Denios SpillGuard User manual

Technical changes reserved

Operating instructions

SpillGuard®

Output 2020-08

Original instructions

Copyright

DENIOS AG

Dehmer Straße 58-66

32549 Bad Oeynhausen

Tel. +49 5731 753-0

Fax +49 5731 753-199

Email info@denios.de

These instructions contain texts, images and drawings which need express written

authorisation before they can be reproduced, distributed or otherwise shared, in part or

in full.

These instructions represent the legal situation in Germany.

IMPORTANT

Read carefully before commissioning

Keep safe for later reference

© Copyright DENIOS AG

3 / 36

Table of contents

1Notes on the operating instructions .......................................................................................5

1.1 Warnings............................................................................................................................5

1.2 Instructions for use............................................................................................................7

1.3 Labelling.............................................................................................................................7

2Safety instructions ......................................................................................................................9

2.1 Intended use ....................................................................................................................10

Misuse .......................................................................................................................10

2.2 Operator duties ................................................................................................................11

Before commissioning...............................................................................................11

Obligation to inspect spill sumps .............................................................................12

Spill sump resistance................................................................................................12

Compliance with the requirements of the safety data sheet .................................12

Training......................................................................................................................13

Use in Ex zones - explosion protection requirements .............................................13

2.3 Personnel requirements ..................................................................................................15

3Transport and storage ..............................................................................................................16

3.1 Unpacking.........................................................................................................................16

4Product description ..................................................................................................................17

4.1 Overview ..........................................................................................................................17

4.2 Dimensions.......................................................................................................................19

4.3 Technical data..................................................................................................................20

Explanation of the nameplate ..................................................................................21

5Installation..................................................................................................................................22

5.1 Requirements for the installation location.....................................................................22

6Operation.....................................................................................................................................24

6.1 Commissioning the product.............................................................................................24

4 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

6.2 Using the product in a new location...............................................................................25

6.3 Carrying out measures if the alarm is triggered ............................................................25

7Faults and incorrect operation...............................................................................................27

7.1 Possible faults..................................................................................................................27

8Maintenance ..............................................................................................................................29

9Decommissioning......................................................................................................................30

9.1 Switching off....................................................................................................................30

9.2 Cleaning ...........................................................................................................................31

10 Disposal.......................................................................................................................................32

11 EU conformity .............................................................................................................................33

Notes on the operating instructions

5 / 36

1Notes on the operating instructions

Before you set up and commission your product, ensure you read these operating

instructions completely. Always take note of the safety notices and warnings.

These operating instructions are for anyone who comes directly into contact with the

product.

These operating instructions form part of the product.

Further applicable documents

Depending on the product, you will receive the following documents separately as part

of your delivery:

Quick Guide

EU Declaration of Conformity (Download)

Resistance list (Download)

Differences are possible depending on country.

1.1 Warnings

Warnings are shown at the start of a chapter or section before instructions for use

where a hazard may occur. The warnings are structured as follows:

Notes on the operating instructions

6 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

DANGER

The symbol shows the type of hazard.

Symbol and signal word show a hazard which leads to

serious injury or death.

Measure.

WARNING

The symbol shows the type of hazard.

Symbol and signal word show a hazard which can lead to

serious injury or death.

Measure.

CAUTION

The symbol shows the type of hazard.

Symbol and signal word show a hazard which can lead to

minor injury.

Measure.

NOTICE

Signal word shows a hazard which can lead to damage to property.

Notes on the operating instructions

7 / 36

Symbol shows instructions for use and other useful

information.

Pictograms are used to warn of hazards:

Pictogram Meaning

General warning

1.2 Instructions for use

These operating instructions contain various instructions for use.

Perform the following action

This is a requirement.

1. This is an action step.

This is an intermediate result.

2. This is another action step.

☑This is the final result.

1.3 Labelling

Italic text Is used to emphasise individual words or

phrases

Notes on the operating instructions

8 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

Cross reference [7 ] Indicates that content is explained on another

page

NOTICE! Text.

CAUTION! Text.

WARNING! Text.

DANGER! Text.

Important information in the text, instructions for

use or tables

Important information for explosion protection

Refers to an audible signal after an action step

Refers to a visual signal after an action step

www.denios.com/spillguard

Further information available to download

LED

Safety instructions

9 / 36

2Safety instructions

This section gives important notices for safe use of the product. These notices are to

protect employees and to ensure safe, fault-free operation. Warnings relating to use

can be found in the corresponding instructions for use.

The product is built in accordance with the state of the art and the recognised technical

rules.

There may be hazards associated with the product if it is used, maintained or repaired in

an incorrect manner, not in accordance with the intended use or by untrained personnel.

Hazards may arise affecting:

Health and life of personnel

Product and other assets near the product

Follow all the safety instructions in these operating instructions as well as all safety

instructions in the operating instructions of our suppliers which have been provided.

Ensure that the national directives and safety regulations relating to hazardous

substances, safety directives, industrial safety and operator duties are observed.

Safety instructions

10 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

2.1 Intended use

SpillGuard® is a mains-power-independent leak recognition system for detecting leaks

of liquids / liquid hazardous substances. SpillGuard® is designed for use in clean,

uncontaminated spill sumps, which are set up indoors.

The spill sumps should preferably be in metal or non-metallic (plastic) materials.

Outdoor use is not permitted.

SpillGuard® may only be used within the limits for use defined on the nameplate.

SpillGuard® is suitable for Ex zone 0, due to gases and vapours.

SpillGuard® may only be used as a precaution with the liquids which have already been

positively tested by DENIOS. The list can be found here:

www.denios.com/spillguard

Suitability must be tested for substances which are not in the list.

The resistance list contains a representative selection of liquid

hazardous substances. If required, DENIOS can carry out a

function and resistance test for your substance. The test

includes checking that the substance is correctly detected and

also that the alarm signal is then maintained for 24 h

(resistance test).

Misuse

DENIOS takes no responsibility for any damage caused by contravention of the intended

use. All warranties and guarantees are excluded in the event of misuse. The party

causing the misuse is solely responsible for any consequential damage.

Safety instructions

11 / 36

The following are considered as not in accordance with the intended use:

Using SpillGuard® in spill sumps for storing non-approved media

Using SpillGuard® in potentially explosive areas outside the nameplate limits

Using SpillGuard® in potentially explosive areas caused by dust

Using SpillGuard® again after a leaked substance has been successfully detected

Using substances which are not suitable for use with SpillGuard® :

www.denios.com/spillguard

Disregarding applications which are expressly described as permitted

Changing the battery

WARNING! If the housing is opened in Ex atmospheres there is a risk of

explosion. Opening the housing can lead to severe injuries or death.

Opening the housing is prohibited.

2.2 Operator duties

Before commissioning

Check the product for damage.

Safety instructions

12 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

Obligation to inspect spill sumps

SpillGuard® is an additional safety measure, which indicates a leak using a visible and

an audible signal.

Regardless of using SpillGuard® the operator of containment devices is obliged to carry

out and document the weekly visual inspections required by the steel spill sump

guidelines (Stawa R) and the General Technical Approval.

Use of SpillGuard® does not mean that the operator of the equipment is no longer

required to comply with this obligation.

Spill sump resistance

The corrosion resistance of the materials used to make the spill

sump and their compatibility with the substances stored must

be demonstrated.

For many chemical substances steel spill sumps (1.0038) may be used. Plastic

(polyethylene) spill sumps are frequently required if corrosive substances (acids /

alkalis) are being stored. Stainless steel offers the best protection, especially against

many aggressive liquids. If no information is given in the resistance lists, the material of

the spill sump may be the same material as the transport container.

Compliance with the requirements of the safety data sheet

A safety data sheet must be prepared by the distributor for each hazardous substance,

in accordance with REACH legislation.

As the operator, you must observe the safety and hazard information in the safety data

sheet.

Safety instructions

13 / 36

Training

Personnel in question must be sufficiently trained at regular intervals, and especially if

changes or adjustments are made. Employees must be trained when the product is used

in Ex zone 0, especially on the measures for the avoidance of explosion hazards set out

in the risk assessment and explosion protection document.

Use in Ex zones - explosion protection requirements

Storage systems for flammable liquids are systems requiring monitoring within the

meaning of the Product Safety Act (ProdSG) § 2 Para. 30 with explosion hazard. The

requirements to be derived from this are described in the applicable technical rules for

the German Industrial safety regulations (BetrSichV) and the Hazardous substance

regulations (GefStoffV). According to the German Industrial safety regulations

(BetrSichV), the operator of this equipment is obliged to carry out a risk assessment. In

addition, the operator is obliged to produce an explosion protection document in which

appropriate protective measures are defined in order to avoid explosion hazards.

In addition, Directive 1999/92/EC sets out the minimum regulations for improving work

health and safety for employees who may be at risk due to explosive atmospheres. The

main contents are:

Duty of coordination

Explosion protection document

Classification of areas where an explosive atmosphere may be present

Safety instructions

14 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

Minimum regulations for improving work health and safety for employees who may

be at risk due to explosive atmospheres as well as criteria for selecting equipment

and protection systems

The explosion protection document produced by the operator specifies the conditions at

the location of use. The operator must test in detail whether the product meet the

requirements of the explosion protection document.

The product is to be included in the preparation of the explosion protection document

and the measures it contains.

Further additional operator measures also include:

Include the storage system in the local equipotential bonding measures to avoid

electrical compensation currents.

The same applies for the avoidance of sources of ignition, discharge of static

electricity, connection to the equipotential bonding system is required here.

If the containers are filled with flammable liquids on the system components:

consider the additional measures regarding discharge of static electricity in

accordance with TRGS 727.

To comply with the discharge values, keep the bearing surface free of paint

residues, hazardous material residues or unwanted insulation.

Operate the storage system so that process-related electrostatic charges are ruled

out (e.g. from cleaning work, see also TRGS 727 Sections 4 and 5).

Safety instructions

15 / 36

2.3 Personnel requirements

Risk-free working is only possible, when only specially qualified personnel set up and

use the product.

Persons undergoing training may only be permitted to work with the product, if a

qualified person is constantly supervising the work.

Transport and storage

16 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

3Transport and storage

The product is supplied in a cardboard pack together with a Quick Guide and inlay sheet.

Store the product as follows:

Dry

At room temperature

NOT outdoors

NOT in direct sunlight

3.1 Unpacking

Perform the following action

The pack is not damaged.

1. Open the cardboard pack.

2. Remove the contents.

3. Keep the Quick Guide to hand near the

product.

Product description

17 / 36

4Product description

4.1 Overview

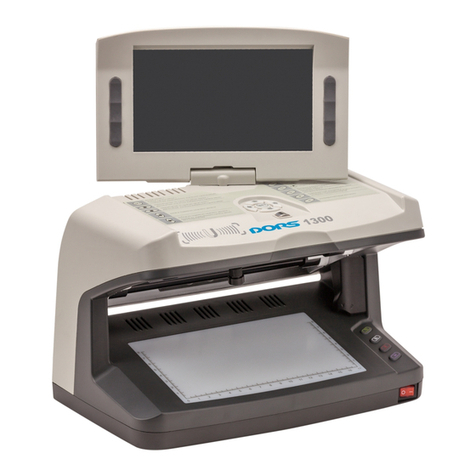

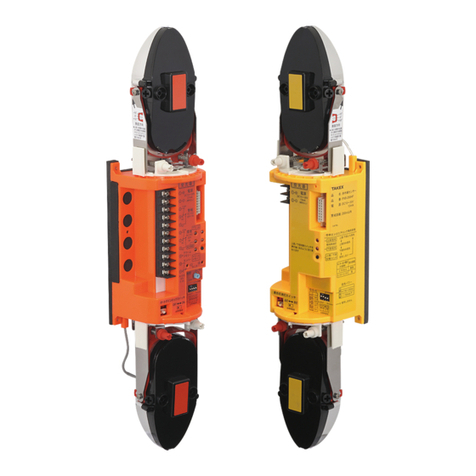

Fig. 1: Top view

1

2

Product description

18 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

Fig. 2: Bottom view

Element Function

1 “Red” LED

The “red” LED illuminates during commissioning,

operation and when an alarm is triggered.

2 Push button The push button is used to switch SpillGuard® on and off

and also to turn off the signal when an alarm has been

triggered.

3 Sensor

surface

If the sensor surface becomes wet, it detects a leak and

triggers the audible and visible signal.

4 Foot The different height feet ensure the product is stable. The

different height feet ensure that a leaked liquid reaches

the sensor surface without any bubbles.

3

4

Push

LED

Product description

19 / 36

4.2 Dimensions

Fig. 3: Dimensions in mm

Product description

20 / 36

271081_SpillGuard_Operating-

instr_003_en.docx

4.3 Technical data

Description Value

Dimensions ∅110 mm, height 40 mm

Operational temperature range 0 °C to a maximum of 40 °C

Temperature class T4 (max.135 °C)

Explosion protection group II B

Ignition protection type Intrinsically safe

Equipment category 1G

Weight 140 g

Nominal voltage 3.6 V

Lifespan Max. 5 years

Liquid level required to wet the sensor 6 mm

Noise in accordance with DIN EN ISO 3744 91.6 dB (A)

EC type examination certificate BVS 19 ATEX E 077

IECEx BVS 19.0073

FM certificate FM 20 US 0051

FM 20 CA 0023

The recommended operational temperature range is the

basis for the specified service life of 5 years. SpillGuard®

may also be used at a temperature down to max. -10°C. The

specified service life of 5 years cannot be guaranteed

however in this temperature range. Repeated false alarms

can be triggered if the temperature fluctuates around the

dew point.

Other manuals for SpillGuard

2

Table of contents

Other Denios Security Sensor manuals