Bierer VD1000 User manual

1

Digital Voltage Detector 0-999kV

Operating Instructions

VD1000TM

2

CONTENTS

Limitation of Warranty and Liability 3

Product Safety Information 4

Design and Function –Battery Replacement 5

Voltage Detection in the “URD” Position 6

Voltage Detection in the “OH” Position 7

Voltage Detection in the “OHT” Position 8

Testing Meter On Known Voltage 9

Notes 10

Part and Accessories 11

3

Limitation of Warranty and Liability

Bierer & Associates Inc. warrants this product to be free from defects in

workmanship and material, under normal use and service conditions for a

period of one year from date of shipment.

Due to continuous product improvement and development, Bierer & Associates

Inc. reserves the right to modify product designs and specifications without

notice.

It is impossible to eliminate all risks associated with the use of high voltage

electrical devices including this device. Risks of serious injury or death are

inherent in working around energized electrical systems. Such risks include but

are not limited to variations of electrical systems and equipment, manner of use

or applications, weather and environmental conditions, operator mentality, and

other unknown factors that are beyond the control of Bierer & Associates Inc.

Bierer & Associates Inc. do not express or imply to be an insurer of these risks,

and by purchasing or using this product you AGREE TO ACCEPT THESE RISKS. IN

NO EVENT SHALL Bierer & Associates Inc. BE LIABLE FOR ANY INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM THE USE OR

HANDLING OF THIS PRODUCT.

SAFETY MESSAGE DEFINITIONS per ANSI Z535

These instructions contain important safety messages to alert the user to

potentially hazardous situations, how to avoid the hazard, and the

consequences of failure to follow the instruction.

The safety alert symbol identifies a safety message. The signal word

following the symbol indicates:

DANGER A hazardous situation which, if not avoided, will result in

death or serious injury and equipment damage.

WARNING A hazardous situation which, if not avoided, could

result in death or serious injury and equipment damage.

CAUTION A hazardous situation which, if not avoided, could

result in minor or moderate injury and equipment damage.

NOTICE Important safety message relating to equipment damage

only.

4

PRODUCT SAFETY INFORMATION

WARNING

1. Meter assembly, interconnect cable assembly, and live line tool

adapters shall be considered non-insulating. Do not let live line tool

fittings come in contact with energized or grounded conductors. The

live line tool adapters, fittings, and handles supplied with meters

shall not be used on any other devices.

2. Use appropriate length live line tools for voltage being worked and

maintain minimum approach distances as outlined in OSHA

1910.269, Table R-6.

3. All Phasing Meters and Voltage Detectors manufactured during and

after 2007 will have a limit mark engraved on the high voltage

probe(s) 2.5 inches from the tip to indicate to the user the physical

limit that should not be exceeded when approaching and contacting

an electrical conductor or other electrical test points. Zero Ohm

insulated adapters (81280IE) should be used if limit mark will be

exceeded.

4. This equipment should be used only by qualified employees, trained

in and familiar with the safety-related work practices, safety rules

and other safety requirements associated with the use of this type

of equipment.

5. These instructions are not intended as a substitute for adequate

training, nor do they cover all details or situations which could be

encountered when operating this type of equipment.

6. Before operating this equipment, read, understand and follow all

instructions contained in this manual. Keep instructions with

equipment.

INSPECTION & MAINTENANCE BEFORE USE

WARNING

1. Prior to using any high voltage test equipment a careful inspection

should be made to ensure the unit is free from any contaminants

such as dirt, grease, etc. and that there are no apparent physical

damages.

2. High voltage probe assemblies shall be wiped clean prior to each use

with a silicone impregnated cloth and kept clean and free of

contaminants. This will prevent tracking on the outside of the probe

and meter error.

3. Always confirm internal battery voltage before and after each use.

4. Unit shall be tested before and after each use on a known voltage

source. Failure to do so could result in false negative indications

5

DESIGN and FUNCTION

WARNING

Limit Mark -see “Product Safety Information”, item 3, page 4.

The VD1000 is a direct contact, capacitive type voltage detector for use

on voltages from 0 to 99.9kV on distributions circuits and 999kV on

Transmission conductors. The 0V is for identifying de-energized lines. For

voltage readings, meter works at or above 1kV.

NOTE: Meter indicates Line-to-Ground values. Not calibrated to read

Phase-to-Phase.

Each unit has a five position switch for the following functions:

OFF Use this position for Storage and Transit

URD Direct Contact, Underground Primary (01.0 - 99.9)

OH Direct Contact, Overhead Lines (01.0 –99.9)

OHTDirect Contact, Substation & Transmission Lines (001 –999)

TEST Displays battery voltage, i.e. 9.0 = 9vdc battery voltage

NOTICE This unit incorporates a battery test when turned to the test

position displaying the battery voltage. A reading less than 07.0 indicates

low battery. Replaceable 9V battery is located behind the live line tool

attachment threaded into the meter housing.

WARNING

As with all voltage detectors, readings can be affected by a variety of field

conditions. For example, if the live line tool attachment is close to another

phase, ground or voltage source, the readings may be high. If the live line tool

attachment is close to the same phase, readings may be low.

If there is any doubt about the meter reading under any circumstances, the line

or equipment shall be considered energized and appropriate safety precautions

taken, i.e., confirm visual open gaps, tag outs, hold orders and sources of

induced voltage.

6

Voltage Detection in the “URD” Position

WARNING

Unit shall be tested before and after each use on a known voltage

source. Failure to do so could result in false negative indications.

1. Test Voltage detector for proper operation by turning selector

switch to the “TEST” position. Meter should display 88.8 then the

current battery voltage and hold it as long as it is held in the test

position.

2. Thread appropriate adapter, bushing or elbow into meter probe.

3. Attach voltage detector to appropriate length live line tool for

voltage being tested.

4. Turn the selector switch to the “URD” position.

5. Make direct contact with URD equipment under test. If

equipment is energized, meter should read approximate Line-to-

Ground voltage (01.0kV –99.9kV).

6. If URD equipment is de-energized, meter should read zero volts.

7. Re-test voltage detector by turning the selector switch to “Off”

and back to “TEST”.

Readings should take into account proximity to other phases and

grounded surfaces and be consistent with previous experience on the

same voltage and circuit configuration with this voltage detector. If there

is any doubt about the meter reading in the “URD” position, the line or

equipment shall be considered energized and appropriate safety

precautions taken.

7

Voltage Detection in the “OH” Position

WARNING

Unit shall be tested before and after each use on a known voltage source.

Failure to do so could result in false negative indications.

1. Test Voltage detector for proper operation by turning selector

switch to the “TEST” position. Meter should display 88.8 then the

current battery voltage and hold it as long as it is held in the test

position.

2. Turn the selector switch to the “OH” position.

3. Attach voltage detector to appropriate length live line tool for

voltage being tested.

4. Make direct contact with line or equipment under test. If

equipment is energized, meter should read approximate Line-to-

Ground voltage (01.0kV –99.9kV).

5. If no voltage is present, meter should read zero volts. Readings

other than zero volts may indicate the presence of induced

voltage.

6. Re-test voltage detector by turning the selector switch to “Off”

and back to “TEST”.

WARNING

Unit shall be tested before and after each use on a known voltage source.

Failure to do so could result in false negative indications.

Readings should take into account proximity to other phases and

grounded surfaces and be consistent with previous experience on the

same voltage and circuit configuration with this voltage detector. If there

is any doubt about the meter reading in the “OH” position, the line or

equipment shall be considered energized and appropriate safety

precautions taken.

8

Voltage Detection in the “OHT” Position

WARNING

Unit shall be tested before and after each use on a known voltage

source. Failure to do so could result in false negative indications.

1. Test Voltage detector for proper operation by turning selector

switch to the “TEST” position. Meter should display 88.8 then the

current battery voltage and hold it as long as it is held in the test

position.

2. Turn the selector switch to the “OHT” position.

3. Attach voltage detector to appropriate length live line tool for

voltage being tested.

4. Make direct contact with line or equipment under test. If

equipment is energized, meter should read approximate Line-to-

Ground voltage (001kV –999kV)

5. If line or equipment is de-energized, meter should read zero volts.

Readings other than zero volts may indicate the presence of

induced voltage.

6. Re-test voltage detector by turning the selector switch to “Off”

and back to “TEST”.

Readings should take into account proximity to other phases and

grounded surfaces and be consistent with previous experience on the

same voltage and circuit configuration with this voltage detector. If there

is any doubt about the meter reading in the “OHT” position, the line or

equipment shall be considered energized and appropriate safety

precautions taken.

9

Testing Unit On Known Voltage

WARNING

Unit shall be tested before and after each use on a known voltage

source. Failure to do so could result in false negative indications.

1. Test Voltage detector for proper operation by turning selector

switch to the “TEST” position. Meter should display 88.8 then the

current battery voltage and hold it as long as it is held in the test

position.

2. Turn the selector switch to any position.

3. Attach voltage detector to appropriate length live line tool for

voltage being tested.

4. Make direct contact with the known voltage source.

5. The meter should display a voltage appropriate for the device

being used for the known voltage. See operating instructions for

the voltage source for normal voltage readings.

6. Re-test voltage detector by turning the selector switch to “Off”

and back to “Test”.

10

Notes

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

11

PARTS & ACCESSORIES

PART NO.

DESCRIPTION

3402

Quick Change to Grip All

Adapter

3403

Quick Change to Universal

Adapter

8128EALB

15 –25kV Elbow Adapter

8128TBALB

15 - 25kV Bushing Adapter

81280LHM

Hook Adapter

81280LPM

Straight Probe Adapter

81280B1

6V Battery for Power Supply

PA25B

20” Storage Box with Foam

PA25T

3kV Power Supply

PAH6TB

26" Storage Box for Handles

PD50B

26" Storage Box with Foam

Technical & Service

Bierer & Associates Inc.

Manufacturing & Repair

10730 Farrow Rd.

Blythewood SC 29016

Tel: (803) 786-4839

Fax: (803)786-5457

BiererMeters.com

12

Other manuals for VD1000

1

Table of contents

Popular Security Sensor manuals by other brands

Honeywell

Honeywell Notifier FST-851 Series quick start guide

Marmitek

Marmitek smart me Sense SE instructions

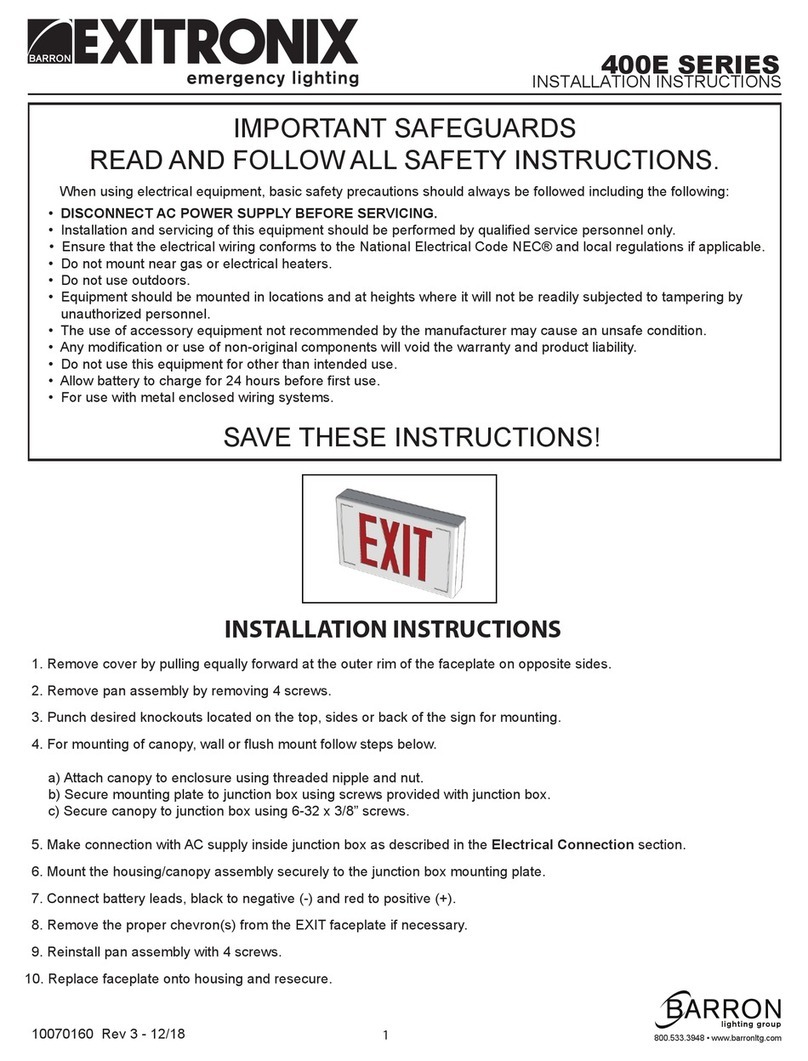

BARRON

BARRON EXITRONIX 400E Series installation instructions

Alula

Alula RE629 Glassbreak Connect+ Encrypted quick start guide

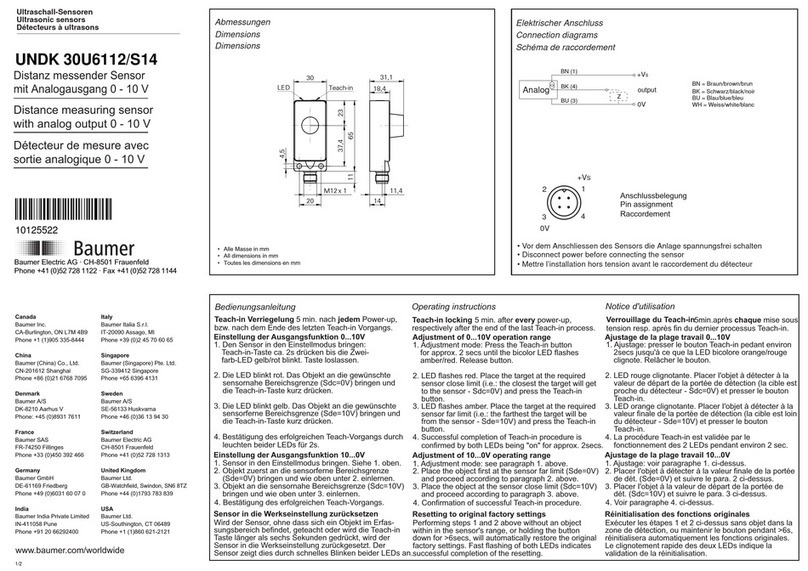

Baumer

Baumer UNDK 30U6112/S14 manual

WITTUR

WITTUR WSE EVO installation manual