Demtech Pro-Tester T-0100 User manual

Services

Inc.

Pro-Tester

TM

Model: T-0100

Field Tensiometer

Operator's Manual

Scope

of

Manual:

This manual contains procedures for general unpacking, installation, setup and operation

of

your

DEMTECH Services, Inc. tensiometer. Revision: B

DEMl)Cii

Rev

B:

December 2006

©

Copyright

2004-2007

by

DEMTECH

Services, Inc.

All

Right

Reserved

The text

of

this publication, or any part thereof, may not be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying, recording, storage in

an information retrieval system, or otherwise, without prior written permission

of

DEMTECH

Services, Inc.

Any software program contained within the Pro-Tester™for operation

of

this system is protected

by copyright laws that pertain

to

computer software. Use

of

this software does not authorize de-

compiling, disassembling or reverse engineering

to

gain access

to

the program code.

DEMTECH Services, Inc. does not authorize any copying, changing, or other use

of

this

software.

Notice

Patents have been granted and/or patent applications are pending or are in the process

of

preparation on all DEMTECH Services, Inc. developments.

The material in the manual is for informational purposes only and is subject

to

change without

notice.

DEMTECH Services, Inc. assumes no responsibility for any errors that may appear in this

manual.

T-Manual

RB

Printed in the USA

Manual Number:T-Manual

RB

DEMTECH Services, Inc.

6414 Capitol Avenue

Diamond Springs, CA 95619 U.S.A.

Telephone: (530) 621-3200

Toll Free: (888) 324-9353

Fax: (530) 621-0150

Web Site: www.demtech.com

Pro-Tester™ Operator's Manual

ii

Rev B: December 2006

DEMUECH

Table

of

Contents

Safety Precautions ........................................................................ iv

1.

General Product Data.................................................................... 1

2.

Site Preparation............................................................................. 2

3.

Installation Instructions ................................................................ 3

3

.1.

Unpacking and Preparation................................................ 3

3.2. Control Panel...................................................................... 5

3.3. Loading Samples ................................................................ 7

3.4. Settings ............................................................................... 8

4.

Elongation Definition ................................................................... 9

5.

Factory Servicing..........................................................................

12

6.

Appendix A, Product Brochure ....................................................

12

7.

Appendix

B,

Menu Tree ...............................................................

12

8.

Appendix

C,

Parts ID....................................................................

13

9.

Appendix D, System Wire Diagram.............................................

13

10.

Appendix E, Warranty..................................................................

13

iii

Pro-Tester™Operator's Manual T-Manual

RB

DEMl)Cii

Rev B: December 2006

Safety Precautions

Safety precautions for operating personnel:

WARNING

1:

Operating personnel should perform only the procedures described and

recommended in this manual. Only qualified service personnel familiar with electrical shock

hazards and mechanical entanglement hazards present inside the equipment should perform

disassembly or corrective maintenance

of

the equipment.

WARNING 2: To avoid shock hazards, the equipment must be grounded with an adequate earth

ground in accordance with local and national electrical codes.

WARNING 3: The locations

of

potentially dangerous voltages and other hazards are identified

and labeled on the equipment. Be careful

to

observe these warnings when installing, operating,

maintaining or servicing the equipment. Observe all warnings in this manual.

WARNING 4: Make sure

to

tum

off

the equipment power and remove the

~

(AC) line cord

from the power outlet before attempting

to

service the equipment. Do not perform service unless

you are qualified and trained

to

do

so.

CAUTION

1:

Observe the precautions given on the equipment and within this manual

to

prevent

damage

to

the equipment.

CAUTION 2: Before connecting the equipment

to

its electrical source, check that

the

~

(AC)

voltage, frequency and current

to

be supplied

to

the equipment are correct and match the serial

plate affixed

to

the system.

CAUTION

3:

Use proper handling and packaging procedures for Electro-Static Discharge

(ESD) sensitive circuit boards. Assume that all circuit boards are sensitive

to

potential damage

fromESD.

CAUTION 4: Unauthorized personnel should not remove from the equipment those panels that

are provided for protection and/or require a tool

to

remove.

T-Manual

RB

Pro-Tester™ Operator's Manual iv

Rev

B:

December 2006

DEMl)Cii

1.

General Product Data

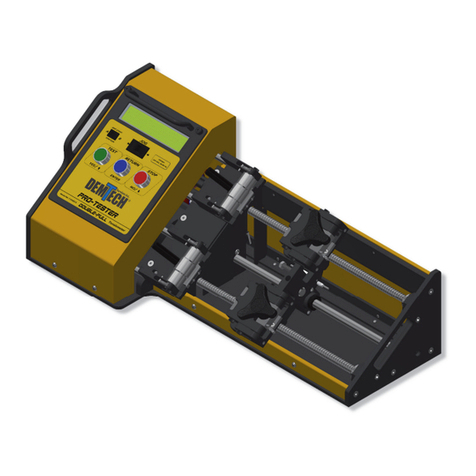

The DEMTECH Services, Inc. Pro-Tester™ Field Tensiometer, hereinafter referred

to

as the Pro-

Tester™, dramatically speeds the field testing

of

welded seam samples by providing a dual test

head configuration. This arrangement combined with state-of-the-art electrical and electronics

controls and an easy

to

use User Interface (UI) makes the task

of

performing field sample tests

much more efficient. The highly integrated and automated operation

of

the Pro-Tester™

eliminates cumbersome setup and speeds up process time while providing a very rugged and

reliable system. The one button operation combined with automatic return saves time. The

enclosed controller system is easy

to

maintain. You can be assured the Pro-Tester™ has been

built using the highest quality materials available which include Billet Aluminum and ground

and hardened steel. DEMTECH Services, Inc. strives

to

make our systems easy

to

use and built

to

last. Just like all other DEMTECH Services, Inc. products, even a first time user will be

productive in minutes. With easy adjustments and a one touch operation, you will be getting test

results within minutes

of

installation.

To operate and navigate the various features

of

the Pro-Tester™ simply follow the text prompts

at the bottom

of

the Liquid Crystal Display (LCD) screen. Significant development was spent

making the system very easy

to

operate by even a novice operator by simply following the screen

prompts.

For additional product information please refer

to

the product data sheet located in Appendix A

of

this manual.

Page 1 Pro-Tester™Operator's Manual T-Manual

RB

DEMl)Cii

Rev B: December 2006

2.

Site Preparation

Before proceeding with the installation instructions in the following section(

s)

make sure the

work site is prepared and ready

to

install the Pro-Tester™. You should have an adequate power

source capable

of

provided clean Alternating Current (AC) power at 110 or 220 Volts at the rated

current. Refer

to

the system serial plate affixed

to

the rear

of

the system for the voltage and

current requirements

of

your system. The install area should be clean, dry and free

of

debris and

provide adequate working area

to

allow efficient and effective use

of

the system.

Follow the detailed installation introductions carefully.

T-Manual

RB

Pro-Tester™ Operator's Manual Page 2

Rev

B:

December 2006

DEMl)Cii

3. Installation Instructions

This section contains instructions for the unpacking, placement and installation

of

the Pro-

Tester™. Carefully review the following information, sub-sections and each procedure before

beginning unpacking and installation

of

the system.

The Pro-Tester™ comes complete in a reusable portable shipping/transport container. The

system can be operated from within the container our removed and placed onto a work bench or

appropriate platform for use. When not in use the Pro-Tester™ should always be stored in the

shipping/transport container

to

protect

if

from the elements and potential damage.

Note: The system illustrated in this manual shows ALL available features for the Pro-

Tester™, therefore, your system may vary slightly in appearance from that depicted.

3.1. Unpacking andPreparation

1.

Before opening the shipping/transport container and unpacking the system, inspect the

outside

of

the container thoroughly for any signs

of

mishandling or damage during

shipping. Report any damage

to

the shipping carrier immediately and do not proceed

with unpacking. Since the shipment is made FOB factory, you should consult your

administration concerning claims for shipping damage. Please notify DEMTECH

Services, Inc. immediately in writing

of

any shipping damage.

2.

Unlatch and open the shipping/transport container lid and inspect inside the container and

equipment thoroughly for any signs

of

mishandling or damage during shipping. Report

any damage

to

the shipping carrier immediately and do not proceed with unpacking.

Since the shipment is made FOB factory, you should consult your administration

concerning claims for shipping damage. Please notify DEMTECH Services, Inc.

immediately in writing

of

any shipping damage.

3.

Make note

of

the orientation

of

the equipment and packing foam inserts inside the

shipping container

to

facilitate any repackaging requirements in the future.

Page 3 Pro-Tester™ Operator's Manual T-Manual

RB

DEMl)Cii

Rev B: December 2006

4.

To avoid injury and/or damage

to

the system, be sure

to

use adequate care when lifting,

removing or replacing the system into the shipping/transport container.

5.

You may operate the system from within the shipping/transport container or remove it

and place it in an appropriate location suitable for the testing you intend

to

perform.

6.

Verify proper operation

of

the Pro-Tester™ before proceeding with the remainder

of

the

installation. The Pro-Tester™is equipped with a "soft-start" feature. This feature utilizes

a toggle power switch on the rear

of

the system. Toggle the switch up

to

tum the system

ON. Toggle the switch down

to

tum the system OFF. This feature provides a built in

safety

to

protect the system during connection

to

a field generator by automatically

turning the power

off

to

the system any time AC power is disconnected either by turning

off

the generator or unplugging the power cord. Upon startup generators can produce

significant power surges which can be harmful

to

the Pro-Tester™. This soft-start feature

eliminates ill effects from this phenomenon. Find the Power Cord included with your

system and plug one end into the appropriate connecter at the rear

of

the system (refer

to

Figure

1).

Plug the other end into an electrical outlet supplying the proper

~

(AC)

power.

Toggle the Power Switch

to

the ON position (refer

to

Figure

1).

T-Manual

RB

Power Cord

with IEC 60320

Connector

Figure 1

Pro-Tester™ Operator's Manual

Power

ON/OFF

Switch

Fuse

Holder

Page 4

Rev B: December 2006

DEMl)Cii

7.

The system LCD should light up, go through a self-diagnostic test and then prompt the

user to press ENTER to initiate the initialization/calibration sequence. Press ENTER

to

perform the initialization/calibration procedure. For proper operation

of

the Pro-Tester™

do not HALT or skip this procedure.

The system will first move the grip heads in (left) to find the home position, then out

(right) to calibrate travel speed. After a short pause the grips will then move back in

(left) and stop at the A

orB

grip separation position depending on which is selected on

the Control Panel. This procedure verifies the Pro-Tester™is in good working condition.

If

the system performs as described you are now ready to operate the system.

If

the

system does not perform any

of

the functions described above please contact DEMTECH

Services, Inc.

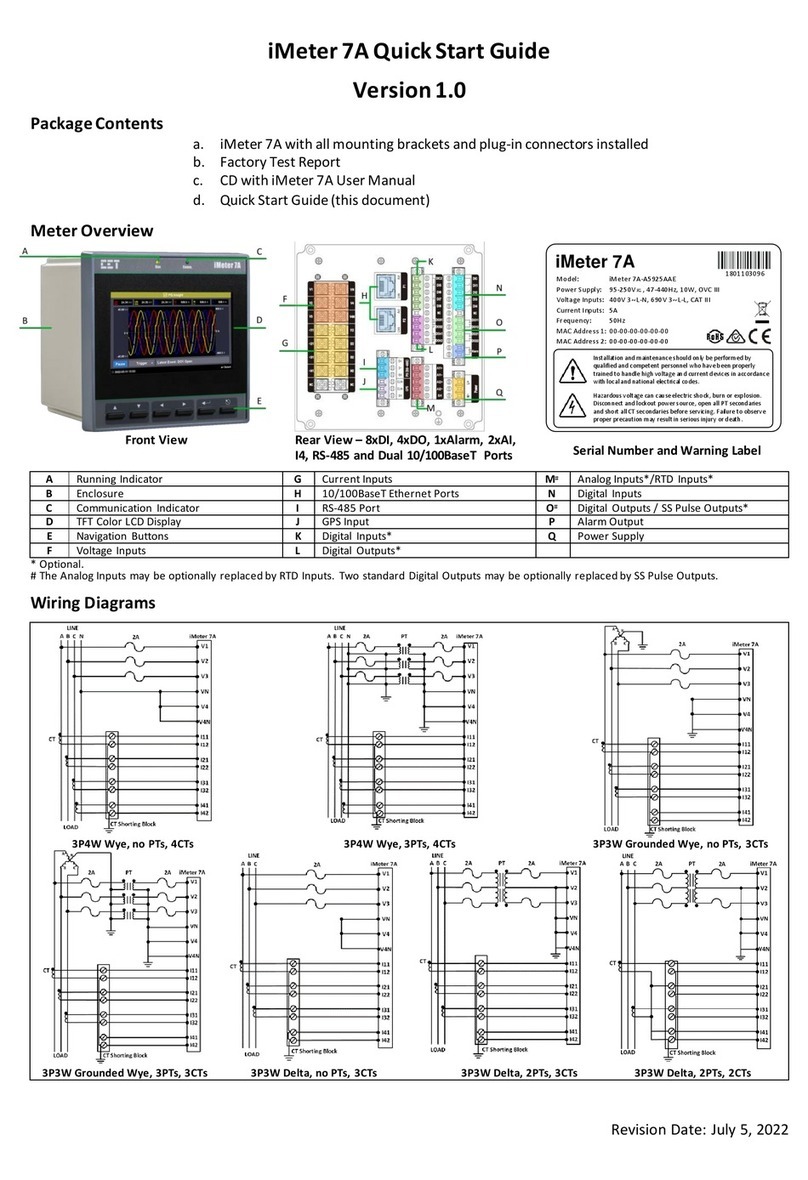

3.2. Control Panel

The User Interface Control Panel is the main operator interface device for operating the Pro-

Tester™. Each component

of

the Control Panel is identified below (refer to Figure 2).

1.

Liquid Crystal Display (LCD): The LCD is a 40 Character by 4 Line display device

which provides main system operation information for the Control Panel.

It

provides all

key operating information and allows the user to input various system settings.

2.

JOG

¢:1

/¢ : This switch allows the user to

jog

(move) the movable sample grips at an

accelerated rate in and out during setup and operation

of

the system and is used to change

various settings during Menu Mode operation (refer to Section 3.4).

3.

Grip Start Position Toggle Switch

AlB

: This switch allows the user to select between

one

of

two grip separation settings. This allows quick transition from one separation

length to another. Grip separations A and B can be set through the Menu Mode (refer

to

Section 3.4).

4.

Test/Yes/

D'

: This button is used to initiate a Test or in Menu Mode to navigate the screen

tree.

5.

Return Enter: This button is used

to

return the grips after a test or in Menu Mode to

navigate the screen tree.

Page 5 Pro-Tester™ Opera

tor's

Manual T-Manual

RB

DEMUECH

Rev

B:

December 2006

6.

Stop/No

/-

0.

: This button is used

to

stop a Test or in Menu Mode

to

navigate the screen

tree.

1

2

3

in

then

Pre

ss

T

EST

to

be9i.n.

4

Ill

5

PRO-TESTER

6

Figure 2

T-Manual

RB

Pro-Tester™Operator's Manual Page 6

Rev B: December 2006

DEMl)Cii

3.3. Loading Samples

Loading samples is very simple with the Pro-Tester™. To load a sample open both jaws

of

the sample grip assemblies. The left grip is a cam clamp and is opened by toggling the cam

handle

to

the right (open). The right grip is a screw clamp and is opened by unscrewing the

tri-handle counter-clockwise (open). The sample is prepared by bending the ends

to

be

clamped

so

they can be easily loaded into the grips. Load the sample from the top

of

the grip

until the sample rests against the stop tabs then apply the left and right grip clamps (refer

to

Figure 3).

Stop Tab

Figure 3

Page 7 Pro-Tester™Operator's Manual T-Manual

RB

DEMliCH

Rev

B:

December 2006

3.

4.

Settings

The Pro-Tester™ requires various settings for proper operation. These settings are easily

accessed via the Menu Mode

of

operation. To enter the Menu Mode make sure the Pro-

Tester™ is on and at the main operating screen (Refer

to

Appendix B). Simultaneously press

and hold the YES and NO buttons on the Control Panel for several seconds. This procedure

puts the system into Menu Mode. This mode

of

operation allows the user the set various

system parameters. For a complete listing

of

all

of

the features refer

to

Appendix B located

at the back

of

this manual.

All

of

the settings required

to

operate the Pro-Tester™ come factory set for most users and

should not need setting. However,

if

your particular installation requires setting any

parameters enter the Menu Mode and follow the screen prompts

to

navigate the screen menu.

Appendix B is a Menu Tree drawing. This drawing can be very helpful

if

you are trying

to

find a particular function or setting you wish

to

access. Use the drawing

to

locate the

particular item you want

to

access. Once located, follow the tree back

to

the top level. Next,

utilizing the user interface on the Pro-Tester™, proceed back down through the menu

structure using the drawing as a guide

to

access the particular screen you want.

T-Manual

RB

Pro-Tester™ Operator's Manual Page 8

Rev

B:

December 2

00

6

DEMl)Cii

4. Elongation Definition

If

you intend to use the strain (elongation) feature

of

the Pro-Tester™ tensiometer it is important

to understand both the definition

of

this feature/function and how it is intended to be used.

Proper understanding requires the definition

of

some basic terms. These terms are defined

below.

Grip Separation (GS): The distance between the grip point

on

each

of

the left and right

sample grip assemblies (refer to Figure 4). There are two user settable distances, A or B,

which have been factory set for 1.7 and 3.5 inches respectively. The operator must be aware

of

these values and change the settings

if

necessary (refer to Section 3.4) to accommodate the

particular sample to be tested.

Weld Extrusion (Squeeze-out): The area

of

a weld whereupon becoming molten the parent

material extrudes (is squeezed) out from between the pressure zone

of

the welding tool and

then cools. This extruded material does not usually provide an acceptable bond

of

the parent

material and should not be considered part

of

the weld (refer to Figure 5C).

Weld Width (WW): The center-to-center distance between the two welds

of

a dual-track

weld (refer to Figure SA) or the edge-to-edge distance on a solid weld (refer to Figure 5B). It

is important when measuring/calculating these distances that the operator only include the

actual width

of

the weld. The width

of

the weld is defined as only that area where the two

sheets

of

parent material have been appropriately bonded by both heat and pressure. During

this process some parent material may extrude beyond the pressure zone

of

the welding tool

(refer to Weld Extrusion definition). This extruded material does not usually provide an

acceptable bond

of

the parent material and should therefore be excluded from any

measurements made for this test.

Gauge Length (GL): This is the base value used by the Pro-Tester™ for determining

elongation percentage. It is the Grip Separation once the initial tension value has been

reached minus the Weld Width

(GS-

WW

= GL). For example

if

your Grip Separation was

4 inches and your Weld Width was 1 1/2 inches then your Gauge Length would be 2 1/2

inches (4 -1.5 = 2.5). It is this value that is used to determine elongation. Elongation is

calculated as the percentage

of

change (increase)

of

the Grip Separation related to Gauge

Length. For example

ifyour

Gauge Length is 2 1/2 inches and the grips had separated 1 1/4

inches at the completion

of

your test then the elongation would be 50% (1.25 I 2.5

=.50).

If

Page 9 Pro-Tester™Operator's Manual T-Manual

RB

DEMl)Cii

Rev

B:

December 2006

your Gauge Length is 2 1/2 inches and the grips had separated 2 1/2 inches at the completion

of

your test then the elongation would be 100% (2.5 I 2.5 = 1.00).

It is on this basis that the Pro-Tester™ has been designed and programmed to operate when

performing elongation testing.

d>

' I I

c<<<

c::<<J

~~

I

©

/x

~

/x

~

/

v

£:::

~

0

~ ~

I I

~

~

\"

--

'

X><'

:XX

>Q¢

(

V'L.

kYX

><rr

l I

~

l

wxx

~

GRIP

SEPARATION

---i-----____,~

Figure 4

T-Manual

RB

Pro-Tester™ Operator's Manual Page

10

Rev B: December 2006

+

+

l

~

r

Page

11

DEMUECH

w

WFI

rJ

WlrJH-

1--------

GRIP

SEPARATION----

A

H

~

WCLD

WIDTII

~

GRIP

SEPARATION

B

W

ldE

e xtrus10n \

(Squeeze-out) I

I

~

I Q

I

c

Figure 5

Pro-Tester™ Operator's Manual

+

g;;::..

T-Manual

RB

DEMUECH

Rev

B:

December 2006

5. Factory Servicing

In the event your Pro-Tester™ should require factory service, the entire system needs to be

returned to the factory. Refer to the following step for preparing the Pro-Tester™ for return.

Carefully pack the Pro-Tester™in the shipping/transport container provided with the system for

return to DEMTECH Services, Inc.'s factory for service. Unless previous arrangements are

made shipping charges and insurance are your responsibility. Ship the Pro-Tester™ to

DEMTECH Services, Inc. at:

6414 Capitol Avenue

Diamond Springs, CA 95619

U.S.A.

6. Appendix A, Product Brochure

Refer to Appendix A for the Pro-Tester™ Product Brochure.

7. Appendix B, Menu Tree

Refer to Appendix B for the Pro-Tester™ Menu Tree drawing. This drawing can be very helpful

if

you are trying

to

find a particular function or setting you wish to access. Use the drawing to

locate the particular item you want to access. Once located, follow the tree back to the top level.

Next, utilizing the user interface on the Pro-Tester™, proceed back down through the menu

structure using the drawing as a guide to access the particular screen you want.

To enter the Menu Mode make sure the Pro-Tester™ is on and at the main operating screen

(Refer to Appendix B). Simultaneously press and hold the YES and No buttons on the Control

Panel for several seconds.

T-Manual

RB

Pro-Tester™ Operator's Manual Page

12

Rev

B:

December 2006

DEMl)Cii

8.

Appendix

C,

Parts ID

Refer

to

Appendix C for the Pro-Tester™ Parts

ID

drawing. This drawing can be very helpful in

identifying components and sub-assemblies

of

the Pro-Tester™ should you ever need

to

replace

these items.

9.

Appendix D, System Wire Diagram

Refer

to

Appendix D for the Pro-Tester™ System Wire Diagram. This drawing can be very

helpful in identifying and/or troubleshooting basic wiring or interconnection issues related

to

the

Pro-Tester™.

10. Appendix E, Warranty

Refer

to

Appendix E for the Pro-Tester™ Product Warranty.

END OF MANUAL

Page

13

Pro-Tester™ Operator's Manual T-Manual

RB

Demtech is proud to introduce the next generation

in destructive seam testers

......

.

The

Pro-Tester

The ultimate Tensiometer for peel, shear,

and

tensile testing of geosynthetic materials.

Just a few

of

the many awesome features:

• Lifetime calibration on microprocessor, GUARANTEED!

• Simple to operate. Large push-button controls and on-screen instructions.

• Fast. Two sets

of

grips, two preset grip return positions, fast "jog" switch, auto stop/return.

• Versatile. Unique grip design for standard 1 inch bones and 4 inch "grab" tensile.

• Accurate. Independent load cells. Test results for both coupons shown on backlit LCD display.

• Cost effective. Cuts pre-weld and destructive sample testing time in half!

Call "Demo" Dave McLaury for more information at (888) 324-WELD

Another

quality

product

proudly

Designed

and

manufactured

in

the

USA by:

DEMTECH Services, Inc. • P.O. Box 2165, Placerville, CA 95667 • 6414 Capitol Ave., Diamond Springs, CA 95619

www.demtech.com • (888) 324-WELD (9353) • (530) 621-3200 • Fax: (530) 621-0150 • demodave@demtech.com

8 I 7 I 6 I 5 • 4 I 3 I l"w•

f:ooo,

APPENDIX

B IT I"8I 1

P

RO

P

RIH

A

RY

D

AT

A NOTICE

RE

V

IS

ION

~IS

TORT

This

doc

ume

nt

,

pre

par

ed e

xc

l

usi

vely f

or

DEM

TEC

H Sc rvlces

TO

ENTER

OR

EXIT

THE

MENU

MODE

ZONE

IR<v.l

I I A

PPR

OVED

i'l

c.,

"

ts

t

~

~

ro

pc

rt

y

crf

DE

MrECH

Serv

i

ces

i'lc

. and

a

~

su

ch DES

CR

IPTION

DATE

lilh<l

ll

b~

::!lu

rn:

ndcred

t

~:J

:

~m

r

nt'

up

oo

rll"q~

c.,

l.

rhi'

ck

>eu

mm

t

MENU

ENTRY

POINT

SIMULTANEOUSLY

PRESS

THE

YES

ALL

I A I OP

ERATOR'S

MANUAL,

APPENDIX

8 1

os;oo;os1

lSD

c

ontain

s c

onfi

den

ti

al and

pro

priet

ary

in

f

orm

oHon

and

1

11

c

dat a di

sc

bsed h

erei

n

or

he

rc

w"tlh

is not to

be

re

produc

ed,

MENU

LOOPS

AND

NO

BUTIONS

u'

"'

d, or

d

l~lo

:~ed

in whol

e>

or in

pq

rt.

t<

J

<my

t hird

per

'on

ALL

B

REVIS

E

MENU

lREE

01/22/07 lSD

or

ent

ity

in

any

manne

r wi

th

out

pr

i

or

written

~

rm

ls&i

o

n

1rom

DE

MTEC

H Services I

nc

..

TO

END

SYSTEM

STARTUP

D

SEQUENCE

f J D

UP

DEMT.,~h

In~orPorat

..d

Pro-T

..

~ter

GriP

Trave

1 SPeed

ENTER

Curl"'ent.

trave

1

sreed

is=

2

in/min

YES

GriP

Travel

SPeed: 2

in/min

</>

l

ENTER

a~~

..

Pt

~Yrr~nt·

NO:

menY

Version

1·

1

of

38-RUG-86

16•23•21

Press

ENTER

to

Ml"d·

WoYid

"o"

lik•

to

chan9"

it?

Pr•ss

</>

to

.adjust

SP@IH'd•

COPYr

i

9ht

2006

PI"I!SS

UP

fOI"'

P't"'@V

i OU:!.,

DOWN

for

M><l·

Prl!ss

YES

to

ehan91!,

NO

fol"

Menu.

DOWN

NO

I

NO/ENTER)

I'

'

UP

! J

Load~ell

Statu~:

GriP

SeParation

R

ENTER

C...rrent

R

seParation

di~

tan~e:

l·o

in

YES

GriP

S..

Parat

ion

R:

1·0

in

<I>

UPPER:

SERNUM001

is

9ood·

l VES:

us•

actual

;riP

s•Parat..ion

NO:

m•n

LOWER:

SERNUM002

is

good.

Prl!ss

ENTER

to

S4!

I

l!et·

Would

"o"

like

to

chang~

it?

ENTER:

~""""t

~YI"I"ent

SI!Parat

ion

Pre~~

RETURN

to

initializl!

s':lsten~~.

PI"

..

SS

UP

for

Pr-evious.

DOWN

for

ne><t. Pr-ess

YES

to

c.han9e,

HO

for

Menu. Pre-ss <./) t.o

.adjust.

seParation.

DOWN

NO

I

YES/NO/ENTER

J

I"'\

UP

f J

Loadcell

Statu~:

GriP

5•Par.ati

on B E

NTER

C~rr•nt

B

s•Par.ation

distan

c.

•=

2·

5

in

YES

GriP

S&oP.aration

B=

2·5

in

</>

UPPER:

SERNUM001

is

good.

r 't'ES: U:!.il!'

aetual

9riP

seoParat.ion

NO:

m•n

LOidER:

SERNUM002

is

9ood.

Pl"ess

ENTER

to

Ml!!et.

lalould

'='OU

lilce

to

c;lrl..,9eo

iL"?

ENTEA: l=lc.c.ePt

current

seParat.

ion

GriP

Calibration

--

Pr""

STOP

to

halt·

Pres~

UP

for

Prev

i

o1.1s.

DOWN

for

n"><t•

Press

'r'ES

to

c.han91e~

HO

for

menu•

Press

</>

t.o

adjust.

seParation•

DOWN

NO

I

YES/NO/ENTER

J

I"

'

c

UP

( J c

MAIN

OPERATING

UPPER:

PE~K: STR~INo

%:

r s

...

st~m

Unit~

ENTER

Cul""rent. sYstem L.-1

it.s

ar-e:

YES

5Y~1.1!M

Ynits:

<I>

LOidER:

PERK:

STRRINo

%:

POL.tnds

and

inches

Pounds

iWld

inches

SCREEN

POS:

in

SPD:

2

in/min

Pres~

ENTER

to

sel!!et•

WoYld

"o"

lik"

to

~an9e

them?

EHlER:

ac;c.ePt..

curr-ent.•

t«l= me,...

Load

samPL.,(s)

then

Pres~

TEST

to

b~9in·

Pr

..

~s

UP

for

Pr-evious.

DOWN

for

n~><t•

Pres~

YES

to

~han9e,

NO

for

m"n"·

Pres~

</>

to

si!Le~t

Ynits.

DOWN

NO

I

NO/ENTER)

r'

UP

(

SriP

Alut.o

Ret~.rn

ENTER

SriP

aut.o

l"'el.ul"'n

is:

YES

YES/NO

l

Press

ENTER

to

Mll!et•

Pri!SS

VES

or

NO

to

~hang.,.

___.

Pr&ss

UP

for

Pr&vious,

DOWN

for

n•xt..•

Pr•ss

EHTER

to

a~

c

..

Pt

•

._

DOWN

ENTER)

I'

'

UP

f

Test

Auto

Tension

ENTER

Test

auto

tension

i~:

VES

YES/NO

r

Press

ENTER

to

S4!

I

l!et·

Prl!ss

YES

or

NO

to

chang.,.

PI"I!SS

UP

fOI"'

P't"'eVi OU:!.•

DOWN

for

ne><l·

Pr~ss

ENTER

to

ae~~Pt.

DOWN

ENTERJ

I"

'

B

UP

f J B

Thr•shold

El

o

n9ation

Tl!flsion

Current

•lon9ation

threshold

i~=

Elon9ation

Thr!!sholcl:

10

lbs

ENTER

10

lb

YES

<I>

[

Prl!ss

ENTER

to

Mll!et•

Would

YOY

lik"

to

chang~

it?

ENTER

aeei!Pt

~Yrrent.

NO:

menu

PI"'IE!'SS

UP

for

Pl"'evious.

DOidN

fol"

ne><t. Pl"'ess

YES

t.o c.han9e.

HO

fof" menu. Pl"'ess

<I>

to

aciJu~L

Ure~olcl.

DOWN

NO

I

NO/ENTER)

I"

'

UP

f J

Weld Wiclth

ENTER

Current

weld

width

is=

YES

Weld

Width•

1

in

<I>

r 1

in

Pl"ess

ENTER

to

Mll!et.

lalould

'='OU

lilce

to

cl-liW19eo

iL"?

ENTER

.ac.c.ePt cul"t"'ent.

HO:

met'lu

Pres~

UP

for

Previous.

DOWN

for

n"><t•

Press

'r'ES

to

c.han91e~

NO

for

menu•

Press

</>

to

aciJYst

width·

DOWN

NO

I

NO/ENTERj

r'

UP

Loade~ll

Information

ENTER

UPP~r

Loac:le~ll:

TCMR1234567

ENTER

Low""

Load~"

II:

TCM~

1234567

ENTER

l

Calibration

dat"'

2/21'/20B!i

Calibration

date:

12/21'/2886

Press

ENTER

to

sel!!et•

Offset=

I·

23456E-01

S~al•=1·23466E-el

Offs•t=l·

23456E-01

Scale=

I·

23456E-01

J

Pri!SS

UP

for

Pr-evious,

DOWH

for

ne><l· Pri!SS

ENTER

to

vi~w

info

f or

lowl!r

Cl!ll·

Pre~s

ENTER

to

ret...rn

to

m~oo.

DOWN

I"

"'\

UN

LE!I:l

0111E

RWI

SE

:lP

ECI'lED

DIMEN:SOK

:!.

AA

E

CONT

R

A~T

NC.

DEM-aEH

AA n I

NCHe;

.

I

NTt:~

DIM

~

~

~

AND

N/A

2.

TO

ENTER THE MENU MODE MAKE SURE THE

PRO-TESTER

IS ON AND

AT

TH

E MAIN OPERATING

TOI.EPANCES

PER

AS

ME

Y1

+.~

hl

-

19a

4

Placerville, Csllfomla

:il

AHQA

Rtl

T

OLE

RAN

~~

S:

SCREEN. SIMULTANEOUSLY PRESS THE YES

AND

NO BUTTONS.

ClE

C

I"'Al5

~~~~~~

E

±

F

I~~5

H

1

2

~

MENU

LOOPS

JIX

± .02. TI

TLE:

TO

BEGINNING

Jl)()( ±

.00~

F

R

ACTI

O

~

S

t

1/1

15

"'PPRO

VAL'S

C

"'TE

MENU

TREE,

1. THIS DRAWING DEPICTS THE MENU SCREEN STRUCTURE

FOR

THE DEMTECH

PRO-

TESTER PRODUCT. l.i

AT

£

RI

A.

L

N/A

DRAWN

USE THIS

DRAWING

TO

LOCATE A PARTICULAR FUNCTION

OR

SETTING YOU

WISH

TO

ACCESS. ONCE

lSD

ps;os;o~

LOCATED FOLLOW THE TREE BACK

TO

THE TOP LEVEL. NEXT, UTlLIZING THE USER INTERFACE

ON

THE CHEt:II\

ED

DEMTECH

PRO-

TESTER

P

RO-

TESTER, PROCEED BACK

DOWN

THROUGH THE MENU STRUCTURE USING THIS DRAWING AS A

F

INI

S ~

N/A

GUIDE TO ACCESS THE PARTICULAR SCREEN YOU WANT. ISSU

E:D

'61

NJA

ID

WOT

N

O.OOO,

I

'Ei

OESJGN

APPENDIX

B

NOTES

(UNLESS

OTHERWISE SPECIFIED):

DO

NOT SCALE DRAWING

lSD

P6/0B/O!

5CAL

£ 1:1 I

IsH

E

fT

1

OF

1

8 I 7 I 6 I 5 t 4 I 3 I 2 I 1

D

c

B

A

8

PROPRIF

'on

and

1hc

da

ta

dis

cbsed

herein

or

here

w"tlh

is not

to

be

re

prod

uce

d,

u'

"'

d, or

d

l~lo

:~

ed

in

wh

ol

e>

or

in

pqrt.

t<

J <my t hird

per

'on

or

ent

ity

in any

ma

nner

wi

th

out

pr

ior

written

~

rm

ls

&ion

1rom D

EMTECH

Services I

nc

..

REFER

TO

DETAIL

1

1. 8 SYMBOL

DESIGNATES

ITEM/QUANTITY BALLOON.

UPPER

DIGIT

IS

ITEM

NUMBER,

LOWER

DIGIT

IS

QUANTITY

REQUIRED

PER

ASSEMBLY.

NOTES

(UNLESS

OTHERWISE

SPECIFIED):

8 7

4

6 5 4

3

ALL

A

OPERATOR'S

MANUAL,

APPENDIX

C

lSD

ALL

B

ADD

T-027,

GRIP

TO

STRAIN

GAGE

ASSEMBLY

DETAIL

01/22/07

lSD

36

STOCK

35

T-096A

34

T-065

33

T-035

32

T-026

31

T-025

3D

T-024

29

T-D23

28

STOCK

27

STOCK

26

STOCK

25

STOCK

24

STOCK

23

STOCK

22

STOCK

21

STOCK

20

STOCK

19

T-109

18

T-1D7

17

T-1D6

16

T-1D5

15

T-10J

14

T-101

13

T-100

12

T-097

11

T-OBB

10

T-087

9

T-086

8

T-072

7

T-066

6

T-059

5

T-057

4

T-D56

T-028

2

T-027

T-022

Item Part Number

BOLT,

1.48

X

1.25

X

70mm

LONG,

HEX

HEAD

CAP,

SS

LOAD

CELL. TENSION

COt.APRESSION,

500

L.B

STANDOFF,

STRAIN

GAUGE

BRACKET

SAt.APLE

GRIP

ASSEt.ABLY,

CA1o4

STYLE

PIN, QUICK RELEASE,

1/2"

DIA

X

1.3"

GRIP LENGTH, ZINC

PLATED

STEEL

ROD

END,

STRAIN

GAGE,

MODIFIED

BRACKET,

STRAIN

GAGE,

MOUNT

BRACKET,

STRAIN

GAGE,

GRIP

ASS!

SCREW,

SHOUUDER,

3

8"

OD

X 1

4"

LONG,

SS

SCREW,

MS

X

1.25

X

20mm

LONG,

FLAT

HEAD

CAP,

SS

SCREW,

M6

X 1 X

Bmm

LONG,

BOTION

HEAD

CAP,

SS

SCREW,

M6

X X

20mm

LONG, SOCKET

HEAD

CAP,

SS

SCREW,

M6

X X

20mm

LONG, FlAT

HEAD

CAP, SS

SCREW,

M6

X X

14mm

LONG, FlAT

HEAD

CAP,

SS

SCREW,

1.45

X

.8

X

12mm

LONG,

BOTION

HEAD

CAP,

SS

SCREW.

1.410

X

1.5

X

16mm

LONG.

SOCKET

HEAD

CAP.

SS

NUT.

M4 X .7 HEX,

NYLON

INSERT LOCKING. ZINC

PLATED

STEEL

MOTOR

SUPPORT

PLATE

ASSEMBLY

SHAFT

CARRIAGE

PLATE

ASSEMBLY

GUID

E

SHAFT

SUPPORT ASSEMBLY

RIGHT

SIDE

PLATE

ASSEMBLY

LE

FT

SIDE

PLATE

ASSEMBLY

MAIN

BASE

PLATE

ASSEMBLY

SHAFT,

STIFFENER

SNAP

RING,

1

Omm

EXTERNAL,

HEAVY

DUTY

COVER,

BELT

DRIVE,

INSIDE

COVER,

REAR

COVER,

FRONT

HOUSING,

MAIN

CONTROL PANEL

SHAFT,

GUIDE,

LINEAR

BEARING

PULLEY,

10

TOOTH

X

3/B"

PITCH,

10mm

BORE,

AILUMINUM

W/

FlANGES

SCREW,

5

8"

X

.20"

UEAD,

GRIP

DRIVE

CONTROLL

E

R,

1/2

HP,

INVERTER

DUTY

MAIN

CONTROL PANEL ASSEMBLY

GRIP

TO

STRAIN

GAGE

ASSY

SAMPLE

GRIP ASSEMBLY,

TENSIOMETER

Title Descri tion

Parts List

UNLE:I:l

0111ERWI

SE :'iPECI'lED

DIM

EN:SOK:!.

AAE

CONT

R

A~T

NC.

DEME'H'"~

n i

NCH

e;.

I

NTt:~

DI

M~

~

~

AND

TOLEPANCES

PE

R

AS

ME

Y1

+.~hl-19

a

+

N

/A

STANDARD TOLERANC E

S:

~~

r;;

~~~S:C.

~~~~~~

E

±

F

I~~5H

1

2~

1-----.f._---,-----11-;T;T

I

TL"E----------------------j

Placerville, Csllfomla

t.t:~~R~A~oo~

FRACTI O

~S

t 1 HI

~PPROVAL'S

C~TE

PRQ-

TESTER

SEE

DRAWN

PAATS

LIST

CHEmo

lSD

12128106

TENSIOMETER

PARTS

10

N/A

F

INI

S ~

ISSUE:D

SIZE:

"'·

lSD

OESJGN

DO

NOT SCALE

DRAWING

12/28/06

SCALE

D B

3 2

D

c

B

A

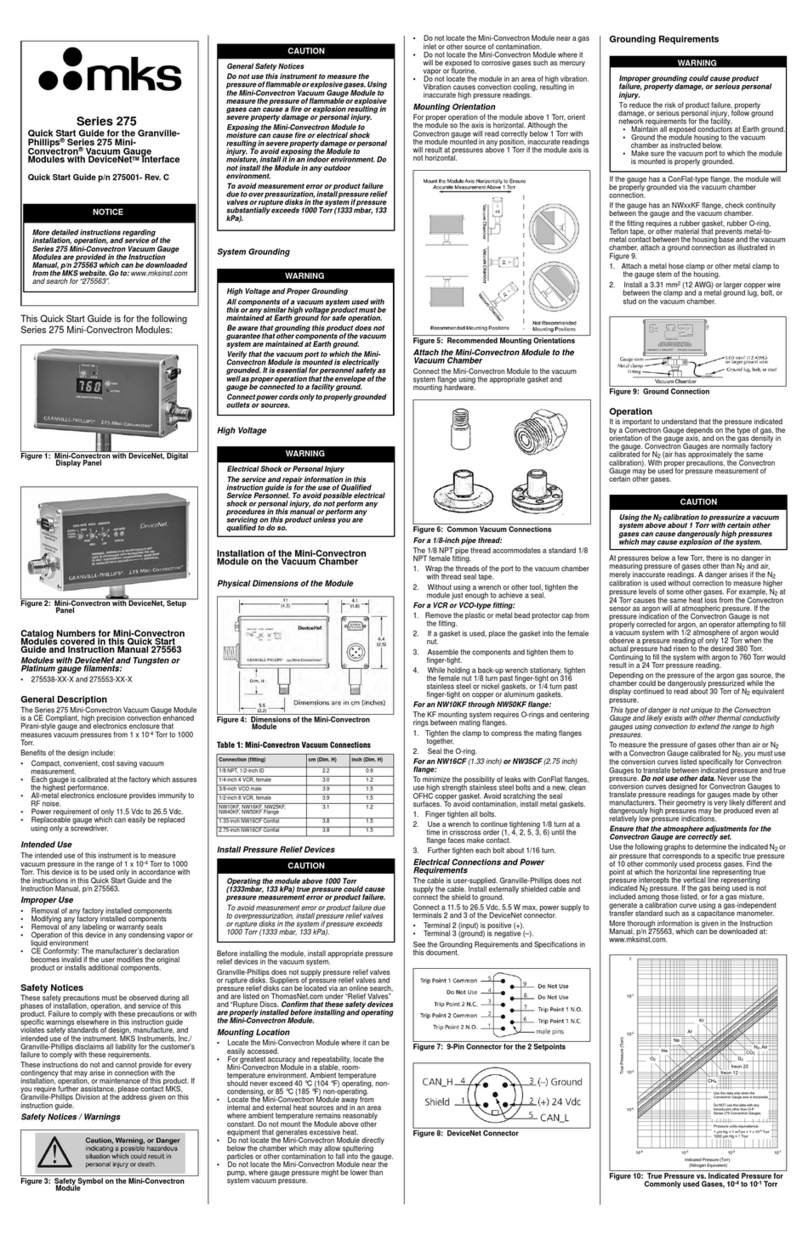

Table of contents

Other Demtech Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

MKS

MKS Granville-Phillips Mini-Convectron 275... quick start guide

ETI

ETI 6500 user manual

Contrel

Contrel EMM-4h instruction manual

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-734 quick start guide

Tegam

Tegam 1830A Instruction and service manual

BRONKHORST

BRONKHORST EL-FLOW Select Series Quick installation guide