Demtech Pro-Tester SE User manual

Pro-Tester SE

Pro-Tester SE Operator’s Manual

Model Number: T-0100SE/A

Revision: B

Rev. B, October 2020

Page ii Pro-Tester SE Operator’s Manual

© Copyright 2020 by DEMTECH Services, Inc.

All Rights Reserved

Scope of Manual:

This manual contains procedures for safety, general unpacking,

set-up, and operation of your DEMTECH Services, Inc. Pro-Tester Hi-Pull

TM

Field

Tensiometer.

The text of this publication, or any part thereof, may not be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying, recording, storage in

an information retrieval system, or otherwise, without prior written permission of DEMTECH

Services, Inc.

Notice

Patents have been granted and/or patent applications are pending or are in the process of

preparation on all DEMTECH Services, Inc. developments.

The material in the manual is for informational purposes only and is subject to change without

notice.

DEMTECH Services, Inc. assumes no responsibility for any errors that may appear in this

manual.

Printed in the USA

Manual Number: T-OPERATOR’S MANUAL/PRO-TESTER SE, Revision: B

DEMTECH Services, Inc.

6414 Capitol Avenue Diamond Springs, CA 95619 U.S.A.

Telephone: (530) 621-3200

Toll Free: (888) 324-9353

Fax: (530) 621-0150

Web Site: www.demtech.com

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page iii

Table of Contents

1

SAFETY PRECAUTIONS…………………………………………………..PAGE 1

2

GENERAL SAFETY & MAINTENANCE INFORMATION…………….PAGE 2

2.1

Intended Use…………………………………………………………………...Page 2

2.2

Maintenance…………………………………………………………………...Page 2

3

GENERAL PRODUCT DATA……………………………………………...PAGE 3

4

SITE PREPARATION……………………………………………………….PAGE 4

5

UNPACKING & INSTALLATION INSTRUCTIONS……………………PAGE 4

5.1

Unpacking and Preparation…………………………………………………...Page 5

5.2

Electrical Plug Connection……………………………………………………..Page 5

5.3

Control Panel…………………………………………………………………..Page 7

5.4

Loading Samples………………………………………………………………Page 9

5.5

Settings……………………………………………………………………….Page 10

5.6

Elongation Definition………………………………………………………...Page 10

6

FACTORY SERVICING…………………………………………………...PAGE 13

7

USER INTERFACE MENU TREE………………………………………..PAGE 13

8

SYSTEM WIRING DIAGRAM……………………………………………PAGE 14

9

PRO-TESTER HI-PULL

TM

WARRANTY…………………………………PAGE 14

Rev. B, October 2020

Page 1 Pro-Tester SE Operator’s Manual

1Safety Precautions

Safety precautions for operating personnel and equipment:

WARNING 1: Operating personnel should perform only the procedures described and

recommended in this manual. Only qualified service personnel familiar with electrical

shock hazards and mechanical entanglement hazards present inside the equipment should

perform disassembly or corrective maintenance of the equipment.

WARNING 2: To avoid shock hazards, the equipment must be grounded with an adequate

earth ground in accordance with local and national electrical codes.

WARNING 3: The locations of potentially dangerous voltages and other hazards are

identified and labeled on the equipment. Be careful to observe these warnings when installing,

operating, maintaining or servicing the equipment. Observe all warnings in this manual.

WARNING 4: Make sure to turn off the equipment power and remove the ~ (AC) line cord

from the power outlet before attempting to service the equipment. Do not perform service

unless you are qualified and trained to do so.

WARNING 5: This product is intended for operator attended operation only. This product

should never be left unattended at any time while it is plugged in and the power is turned on.

Incorrect use of the product such as overheating of the material can present a fire and explosion

hazard, especially near combustible materials and explosive gases.

WARNING 6: This product is intended for operation in dry environments only. Higher

humidity environments should be kept non-condensing by avoiding large temperature swings.

WARNING 7: Do not touch the main housing, air nozzle and/or output molten material when

they are hot as they can cause burns. After use allow sufficient time for the product to cool to

room temperature before handling and stowing. Do not point or direct the hot air flow and the

output molten material in the direction of personnel.

CAUTION 1: Observe the precautions given on the equipment and within this manual to

prevent damage to the equipment.

CAUTION 2: Before connecting the equipment to its electrical power source, check that the

~ (AC) voltage, frequency and current to be supplied to the equipment are correct and

match the serial plate affixed to the system.

CAUTION 3: Use proper handling and packaging procedures for Electro-Static Discharge

(ESD) sensitive Printed Circuit Boards (PCB’s). Assume that all PCB’s are sensitive to

potential damage from ESD.

CAUTION 4: Unauthorized personnel should not remove from the equipment those panels or

covers that are provided for protection and/or require a tool to remove.

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 2

2General Safety & Maintenance Information

The DEMTECH Services, Inc. Pro-Tester SE

TM

field tensiometer, hereinafter referred to as

the Pro-Tester SE

TM

, Pro-Tester

TM

, or tensiometer is a high voltage piece of equipment.

Always disconnect the power source before performing any service and/or maintenance

procedures on the tensiometer. Never lift, pull or carry the welder by the power cord or

electrical connection. Always maintain slack in any extension cords connected to the

tensiometer while in operation to avoid damage to the power connections. At all times

while operating the tensiometer keep hands, fingers and other body parts well clear of the

rotating screw and grip assemblies.

2.1

Intended Use

The Pro-Tester SE

TM

is intended as professional use equipment and is not intended for sale

to the general public.

The Pro-Tester SE

TM

has been manufactured utilizing the latest technology and current

safety standards and regulations. However, improper use or abuse may lead to hazardous

conditions for the user or other personnel or cause damage to the tensiometer.

Always keep this manual with the Pro-Tester

TM

at or near the location where the tensiometer

is being used so that it can be referred to quickly and easily.

The technician assigned to operate this tensiometer must have read through and become

familiar with this manual, particularly all safety information, before operating the Pro-

Tester

TM

.

No changes and/or modifications shall be made to the Pro-Tester

TM

especially as it relates

to safety.

2.2

Maintenance

Maintenance, inspection and adjustment of the Pro-Tester

TM

shall only be carried out by

qualified personnel. Before removing or installing spare parts or performing other repair

operations to the tensiometer, consult DEMTECH Services, Inc. or your authorized

DEMTECH service center for advice on proper procedures. This will help insure a safe

and successful outcome. Always make sure all screw connections are tight before

attempting to operate the welder after maintenance and/or repair procedures. Also make

sure all covers, guards, and other safety devices have been fully reinstalled before use.

Rev. B, October 2020

Page3 Pro-TesterSEOperator’sManual

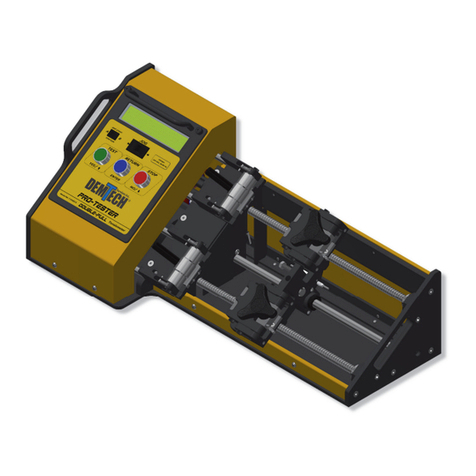

3General Product Data

The DEMTECH Services, Inc. Pro-Tester SE

TM

Field Tensiometer, hereinafter referred to

as the Pro-Tester

TM

, dramatically speeds the field testing of welded seam samples by

providing an easy to load grip. This arrangement combined with state-of-the-art electrical

and electronics controls and an easy to use User Interface (UI) makes the task of performing

field sample tests much more efficient. The highly integrated and automated operation of

the Pro-Tester

TM

eliminates cumbersome setup and speeds up process time while providing

a very rugged and reliable system. The one button operation combined with automatic

return saves time. The enclosed controller system is easy to maintain. You can be assured

the Pro-Tester

TM

has been built using the highest quality materials available which include

Billet Aluminum and ground and hardened steel. DEMTECH Services, Inc. strives to make

our systems easy to use and built to last. Just like all other DEMTECH Services, Inc.

products, even a first-time user will be productive in minutes. With easy adjustments and

a one touch operation, you will be getting test results within minutes of installation.

To operate and navigate the various features of the Pro-Tester

TM

simply follow the text

prompts at the bottom of the Liquid Crystal Display (LCD) screen. Significant

development was spent making the system very easy to operate by even a novice operator

by simply following the screen prompts.

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 4

4Site Preparation

Before proceeding with the unpacking and installation instructions in the following

section(s) make sure the work site is prepared and ready to use the Pro-Tester

TM

. You should

have an adequate power source capable of providing clean Alternating Current (AC)

power at 110 or 220 Volts at the rated current. Refer to the system serial plate affixed to

the rear of the system for the voltage and current requirements of your system. The install

area should be clean, dry and free of debris and provide adequate working area to allow

efficient and effective use of the system.

Carefully follow the detailed unpacking and installation instructions provided in this

manual.

5Unpacking & Installation Instructions

This section contains instructions for the unpacking, placement and installation of the Pro-

Tester

TM

. Carefully review the following information, sub-sections and each procedure

before beginning unpacking and installation of the system.

The Pro-Tester

TM

comes complete in a reusable portable shipping/transport container. The

system can be operated from within the container our removed and placed onto a work bench

or appropriate platform for use. When not in use the Pro-Tester

TM

should always be stored in

the shipping/transport container to protect it from the elements and potential damage.

Note: The system illustrated in this manual shows ALL available features for the Pro-

Tester

TM

, therefore, your system may vary slightly in appearance from that depicted.

Rev. B, October 2020

Page5 Pro-TesterSEOperator’sManual

5.1

Unpacking and Preparation

a. Before opening the shipping/transport container and unpacking the system, inspect the

outside of the container thoroughly for any signs of mishandling or damage during

shipping. Report any damage to the shipping carrier immediately and do not proceed

with unpacking. Since the shipment is made FOB factory, you should consult your

administration concerning claims for shipping damage. Please notify DEMTECH

Services, Inc. immediately in writing of any shipping damage.

b. Unlatch and open the shipping/transport container lid and inspect inside the container

and equipment thoroughly for any signs of mishandling or damage during shipping.

Report any damage to the shipping carrier immediately and do not proceed with

unpacking. Since the shipment is made FOB factory, you should consult your

administration concerning claims for shipping damage. Please notify DEMTECH

Services, Inc. immediately in writing of any shipping damage.

c. Make note of the orientation of the equipment and packing foam inserts inside the

shipping container to facilitate any repackaging requirements in the future.

d. To avoid injury and/or damage to the system, be sure to use adequate care when lifting,

removing or replacing the system into the shipping/transport container.

e. You may operate the system from within the shipping/transport container or remove it

and place it in an appropriate location suitable for the testing you intend to perform.

5.2

Electrical Plug Connection

a. Verify proper operation of the Pro-Tester

TM

before proceeding with the remainder of the

installation. The Pro-Tester

TM

is equipped with a “soft-start” feature. This feature

utilizes a toggle power switch on the rear of the system. Toggle the switch up to turn

the system ON. Toggle the switch down to turn the system OFF. This feature provides

a built in safety to protect the system during connection to a field generator by

automatically turning the power off to the system any time AC power is disconnected

either by turning off the generator or unplugging the power cord. Upon startup

generators can produce significant power surges which can be harmful to the Pro-

Tester

TM

. This soft-start feature eliminates ill effects from this phenomenon. Find the

Power Cord included with your system and plug one end into the appropriate connecter

at the rear of the system (refer to Figure 1). Plug the other end into an electrical outlet

supplying the proper ~(AC) power. Toggle the Power Switch to the ON position (refer

to Figure 5.1).

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 6

b. The system LCD should light up, go through a self-diagnostic test and then prompt the

user to press ENTER to initiate the initialization/calibration sequence. Press ENTER

to perform the initialization/calibration procedure. For the proper operation of the Pro-

Tester

TM

do not HALT or skip the procedure.

c. The system will first move the grip head in (left) to find the home position, then out

(right) to calibrate travel speed. After a short pause the grip will then move back in

(left) and stop at the A or B grip separation position depending on which is selected on

the Control Panel. This procedure verifies the Pro-Tester

TM

is in good working

condition. If the system performs as described, you are now ready to operate the system.

If the system does not perform any of the functions described above please contact

DEMTECH Services, Inc.

Figure 5.1

M002

Power Cord

With IEC 60320

Connector

(P/N T-111)

Fuse

Holde

r

Power

ON/OFF

Switch

Rev. B, October 2020

Page7 Pro-TesterSEOperator’sManual

5.3

Control Panel

The User Interface Control Panel is the main operator interface device for operating the

Pro-Tester

TM

. Each component of the Control Panel is identified below (refer to Figure 5.3).

Figure 5.3

A

B

C

D

E

F

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 8

a. Liquid Crystal Display (LCD): The LCD is a 40 Character by 4 Line display device

which provides main system operation information for the Control Panel. It provides

all key operating information and allows the user to input various system settings.

b. JOG

/

: This switch allows the user to jog (move) the movable sample grip at an

accelerated rate in and out during setup and operation of the system and is used to

change various settings during Menu Mode operation (refer to Section 6.5).

c. Grip Start Position Toggle Switch A/B: This switch allows the user to select between

one of two grip separation settings. This allows quick transition from one separation

length to another. Grip separations A and B can be set through the Menu Mode (refer

to Section 6.5).

d. Test/Yes/: This button is used to initiate a Test or in Menu Mode to navigate the

screen tree.

e. Return Enter: This button is used to return the grips after a test or in Menu Mode to

navigate the screen tree.

f. Stop/No/⇩: This button is used to stop a Test or in Menu Mode to navigate the screen

tree.

Rev. B, October 2020

Page9 Pro-TesterSEOperator’sManual

5.4

Loading Samples

Loading samples is very simple with the Pro-Tester

TM

. To load a sample open both jaws of

the sample grip assemblies. The left grip is a cam clamp and is opened by toggling the

cam handle to the right (open). The right grip is a screw clamp and is opened by unscrewing

the tri-handle counter-clockwise (open).The sample is prepared by bending the ends to be

clamped so they can be easily loaded into the grips. Load the sample from the top of the

grip until the sample rests against the stop tabs then apply the left and right grip clamps

(refer to Figure 5.4). If loading a 4” (100 mm) test coupon, align the edges of the sample

with the edges of the grip frame in order to center the coupon. The stop tabs will need to

be removed in order to load a 4” (100 mm) coupon.

Figure 5.4

Stop

Tab

T-035 A M004

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 10

5.5

Settings

a. The Pro-Tester

TM

requires various settings for proper operation. These settings are

easily accessed via the Menu Mode of operation. To enter the Menu Mode, make sure

the Pro-Tester

TM

is on and at the main operating screen (Refer to Page 15).

Simultaneously press and hold the YES and NO buttons on the Control Panel for

several seconds. This procedure puts the system into Menu Mode. This mode of

operation allows the user the set various system parameters. For a complete listing of

all of the features refer to the diagram on page 15.

b. All of the settings required to operate the Pro-Tester

TM

come factory set for most users

and should not need setting. However, if your particular installation requires setting

any parameters enter the Menu Mode and follow the screen prompts to navigate the

screen menu.

c. Figure 7.1 on page 15 is a Menu Tree drawing. This drawing can be very helpful if

you are trying to find a particular function or setting you wish to access. Use the

drawing to locate the particular item you want to access. Once located, follow the

tree back to the top level. Next, utilizing the user interface on the Pro-Tester

TM

,

proceed back down through the menu structure using the drawing as a guide to access

the particular screen you want.

5.6

Elongation Definition

If you intend to use the strain (elongation) feature of the Pro-Tester

TM

tensiometer it is

important to understand both the definition of this feature/function and how it is intended

to be used. Proper understanding requires the definition of some basic terms. These

terms are defined below.

a. Grip Separation (GS): The distance between the grip point on each of the left and

right sample grip assemblies (refer to Figure 5.5). There are two user settable

distances, A or B, which have been factory set for 1.7 and 3.5 inches respectively.

The operator must be aware of these values and change the settings if necessary (refer

to Section 5.5) to accommodate the particular sample to be tested.

b. Weld Extrusion (Squeeze-out): The area of a weld whereupon becoming molten the

parent material extrudes (is squeezed) out from between the pressure zone of the

welding tool and then cools. This extruded material does not usually provide an

acceptable bond of the parent material and should not be considered part of the weld

(refer to Figure 6C).

Rev. B, October 2020

Page11 Pro-TesterSEOperator’sManual

c. Weld Width (WW): The center-to-center distance between the two welds of a dual-

track weld (refer to Figure 6A) or the edge-to-edge distance on a solid weld (refer to

Figure 6B). It is important when measuring/calculating these distances that the

operator only include the actual width of the weld. The width of the weld is defined

as only that area where the two sheets of parent material have been appropriately

bonded by both heat and pressure. During this process some parent material may

extrude beyond the pressure zone of the welding tool (refer to Weld Extrusion

definition). This extruded material does not usually provide an acceptable bond of

the parent material and should therefore be excluded from any measurements made

for this test.

d. Gauge Length (GL): This is the base value used by the Pro-Tester

TM

for determining

elongation percentage. It is the Grip Separation once the initial tension value has been

reached minus the Weld Width (GS – WW = GL). For example if your Grip

Separation was 4 inches and your Weld Width was 1 1/2 inches then your Gauge

Length would be 2 1/2 inches (4 - 1.5 = 2.5). It is this value that is used to determine

elongation. Elongation is calculated as the percentage of change (increase) of the

Grip Separation related to Gauge Length. For example if your Gauge Length is 2 1/2

inches and the grips had separated 1 1/4 inches at the completion of your test then the

elongation would be 50% (1.25 / 2.5 = .50). If your Gauge Length is 2 1/2 inches and

the grips had separated 2 1/2 inches at the completion of your test then the elongation

would be 100% (2.5 / 2.5 = 1.00).

It is on this basis that the Pro-Tester

TM

has been designed and programmed to operate when

performing elongation testing.

Figure 5.5

T-035 A M004

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 12

Figure 6A

Figure 6B

Figure 6C

Figure 6

Rev. B, October 2020

Page13 Pro-TesterSEOperator’sManual

6Factory Servicing

In the event your Pro-Tester SE

TM

should require factory service, the entire welder needs to

be returned to the factory. Refer to the following step for preparing the Pro-Tester SE

TM

for

return.

Carefully pack the Pro-Tester SE

TM

in the reusable portable shipping/storage case provided

with the welder for return to DEMTECH Services, Inc.’s factory for service. Unless

previous arrangements are made, shipping charges and insurance are the responsibility of

the customer. Ship the packaged Pro-Tester SE

TM

to DEMTECH Services, Inc. at:

DemTech Services, Inc

Ship to address: 6414 Capitol Avenue

Diamond Springs, CA 95619

U.S.A.

7User Interface Menu Tree

Refer to Page 15 for the Pro-Tester SE

TM

Menu Tree drawing. This drawing can be very

helpful if you are trying to find a particular function or setting you wish to access. Use the

drawing to locate the particular item you want to access. Once located, follow the tree

back to the top level. Next, utilizing the user interface on the Pro-Tester

TM

, proceed back

down through the menu structure using the drawing as a guide to access the particular

screen you want. To enter the Menu Mode make sure the Pro-Tester

TM

is on and at the main

operating screen (Refer to Page 15). Simultaneously press and hold the YES and No

buttons on the Control Panel for several seconds.

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 14

8System Wiring Diagram

Refer to Page 16 for the Pro-Tester

TM

System Wire Diagram. This drawing can be very

helpful in identifying and/or troubleshooting basic wiring or interconnection issues related

to the Pro-Tester

TM

.

9Pro-Tester SE

TM

Warranty

See page 17 for the DEMTECH Services, Inc. product warranty.

Rev. B, October 2020

Page15 Pro-TesterSEOperator’sManual

Figure 7.1

T-0100HP A M001

Rev. B, October 2020

Pro-Tester SE Operator’s Manual Page 16

Figure 8.1

Rev. B, October 2020

Page17 Pro-TesterSEOperator’sManual

Warranty

DEMTECH Services, Inc. warrants all equipment of its manufacture to be free from defects in

materials, workmanship, mechanical parts, and labor for a period of one year from the date of shipment

to the original buyer and ninety days for electrical. This warranty excludes normal wear items such as

gears, bearings and chains. The liability under this warranty is limited to replacement parts and labor

on equipment when the equipment is returned prepaid to the factory or its authorized service center with

prior authorization from DEMTECH Services, Inc., and upon examination by DEMTECH Services, Inc.,

is determined to be defective. At DEMTECH Services, Inc.'s option, a service representative may be

dispatched to the equipment location.

As an additional protection, DEMTECH Services, Inc. warrants that for a period of 90 days from the

date of shipment to the original buyer, pending prior authorization from DEMTECH Services, Inc., there

will be no charge for service related shipping of parts and/or equipment or for authorized travel of a

service representative to the equipment location. After 90 days, all costs incurred for shipping the

equipment or parts thereof or for travel are the responsibility of the buyer. Our warranty for this equipment

is rendered void if the unit has been repaired, taken apart or modified, or attempted to be, unless such

actions have been taken in accordance with written instructions received from DEMTECH Services,

Inc. The warranty is also void if the equipment has been subjected to abuse, accident or other abnormal

conditions.

IF ANY FAULT DEVELOPS,

THE FOLLOWING STEPS SHOULD BE TAKEN:

1.

Notify DEMTECH Services, Inc. by calling 1-888-324-9353. Overseas customers should contact

the local DEMTECH authorized service center. Please be prepared with the model number, serial

number and full details of the difficulty. Upon receipt of this information, service data or shipping

instructions will be provided by DEMTECH Services, Inc. Do not return the unit for repair without

first contacting the factory or its representative for instructions.

2.

After the initial 90 day period, on receipt of shipping instructions, forward the equipment prepaid

to the factory or its authorized service center as instructed. If requested, an estimate of the

charges will be made before work begins, especially with those cases where the DEMTECH Services,

Inc. product is not covered by the warranty.

3.

If the original carton and packing are not available, the product should be packed in a container

with a strong exterior and surrounded by a protective layer of shock-absorbing material.

DEMTECH Services, Inc. advises returning the equipment at full value to the carrier.

DEMTECH Services, Inc. reserves the right to make changes in design at any time without incurring

any obligation to install the same changes on units previously purchased.

This warranty states the essence of the obligations or liabilities on the part of DEMTECH Services, Inc.

THE FORMAL, COMPLETE AND EXCLUSIVE STATEMENT OF DEMTECH SERVICES, INC.’S

WARRANTY IS CONTAINED IN ITS QUOTATIONS, ACKNOWLEDGEMENTS AND INVOICES.

DEMTECH Services, Inc. neither assumes, nor authorizes any person to assume for it, any liability in

connection with the sale of its equipment other than those set forth herein.

This manual suits for next models

1

Table of contents

Other Demtech Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics ICP 350C24 Installation and operating manual

KROHNE

KROHNE OPTIWAVE 6300 C Handbook

Lovato

Lovato DMG7000 instruction manual

PRECISION DIGITAL

PRECISION DIGITAL PD6800 instruction manual

Ampetronic

Ampetronic Loopworks R1 Quick-Start Guide & Handbook

Tenmars

Tenmars TM-197 user manual