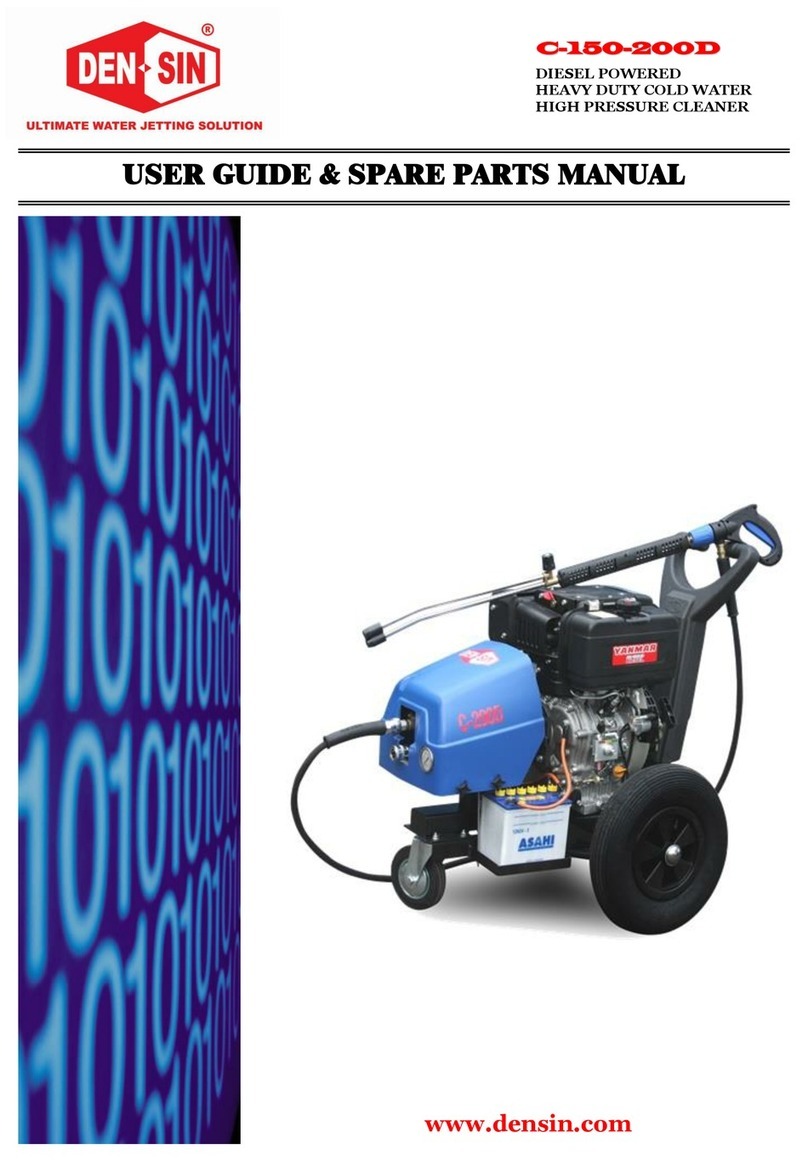

Den-Sin Merlion Plus E500 Guide

www.densin.com

USER GUIDE & SPARE PARTS MANUAL

Electrical Powered

Heavy Duty Cold Water High

HIGH PRESSURE CLEANER

Original Instruction

Merlion Plus

E500

INTRODUCTION

MERLION PLUS - E500 STD04

Page 1 of 50

Disclaimers

Den-Sin reserves the right to change specifications and to improve our products without notice or

obligation.

All Rights Reserved

This document or part of it may not be photocopied, or in any other way reproduced, or translated to other

languages without the prior written consent of

DEN-SIN.

Warning

Read this user manual before you start up your Heavy Duty Pressure Washer for the first time.

This Heavy Duty Pressure Washer producing water jet under high-pressure, which is why severe injuries

can occur if the safety precautions are not observed.

Therefore a full understanding of the contents of this instruction manual is required, in order to prevent

injuries to you, objects and persons nearby.

Safety

The following symbols are used in this manual to indicate procedures that if not followed, may results in

personal injuries or damage to equipment.

WARNING

is used to alert the reader of procedures or practice which if not

followed correctly could result in personal injuries.

CAUTION

is used to alert the reader of procedures or practice which if not

followed correctly could result in damage to machine or other equipment.

NOTE

is used to highlight important information that may assist the reader

carrying out the procedure or understanding the text.

EAR PROTECTION

is used to caution of high noise machine level. User

must wear ear plug or ear muffler. High noise level will damage user hearing.

HOT SURFACE

is used to caution user of hot surface that may cause injuries.

Any maintenance work to be done after the surfaces had cool down.

WARNING

CAUTION

NOTE

INTRODUCTION

MERLION PLUS - E500 STD04

Page 2 of 50

INTRODUCTION............................................................................................................................1

1. Getting acquainted with your Heavy Duty Pressure Washer ................................................2

OPERATIONAL INFORMATION .................................................................................................3

MACHINE DIMENSION................................................................................................................5

High Pressure Machine Schematic Diagram....................................................................................6

Marking & Indication.......................................................................................................................7

Machine Highlights ..........................................................................................................................8

HIGH PRESSURE MACHINE LOCKOUT/TAGOUT PROCEDURE .........................................8

2. Safety and protection information..........................................................................................13

General safety.................................................................................................................................13

WARNING.....................................................................................................................................14

Safety devices.................................................................................................................................15

Transporting the machine...............................................................................................................15

Safety PPE......................................................................................................................................17

Operations ......................................................................................................................................18

Application Guidelines...................................................................................................................18

3. Maintenance and troubleshooting ..........................................................................................19

Maintenance Schedule....................................................................................................................19

Troubleshooting..............................................................................................................................21

Pump Service Instructions..............................................................................................................22

Torque Specification ......................................................................................................................24

4. Machine Spare Parts Lists.......................................................................................................25

Motor/Pump Assembly Spare-Parts List........................................................................................26

Water Tank Assembly Spare-Parts List .........................................................................................27

Filter Assembly Spare-Parts List....................................................................................................28

E500 Pump Assembly Spare-Parts List..........................................................................................29

E500 Trigger Gun / lance & hose assembly...................................................................................37

4. Electrical Assembly ..................................................................................................................39

Wiring diagram...............................................................................................................................39

Main Contactor Overload Setting...................................................................................................40

Motor Switch Timer Setting...........................................................................................................40

5.Optional Rotating Nozzle..........................................................................................................44

E500 Bar Rotating Nozzle – Type 3 ..............................................................................................45

Operation & Use of Rotating Nozzle –E500..................................................................................48

Optional sand & slurry blasting kit E500.......................................................................................49

6. Warranty...................................................................................................................................50

Revison History:-

1. Getting acquainted with your Heavy Duty Pressure Washer

Date Revision Rev. No.

03/08/2016 Added start-up issues and troubleshooting guide 01

19/04/2017 Updating 220V components 02

05/06/2017

Pump and Component Changeover and removal of CE declaration

03

25/09/2017

Manual Content U

pdating. Cable and Water Tank P/N update.

04

The information contained in this user guide is subject to change without notice.

Getting Acquainted with your Heavy Duty Pressure Washer

MERLION PLUS - E500 STD04

Page 3 of 50

The DEN-SIN Merlion Plus E500 facilitates cleaning in less time at high performance. The compact

design enables the machines to be agile within tight/ narrow places, and the high performance gives you the

opportunity to solve an array of cleaning tasks. With built in water tank, machine now works even more

efficient and reliable.

All pump parts, fittings and pipes in contact with water are made of non-corrosive materials. Together with

the ceramic pistons, long life seals and stainless steel valves, it ensures long life and high durability.

Applications

These Heavy Duty Pressure Washers are capable of removing any kind of dirt:

•Algae off concrete constructions

•Paint and graffiti off walls

•Dust, dirt, soil & mud off floors

•Oil & grease off engines and other mechanical parts

•Rust, dirt, salt, scale and paint off ship decks

The Heavy Duty Pressure Washer can also be used for tasks such as:

•Surface preparation

•Concrete removal

And with the option of using different accessories, many more jobs can be dealt with:

•Sandblasting

•Drain-cleaning

•Extra-long / short lances for hard to reach places

•Rotating nozzle

This machine is only to be used for the purposes it is designed for. Any other use shall

be considered improper and therefore potentially dangerous. The manufacturer is NOT

to be held responsible for any damages caused by improper use.

Unpacking

Remove the Heavy Duty Pressure Washer and its accessories from the packing material. For transport and

packing reasons some accessories are supplied disassembled. Make sure all components are present:

Standard items:

CAUTION

Trigger Gun

Machine Manual

Nozzle

Machine

High Pressure Hose

Getting Acquainted with your Heavy Duty Pressure Washer

MERLION PLUS - E500 STD04

Page 4 of 50

1.1 OPERATIONAL INFORMATION

High Pressure Machine has IP55 rating. Parking the machine outdoor will not pose any damage to

the machine. Ensure that the ventilation to the motor must not be blocked. During operation, the

machine must not park at an incline angle of 10deg. The machine will become unstable and may

endanger user. When hose is pull up to a high, pressure will drop due to gravity.

This machine is designed to deliver clean water or non-aggressive water. Using any other water

source or sea water will damage the pump unless authorized in writing by Den-Sin.

Prior to beginning work, all equipment must be inspected to ensure that it is in safe working

condition. Inspection shall include verifying the integrity of hoses and connections, tips, lances.

Personal protective equipment must be worn.

Prior to commencing any water blasting work, the area must be barricaded to restrict unauthorized

access.

We recommend to practice to employ 2 operators* blasting method. The role of the 2

nd

operator is

to attend the pump unit keep close watch on the 1

st

operator for tiredness. Therefore, the operators

can take turns to operate the machine.

∗Operators must be trained on how to operate the machine (DENSIN) and the basic blasting

protocol before allow to use the machine.

How to prepare machine for usage

Correct way of holding the trigger gun for blasting due to the recoil force from the

trigger gun.

Understand how to operate the machine correctly.

Basic Maintenance and Troubleshooting.

** Den-Sin Training program is available upon request. Please contact us for more details **

IMPORTANT

that user read the manual guide to understand the operation of the

machine before usage.

NOTE

Table of contents

Other Den-Sin Pressure Washer manuals