DeclarationofConformity

(E.H.S.R.)

We,DemonInternationalLimitedofAbbotsClose,LeeMillIndustrialEstate,

Ivybridge,Devon,PL219GA,declarethatthismachinemustbeoperatedin

accordancewiththeoperationandsafetyinstructionsassuppliedwiththis

machine.

Thismachineismanufacturedinaccordancewiththefollowingstandards

andrecommendations.

HSEPVBPM29‐BS5415Part‐BS5415Section2.41986

Thisinstructionmanualisrelevantonlytothefollowingmachineandwillnot

bekeptupdatedunlessspecificallyrequestedbythecustomer.However,

anychangestotheoperatingprocedureorchangeswhichmightaffectthe

safetyofthismachinewillbenotifiedtotheregisteredowner

MachineType

SerialNumber

WorkingPressure

DateofSupply

TornadoP2

Engine HondaGX2006.5HP@3600rpm

PumpARXT13‐15

Pressure 1300psi/90bar

Flow 13lpm/2.9gpm

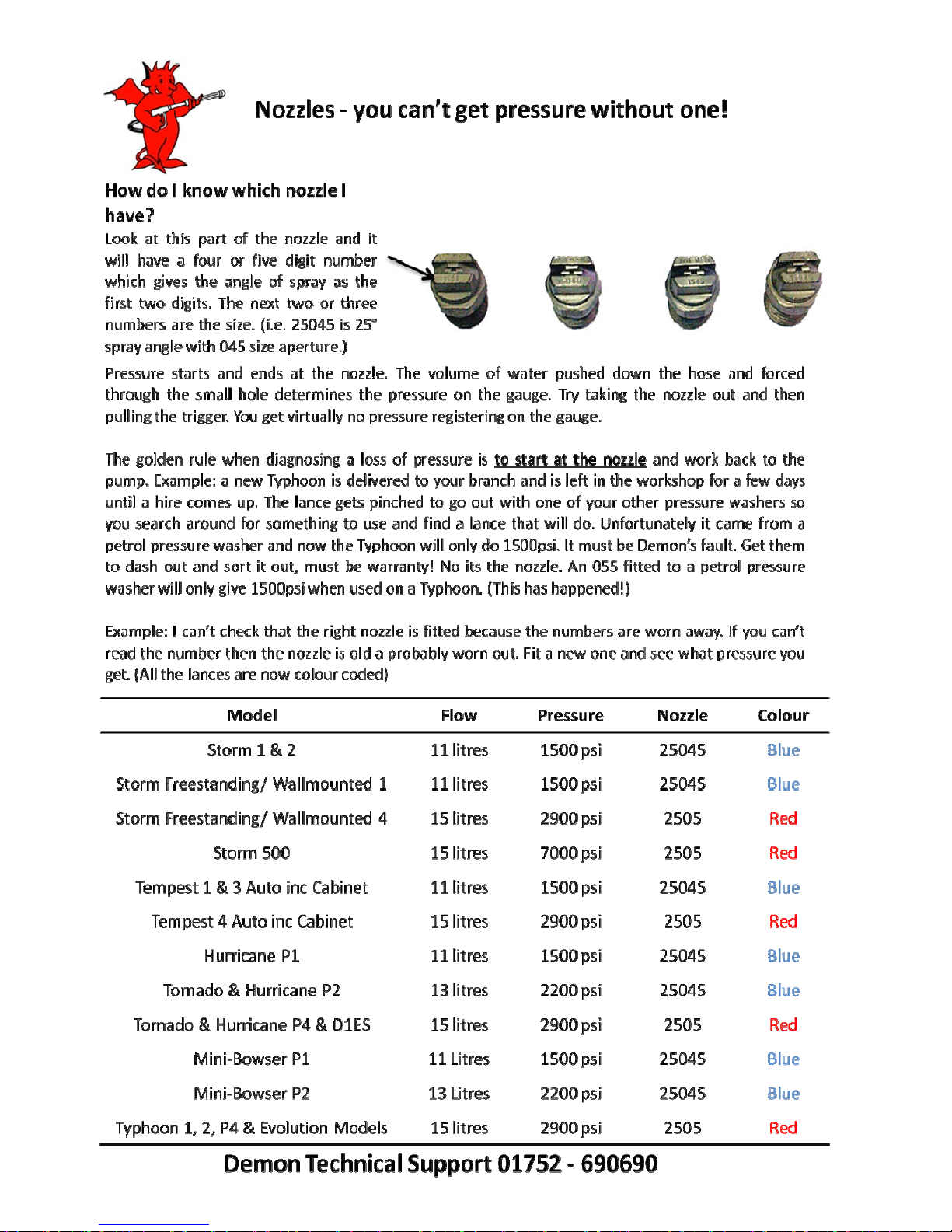

HPNozzle 25045

Gearbox 2:1Reduction

Unloader Minimatic4B

PumpOil 10W/40

GearboxOilEP90

Noise

TornadoP4

Engine HondaGX34011HP@3600rpm

PumpARRK15‐20H

Pressure 2900psi/200bar

Flow 15lpm/3.3gpm

HPNozzle 2505

Gearbox 2:1Reduction

Unloader Gymatic3B

PumpOil 10W/40

GearboxOilEP90

Noise

TornadoD1ES

Engine YanL10010HP@3600rpm

PumpARRK15‐20H

Pressure 2900psi/200bar

Flow 15lpm/3.3gpm

HPNozzle 2505

Gearbox 2:1Reduction

Unloader Gymatic3B

PumpOil 10W/40

GearboxOilEP90

Noise

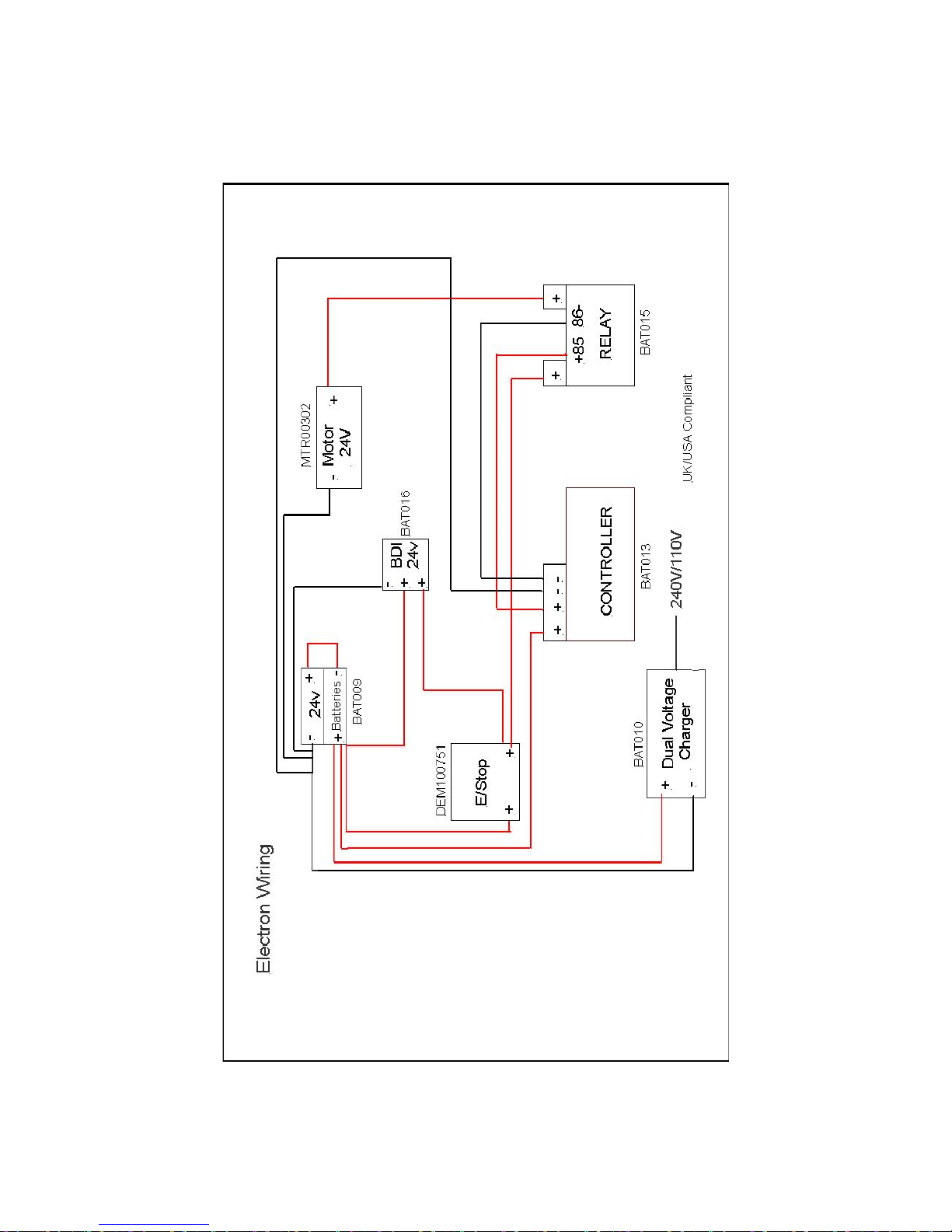

Electron

Motor24vDCHPNozzle1505

PumpARXT13‐15UnloaderARMM4B/C

Pressure1300psi/90barPumpOil10W/40

Flow13lpm

Battery4x6v225amp/hour

MicroprocessorControlledAutomaticBatteryCharger

24Volt30AmpCharger

TechnicalSpecifications

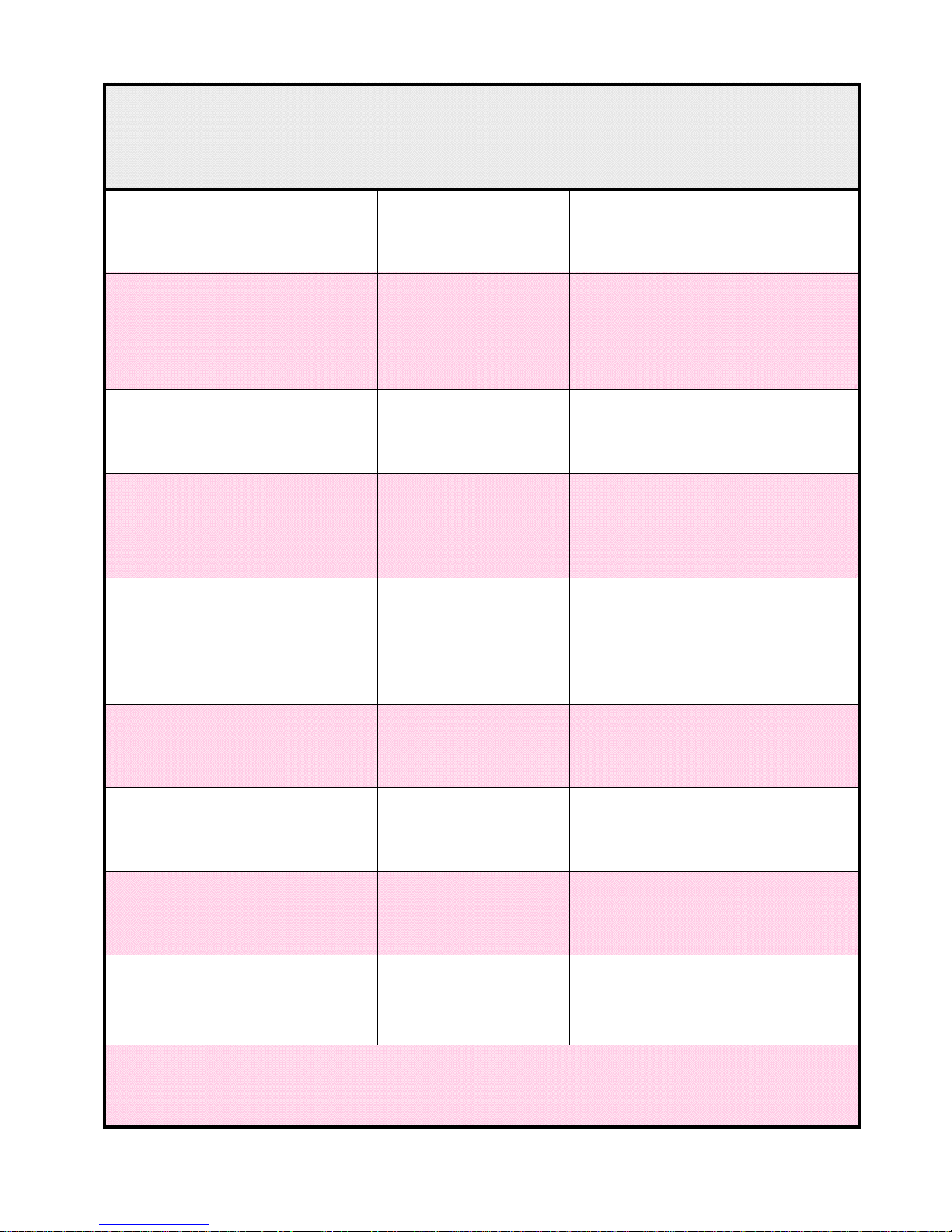

FAULTFINDER

FAULT

CAUSE

REMEDY

Machinestopssuddenly

Orwillnotstart.

P4—lowoil

D1—flatbattery/fuse

• checkandtopupoil

• Check/replacebattery,re‐

placefuse

Suddenpressureloss.Watersupplyfailed.

Nochemical

Checkwatersupply.

Checkchemicaldrum,closevalve

LowpressureHPnozzlewornor

unloaderset

Incorrectly.

ReplaceHPnozzle.Setunloader

tocorrectsetting.

Lowpressurewithnoiseand

vibration.

Valveswornor

blocked.Pistonseals

worn.

Pumpsuckingair.

Clean/replaceasrequired.

Replace.

Checkwatersupplypipeand

unions.

Pumpwillnotby‐pass.Nonreturnvalve

dirtyorjammed.

Cleanorreplace.

Waterdripsfrompumpbox.Pumpsealsworn.Replace.

Oildripsfrompumpbottom.Oilsealworn.Replace.

Oilismilkyincolour.Wateringress

throughoilfilterplug.

Rinsepumpoutandreplaceoil.

IFINDOUBTASK—OURADVICEISFREEANDCANSAVEYOUMONEY

DAILYCHECKTHEFOLLOWING

a.Oillevel‐topupasrequired.

b.Fueltank‐topupasrequired.

c.Allhoseunionsforleaks‐replaceOringsifleaking.

d.Hosecondition‐cutsetc.

EVERY500HOURSORSIXMONTHS(WHICHEVERCOMESFIRST)

a.Drainandreplacepumpoil.

b.Drainandrefillfueltank.

c.Replacefuelfilter.

d.Cleanwaterfilter.

e.Replacehighpressurenozzle.

EVERY1000HOURSOR12MONTHS(WHICHEVERCOMESFIRST)

a.Complete500hourservice.

b.Replacepumpseals.

c.Replaceoilseals.

d.Checkunloadingpressureandsafetyvalvepressureandadjust.

Theaboveserviceschedulesareintendedasaguideonly,actualservicetimes

andreplacementspartsrequiredwillvaryaccordingtotheareaandtheusage

ofthemachine.

MINIMUMSERVICESCHEDULES

OPERATINGINSTRUCTIONS

SAFETY

IWaterathighpressureisdangerousandcancauseseriousinjury.Thismachineistobe

usedwithgreatcaution.

IIPetrolisextremelyflammableandexplosiveundercertainconditions.

EXHAUSTFUMESCONTAINCARBONMONOXIDE–InhalationofsuchfumescanKILL.

IIIDieselisflammableandharmfulifswallowed.

AAlwaysrefuelinanareawhichisadequatelyventilated.

BDONOTsmokewhenrefueling.

CAvoidoverfilling.

DShouldfuelbespilt,wipeoffanyfuelspiltonmachineorengine.

EMovetheequipmentawayfromtheareawherefuelhasbeenspilt.

FDONOTrefuelwhentheengineisrunning.

GDONOTruntheengineinanareawhichhasahazardousorexplosiveatmosphere.

HAlwaysensurethatthefuelcapissecureafterrefueling.

IKeeptheengineatleast3metresormoreawayfromanyotherequipmentor

Building.

JTakecarenottogetfuelonyourclothing.Ifthishappens–CHANGEyourclothing

IMMEDIATELY.

DONOTstartanenginewhenclothinghasbeencontaminatedwithfuel.

KUseonlyapprovedtypecontainersforfuel.DONOTstandthemoutinstrongsunlight,

keepthemintheshade.

LAlwaysensurethatthereisasuitabletypefireextinguisheravailableandiswithin easy

access.

MDONOTleaveanenginerunningunattended,ALWAYSSTOPitbeforeleavingthearea.

NNEVERpointthehighpressuresprayjetatanyperson,animal,glassorother

Materialwhichmayshatter.

O PREVENTanyoversprayfrominjuringotherpeopleordamagingproperty.

PDONOTeventrytouseapressurewasheronmachineryorelectricalequipmentthatis

connectedinanywaytothemainssupply(ALLswitchesintheOFFposition,pulloutplugs,

ifpossibleremovefuses).Coverorsealelectricmotorsandfittingstoprevententryof

water.Beforereconnectingelectricmainssupplycheckforwaterpenetration.

QDOALLyoucantokeepplugsandsocketsinadryplaceorcoveredtoprevententryof

water.

RALWAYSwhenusingthismachine:‐

• wearsafetygogglesandhelmetorhelmetwithavisor.

•Wearwaterproofclothingandgloves.

• Takepaticularcarewithdetergentsandchemicals.

SNEVERattempttodisconnectanyhosewithpressureinitorallowthehosetobeflattened

orkinked.

TDONOTuseahighpressurehosefromaladder.Useaplatformtowerorproper

scaffolding.

UShouldtheequipmentfailtooperate,DONOTattempttorectifyorrepair,butcontactthe

nearestServiceCentreforadvice.

VAlwaysrinseyourpumpoutafterusingseawater.

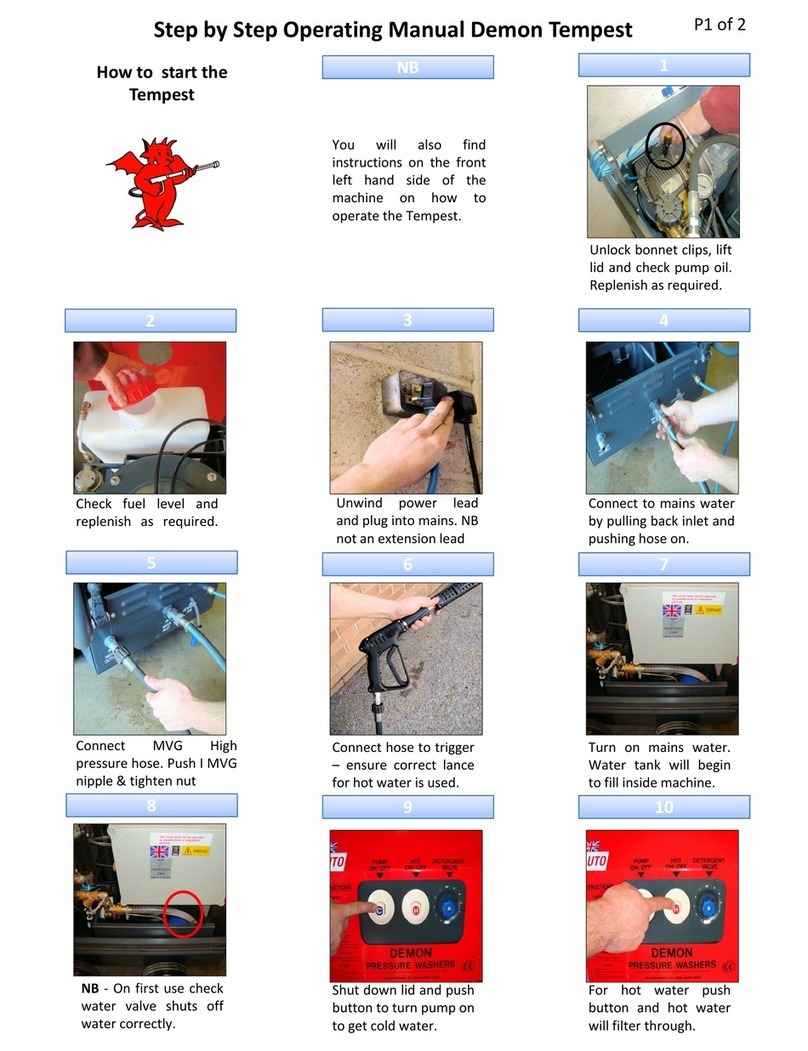

PREPARATION

WaterSupply:

AEnsurethereisanadequatewatersupplyeitherfromthemainsorareservoir.

BAttachwatersupplyhosestosuitabletaporimmersethesuctionhosewithapprovedsuc‐

tionfilterintothereservoir.

NOTE:ONLYCLEANWATERSHOULDBEUSED.THEPUMPMAYBEDAMAGEDIFDIRTYOR

CONTAMINATEDWATERISALLOWEDTOPASSTHROUGHTHEPUMP.

Hoses:Lowpressureinlet.

Formodelsupto13litresperminuteuse½“boresuctionhoseorfeedpipe.

Formodelsfrom13litresto24litresperminuteuse¾”boresuctionhoseorfeedpipe.

Hoses:Highpressureoutlet.

Forallmodelsuse3/8”RITor3/8”R2Thoses.

AChecktheconditionofthe“O”ringsintheendsofthehose.

BAttachthehighpressurehosetothepumpconnection.

CAttachthesprayguntooppositeendsofthehighpressurehose.

OPERATION

ATurnonthewatersupply.

BStarttheengine

CDirectlanceontosurfacetobecleaned.Pressthelancetrigger.

DAdjustpressureregulatorasrequiredtoobtainworkingpressureifrequired.

ENOTE;:Thehighpressurewaterwillcausethegunto“kick”.Makesureyouhaveafirmgrip

ofgunandlance.

FOncompletionofoperationstoptheengine.

g.Operatelancetrigger

h.Turn“OFF”watersupply

i.Releaseresidualpressureingunandlancebyoperatingtrigger.

WhenusingCleaningAgents:

A.Setmachineupasforwater.

B.Connectdetergenthosetomachineandplacefilterendintodetergent.

C.Oncompletionofwork,flushthroughhoseandgunwithcleanwatertoremoveanyresid‐

ualdetergent.

NOTE:CHEMICALPICKUPONLYOPERATESATPRESSURESBELOW250PSI.

OPENLANCEVALVEFULLYTOOBTAINTHISPRESSURE.

Electron

TheElectronisfittedwithabatterymonitorwhichwillcutthebatteriesoutatadischargelevel

of20volts.Thebatterieswillthenneedtobere‐chargedwiththeonboardbatterycharger,

thesystemwillbereactivatedatalevelof25volts.

Batteriesmustbere‐chargedfullyusingthesuppliedintelligent24vchargerbeforeusingthe

Electron,afterthevoltagecutouthasbeenactivated.Failuretodosomayleadtodamageand

reducethelifeexpectancyofthebatteries.

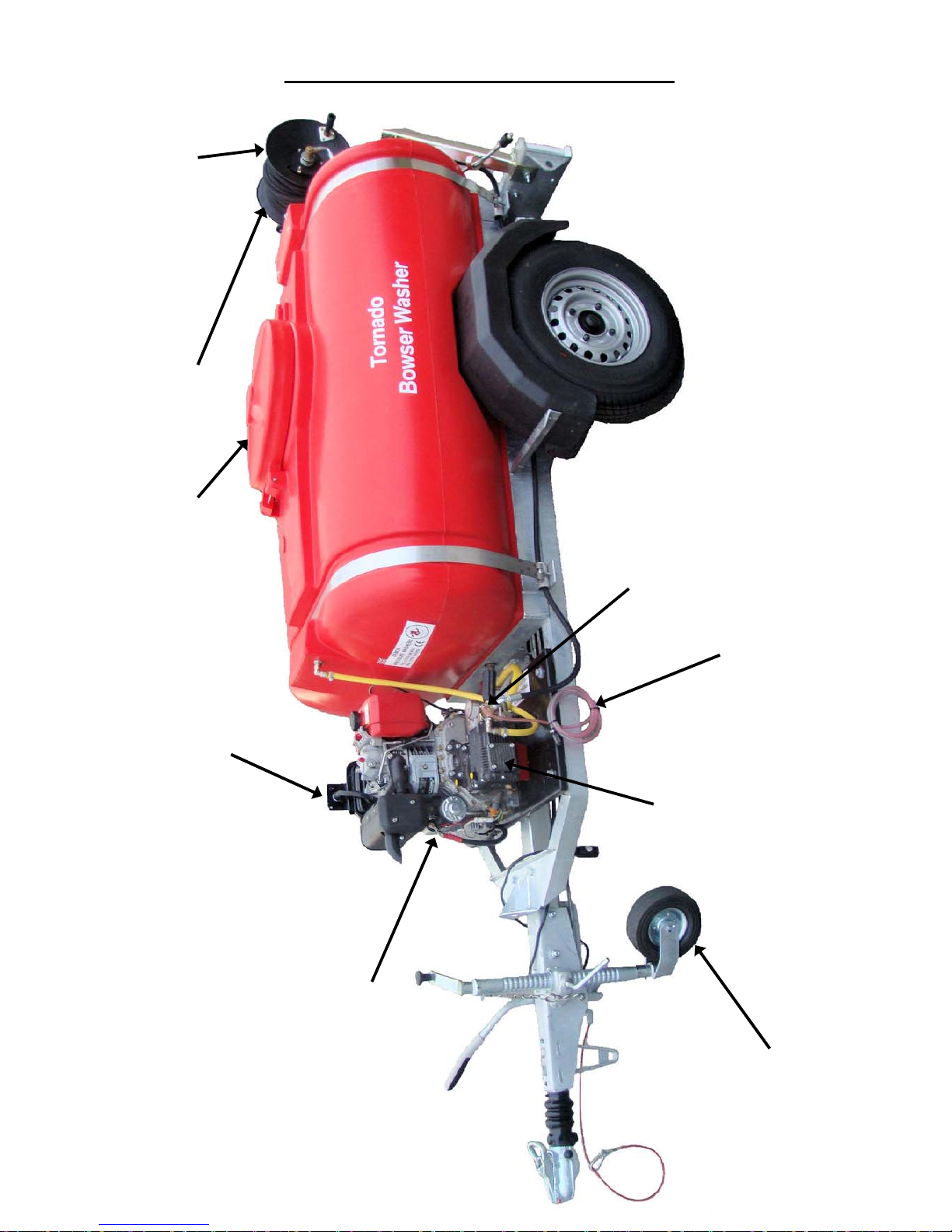

TornadoBowser‐GeneralArrangement

KeyStart(DieselOnly)

Engine

YanmarL100Diesel

HondaGX340Petrol

JockeyWheel

XLE00320

Pump

ARRK15:20

ChemicalPickUpPipe

DEM10115

UnloaderValve

ARGM3B250

30MtrHose

HH00100MVGHR

HoseReel

MTM20022

SuctionFilter

(InsideTank)

DEM10041

TornadoElectron—GeneralArrangement

Registered Design Applied - UK

Patent Pending - US

BAT011

Gel

Batteryx4

225amp

BAT016

Battery Discharge

Indicator

DEM100751

Lockable

On/off switch

BAT013

Battery Charger

DEM100876

Electrical

Controller Box

BAT015

Battery

Controller

BAT013

Battery

Controller

Cut Out

MTM20022

Hose Reel

HH00100MVGHR

30 Mtr Hose

ARMM4B/C

Unloader Valve

DEM10115

Chemical Pick Up Pipe

Tornado Electron –General Arrangement

Registered Design Applied - UK

Patent Pending - US

WARRANTY

Thiswarrantycoversthecostofallreplacementpartsandlabourchargesincurred,butdoesnot

coverthecostoftransportorcarriage.Itistheownersresponsibilitytoreturnthemachinetoa

servicedepotorpaythetravellingexpensesofaengineertoattend.DemonInternationals

decisioninwarrantymattersisfinalandbinding.

DemonInternationalLtd,undertaketorepairorreplaceattheirdiscretion,anycomponentwhich

mayfailduetoamanufacturingfaultwithinaperiodof12monthsfromthedateofpurchase,

providedthatanyfaultordamagewasnotsustainedby;

ALackofregularandpropermaintenance,usernegligence,misuse,ordamagecausedby

iceorfrost.

BTheeffectsofcontaminatedfuelorwater,theuseofnon‐approvedchemicals,oranin

sufficientorunsuitableelectricalsupply.

CTheeffectsofun‐authorisedmodificationanduse.

DCompressiondamagetohighpressurehose.(Hosesarewarrantedforonemonthonly)

EWornoutitemsconsideredwearandtear.

Partswhichmayormaynotwearoutduringthefirstyearandwhichareconsideredservice

itemswhichwillneedreplacingfromtimetotime:Highpressurenozzle,lance,trigger,hoses,

fuelnozzle,fuelfilter,pistonseals,valves,unloaderseatsandseals,waterfilter,non‐return

valve,chemicalbarbs,chemicalpipes,andpumpoilseals.

Itistheownersresponsibilitytoensurethepressurewasheriskeptinasafeandsuitableenvi‐

ronmentandanyfaultsreportedbyoperativestoberectifiedattheearliestpossibledate.

Itistheoperatorsresponsibilitytocheckthepressurewasherforanyfaultsandreportthemim‐

mediately,andtousethepressurewasherinaccordancewiththemanufacturersspecifications

andguidelines.

DemonInternationalLtd,undertaketousethehighestqualitycomponentsavailableduring

manufacture,butcannotbeheldresponsibleforanyundueconsequencearisingfromtheuseof

theirpressurewashers.

Thiswarrantyisgiventheoriginalpurchaseronlyandisnottransferablewithoutthefullyauthor‐

izedandwrittenconsentofDemonInternationalLtd.

WarrantyProcedure

EndUsers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblemasbestyoucan.

3.Iftheproblemcannotberesolvedoverthephonethenthemachinecanbebookedinfor

repairandifthefaultsarecoveredbythewarrantytherepairwillbecarriedoutfreeofcharge.

4.Ifyoucannotbringthemachineinforrepairthenwewilldespatchanengineer.Ifthefault

iscoveredbythewarrantythenwewillnotchargeforlabourorsparesused,howeverthe

transportchargewillbepayableweatherornottherepairiswarranty.

HireCentresandDealers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblem.

3.Wewilladviseyouonthebestcourseofaction,howeverifpartsarerequiredyoumustraise

apurchaseordernumbertocovertheparts.Whenthepartsarefittedtheymustbereturned

forexaminationbeforeacreditnoteisissued.

4.Ifyouareunabletorepairthemachinethenwewilldespatchanengineertocarryoutthe

repair.Wewillneedapurchaseordertocoverthecostoftransporttoandfromthesiteandfor

partsandlabouriftherepairisnotcoveredunderthewarranty.

5.IfrequiredDemonwillarrangeforacarriertocollectadamagedmachine,ifthewarranty

claimisvalidwewillpaythiscost,ifnotitwillbechargedtothecustomer.

ForpartswarrantyringDemonandrequestawarrantyclaimformfaxedtoyou.Thisformmust

accompanyanyreturnedparts.

Notes:

Youwillnotinvalidatethewarrantybyinvestigatingfaultsandrepairingthemyourselfproviding

youfollowouradvice.HireCentresandDealersareexpectedtocarryoutallrepairsthemselves

withDemoncreditingfaultypartsuponreceiptandinspection.

Sparepartsfittedtomachinesareguaranteedfor1monthonlyortheremainderofthewar‐

rantyperiodwhicheverislonger.

LanceandMachineColourCodes

Part

Number Description Storm Wall

Mounted Hurricane Tempest

Inc Cabinet Typhoon Evolution Tornado &

Mini-Bowser

DEM10031B Cold Water Lance

045 Blue

Storm

1 & 2,

FS1 WM1 P1 & P2 N/A N/A N/A P1 & P2

DEM10031R Cold Water Lance

05 Red FS4 WM4 P4 & D1 N/A N/A N/A P4 & D1

DEM10032B Hot Water Lance

045 Blue N/A N/A N/A Tempest

1, 3 &

4 (13.17 pump) N/A N/A N/A

DEM10032R Hot Water Lance

05 Red N/A N/A N/A Tempest 4

(15.20 Pump) Typhoon

1, 2 & P4 Evo1 &

Evo 2 N/A

Company/marketing/lancechartissue306/10

PosPartNoDescriptionQty

1N26001/1504NozzleP11

1N26001/15045NozzleP21

1N26001/1505NozzleP4&D1ES1

2MTM90040AdjustableNozzle1

3DEM10031BQRLamceP21

3DEM10031YQRLanceP11

3DEM10031RQRLanceP4&D1ES1

4DEM10030QRTrigger1

5MTM70012MVGCoupling1

COLDWATERLANCES

High Pressure Hoses

12

3 4

1.HoseInsertMV00490(items1&2)

2.Nut

3.HighPressureHoseHH00030MVG

4.HoseJoinerMV00500

15MetreHH00050MVG

30MetreHH00100MVG

AlternativeHoseLengths

This manual suits for next models

3

Table of contents

Other Demon Pressure Washer manuals