Den-Sin HB-200 Guide

www.densin.com

USER GUIDE & SPARE PARTS MANUAL

HB-200

ELECTRICAL POWERED

HEAVY DUTY HOT WATER

HIGH PRESSURE CLEANER

Introduction

HB-200 V00 Page 1

Introductions

Congratulations on your purchase of the DEN-SIN High Pressure Cleaner.

Model: HB-200

Read this user manual before you start up your High Pressure Cleaner the first time.

This document or part of it may not be photocopied, or in any other way reproduced, or

translated to other languages without the prior written consent of DEN-SIN.

This machine is a High Pressure Cleaner producing water jet under high-pressure, which is

why severe injuries can occur if the safety precautions are not observed.

Therefore a full understanding of the contents of this instruction manual is required, in order

to prevent injuries to you, objects and persons near-by.

Safety

The following symbols are used in this manual to indicate procedures that if not followed,

may results in personal injuries or damage to equipment.

The information contained in this user guide is subject to change

without notice.

Version 00: May 2015

Revision History

Date

Revision

Rev.No.

WARNING is used to alert the reader of procedures or

practice which if not followed correctly could result in personal

injuries.

WARNING

CAUTION

CAUTION is used to alert the reader of procedures or

practice which if not followed correctly could result in damage

to machine or other equipment.

NOTE is used to highlight important information that may

assist the reader carrying out the procedure or understanding the

text.

NOTE

NOTE

Table of Contents

HB-200 V00 Page 2

Table of contents

Introductions...............................................................................................................1

Table of contents..........................................................................................................2

Specifications ......................................................................................................................... 3

Applications............................................................................................................................ 3

Unpacking .............................................................................................................................. 4

Installation.............................................................................................................................. 4

ID-plate................................................................................................................................... 7

2. Safety and protection information.............................................................................8

General safety & application guidelines ................................................................................ 8

Safety devices......................................................................................................................... 8

3. Maintenance and troubleshooting.............................................................................9

Maintenance ........................................................................................................................... 9

Troubleshooting.................................................................................................................... 10

Boiler Servicing and Maintenance / 200hrs*....................................................................... 11

4. Accessories List......................................................................................................12

Chassis assembly.................................................................................................................. 12

Chassis assembly spare-parts list ......................................................................................... 12

Electrical Box assembly....................................................................................................... 13

Electrical Box assembly spare-parts list............................................................................... 13

Boiler assembly.................................................................................................................... 14

Boiler assembly spare-parts list............................................................................................ 15

Wiring diagrams................................................................................................................... 16

5. Declaration and Warranty......................................................................................17

EU declaration of conformity............................................................................................... 17

Warranty............................................................................................................................... 17

6. Spare Parts Request Form...................................................................................... 18

7. Maintenance Log Book...........................................................................................19

1. Getting acquainted with your High Pressure Cleaner

HB-200 V00 Page 3

1. Getting acquainted with your High Pressure Cleaner

Fast and efficient cleaning

The DEN-SIN high-pressure hot-water cleaners in the HB-200 series enables you to get more

cleaning done in less time.

This series of DEN-SIN high-pressure cleaners offers you high performance yet a compact

design. The compact design enables the machines to be agile within inconvenient places, and

the high performance and possibility to use hot water gives you the opportunity to solve an

array of cleaning tasks. The high-pressure cleaners in this series are designed for industrial use

as well as for cleaning contractors.

Specifications

Model

Working

Pressure

Flow Capacity

Power Supply

Dimension

LxWxH

Weight

psi

Bar

gpm

l/min

Voltage

mm

kg

HB-200

2900

200

5.5

21

230 / 1ph / 50Hz

940x650x900

44

Applications

These heavy-duty high-pressure cleaners are capable of removing any kind of dirt:

Algae off concrete constructions

Paint and graffiti off walls

Dust, dirt, soil & mud off floors

Oil & grease off engines and other mechanical parts

Dirt and salt deposits off ship decks

The High pressure cleaner has built in chemical injector

And with the option for use of accessories even many more jobs are to be dealt with:

Sand-blasting

Drain-cleaning

Dispensing of soaps and chemicals

Floor cleaning equipment

Rotary brushes

This machine is only to be used for the purposes it is designed for. Any other

use shall be considered improper and therefore potentially dangerous. The

manufacturer is not to be held responsible for any damages caused by improper

use.

CAUTION

1. Getting acquainted with your High Pressure Cleaner

HB-200 V00 Page 4

Unpacking

Remove the high-pressure cleaner and its accessories from the packing material. For transport

and packing reasons some accessories may be supplied disassembled.

Make sure all components are present:

Machine

Electrical cord (attached)

10m High pressure hose w/ Male and Female Quick Coupling

Machine Installation / Setup

Step 1: Ensure machine is place on a flat floor or inclined position not more than 10.

Step 2: Insert the male quick coupling end of the high pressure hose (included) into the inlet

female quick coupling of the machine and connect the female quick coupling end to the outlet

of the cold water machine.

Step 3: Connect the complete assembled spray lance and trigger gun of the cold water

machine and insert the female quick coupling end to the outlet male quick coupling of the

machine.

Step 4: Plug in the power-plug into a main power supply socket and turn on the power.

Switch on both the high-pressure cleaner and HB-200 by depressing the on/off switch.

Inlet of HB-200

Connect to Inlet of

HB-200

Connect to outlet of

cold water machine

10m Hose w/ Male and Female

Quick Coupling

Outlet of HB-200

Connect to outlet of

HB-200

1. Getting acquainted with your High Pressure Cleaner

HB-200 V00 Page 5

The high pressure cleaner is now ready for operation. The spray-gun lance will experience a

recoil force during operation –therefore keep a firm grip with both hands on the Spray-gun

handle and the lance. Press the trigger and start cleaning.

-Pressure can be regulated by adjusting the knob on the spray-gun lance.

-When using the chemical injector, pressure must be adjusted to low.

Make sure your local power supply specifications are in accordance with the

motors requirement. Refer to the ID-plate on the machine. Do Not run the High

Pressure Cleaner without sufficient potable water supply as it can cause

cavitation and serious damage to internal pump parts. Do not let the machine

recycle the water (running with Spray-gun trigger not activated) for more than

a few minutes as this can cause serious damage to the seals.

Starting up for the 1st time

1. Allow water to flow within the machine for about 3 to 5 minutes without turning on the

machine to allow any dirt or air to be vented out from the delivery outlet.

2. Ensure the mains voltage is the same as that of the machine printed on the technical data

plate.

Failure to comply with the regulations stated above, manufacturer declines all

responsibilities for the staff and provides no warranty.

Water Connection

1. Connect the inlet hose to the water mains using the

High Pressure hose which comes together with the

machine. (Max Pressure: 200Bar).

Filling up with Fuel

1. Fill the tank with the Diesel.

2. Avoid running the machine when diesel tank is empty in

order not to damage the fuel pump.

CAUTION

NOTE

1. Getting acquainted with your High Pressure Cleaner

HB-200 V00 Page 6

Stopping the Machine

1. Turn the burner thermostat to ‘0’ and wait for the water to cool completely to prevent

scale deposits and overheating of the coil and boiler.

2. Ensure electrical cable is not damage. If damage, replace it with approved cable with

connections following the wiring diagram as shown in Pg.17.

3. Check fuel filter as shown above periodically and replace when necessary.

Operation Flow Diagram

Operation To prevent accidents from happening, ensure the safety of the person(s) who

uses the equipment and to protect bystanders and nearby placed inventory or

machinery, a few safety precautions needs attention.

WARNING

1. Getting acquainted with your High Pressure Cleaner

HB-200 V00 Page 7

1) Treat the machine as a high-speed cutting tool.

2) Anyone under the age of 18 is NOT allowed to use the machine.

3) Always use a proper plug and socket specially designed with ground to earth wiring. Only

connect to an installation with earth wiring. A certified electrician shall make the

installation. It is strongly recommended that the electric supply to the machine include a

Residual Current Device/GFCI.

4) Always keep the machine and its accessories in good working condition. Check the

machine for defects, especially the insulation on the electric cable. Do NOT start up the

machine if there is any defect. Have the machine serviced.

5) When using the Water Blaster and its accessories, eye protection must be worn to protect

against repelling or ricocheting matters causing eye damage.

6) Suitable clothing and footwear must be worn while using the equipment to protect the

operator. Do not try to clean clothes or footwear with the machine.

7) Precautions must be made to keep bystanders away from the working range.

8) Do NOT spray-clean on yourself, others or live animals. The

high-pressure beams are capable of making severe injuries.

9) Do NOT spray at electrical equipment OR the machine itself.

10) While repairing or servicing the equipment and its accessories always make sure the

machine is turned off and disconnected from the main power supply.

11) Only allow instructed personnel to operate the machine.

12) Activating the trigger/gun can cause backward force therefore always hold spray lance

with both hands.

13) When pausing during operation, turned off the main switch of the machine and ensures

that the trigger/gun is locked.

14) Only use high-pressure hoses, connections and nozzles specified by DEN-SIN.

15) IMPORTANT –Do not use the machine in a possible explosive environment in

accordance with EN-50014.

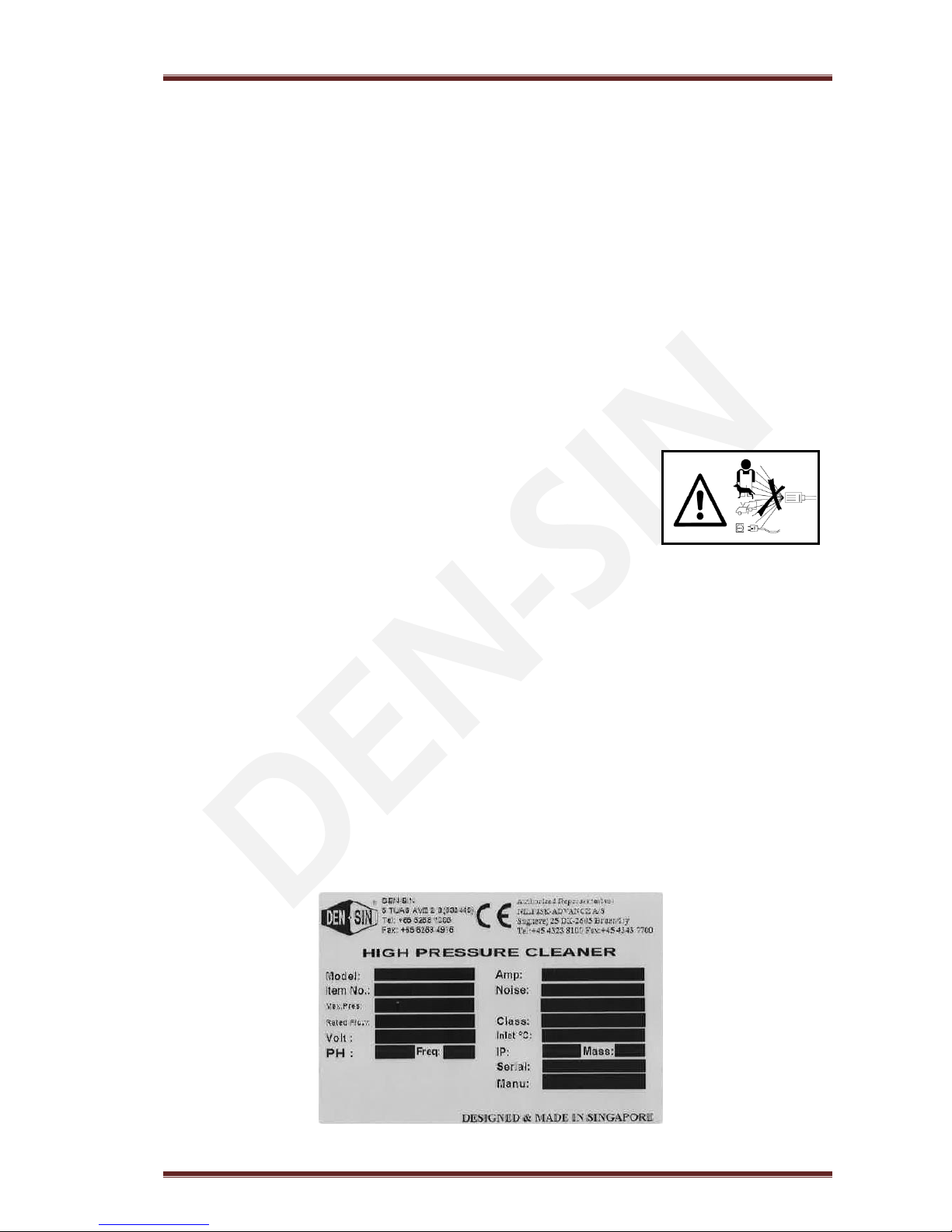

ID-plate

Refer to the identification plate on the machine:

2. Safety and Protection information

HB-200 V00 Page 8

2. Safety and protection information

General safety & application guidelines

1) It is not allowed to clean asbestos containing surfaces with high-pressure, unless using

special equipment.

2) Persons under the influence of alcohol, drugs or medicine should not operate the machine.

3) Do not touch plug and socket with wet hands.

4) This machine has been constructed for use with Nilfisk-ALTO detergents. The use of

other detergents or chemicals may cause problems as to the operation and the safety.

5) When using detergents the instructions should always be strictly observed.

6) Always flush the machine with clean water after use of chemical/detergents.

7) Always unplug power supply when cleaning and maintaining the machine.

8) Do not use machine if important parts are damaged –i.e. safety devices, high-pressure

hoses, spray handle.

9) The user is obliged to observe all national working environment and working safety

regulations concerning “operation of high-pressure washers”.

10)It is not allowed to connect this machine directly to a potable water supply.

11)If the machine is to be connected to potable water supply it is strictly necessary to fit the

machine with a water break tank, in accordance with EN1717.

Safety devices

The machine is equipped with the following safety devices:

1) Stop button. The stop button stops the machine when pushed.

2) Locking device on spray-gun handle. The locking device prevents the trigger from being

activated when pulled out.

3) Thermal sensor and over load relay protects the motor against overloading. The machine

can be switched on again after a few minutes, when the sensor has cooled.

4) Burner safety devices; the burner safety device protects the machine against faulty

ignition.

DO

DON’T

3. Maintenance and Troubleshooting

HB-200 V00 Page 9

3. Maintenance and troubleshooting

Maintenance

Subject

Matter / Procedure

Cleaning

Use a damp cloth to wipe the cabinet. Do not use detergent cleaning

chemicals.

Notice: To prevent electrical shock. DO NOT SPRAY DIRECTLY

UPON THE MACHINE WITH HIGH PRESSURE.

Occasionally clean the fan cover of the blower to ensure sufficient

airflow.

Do NOT operate the machine with damaged or removed fan cover.

Inspection

To prevent electrical shock and spills of leaking water. Check

electrical cord and high-pressure hose for wear and cracks. Keep

coupling parts free of dirt to ensure long life of O-ring seals

preventing water leak.

Notice: To prevent damage on hoses and cord, be careful not to have

them run over by heavy vehicles or squeezed in door openings etc.

Replace if necessary.

Storage

Be sure the cleaner is kept frost-free, if not possible flush the inlet of

the cleaner with antifreeze fluids.

Depending on water quality,

clean the strainer in the water

tank regularly.

Depending on Fuel quality

clean the fuel filter regularly.

3. Maintenance and Troubleshooting

HB-200 V00 Page 10

Troubleshooting

Symptom

Cause and Rectification

When the main

switch is turned on

the high-pressure

cleaner will not run.

Fault somewhere in the power supply.

Make sure the socket is inserted correctly. Inspect cord for cracks

and wears. Check if fuse is blown, replace if necessary.

The blower motor

does not start.

Too low voltage.

Check the mains voltage.

Check the connection box voltage with a meter.

With the machine turned off, turn the motor, at the fan,

The pressure drops

and the high-

pressure cleaner

works irregularly.

The strain filter is clogged or the water supply from the tap is

insufficient.

Ensure sufficient water-flow through the cold water machine.

The boiler will not

burn

The fuel tank is empty. The fuel filter is clogged. The fuel nozzle is

clogged. The spark electrodes are worn or out of alignment. The

flame censor device is active. The glass between the flame censor

and the boiler is dirty.

Fill up the fuel-tank. Clean or replace the fuel filter. Clean or

replace the fuel nozzle. Adjust or replace the spark electrodes.

Reset the device by pushing the reset button at the control panel.

Clean the glass between the censor and boiler.

The high-pressure

cleaner does not suck

chemicals

The chemical container is empty. The high-pressure cleaner has

not been set to low-pressure (on the double barrel lance cock).

The low-pressure nozzle is clogged, or partly clogged. The non-

return valve of the chemical injector is stuck.

Ensure the chemical container contains sufficient fluid for proper

suction.

Set the spray-lance to low pressure by turning the cock on the

lance counter-clockwise.

Clean or replace the low-pressure nozzle.

Clean, correct or replace the non-return valve of the chemical

injector.

For any further inconveniences, not mentioned in this user guide or any

damages of the machine, we strongly suggest you to make contact with your

dealer for the repair or possible replacement of any original spare-parts.

NOTE

3. Maintenance and Troubleshooting

HB-200 V00 Page 11

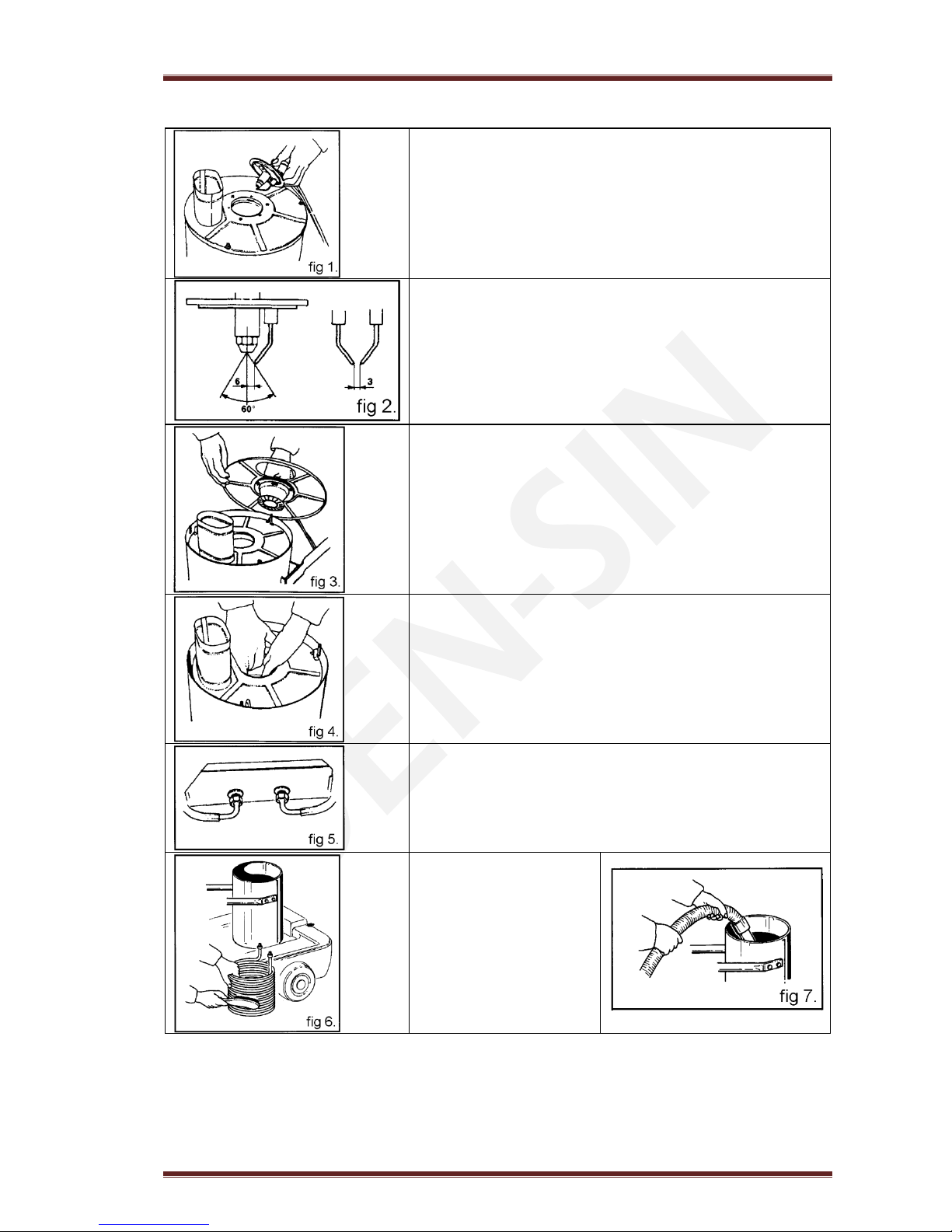

Boiler Servicing and Maintenance / 200hrs*

Carefully remove the nozzle holder flange and the

electrodes holder (boiler burner head).

*Clean the small glass in the flange every 50 hours of

use.

Clean the fuel nozzle filter with compressed air and

check the position and wear of the spark electrodes.

Remove the boiler cap by unscrewing the 3 nuts and

clean the deflector with a brush and/or with compressed

air.

Manually take away the interior cap.

Remove the high pressure hoses and unscrew the locking

nuts from beneath. Pull out the boiler coil.

Clean the boiler coil for

residue with a wire

brush.

Vacuum clean the

residue from the boiler

housing.

5. Declaration and Warranty

HB-200 V00 Page 12

4. Accessories List

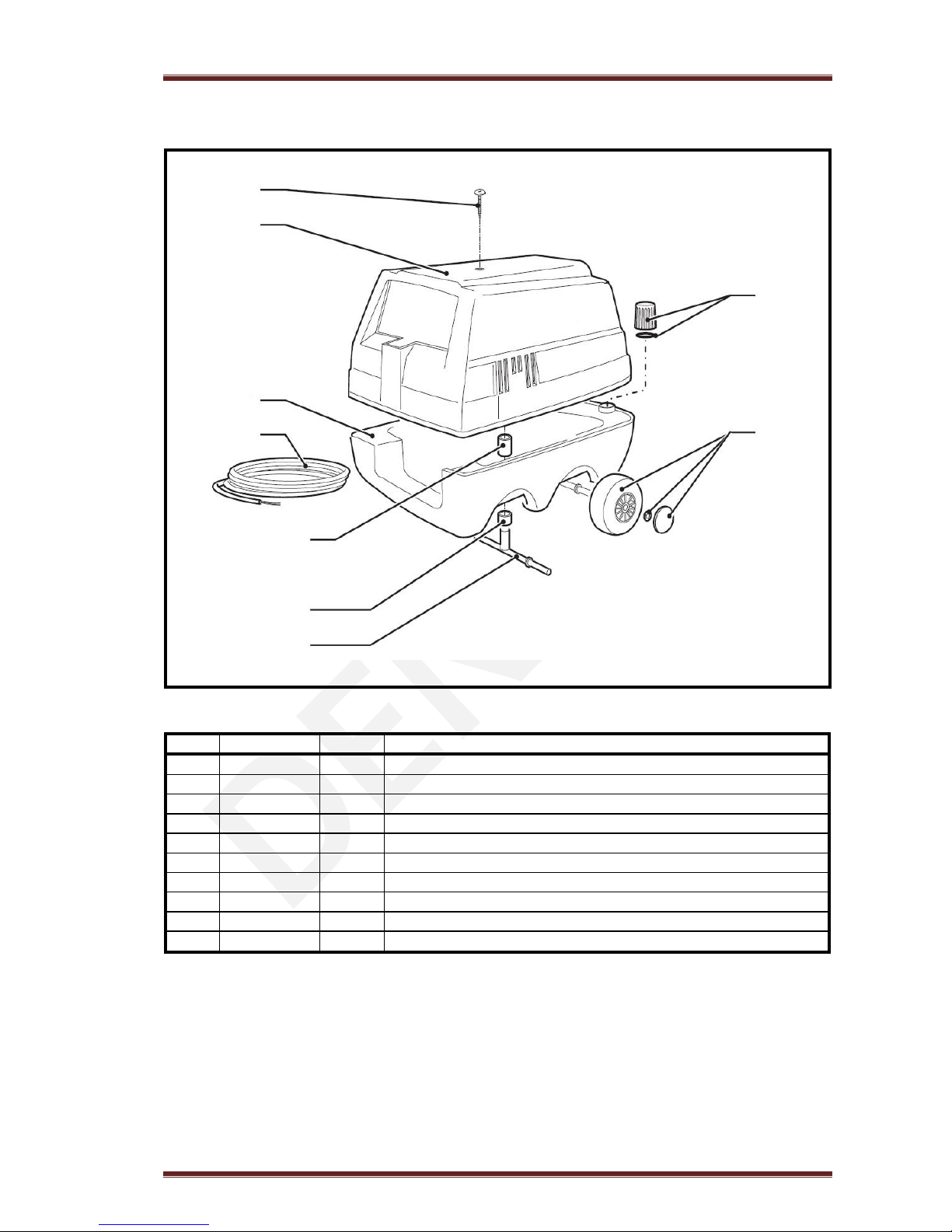

Chassis assembly

Chassis assembly spare-parts list

Pos:

Part No:

Qty:

Description

1

-

1

Screw M6x12

2

700590143

1

Top Cover

3

700590144

1

Diesel Tank

4

700951501

10m

Cable 3G2.5

5

-

4

Long Spacer

6

-

4

Axle Spacer

7

-

2

Wheel Axle

8

700590145

1

Diesel Tank Cap W/Gasket

9

700590060

4

Wheel W/Cover

*

700550042

10m

Hose Extension M-F

1

2

3

4

5

6

5

7

8

9

5. Declaration and Warranty

HB-200 V00 Page 13

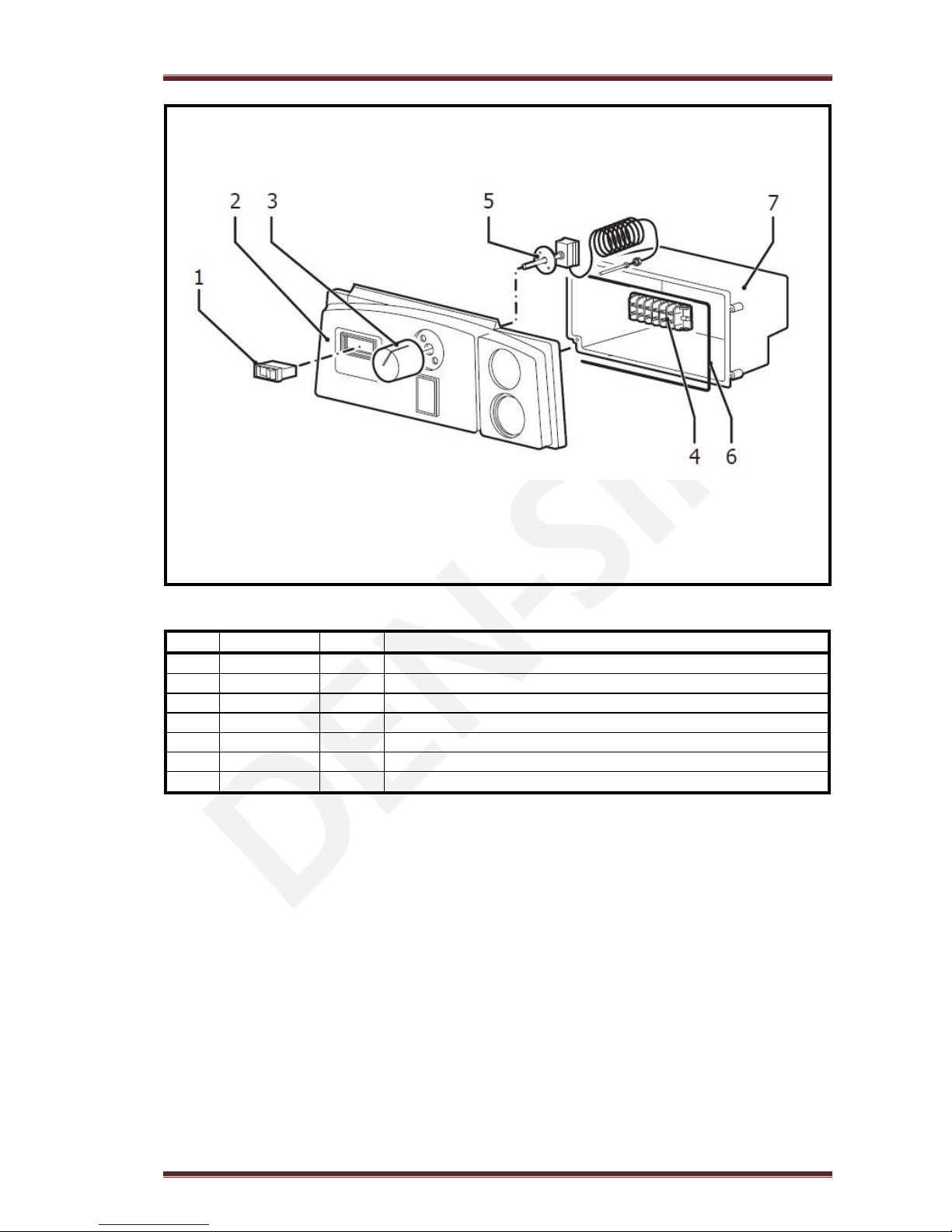

Electrical Box assembly

Electrical Box assembly spare-parts list

Pos:

Part No:

Qty:

Description

1

700590146

1

Switch

2

700590147

1

Control Panel

3

700530266

1

Knob Thermostat

4

700530272

1

TERMINAL BLOCK

5

700530267

1

Thermostat

6

700590148

1

EL-Box Gasket

7

-

1

Electrical Box

5. Declaration and Warranty

HB-200 V00 Page 14

Boiler assembly

5. Declaration and Warranty

HB-200 V00 Page 15

Boiler assembly spare-parts list

Pos:

Part No:

Qty:

Description

1

700590039

1

Ignition Electrode

2

700590025

1

Elbow Dia.4 –1/8”

3

-

1

Ring Seeger

4

700590003

1

Sight Glass

5

-

1

Wrought Burner Flange

6

-

1

Diesel Nozzle 1.50

7

700590149

1

Boiler Flange Complete

8

700590150

1

Ignition Transformer HB-200

9

700590027

2

Electrode L=480mm

10

700590151

1

Chimney Inward Cover

11

700590099

1

Burner Cover

12

700590152

1

Upper Coil H.500

13

700590153

1

Boiler Body

14

700590154

1

Copper Pipe

15

-

1

Band for Burner Cover

16

700590006

1

Fan Protection Cage

17

700590028

1

Blower Coil

18

700590044

1

Fuel Pump Coil

19

-

1

Plastic Coupling

20

700590046

1

Blower Motor 50Hz

21

700590008

1

Blower Fan

22

700590031

1

Refractory Bottom

23

700590043

1

Coil Fixing Strip Plate

24

700590036

1

Insulating Rope for Boiler Base

25

700590155

1

Tube R2

26

-

1

Handle Bracket

27

-

1

Handle

28

1

Oil Filter Unit

29

700590156

1

Flow Switch 3/8”

30

700590157

1

Pivoting Connection

31

700590158

1

Safety Valve 250Bar

32

700540026

1

Quick Coupling 3/8” M

33

-

1

Bulb Assembly

34

-

1

Aluminium Washer

35

-

1

Coupling Nipple 1/2" –3/8”

36

-

1

Bulb Bracket

37

700590076

1

Bulb Assembly Complete

5. Declaration and Warranty

HB-200 V00 Page 16

Wiring diagrams

HB-200E 230V 50Hz Standard

5. Declaration and Warranty

HB-200 V00 Page 17

5. Declaration and Warranty

EU declaration of conformity

EU Declaration of Conformity

Product:

Electric powered

Heavy duty

Hot Water high-pressure cleaner

Type:

HB-200 50Hz

Description:

230V 0~ 50Hz, IP 54

200 [bar]

20 [MPa]

The design of the unit corresponds to the following

pertinent regulations:

EC Machine Directive 2006/42/EC

EC EMC Directive 2004/108/EC

Applied harmonized standards:

EN 12100-1, EN 12100-2, EN 1829-1/EN 60335-2-79

EN 55014-1, EN 55014-2, EN 61000-3-2

Applied national standards and technical specifications:

DIN EN 60335-2-79

DEN-SIN –a division Nilfisk-Advance Pte Ltd.

No 5 Tuas Ave 2

Singapore 639445

Tel: +65 62681006

Fax: +65 62684916

Singapore, Jan 2014

Warranty

DEN-SIN warrants all equipment of its manufacture furnished under this agreement to be free

from defect in workmanship and material for a period of one year from the date of invoice of the

equipment. This warranty does not cover normal wear and tear, consumable items, or part

failures caused by (i) accident, (ii) abuse, or (iii) failure to maintain the DEN-SIN system

containing the affected parts in accordance with DEN-SIN technical specification. All labour is

the responsibility, and the expense of the Buyer. The liability of Seller under this warranty is

limited, at Seller's option, solely to repair or replacement with equivalent articles. This warranty

is condition upon (a) Seller being notified in writing by Buyer within one week after discovery of

defects;

(b) the return of defective articles to Seller, transportation charges prepaid by Buyer; and (c)

Seller's examination of such article disclosing to its satisfaction that such defects were not caused

by negligence, misuse, improper maintenance, improper installation, accident, or unauthorized

repair or alteration.

Accessories or equipment furnished by DEN-SIN but manufactured by others, shall carry the

warranty that its manufacturer has conveyed to DEN-SIN, and which may be passed on to the

purchaser. The original warranty period of any article, which has been repaired or replaced by

DEN-SIN, shall not thereby be extended.

6. Spare Parts Request Form

HB-200 V00 Page 18

6. Spare Parts Request Form

Company Name:

Delivery Address:

Country:

Postal Code:

Contact Name:

Contact Number:

Fax Number:

Mobile Number:

Email:

S/N

Part Number

Description

QTY

Machine Model

or Serial Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Special Instructions:

7. Maintenance Log Book

HB-200 V00 Page 19

7. Maintenance Log Book

This maintenance logbook will assist you to keep track on the servicing of your equipment.

Please record after service your machine.

Purchase date of the machine:

S/N

Service Description

Date

Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Table of contents

Other Den-Sin Pressure Washer manuals

Popular Pressure Washer manuals by other brands

blueclean

blueclean Take-Along Assembly, care and use instructions

Powerplay

Powerplay SPYDER SPY1500VC Assembly, care and use instructions

FERREX

FERREX Q1W-SP07-2200A user manual

Alto

Alto Wap SC 710 W operating instructions

Kärcher

Kärcher HDS-E 3.3/25-4M Ec user manual

Mountfield

Mountfield Patriot PW 130 Instruction manual for use and maintenance