Den-Sin C-250E User manual

Introduction

C-250E R14 Page 1

1. Introduction

Congratulations on your purchase of the DEN-SIN High Pressure Cleaner.

Model: C-250E

Read this user manual before you start up your High Pressure Cleaner the first time.

This document or part of it may not be photocopied, or in any other way reproduced, or

translated to other languages without the prior written consent of DEN-SIN.

This machine is a High Pressure Cleaner producing water jet under high-pressure, which is

why severe injuries can occur if the safety precautions are not observed.

Therefore a full understanding of the contents of this instruction manual is required, in order

to prevent injuries to you, objects and persons nearby.

Safety

The following symbols are used in this manual to indicate procedures that if not followed,

may results in personal injuries or damage to equipment.

Version 14: Apr 2018

Revision History

Revision Rev.No.

Cha

nge pump no.

10

Manual updating

11

Manual update, removal of CE declaration.

12

Manual Content Updating. Cable P/N Update

13

Manual Content Updating.

14

WARNING

is used to alert the reader of procedures or

practice which if not followed correctly could result in personal

injuries.

WARNING

CAUTION

CAUTION

is used to alert the reader of procedures or

practice which if not followed correctly could result in damage

to machine or other equipment.

NOTE

is used to highlight important information that may

assist the reader carrying out the procedure or understanding the

text.

NOTE

Table of Contents

C-250E R14 Page 2

Table of contents

Table of contents....................................................................................................................... 2

1. Getting acquainted with your High Pressure Cleaner...................................................... 3

Fast and efficient cleaning...................................................................................................... 3

Specifications ......................................................................................................................... 3

Applications............................................................................................................................ 3

Unpacking .............................................................................................................................. 4

Machine Installation / Setup................................................................................................... 4

Machine Shut Down Procedure.............................................................................................. 6

Operations .............................................................................................................................. 7

2. Safety and protection information...................................................................................... 8

General safety & application guidelines ................................................................................ 8

Safety devices......................................................................................................................... 9

Important medical information............................................................................................. 10

WARNING.............................................................................................................................. 10

Safety precautions ................................................................................................................ 11

3. Maintenance and troubleshooting .................................................................................... 12

Maintenance Schedule.......................................................................................................... 12

Machine Prevention.............................................................................................................. 12

Troubleshooting.................................................................................................................... 13

4. Available accessories.......................................................................................................... 21

ID-plate................................................................................................................................. 21

Chassis assembly.................................................................................................................. 22

Chassis assembly spare-parts list ......................................................................................... 23

Machine Model..................................................................................................................... 23

Pump assembly spare-parts list ............................................................................................ 26

Un-loader valve assembly .................................................................................................... 28

Un-loader valve assembly spare-parts list............................................................................ 29

Repair kit Unloader valve..................................................................................................... 30

Safety valve assembly .......................................................................................................... 31

Safety valve assembly spare-parts list.................................................................................. 31

Lance Assembly (Standard) ................................................................................................. 32

Lance assembly spare-parts list............................................................................................ 32

Trigger gun assembly ........................................................................................................... 33

Trigger / gun & assembly spare-parts list E250 ................................................................... 33

Repair Kit Trigger Gun ........................................................................................................ 33

Electrical Box ....................................................................................................................... 34

Wiring diagrams ................................................................................................................... 35

5. Warranty............................................................................................................................. 36

The information contained in this user guide is subject to change without

notice.

NOTE

1. Getting acquainted with your High Pressure Cleaner

C-250E R14 Page 3

1. Getting acquainted with your High Pressure Cleaner

Fast and efficient cleaning

The DEN-SIN High Pressure Cleaners in the C-250E series enables you to get more cleaning

done in less time.

This series of DEN-SIN High Pressure Cleaners offers you high performance yet a compact

design. The compact design enables the machines to be agile within inconvenient places even

at staircases, and the high performance gives you the opportunity to solve an array of cleaning

tasks. The High Pressure Cleaners in this series are designed for industrial/ Trucking &

Livestock transport companies/ Agriculture & Farming/ Shipping & Bulk carrying barges

and offshore use as well as for cleaning contractors. All pump parts, fittings and pipes in

contact with water are made of non-corrosive materials. Together with the ceramic pistons,

long life seals and stainless steel valves, it ensures long life and high durability.

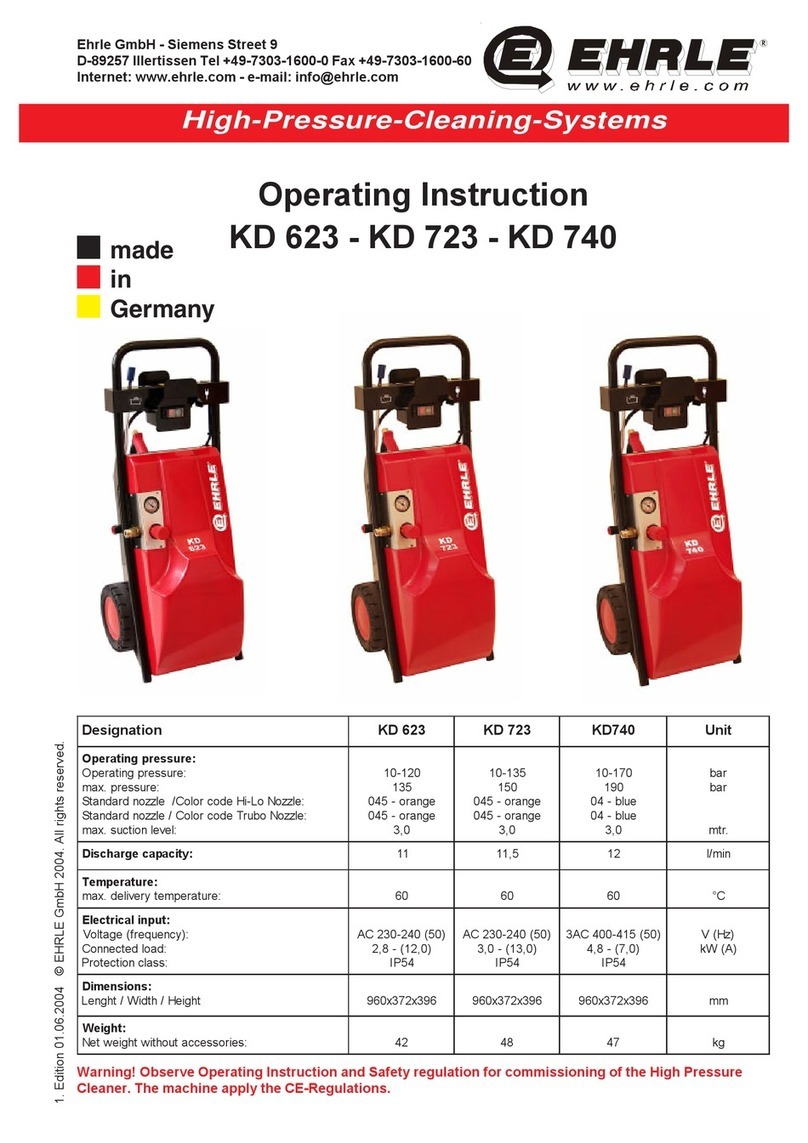

Specifications

Model Motor Motor

Speed

Working

Pressure

Flow Capacity Power Supply

Dimensions

x W x H

Weight

Hp

kW

rpm

psi

Bar

gpm

/min

Voltage

mm

kg

C-250E

(700995661)

10 7.5

1500 3625 250 2.6 15

380-400Vac

( 5 0 H z ) 930x585x940

95

C-250E

(700995655)

10 7.5

1800 3625 250 2.6 15

4 4 0 V a c

( 6 0 H z ) 930x585x940

95

Applications

These heavy-duty High Pressure Cleaners are capable of removing any kind of dirt:

Algae off concrete constructions

Paint and graffiti off walls

Dust, dirt, soil & mud off floors

Oil & grease off engines and other mechanical parts

Dirt and salt deposits off ship decks

And with the option for use of accessories even many more jobs are to be dealt with:

Sand-blasting

Drain-cleaning

Dispensing of soaps and chemicals

Sludge pumping

Extra long lances for hard to reach places

Floor cleaning equipment

Rotary brushes

This machine is only to be used for the purposes it is designed for. Any other use shall be

considered improper and therefore potentially dangerous. The manufacturer is not to be held

responsible for any damages caused by improper use.

CAUTION

1. Getting acquainted with your High Pressure Cleaner

C-250E R14 Page 4

Unpacking

Remove the High Pressure Cleaner and its accessories from the packing material. For

transport and packing reasons some accessories may be supplied disassembled.

Make sure all components are present:

1) High-pressure machine itself

2) Chemical Tank

3) Electrical cord (attached)

4) High pressure hose with Lance Trigger

5) Water inlet male hose coupling

Machine Installation / Setup

Mount the high-pressure hose on to the High Pressure Cleaner by

pulling back the retainer on the high-pressure hose coupling, while

sliding it onto the male outlet of the unloader till a click sound could be

heard.

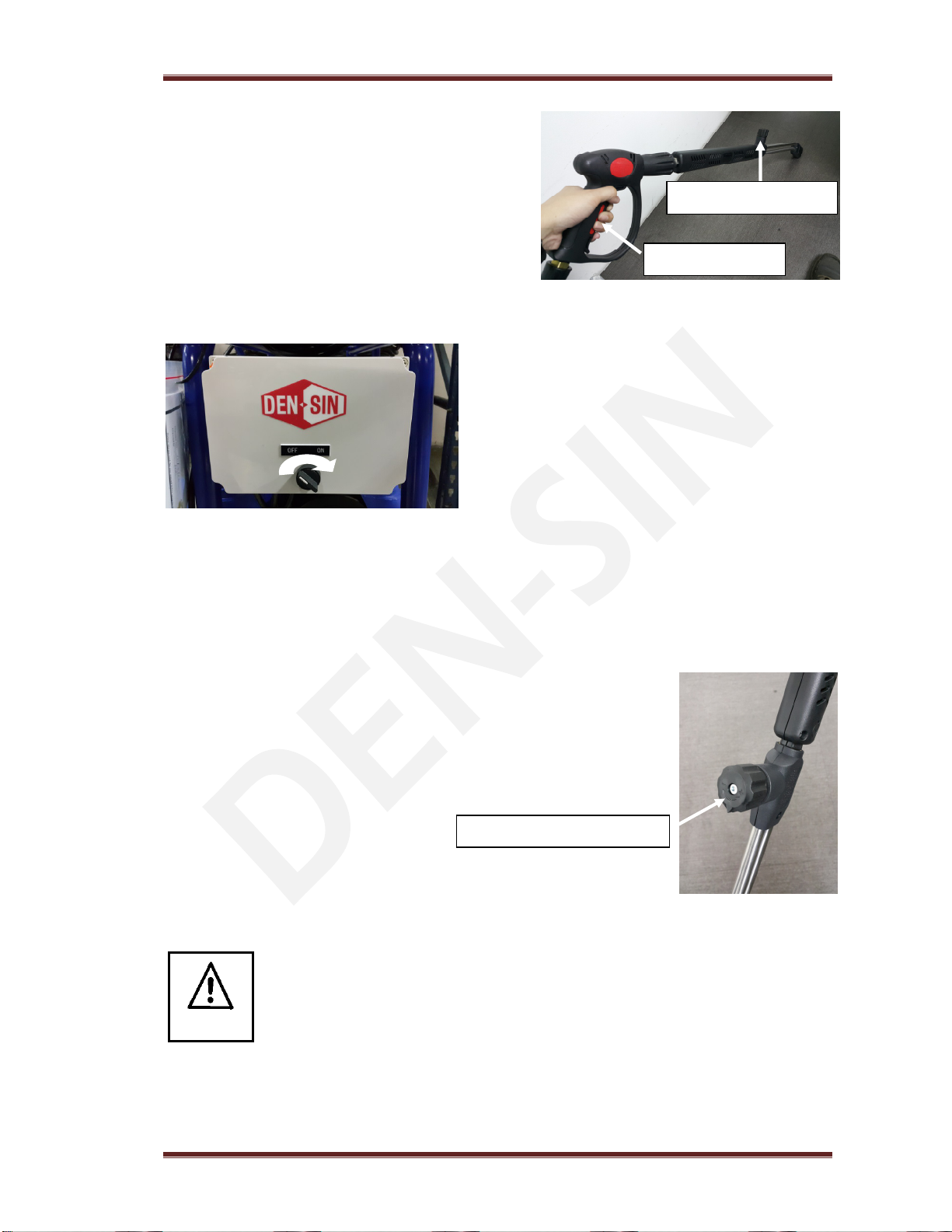

Assemble the double barrel spray-lance. To mount the

assembled spray-lance on to the Spray-gun trigger, pull

forward the front of the Spray-gun trigger (A) while

sliding in the male swivel coupling part of the spray-

lance. (B)

Prepare the water supply for the High Pressure Cleaner by attaching a

hose to the supplied low pressure inlet male-coupling. Connect the other

end of the water supply hose to a potable water tap. Turn on tap.

Connect to the public mains water supply in accordance to

regulations.

Notice

(A)

(B)

1

2

3

4

5

1. Getting acquainted with your High Pressure Cleaner

C-250E R14 Page 5

The high pressure cleaner is now ready for

operation. The spray-gun lance is affected by a

recoil force during operation – therefore keep a

firm grip with both hands on the Spray-gun handle

and the lance. Press the trigger and tighten pressure

regulating knob to achieve maximum pressure for

effective cleaning.

Put the power-plug into a main power supply

socket. Turn on the power of the High Pressure

Cleaner by turning the knob clockwise to the ON

position.

The high pressure cleaner is now ready for operation. The contractor lance is affected by a

recoil force during operation – therefore keep a firm grip with both hands on the contractor

lance. Open ball valve and tighten the needle valve to achieve maximum pressure for effective

cleaning.

The pressure can be regulated by turning the knob on the spray-gun

lance. Tighten knob for maximum pressure and loosen for low

pressure washing. When using chemical injector, pressure must be

adjusted to low.

Make sure your local power supply specifications are in accordance with the

motors requirement. Refer to the ID-plate on the machine. Do NOT run the

High Pressure Cleaner without sufficient potable water supply as it can cause

cavitation and serious damage to internal pump parts. Do not let the machine

recycle the water (running with Spray-gun trigger not activated) for more than

a minute. This can cause serious damage to the seals.

CAUTION

D

epress Trigger

Knob fully tighten

Pressure Regulating Knob

1. Getting acquainted with your High Pressure Cleaner

C-250E R14 Page 6

Machine Shut Down Procedure

Release trigger and lower down the pressure by loosening the knob on

the lance.

Turn off the High Pressure Cleaner by turning the

knob anti-clockwise to the OFF position. Switch off

the main power supply

Once machine stop, open the ball valve and needle valve to release trap pressure in the pump

and hose line. Make sure lance is pointing downwards when doing this as pressure could

cause injury.

Once pressure is release, turn off water supply and disconnect inlet

and outlet hose from machine. Dry the machine and store it.

1. Getting acquainted with your High Pressure Cleaner

C-250E R14 Page 7

Operations

To prevent accidents from happening, ensure the safety of the person(s) who

uses the equipment and to protect bystanders and nearby placed inventory or

machinery, a few safety precautions needs attention.

1) Treat the machine as a high-speed cutting tool.

2) Anyone under the age of 18 is NOT allowed to use the machine.

3) Always use a proper plug and socket specially designed with ground to earth wiring.

4) Only connect to an installation with earth wiring. A certified electrician shall make the

installation. It is strongly recommended that the electric supply to the machine include a

Residual Current Device/GFCI.

5) Always keep the High Pressure Cleaner and its accessories in good working condition.

Check the machine for defects, especially the insulation on the electric cable. Do NOT

start up the machine if there is any defect. Have the machine serviced.

6) When using the High Pressure Cleaner and its accessories, eye protection must be worn

to protect against repelling or ricocheting matters causing eye damage.

7) Suitable clothing and footwear must be worn while using the equipment to protect the

operator. Do not try to clean clothes or footwear with the machine.

8) Precautions must be made to keep bystanders away from the working range.

9) Do NOT spray-clean on yourself, others or live animals. The

high-pressure beams are capable of making severe injuries.

10) Do NOT spray at electrical equipment OR the machine itself.

11) While repairing or servicing the equipment and its accessories always make sure the

machine is turned off and disconnected from the main power supply.

12) Only allow instructed personnel to operate the machine.

13) Activating the trigger/gun can cause backward force therefore always hold spray lance

with both hands.

14) When pausing during operation, turned off the main switch of the machine.

15) Only use high-pressure hoses, connections and nozzles specified by DEN-SIN.

16) IMPORTANT – Do not use the machine in a possible explosive environment in

accordance with EN-50014.

WARNING

2. Safety and Protection information

C-250E R14 Page 8

2. Safety and protection information

General safety & application guidelines

1) It is not allowed to clean asbestos containing surfaces with high-pressure, unless using

special equipment.

2) Persons under the influence of alcohol, drugs or medicine should not operate the machine.

3) Do not touch plug and socket with wet hands.

4) This machine has been constructed for use with Nilfisk-ALTO detergents. The use of

other detergents or chemicals may cause problems as to the operation and the safety.

5) When using detergents the instructions should always be strictly observed.

6) Always flush the machine with clean water after use of chemical/detergents.

7) Always unplug power supply when cleaning and maintaining the machine.

8) Do not use the machine if important parts are damaged – i.e. safety devices, high-pressure

hoses, spray handle.

9) The user is obliged to observe all national working environment and working safety

regulations concerning “operation of high-pressure washers”.

10) It is not allowed to connect this machine directly to a potable water supply.

11) If the machine is to be connected to potable water supply it is strictly necessary to fit the

machine with a water break tank, in accordance with EN1717.

2. Safety and Protection information

C-250E R14 Page 9

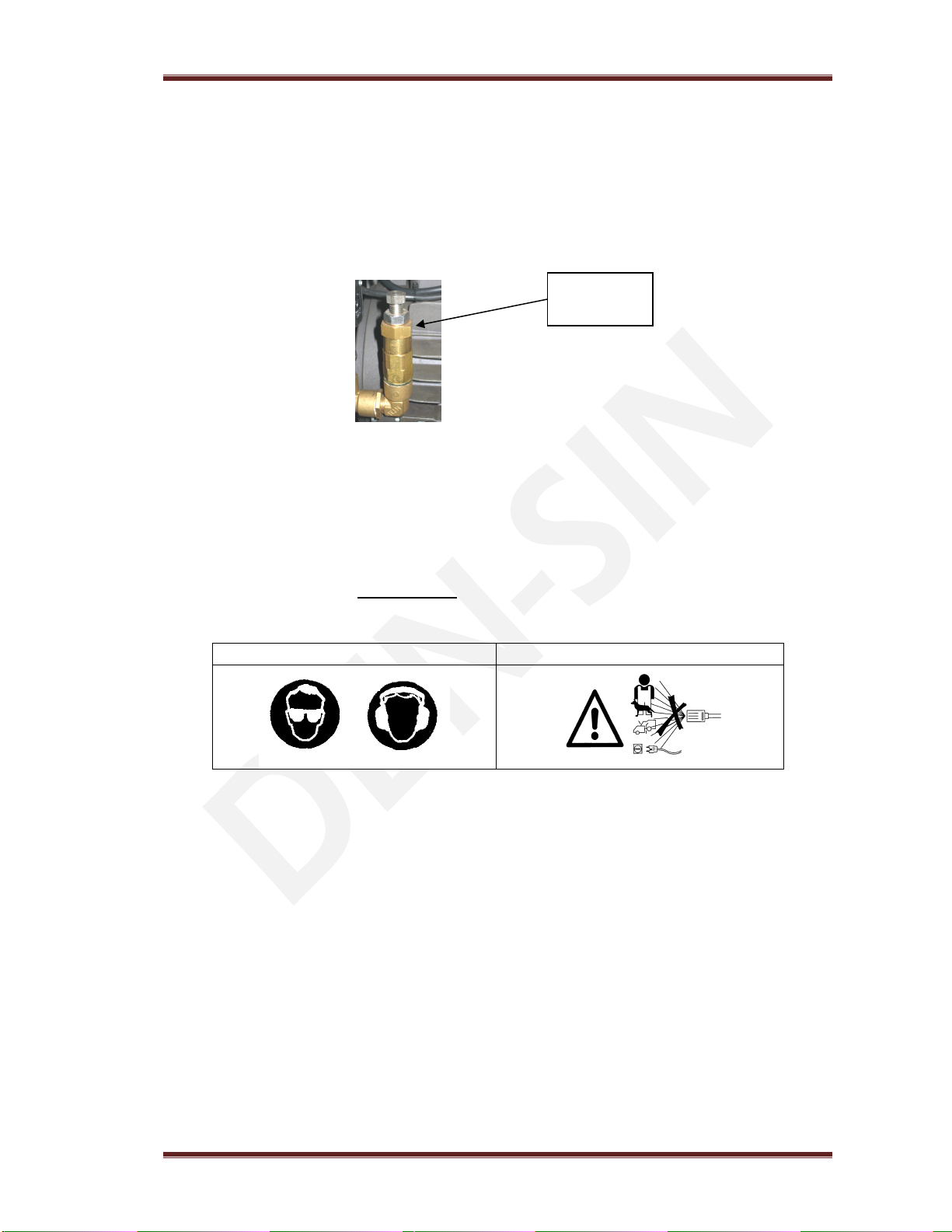

Safety devices

The machine is equipped with the following safety devices:

1) Safety Valve protects the machine from over pressure. Once the pressure is set higher than

260~280Bar, the safety valve will open and water will leak out. These indicate, unloader

was adjusted too high. Adjust the unloader back to its rated pressure 250Bar.

4)

Automatic Start / Stop:

These Pressure Washer comes with Automatic Start/ Stop

function for extended life span of the pump. If the machine is running for more than (1.5

minutes) without trigger/ gun being activated then it will shut down automatically. To restart

the machine, simply press the trigger/ gun and the machine will start automatically.

The timer is preset to 1.5 minutes - do NOT change the setting.

DO DON’T

Safety

Valve

2. Safety and Protection information

C-250E R14 Page 10

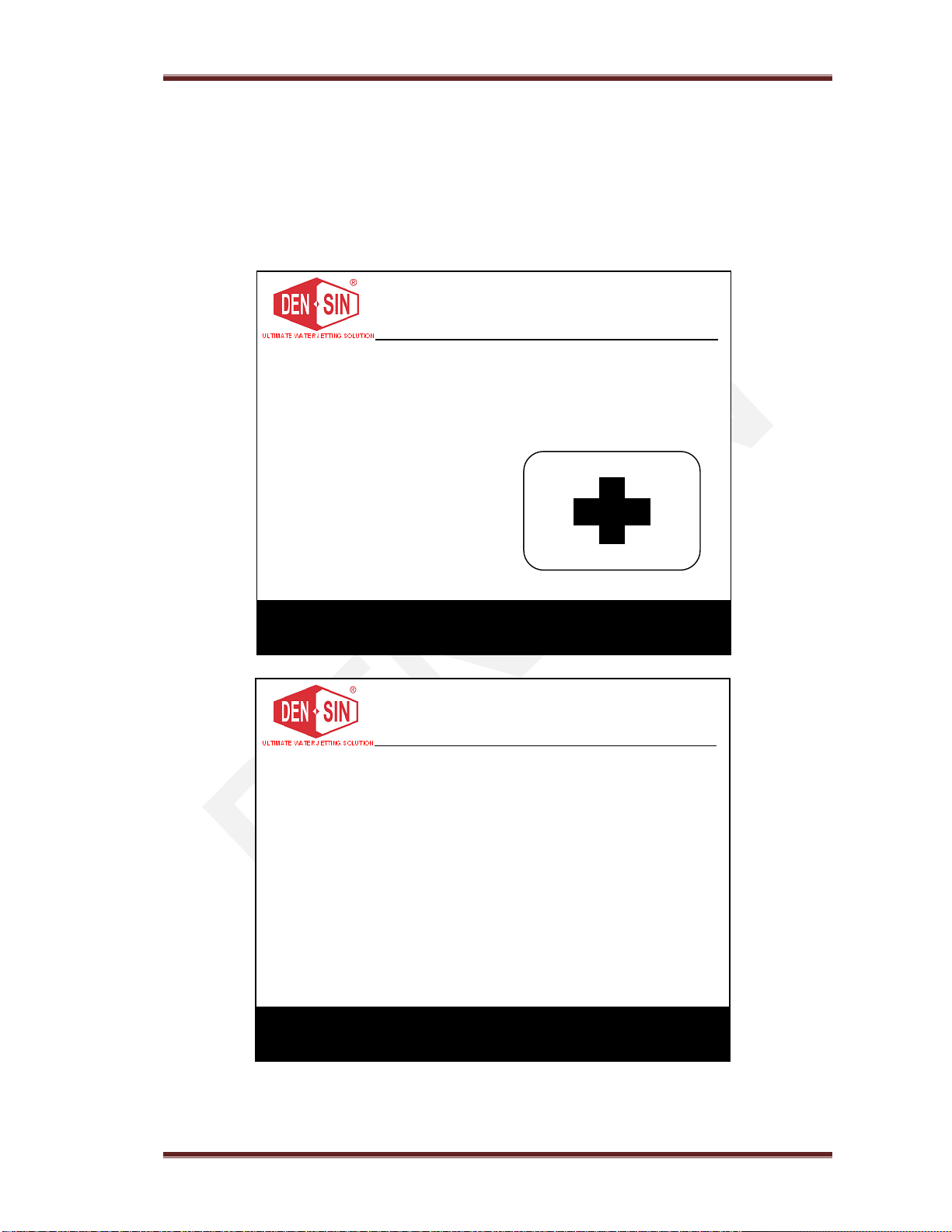

Important medical information

Immediate hospital attention should be given personnel who sustain equipment related injuries

while operating the system. In such cases, it is vital that medical personnel be apprised of all

facts relevant to such injuries. Therefore, all operating personnel should be provided with

waterproof emergency medical alert tags or cards, describing the nature of their work and the

possibility of injury inherent in the use of water jetting equipment. The below example of a

standard card can be photo copied, laminated and used as medical alert tag.

WARNING

DEN-SIN - a division of Nilfisk Pte Ltd.

05 Tuas Ave 2 Singapore 639445

Tel: +65 6268 1006 Fax: +65 62684916

Obtain medical treatment

immediately for ANY high-pressure

water-jet injuries.

Inform the doctor of the cause of the

injury.

Show this card to the doctor.

This card is to be carried by

personnel working with high-

pressure water jetting equipment.

IMPORTANT

MEDICAL INFORMATION

MEDICAL ALERT

NOTE TO PHYSICIAN

This patient may be suffering from a water jet

injury. Evaluation and management should

parallel that of a gunshot injury. The external

manifestations of the injury cannot be used to

predict the extent of internal damage. Initial

management should include stabilization and

a thorough neurovascular examination.

X-rays can be used to access subcutaneous air

and foreign bodies distant from the site of

injury. Injuries to the extremities can involve

extensive nerve, muscle, vessel damage, as

well as cause a distal compartment syndrome.

Injuries to the torso can involve internal

organ damage. Surgical consultation should

be obtained. Aggressive irrigation and

debridement is recommended.

Surgical decompression and exploration may

also be necessary. Angiographic irrigation

studies are recommended pre-operatively if

arterial injury is suspected. Bandages with a

hygroscopic solution (MgSO

4

) and

hyperbaric oxygen treatment have been used

as adjunctive therapy to decrease pain, edema

and subcutaneous emphysema.

Unusual infections with uncommon

organisms in immune competent patients

have been seen; the source of the water is

important in deciding on initial, empiric

antibiotic treatment, and broad spectrum

intravenous antibiotics should be

administered.

Cultures should be obtained

DEN-SIN - a division of Nilfisk Pte Ltd.

05 Tuas Ave 2 Singapore 639445

Tel: +65 6268 1006 Fax: +65 62684916

2. Safety and Protection information

C-250E R14 Page 11

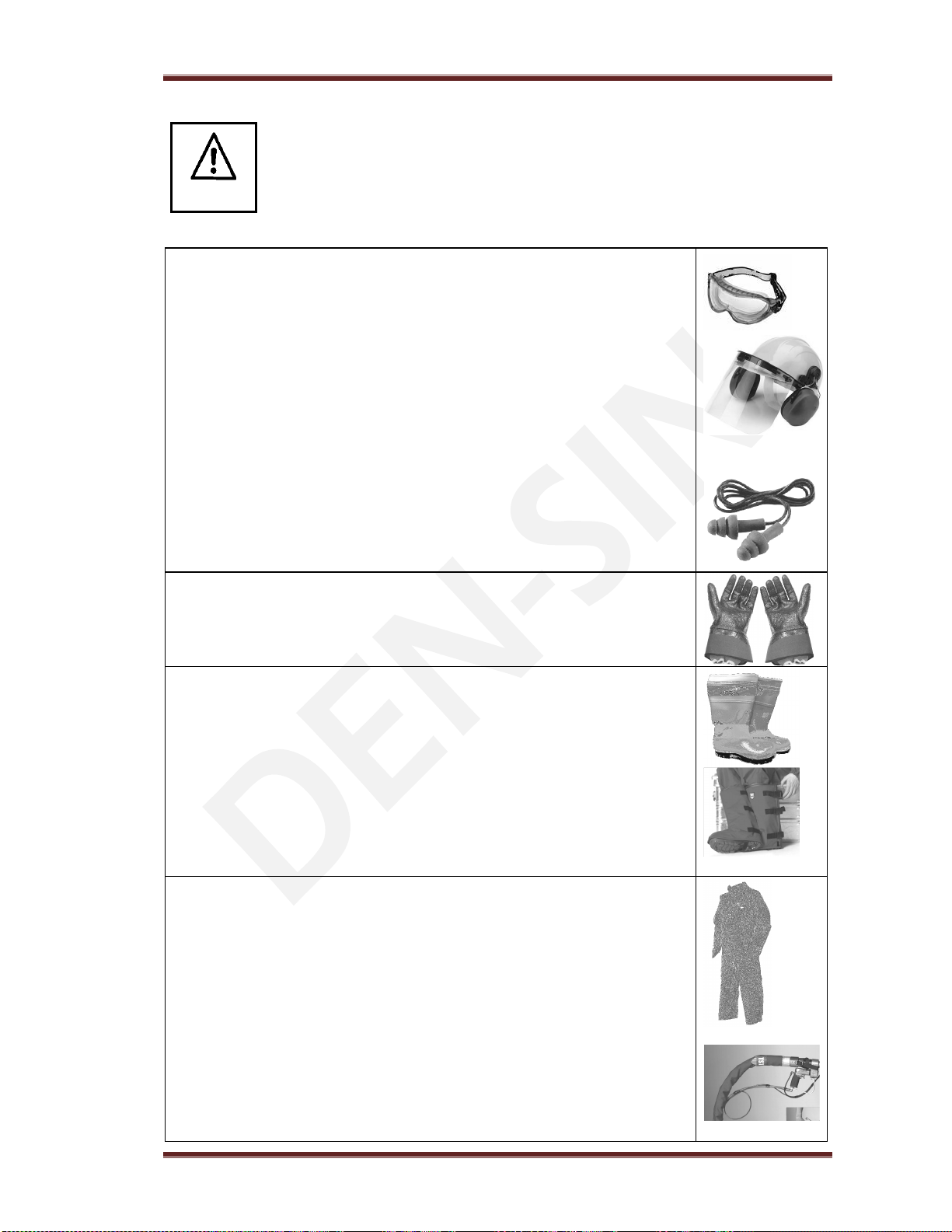

Safety precautions

The following protective clothing and devices should be worn both by

personnel operating the water blaster system and equipment and by those

working nearby:

Please contact DENSIN for various type of safety equipment available

Eye protection- Operators must wear visors and goggles to guard

against spray and flying debris. A combination of both goggles and visor

is advisable. And will protect the eyes and the face during both water-

blasting as well as abrasive water-blasting

Head protection- Helmets must be worn at all time by personnel within

the work area.

Helmet material must be able to withstand mechanical shock without

fracturing.

Hearing protection- Operators and other personnel exposed to noise

levels of more than 90-dBa for more than 1 hour must wear suitable ear

protection. Ear plugs or ear muffs are usually sufficient.

Hand protection- Shear proof gloves must be worn by the operator at

all times. A glove combination of a cloth inner lining and a water tight

outer layer is preferred.

Foot protection- Safety footwear with steel toecaps must be worn. Basic

safety footwear must also be equipped with metatarsal guards to protect

the instep. Safety boots are available in other designs than the

illustration.

Gaiters- This is an additional layer of protection to the user foot that are

not protected by the steel top cap. It is intended to be worn outside of the

user’s regular protective boots. Five clips ensure that gaiters securely

stay in place. The entire area is protected. Very comfortable and light to

wear.

Body protection- Waterproof garments protect the operator only from

spray and flying debris. They do NOT deflect direct jet impact.

Therefore, an operator must take care never to point a water-jet either at

themselves or other personnel.

Hose protection- Protect user from high pressure water injuries incase

hose connection is loose.

WARNING

3. Maintenance and Troubleshooting

C-250E R14 Page 12

3. Maintenance and troubleshooting

Maintenance Schedule

Regular Service

Period as

indicated

Each

use

1

st

50hrs

Every

month /

Every

500hrs

When

needed

Procedure / Remarks

Check pump oil

level

•Top up if necessary.

Change pump oil

Recommended Oil :

SAE 15W40

Usage :

Approx. 0.4kg of

oil

Renewal of oil:

•Turn off High Pressure Cleaner.

•Loosen bolt(Hex) at bottom of pump housing.

•Drain oil into a waste oil-tray.

•Tighten bolt(Hex)

•Add oil through pump inlet on top of the pump

until the red point of the oil control glass has

been reached.

Notice:

Do not dispose of used oil in drain.

Cleaning of

machine

•Use damp cloth to wipe the cabinet and handle

bar.

Notice:

Do not use detergent cleaning chemicals

Cleaning of

motor fan

(

to ensure sufficient

airflow )

•Clean the motor fan cover.

•Clean the motor fan blade.

Do NOT operate the machine with damaged or

removed fan cover.

Machine Prevention

Do

Don

’

t

Action

Cause

Spray directly onto the machine with high

pressure water

Electrical shock may occurs

Operate the machine with damaged or removed

fan cover

Motor will be overheated and malfunction

Operate/keep machine with frost built up

Flush pump with antifreeze fluids before use.

Check hose and cord are not vehicle run over

by heavy or

squeezed

in door opening

May cause machine not function properly.

Check electrical cord and high pressure hose

for wear and cracks

To prevent electrical shock and safety to the user

Ensure coupling parts free of dirt to ensure

long life of O-ring seals preventing water leaks.

Extend life span of the pump seals and

maintaining correct pressure.

3. Maintenance and Troubleshooting

C-250E R14 Page 13

Troubleshooting

Symptom

Rectification

Main switch is turned on the High Pressure

Cleaner will not run.

•Check power supply connection for faulty components.

•Make sure the socket is inserted correctly

•Check if fuse is blown, replace if necessary.

Motor is humming & Pump does not give

pressure or low pressure

•

Voltage is too low as compare to specification.(Check main voltage)

•Motor phase is missing (For 3 phase application).

Check the connection box voltage with a meter

•High-pressure pump is blocked

Pump pressure drops and the High Pressure

Cleaner works irregularly

•

Strain filter is clogged.

•Water supply from the tap is insufficient.

•Clean the strain water filter

Pump continuously stops and starts, when the

spray-gun trigger is activated.

•

The high pressure nozzle is partly clogged.

Turn off the High Pressure Cleaner, dismantle the high-pressure nozzle

and remove the extraneous matter. Replace if damaged

High pressure cleaner does not reach the proper

working pressure when the spray-gun handle is

activated

•

The high-pressure nozzle is clogged.

•Dirt in the by-pass valve.

•The pump sucks air.

•Turn off the High Pressure Cleaner. Clean the nozzle.

•Inspect the low pressure supply, while spray-gun trigger is activated,

ON the machine on again.

•Repeat the procedure again; now with the trigger released. If the

problem still occurs, by-pass valve should be dismantled and the

extraneous matter removed.

High Pressure Cleaner only works with

approximately 2/3 of the maximum pressure,

a

nd the high

-

pressure hose is vibrating.

•

Valves are dirty

•Remove the dirt and check to ensure the valve flaps are movable and

fit tightly.

Noisiness

•

The pump sucks air.

•One or more valve springs are broken or down.

•Extraneous matter in the valves.

•Crankcase or motor bearings worn out.

•Inspect the low-pressure supply. Replace springs.

•Clean the valves. Replace the bearings.

Water in the oil

•

The O-ring casing is worn out.

•High moisture in the air (condensing inside the crankcase)

•The seals are completely worn out.

•Check or replace the O-ring.

•Renewal of the crankcase oil more often.

•

Replace the seals.

The High Pressure Cleaner does not suck

chemicals

•

The chemical container is empty.

•The High Pressure Cleaner has not been set to low-pressure (on the

double barrel lance cock).

•The low-pressure nozzle is clogged, or partly clogged.

•The non-return valve of the chemical injector is stuck.

•Ensure the chemical container contains sufficient fluid for proper

suction.

•Set the spray-lance to low pressure by turning the cock on the lance

counterclockwise.

•Clean or replace the low-pressure nozzle.

•Clean, correct or replace the non-return valve of the chemical injector.

For any further inconveniences, not mentioned in this user guide or any

damages of the machine, we strongly suggest you to make contact with your

dealer for the repair or possible replacement of any original spare-parts.

NOTE

3. Maintenance and Troubleshooting

C-250E R14 Page 14

Pump Maintenance Instructions

Detach the high pressure hose, dump back hose, inlet hose, safety valve, and parts on the

pump head before serving the pump.

Valve Removal:

1. Remove the valve cap.

2. Inspect the valve cap O-ring for any damage, replace if necessary. (See Fig. 1)

3. Use the needle nose pliers to remove the valve. (See Fig. 2)

4. Use a small probe to move the poppet up and down to assure that the valve is functioning

properly and that no debris is stuck in the valve. (See Fig.3)

5. Using the mechanics pick remove the valve seat O-ring and inspect for any damage, replace

if necessary. (See Fig. 4)

Fig.1 Fig. 2

Fig.3 Fig.4

3. Maintenance and Troubleshooting

C-250E R14 Page 15

Valve Assembly:

1. Install the valve seat O-ring squarely into the bottom of the manifold. (See Fig.5)

2. Insert the valve assembly squarely into the port pushing it into the O-ring. (See Fig.6)

3. Install the valve cap and torque to the proper specification. (See Fig.7)

Fig.5 Fig.6

Fig.7

3. Maintenance and Troubleshooting

C-250E R14 Page 16

Servicing the Packing / Seals

Disassembly:

1. First remove the eight 6mm head bolts. (See Fig. 8)

2. Place the screwdrivers as shown between the head and crankcase of the pump, lifting one

up and the other down. The head should start to lift off of the plungers. (See Fig.9)

3. When you remove the head you may notice that some of the water seals have stayed on the

plungers and some in the head. (See Fig.10) To remove the seals from the plungers simple

turn the assemblies and pull off.

4. If the seal assemblies are in the head use the reversible pliers to grab the seal retainer on the

inside bore (NOTE: Use a rag so you do not mar the piston guide area), twist the retainer in

either direction. (See Fig.11)

5. With your fingers pull the high pressure seal and head ring out of the head.(See Fig.12)

6. The low-pressure seal is located in the brass seal retainer. Using the mechanics pick go in

between the seal and retainer, twist and pull, the seal will come out of the gland.

(See Fig.13 & 14)

7. Remove the seal retainer O-ring with the mechanics pick. (See Fig.15)

Fig.8 Fig.9

Fig.10 Fig.11

Fig.12 Fig.13

Fig.14 Fig.15

3. Maintenance and Troubleshooting

C-250E R14 Page 17

Assembly:

1. Install the plastic head ring into the head (the flat side is on the bottom). (See Fig. 16)

2. Install the high-pressure seal. Place the seal so the open “V” portion is toward the head ring.

You need to place the seal at an angle and pull and push to work the seal into position with

your fingers (do not use and tools you may damage the seal). Make sure the seal is totally

seated against the head ring. (See Fig. 17)

3. Installing the low-pressure seal. You want the open side of the seal to be pointed toward the

water side of the head (toward the high-pressure seal) and the flat side toward the drive end

of the pump.

Place the seal into the gland at an angle, with your finger push the exposed side of the seal

towards the center and work the seal (See Fig. 18, 19) into position. After the seal is in the

gland you can work it into it proper position.

4. Install the retainer O-ring. (See Fig. 20)

5. Squarely seat the retainer into the head and push with even pressure until it snaps into

position. (See Fig.21)

Fig.16 Fig.17

Fig.18 Fig.19

Fig.20 Fig.21

3. Maintenance and Troubleshooting

C-250E R14 Page 18

Servicing the Plungers

Disassembly :

1. Remove the plunger retainer nut. (See Fig. 22)

2. Insert the gasket scraper between the copper washer and plunger to remove the washer.

(See Fig. 23)

3. Twist and pull the plunger off the plunger rod.

4. Remove the plunger rod O-ring seal and split back-up ring with the mechanics pick. (See

Fig. 24)

5. Remove brass slinger. At this point clean any thread locker that is left on the plunger rod

and retaining nut threads. (See Fig. 25)

Fig.22 Fig.23

Fig.24 Fig.25

3. Maintenance and Troubleshooting

C-250E R14 Page 19

Assembly:

1) Install the slinger washer. (See Fig.26)

2. Install the plunger rod O-ring and split back-up ring. Place a light film of oil on the O-

ring and back-up ring. (See Fig. 27)

3. Install the plunger by pushing straight down and twisting slightly in either direction (See

Fig. 28)

4. Install the small copper washer on top of the plunger and place a small quantity of thread

sealant in the thread. Install the plunger nut and tighten to the required torque. (See Fig. 29

& 30)

Fig.26

Fig.27 Fig.28

Fig.29 Fig.30

3. Maintenance and Troubleshooting

C-250E R14 Page 20

Pump head to drive end Installation

1. Turn the crankshaft to align the plungers as shown. (See Fig.31)

2. Place the head evenly onto the plungers and push it until it makes contact with the drive end

of the pump. (See Fig.32)

3. Torque the head bolt as shown in the tightening sequence diagram. (See Fig. 33 & 34)

Fig.31

Fig.32

Fig.33 Fig.34

D es c riptio ns H e ad (F ig .3 4) P is t on N u t V a lve C ap

In.lbs 133 10 6 4 42

K g .m /N .m 1 5 1 2 5 0

Table of contents

Other Den-Sin Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Snapper

Snapper SP3400 Quick Start Up/Shutdown Guide

Elektro Maschinen

Elektro Maschinen HDEm 2550 user manual

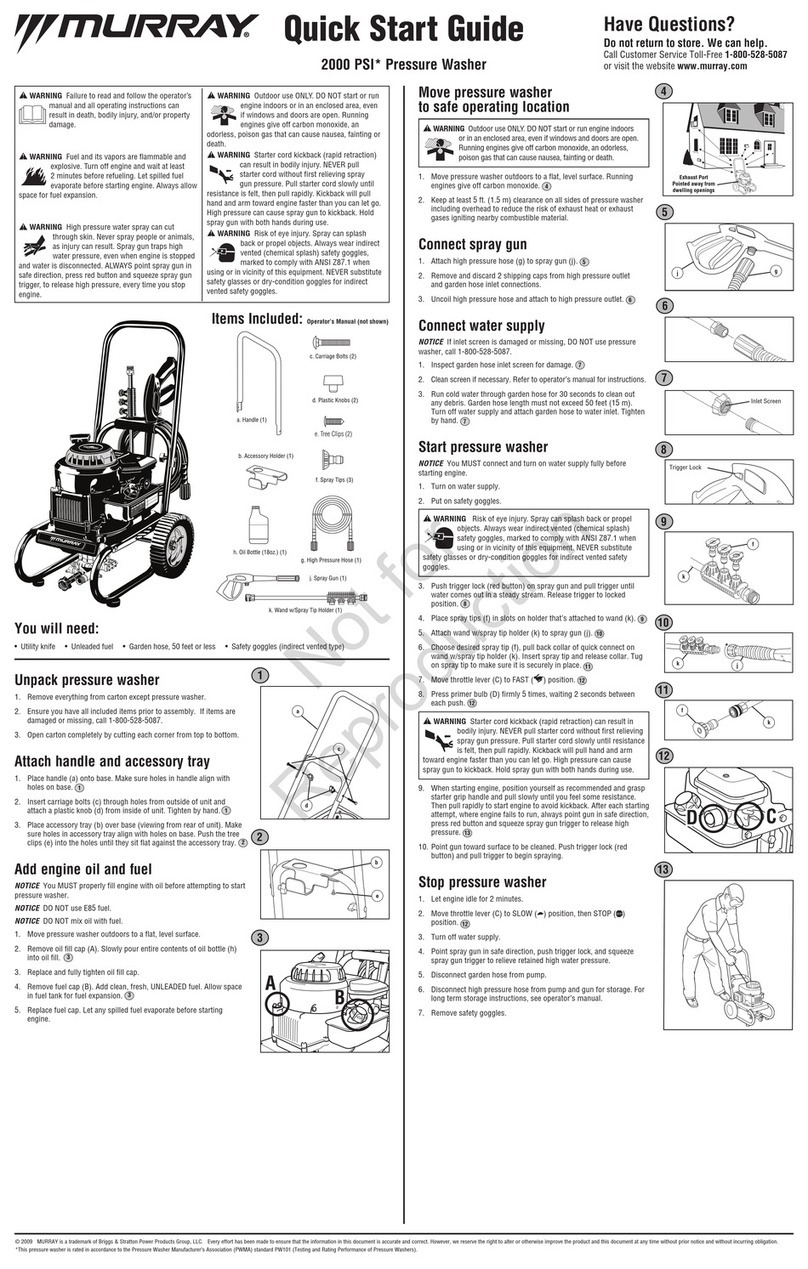

Murray

Murray 2000 PSI Series quick start guide

Xstream

Xstream PE-5024HWEBGEN Operation manual

Kärcher

Kärcher K2.01 operating instructions

Shark

Shark HPB HPB-3520 Operating instructions and parts manual