Denison Hydraulics Goldcup M11 Series User manual

DENISON HYDRAULICS

Axial Piston Motor

Variable Displacement

Installation and Overhaul Instructions

Goldcup Series M11

Goldcup Series M14

SVM-M11/M14-D

Revised 7/03

www.comoso.com

TABLE OF CONTENTS

PAGE

Introduction----------------------------------------------------------------------------------------------------------------------------------- 3

Installation

Mounting--------------------------------------------------------------------------------------------------------------------------------------- 4

Piping------------------------------------------------------------------------------------------------------------------------------------------- 4

Fluid recommendation & maintenance------------------------------------------------------------------------------------------------- 4

Start-Up Procedures------------------------------------------------------------------------------------------------------------------------ 4

Table II: Troubleshooting------------------------------------------------------------------------------------------------------------------ 6

Rework limits--------------------------------------------------------------------------------------------------------------------------------- 7

Disassembly

Controls---------------------------------------------------------------------------------------------------------------------------------------- 8

Barrel holddown------------------------------------------------------------------------------------------------------------------------------ 8

Port block-------------------------------------------------------------------------------------------------------------------------------------- 8

Barrel and holddown shaft---------------------------------------------------------------------------------------------------------------- 8

Drive shaft------------------------------------------------------------------------------------------------------------------------------------- 8

Housing---------------------------------------------------------------------------------------------------------------------------------------- 8

Rocker cam and control stroking assembly------------------------------------------------------------------------------------------- 9

Assembly

Drive shaft assembly----------------------------------------------------------------------------------------------------------------------- 10

Rocker cam and stroking assembly---------------------------------------------------------------------------------------------------- 11

Vane seal cartridges------------------------------------------------------------------------------------------------------------------------ 11

Control chambers---------------------------------------------------------------------------------------------------------------------------- 11

Servo assembly------------------------------------------------------------------------------------------------------------------------------ 12

Piston and shoe assembly---------------------------------------------------------------------------------------------------------------- 12

Barrel and holddown shaft assembly--------------------------------------------------------------------------------------------------- 15

Barrel and stroking assembly to mounting flange----------------------------------------------------------------------------------- 16

Housing assembly--------------------------------------------------------------------------------------------------------------------------- 17

Housing assembly installation------------------------------------------------------------------------------------------------------------ 18

Port block installation----------------------------------------------------------------------------------------------------------------------- 19

Barrel holddown----------------------------------------------------------------------------------------------------------------------------- 19

Shaft assembly------------------------------------------------------------------------------------------------------------------------------- 22

Seal assembly-------------------------------------------------------------------------------------------------------------------------------- 22

Counterbalance servo stem assembly------------------------------------------------------------------------------------------------- 22

Control cover assemblies----------------------------------------------------------------------------------------------------------------- 23

Shuttle valve assembly-------------------------------------------------------------------------------------------------------------------- 25

Ordering code-------------------------------------------------------------------------------------------------------------------------------- 27-28

See catalog S1-2AM-7501-A for all available kits.

The product information, specifications, and descriptions contained in this publication have been compiled for the use and

convenience of our customers from information furnished by the manufacturer; and we can not, and do not, accept any responsibility

for the accuracy or correctness of any description, calculation, specification, or information contained herein. No such description,

calculation, specification, or information regarding the products being sold has been made part of the basis of the bargain, nor has

same created or amounted to an express warranty that the products would conform thereto. We are selling the goods and

merchandise illustrated and described on this publication on an “as is” basis, and disclaim any implied warranty,

including any warranty of merchantability or warranty of fitness for any particular purpose whatsoever, with respect to the

goods and merchandise sold. All manufacturer warranties shall be passed on to our customers, but we shall not be responsible

for special, indirect, incidental, or consequential damages resulting from the use of any of the products or information contained or

described on this publication. Further, we reserve the right to revise or otherwise make product improvements at any time without

notification.

2

www.comoso.com

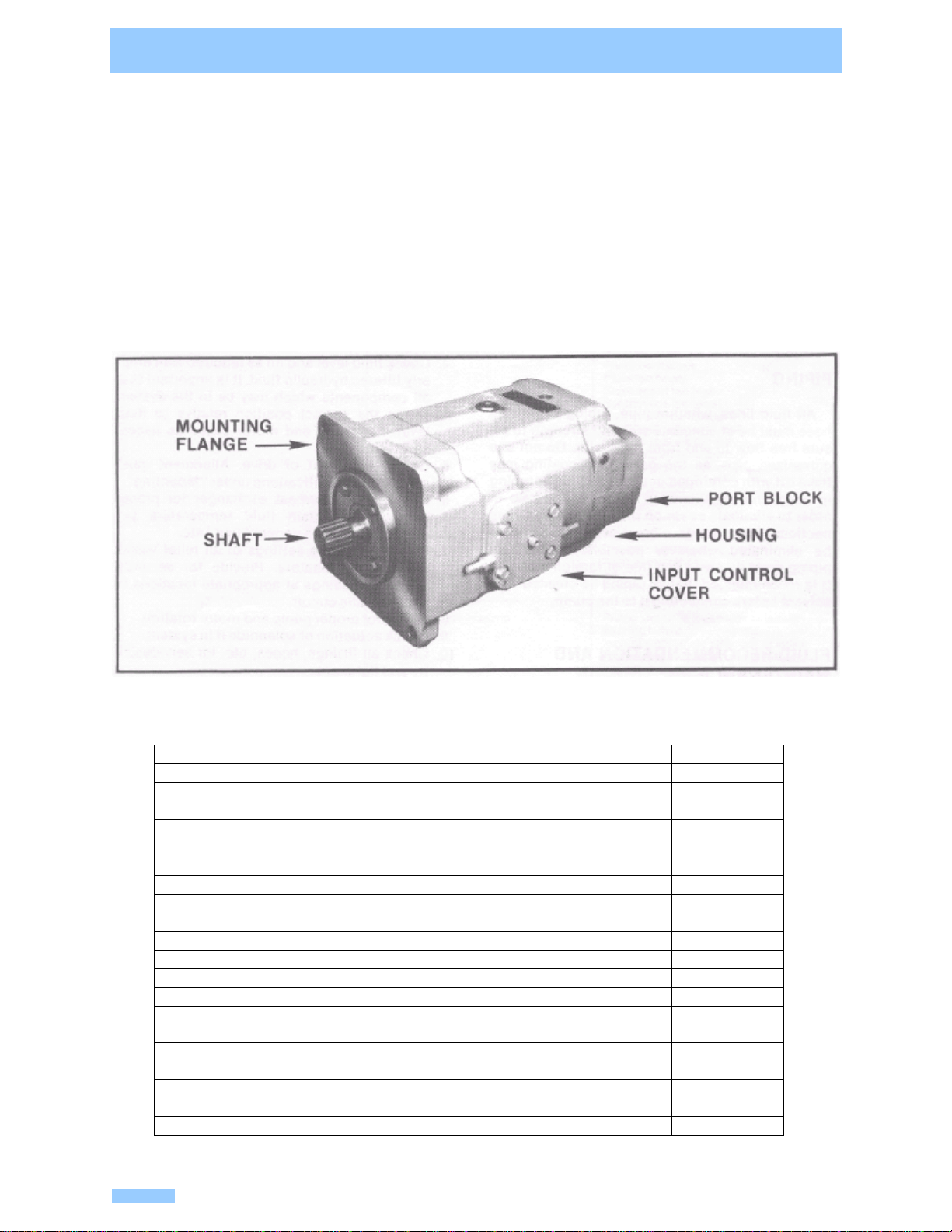

INTRODUCTION

GENERAL

The Denison Goldcup series 11 and 14 axial piston motors feature advanced design concepts which are

time proven and aid in providing smooth controlled power in a compact package. The instructions

contained in this manual cover installation, maintenance and repair of the Goldcup series motors. Before

proceeding with the disassembly or reassembly of any unit, study this manual to become familiar with the

basic fit and function of the internal parts. Refer to the troubleshooting chart when diagnosing any

malfunction. Disassemble only as far as necessary to replace or repair any worn parts.

DESCRIPTION

The Goldcup series axial piston motors feature the use of a rocker cam and cradle stroking control to vary

displacement. This allows a compact unit while retaining the flow capacity of a larger motor, as well as

reducing wear and speeding control response. A vane actuator with a rotary servo operates the stroking

control thus varying flow.

Table 1

TYPICAL CHARACTERISTICS

Specification Term Goldcup 11 Goldcup 14

Displacement at max. angle In. 3/rev 11 14

Pressure Ports A or B max. continuous PSI 5000 5000

Intermittent (not to exceed 6 sec/min) PSI 6000 6000

Mounting Standard SAE 4-Bolt

fluid connections, Ports A & B SAE-ESAE-E

4-Bolt Pad for 6000 PSI Split Flange SAE –1 1/2” SAE –1 1/2”

Speed, max. continuous @ full displ. RPM 2400 2400

Speed, max. continuous @ 50% displ. RPM 2800 2800

Flow, Theor. max @ 100 RPM GPM 4.75 6.06

Flow, Theor. max @ 2400 RPM GPM 114 145

Torque Theor. max. per 100 PSI IN# 175 222

Torque Theor. max. @ 5000 PSI IN# 8750 11,100

Torque Theor. max @ 6000 PSI IN# 10,500 13,300

Power Theor. max @ 5000 PSI per 100

RPM HP 13.8 17.6

Power Theor. max @ 5000 PSI per 2400

RPM HP 330 425

Efficiency Torque approx.—stalled % theor. 81 81

-- running 93 93

Pkg. motor variable displ. 2AO control lbs. 300 300

3

www.comoso.com

INSTALLATION

MOUNTING

The mounting hub and four bolt mounting flange conform to SAE-E configuration. The motor must be

mounted on a base or bracket of sufficient strength to support the unit without flexing or movement. It is

recommended that a dial indicator be used when checking alignment. The concentricity of the pump

shaft and driven load shaft must not exceed .010” T.I.R. and ideally should be .006”-.008” T.I.R.

maximum. Shaft concentricity is particularly important if the motor is rigidly connected without a flexible

coupling or a coupling that allows only for minor misalignment.

PIPING

All fluid lines, whether pipe, tubing or flexible hose must be of adequate size and strength to assure free

flow to and from the motor. Do not use galvanized pipe, as the galvanized coating may flake off with

continued use. If rigid pipe or tubing is used, the workmanship must be accurate in order to eliminate

strain on the pump or fluid connections. Sharp bends, elbows or reducers should be eliminated wherever

possible. All system piping must be clean and free of foreign material. It is recommended that all piping

be cleaned with solvent before connecting it to the pump.

FLUID RECOMMENDATION AND MAINTENANCE

Satisfactory operation depends on many factors, the most important of which is the selection of the

proper hydraulic fluid and its subsequent maintenance. Select only high quality fluids which conform to

Denison HF-0 and HF-1 specifications. If in doubt concerning the correct fluid for use, contact a Denison

sales representative. Efficient filtration is essential and cannot be overemphasized. Fluid cleanliness

must conform to NAS class 8 or 9, 15 micron and under. Effective continuous use of 10 micron filters will

assure compliance to this standard. Operating temperature is determined by the viscosity characteristics

of the fluid selected. Because high operating temperatures degrade seals, reduce the service life of the

fluid and pose potential hazards, fluid temperatures should not exceed 180°F at the case drain.

START UP PROCEDURE AND INSTALLATION

1. Read and understand the equipment manual before installation of the Goldcup motor. Identify

system components (relief valves, solenoids, etc.) and their function is essential to satisfactory

operation.

2. Visually inspect system components. Their proper placement and function is essential to

satisfactory operation.

3. Check reservoir for cleanliness per instructions outlined under “Fluid Recommendation and

Maintenance”. Drain and/or filter system fluid as required.

4. Check fluid level and fill as required with properly filtered hydraulic fluid. It is important that all

components which may be in the system are in the correct position relative to fluid level. Fill

pump and motor cases as necessary.

5. Check alignment of drive. Alignment must conform to specifications under “Mounting”.

6. Check oil cooler/heat exchanger for proper operation. Maintain fluid temperature per

recommendations under “Fluid”. etc.

7. Reduce pressure settings of all relief valves and/or compensators. Provide for accurate pressure

readings at appropriate locations in the hydraulic circuit.

8. Check for proper pump and motor rotation.

9. Check actuation of solenoids if in system.

10. Check all fittings, hoses, etc. for serviceability and tightness.

11. Start pump drive at reduced speed if possible and make sure units fill properly.

4

www.comoso.com

INSTALLATION (continued)

12. Cycle unloaded equipment at low speed and pressure. Observe for proper function of all

components.

13. Bleed system of any trapped air. Re-check fluid level and fill as necessary.

14. Gradually increase speed and pressure settings. Be alert for leaks, particularly in pump and

motor inlet lines, as these may cause cavitation and eventual pump failure.

15. Check for possible trouble indicated by changes in sounds, system shocks and air in fluid.

16. Equipment is now operational.

5www.comoso.com

TABLE II

TROUBLESHOOTING CHART

TROUBLE SHOOTING

Component problems and circuit problems are often inter-related. An improper circuit may operate with apparent success but will

cause failure of a particular component within it. The component failure is the effect, not the cause of the problem.

This general guide is offered to help in locating and eliminating the cause of problems by studying their effects.

EFFECT OF TROUBLE POSSIBLE CAUSE FAULT WHICH NEEDS REMEDY

Air in Fluid Leak in suction line

Leak at shaft seal

Low fluid level

Turbulent fluid

Return lines above fluid level

Gas leak from accumulator

Excessive pressure drop in the inlet line

from a pressurized reservoir

Suction line strainer acting as air trap

Cavitation in motor rotating group Fluid too cold

Fluid too viscous

Fluid too heavy

Shaft speed too high

Suction line too small

Suction line collapsed

Suction strainer too small

Suction strainer too dirty

Operating altitude too high

Boost or replenishment pressure too low

Replenishment flow too small for dynamic

conditions

Misaligned shaft Faulty installation

Distortion in mounting

Axial interference

Faulty coupling

Excessive overhung loads

Noisy Motor

Mechanical fault in pump Piston and shoe looseness or failure

Bearing failure

Incorrect port plate selection or index

Eroded or worn parts in the displacement

control

Air in fluid See aboveErosion on barrel ports and port plate Cavitation See above

Excessive loads Reduce pressure settings

Reduce speeds

Contaminant particles in fluid Improper filter maintenance

Filters too coarse

Introduction of dirty fluid to system

Reservoir openings

Reservoir breather

Improper line replacement

Improper fluid Fluid too thin or thick for operating

temperature range

Breakdown of fluid with

time/temperature/shearing effects

Incorrect additives in new fluid

Destruction of additive effectiveness with

chemical aging

Improper repair Incorrect parts

Incorrect procedures, dimensions,

finishes

High wear in motor

Unwanted water in fluid Condensation

Faulty breather, strainer

Heat exchanger leakage

Faulty clean-up practice

Water in make-up fluid

6

www.comoso.com

TABLE II

TROUBLESHOOTING CHART (continued)

EFFECT OF TROUBLE POSSIBLE CAUSE FAULT WHICH NEEDS REMEDY

Cogging load

Worn relief valve Mechanical considerations

Needed repairs

Servo pressure too low to maintain firm

control Increase pressure and check pressure

drop through servo filter

Excessive line capacitance (line volume,

line stretch, accumulator effects) Reduce line size or lengths. Eliminate

hose.

Pressure shocks

Barrel blow-off Re-check pump hold-down, rotating

group, drain pressure

Excessive motor leakage Re-check case drain flow and repair as

required

Fluid too thin

Improper assembly, port timing

Relief valve Set too low (compared to load or to

compensator)

Instability caused by back pressure, worn

parts

Heat exchanger Water turned off or too little flow

Water too hot

Fan clogged or restricted

Efficiency reduced by mud or scale

deposits

Intermittent hydraulic fluid flow

Heating of fluid

Reservoir Too little fluid

Entrained air in fluid

Improper baffles

Insulating air blanket that prevents heat

rejection

Heat pick-up from adjacent equipment

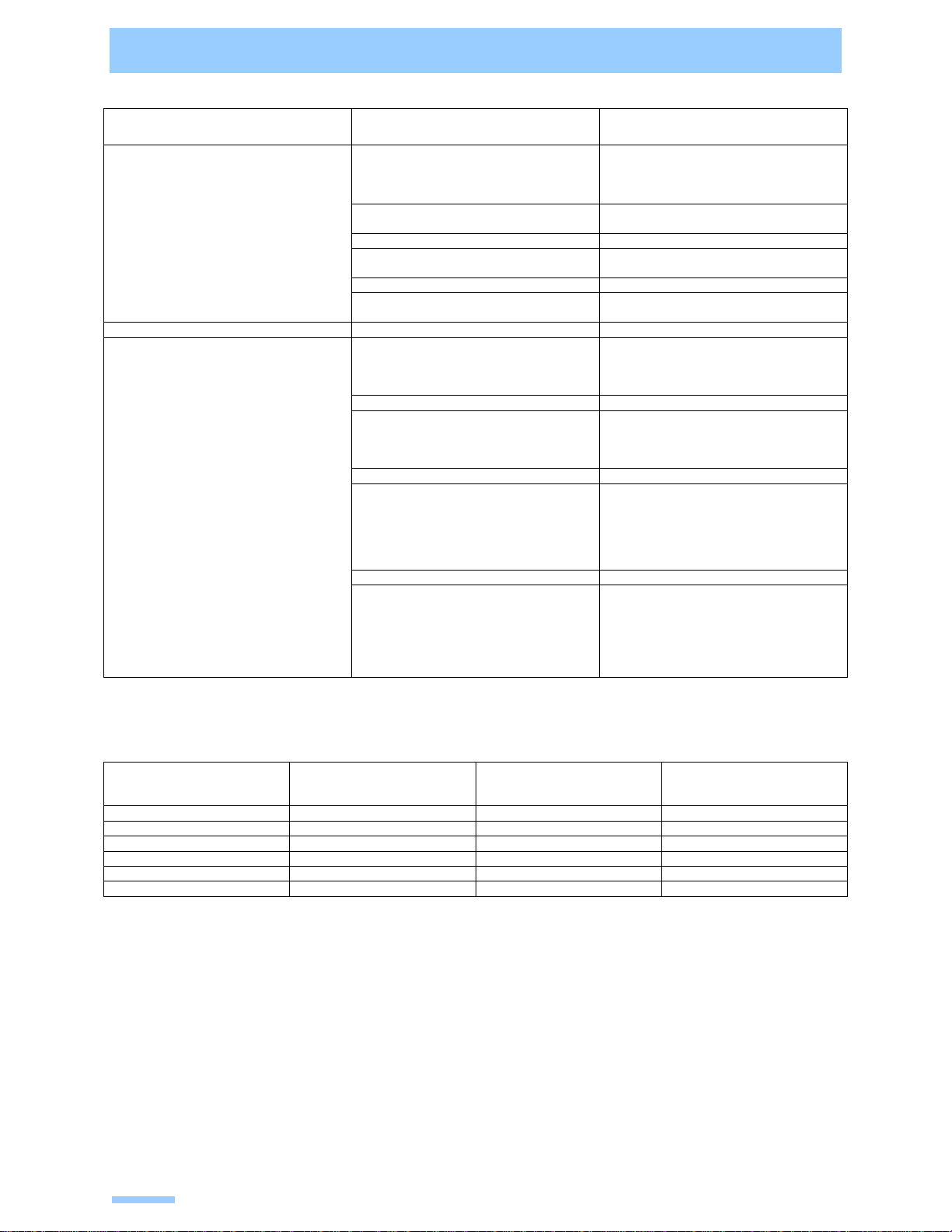

REWORK LIMITS OF WEAR PARTS

11 and 14 in.3 Original

Dimension Max. Rework

From Original

Dimension

Min. Dimension

After Rework

Port plate face .725/.715” .010” .705”

Cylinder barrel face 5,880” .010” 5.870”

Shoe retainer face .438/.437” .005” .432”

Piston shoe face (pocket) .020” .010” .010”

Creep plate face .251/.250” .010” .240”

Face plateNone Replace

7

www.comoso.com

UNIT DISASSEMBLY

The instructions contained in this section cover complete disassembly of the Denison Goldcup 11 and 14

motors. Disassemble only as far as necessary to replace or repair any worn parts. A clean bench or

similar surface capable of supporting unit should be used. After disassembly, internal parts should be

coated with a film of clean oil and protected from dirt and moisture. Excessive handling will cause parts

to rust and should be avoided.

CONTROLS (Figure 9)

1. Remove the four screws (15) from the side cover (17) and remove the input shear seal valve

assembly.

2. Remove the four screws (15) from the remaining side cover (16) and remove the counter balance

shear seal assembly.

3. Remove the two screws (13) and spacers (12). Remove the balance plate (11).

4. Remove the two screws (10) and balance stem (9).

BARREL HOLD-DOWN (Figure 8)

1. Remove retaining ring (3), end cover (5) and O-ring (4).

2. Remove cotter pin (6), hold-down nut (7), thrust washers (10), bearing (9) and seal ring (8).

PORT BLOCK (Figure 7)

1. Remove four screws (1) that secure the port block (2) to the housing (6).

2. Remove port block, gasket (5), port plate (4) and port plate pins (3).

CAUTION: The port plate may cling to the barrel face because of oil film. Do not allow the port plate to

fall and become damaged.

SHUTTLE VALVE (Figure 9)

1. Remove the screws (20) that secure the shuttle valve (18) to the port block.

2. Remove the shuttle valve and O-rings (19) from the port block. The valve is a complete assembly

and should not be disassembled.

BARREL AND HOLD-DOWN SHAFT (Figure 6)

1. Remove the face plate (2) and face plate pins (1) from face of the barrel assembly.

2. Remove barrel assembly by grasping hold-down shaft and lifting entire assembly from the

housing.

DRIVE SHAFT (Figure 9)

1. Remove four screws (8), gaskets (7), seal retainer (6), gasket (5), seal stop (4a), and stationary

part of shaft seal assembly (4). Refer to view of item 4.

2. Remove the carbon ring and the remainder of the shaft seal from the shaft.

3. Remove retaining ring (3), shaft and bearing assembly (1) and shim (2) if used.

HOUSING (Figure 6)

1. After removal of the shaft and bearing assembly, position the unit so that it rests on the mounting

flange.

2. Push the ends of pressure feed tubes away from the housing so as not to bend or damage them.

3. Lift the housing from the mounting flange. Remove the gasket and dowel pins. Mounting flange

must be driven off housing.

NOTE: Do not remove the roll pins or bearing from the housing unless bearing is damaged and

replacement is necessary.

8

www.comoso.com

UNIT DISASSEMBLY (continued)

ROCKER CAM AND CONTROL STROKING ASSEMBLY (Figure 4)

1. Remove pressure feed tubes (5 and 6) from the cradle. DO NOT BEND THESE LINES.

2. Remove the assembly from the mounting flange and position on a clean surface with the override

tubes (2) in a horizontal position and located at the top.

3. Mark the cam (24) and cradle (20) as indicated in Figure 2. These marks will determine

positioning of parts during reassembly.

4. Position the assembly in an upright position on the flat surface of the cradle (see Figure 2).

5. Remove the retaining ring (1), thrust washer (2), flange bearing (3), piston and shoe assembly (4)

and creep plate (5) from the rocker cam (22).

6. Remove the two differential screws (9) from the rocker cam and remove the servo input parts (6,

7, 8 and 10).

CAUTION: Differential screws must be alternately removed one turn at a time.

7. Remove the four 1/2” screws (11) and four 3/8” screws (13) from the control chamber covers

(14R and 14L).

8. Remove the control chambers (16). Remove the seals (18), four steel balls (17) and dowel pins

(15).

9. Remove the vane seal cartridges (25), hold-down vanes (24) and springs (23) from the rocker

cam (22).

10. Remove the rocker cam from the cradle (19).

9

www.comoso.com

ASSEMBLY PROCEDURES

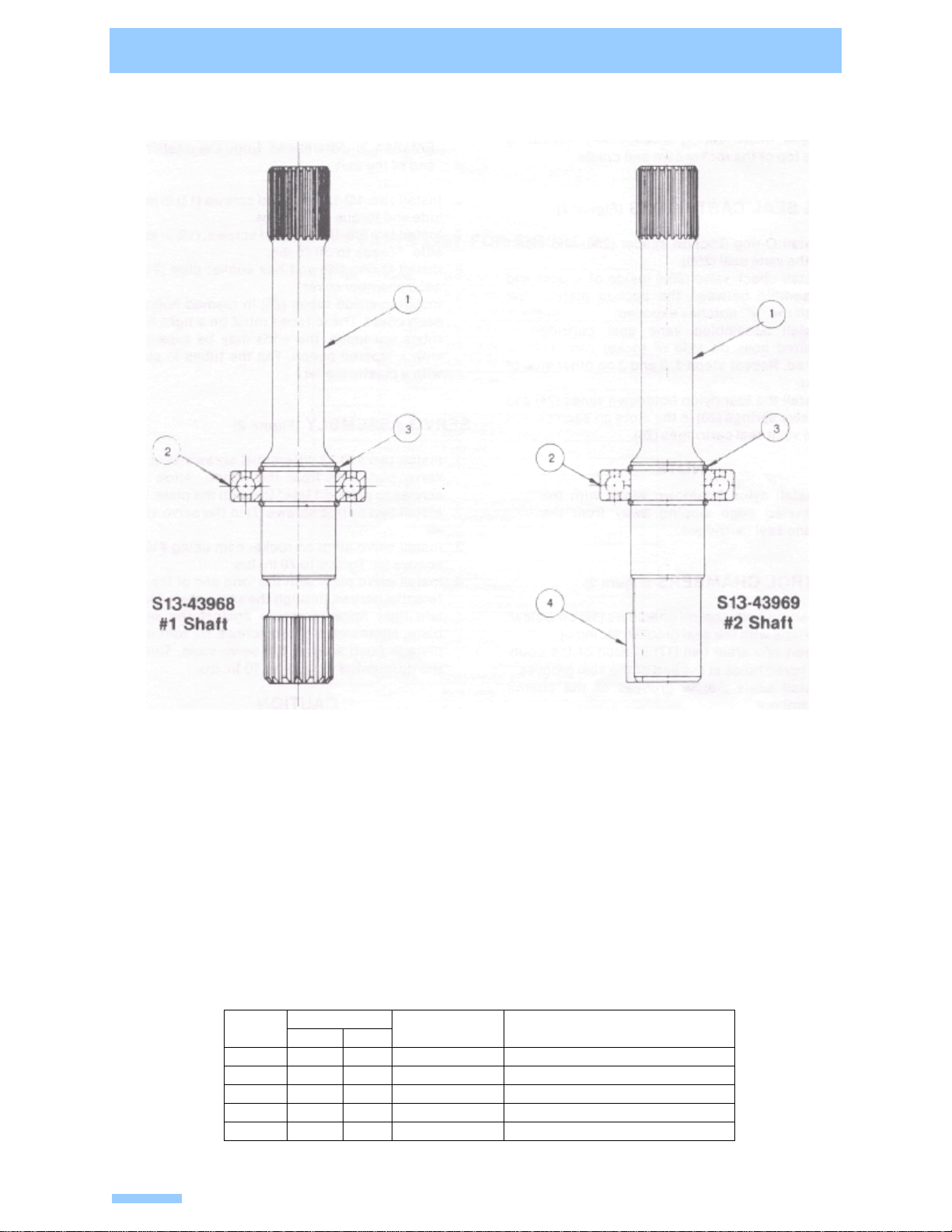

DRIVE SHAFT ASSEMBLY

Figure 1

1. Pass one retaining ring (3) over the internal end of drive shaft (1) and install in the groove near the

shaft seal surface. DO NOT PASS THE RING OVER THE SEAL SURFACE.

2. Slide the bearing (2) over the same end of the shaft and seat against the ring. Support only the

inner race of the bearing and press on the coupling end of the shaft. DO NOT USE EXCESSIVE

FORCE AND DISTORT OR DAMAGE THE RETAINING RING.

3. Install the other retaining ring (3) in the remaining ring groove. Be sure that both rings are fully

seated.

PARTS LIST FOR FIGURE 1

S13-43968 #1 Drive Shaft Assembly (Splined)

S13-43969 #2 Drive Shaft Assembly (W/Keyway)

Qty.Item #1 #2 Part

Number Description

11-- 033-71604 #1 (Splined) Drive Shaft

-- 1033-71601 #2 (W/7/16/KW) Drive Shaft

211230-82148 Shaft bearing MRC 110 KS

322033-71641 Retaining Ring

4-- 1033-71514 Square Key 7/15 x 1-1/2

10

www.comoso.com

ASSEMBLY PROCEDURES

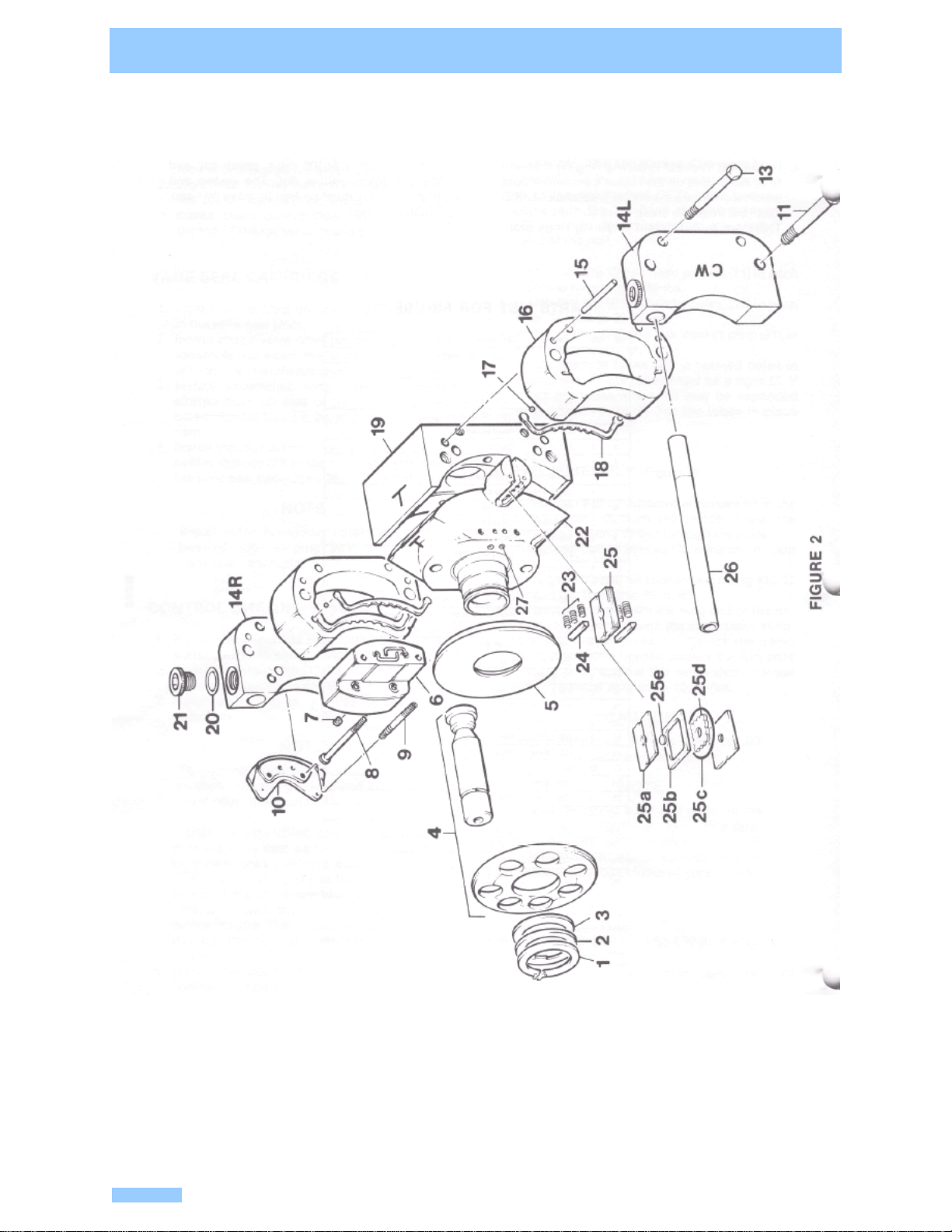

ROCKER CAM ASSEMBLY (Figure 2

1. Position the rocker cradle (19) on a clean surface with the large flat side down.

2. Lightly oil curved surface of cradle. Position the rocker cam (22) on the cradle. Note the marks

made during disassembly indicating the top of the rocker cam and cradle.

VANE SEAL CARTRIDGES (Figure 2)

1. Install O-ring (25c) on spacer (25d) and insert in the vane seal (25b).

2. Install check valve (25e) inside of spacer and assemble between the backup plates (25a) with the

“V” notches exposed.

3. Install assembled vane seal cartridge in slotted boss on side of rocker cam as indicated. Repeat

steps 1, 2 and 3 on the other side of cam.

4. Install the four nylon holddown vanes (24) and twelve springs (23) in the slots on each side of the

vane seal cartridges (25).

NOTE: Install nylon holddown vanes with the beveled edge sloping away from the vane seal

cartridges.

CONTROL CHAMBERS (Figure 2)

1. Position both control chambers (16) on a clean surface with the seal grooves facing up.

2. Insert one steel ball (17) in each of the counter-bored holes at the end of the seal grooves.

3. Install seals (18) in grooves of the control chambers.

NOTE: The tapered side of the seals must be pushed into the grooves and the ends must cover

the steel balls.

4. Install the assembled control chambers (16) over the vane seal cartridges by rotating the chambers

until they slip over the vane seal cartridges, then rotate in the opposite direction until the 3/8” dowel

pin holes in the chambers align with the dowel pin holes in the rocker cradle (19). Install dowel pins

(15) through the control chambers and into the cradle.

5. Install chamber covers (14R) and (14L) on the control chambers (16). The covers must be installed

with the override tube (26) holes at the top. Note the marks made during disassembly to indicate the

top of rocker cam and cradle.

NOTE: Two sets of control chamber covers are available. The set marked CW must be installed in

the right hand rotation pump and the set marked CCW must be installed in the left hand rotation

pump. Rotation is determined from the shaft end of the unit.

6. Install two 1/2-13 hex head screws (11) in each side and torque to 75 ft.-lbs.

7. Install two 3/8-16 hex head screws, (13) in each side. Torque to 30 ft.-lbs.

8. Install O-ring (20) and hex socket plug (21) in each chamber cover.

9. Install override tubes (26) in reamed holes in each cover. These tubes must be a tight fit. If tubes

are loose, the ends may be expanded with a tapered punch. Tap the tubes in place with a plastic

mallet.

11

www.comoso.com

ASSEMBLY PROCEDURES

SERVO ASSEMBLY (Figure 2)

1. Install two #10-32 differential screws (9) in the servo plate (10) from the inside. Allow the screws to

extend 11/64” through the plate.

2. Install two orifice screws (7) in the servo stem (6).

3. Install servo stem on rocker cam using #10-32 screws (8). Torque to 70 in. lbs.

4. Install servo plate with the long end of the differential screws through the servo stem. Maintain light

finger pressure against the servo plate, alternately tighten screws 1/2 turn until plate is flush against

the servo stem. Torque the differential screws to 10 in.-lbs.

CAUTION: When tightened, screws must be .03-.10” below surface of servo plate.

NOTE: Install the servo stem and plate on the rocker cam input side. (9 o’clock position on “B”

suffix models, 3 o’clock position on “A” suffix models). Refer to control location column of series

model code.

PISTON AND SHOE ASSEMBLY (Figure 2)

1. Install creep plate (5) over center post of rocker cam (22).

2. Insert pistons and shoes into retainer and install entire assembly (4) against creep plate.

3. Install flange bearing (3) and thrust washer (2) over center post of cam and against shoe retainer.

4. Install the thickest retaining ring (1) that will fit in the groove on the rocker cam center post which will

allow a maximum clearance of .002-.004” between the creep plate and shoe faces. There are four

different retaining rings available for this tolerance. Each retaining ring is marked:.102/.101 thick,

blue dot; .104/.103 thick, red dot; .106/.105 thick, green dot; and .108/.107 thick, yellow dot. The

piston and shoe assembly must be free to move by hand. (5 ft./lbs. or less.)

12 www.comoso.com

ASSEMBLY PROCEDURES

PARTS LIST FOR FIGURE 2

No. Qty. Part No. Description

Retaining ring –use one only

033-71556 107 –108 thick w/yellow dot

033-71557 105-106 thick w/green dot

033-71558 103-104 thick w/red dot

11

033-71559 101-102 thick w/blue doe

21033-71565 Thrust washer

31033-71563 Bearing

S13-48761 Piston shoe & retainer assy. M11 only41S13-48760 Piston shoe & retainer assy. M14 only

51033-71569 Creep plate

61033-71596 Servo stem

72033-20641 Orifice screw

82359-09240 Socket head cap screw

92033-71651 Differential screw

10 1033-70548 Servo plate

11 4306-40189 Hex head screw 1/2-13 x 3

13 4306-40140 Hex head screw 3/8-16x2-3/4

**14R 1033-71598 Right side chamber cover C. W. rotation

**14L 1033-71597 Left side chamber cover C.W. rotation

15 4324-22428 Dowel pin

16 2033-71615 Control chamber

17 4201-06001 Steel ball

18 2606-25040 Control chamber seal

19 1033-71582 Rocker cradle

20 2691-00905 O-ring

21 2488-35020 Hex socket plug

22 1033-71580 Rocker cam

23 12 033-72233 Vane hold-down spring

24 4033-72234 Hold-down vane

25 2See below Vane seal cartridge

25a 4033-71608 Vane seal back-up plate

25b 2033-71611 Vane seal

25c 2691-00125 O-ring

25d 2033-71607 Vane spacer

25e 2033-70803 Check valve

26 2033-71609 Override tube

27 4447-00017 Lee plug

Items 6 through 24 can be ordered as a complete rocker cam & stroking assembly.

S13-43958 is for clockwise rotation motors with “B” suffix (input control on right side)

*Newer model motors don’t require screws #12

**Newer chamber covers are not drilled for use of screw #12.

13

www.comoso.com

ASSEMBLY PROCEDURES

14 www.comoso.com

ASSEMBLY PROCEDURES

BARREL AND HOLD-DOWN SHAFT ASSEMBLY (Figure 3)

1. Position the barrel (1) with the bores

facing down on a clean surface.

2. Install hold-down spring (3) into barrel

counter-bore.

3. Install spring retainer (5) into counter-bore

and seat against spring.

4. Install retaining ring (6) into barrel counter-

bore groove. Make sure retaining ring is

fully seated in groove.

5. Position barrel stop (4) over hold-down

shaft (2). Turn barrel on side and install

shaft and barrel stop through barrel

spline and hold-down spring.

PARTS LIST FOR FIGURE 3

Qty.No. M11 M14 Part

Number Description

1-- S13-45381 Barrel & sleeve assy. M11 only1-- 1S13-43965 Barrel & sleeve assy. M14 only

211033-71573 Hold-down shaft

311033-71562 Hold-down spring

411033-71561 Barrel stop

511033-71560 Spring retainer

611033-71564 Retaining ring

15

www.comoso.com

ASSEMBLY PROCEDURES

BARREL AND STROKING ASSEMBLY

TO MOUNTING FLANGE (Figure 4)

1. Install straight thread connectors (3) and O-rings

(4) into threaded holes in cradle.

2. Install right and left hand pressure feed tubes

(5 and 6) to connectors (3). Tighten connectors

until snug.

3. Position the mounting flange (9) with the large

open end facing up and install two dowel pins (8)

in the cradle mounting surface.

4. Install the rocker cam and cradle assembly (7)

over the dowel pins (8) in the mounting flange.

5. With cam and cradle installed, position mounting

flange on the side and install two 3/8-16 x 2 screws

through the seal retainer area into the cradle.

The screws are required to hold the rocker cam

assembly in place and will be removed later.

6. Return the mounting flange to an upright position

and tilt the rocker cam to either extreme attitude

in the cradle.

7. Position the barrel and shaft assembly (1)

directly over the pistons. Starting with the upper-

most piston, guide them one at a time into the

barrel bores. Return the cam to a level position

in the cradle.

PARTS LIST FOR FIGURE 4

No. Qty. Part No. Description

11See Fig. 3 Barrel & hold-down shaft assy.

22033-71609 Override pressure tubes

32492-15265 Connector

42691-00902 O-ring

51S13-43967 Tubing assy. (right side)

61S13-43966 Tubing assy. (left side)

71See Fig. 2 Rocker cam & stroking assy.

82324-23216 Dowel pin

91033-71546 Mounting flange

10 4033-72664 Locating sleeve

16

www.comoso.com

ASSEMBLY PROCEDURES

S13-43962

HOUSING ASSEMBLY (Figure 5)

1. Position housing (1) on a flat surface with the large open end up.

2. Press the bearing (2) into the housing bore until seated. DO NOT HAMMER OR BEAT BEARING

INTO PLACE.

3. Position housing on side and install roll pin (3) through hole in control cover pad. Roll pin must be

installed 3/8” below pad surface. Install two dowel pins (4) in the blind holes in the same pad.

4. Repeat step 3 on the opposite side of the housing.

5. Install O-ring (5) and plug (6) in the bottom of housing. Roll pins (3) are in the bottom half of the

housing.

PARTS LIST FOR FIGURE 5

Housing Assembly S13-43962

No. Qty. Part No. Description

11033-71578 Housing

21033-71516 Bearing

32325-16320 Roll pin

44324-21608 Dowel pin

52691-00912 O-ring

62488-35014 Plug

17 www.comoso.com

ASSEMBLY PROCEDURES

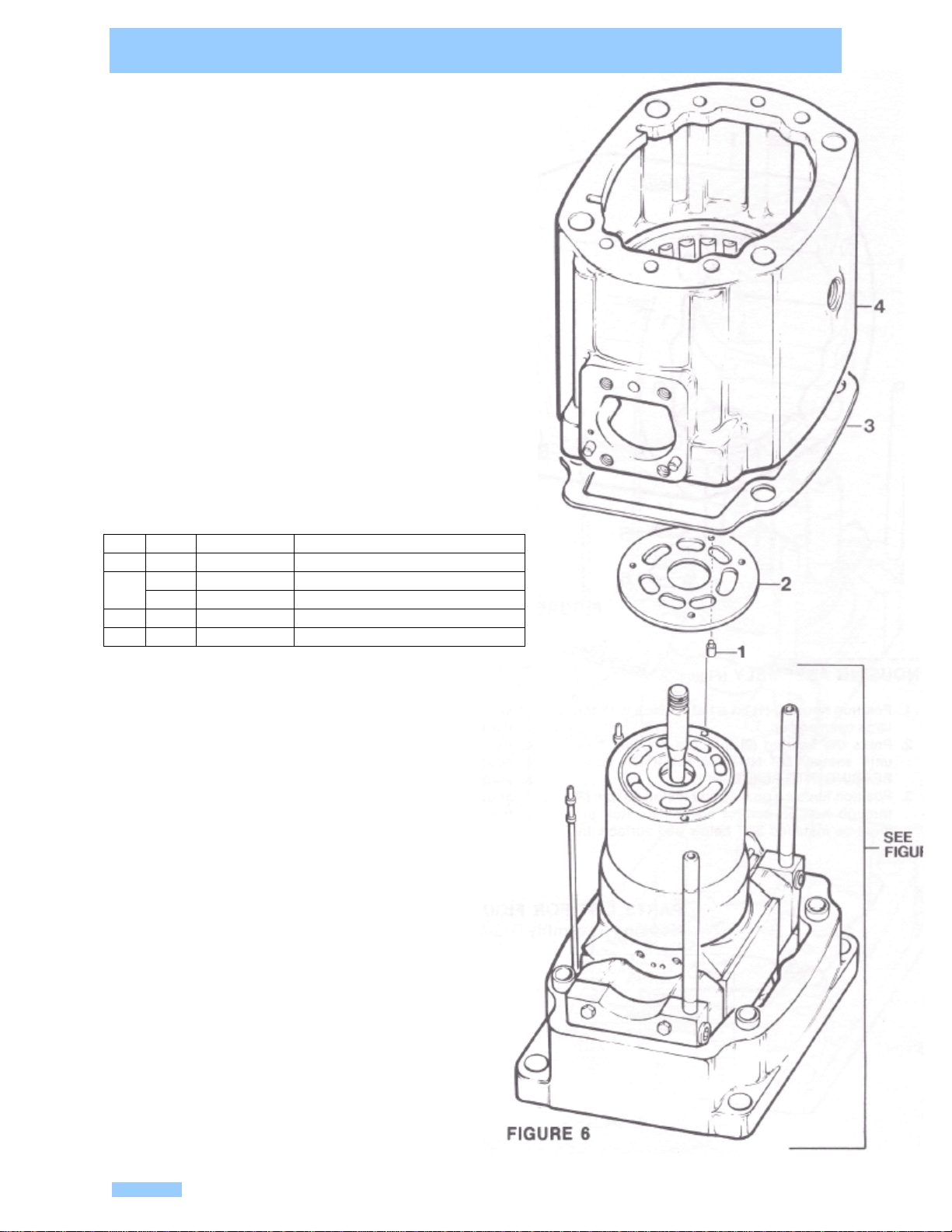

HOUSING ASSEMBLY INSTALLATION (Figure 6)

1. Install face plate pins (1) in the holes provided in

the barrel face.

2. Apply heavy grease to the surface of the barrel and

install the face plate (2) over the face plate

pins.

CAUTION: The face plate must be fully seated on the

barrel face and pins with the steel side towards the

barrel.

3. Install gasket (3) over the 4 locating sleeves in the

mounting flange.

4. Install the housing assembly (4) over the barrel and

auxiliary shaft assembly. Carefully guide the over-

ride tubes and pressure feed tubes (items 2,5 and 6,

Figure 4) through the housing assembly. Position

the pressure feed tubes in the slots in the housing

face.

PARTS LIST FOR FIGURE 6

No. Qty. Part No. Description

12033-49825 Face plate pins

1033-71921 Barrel face plate M11 only2

1033-71575 Barrel face plate M14 only

31033-71602 Housing gasket

41S13-43962 Housing assembly

18 www.comoso.com

ASSEMBLY PROCEDURES

PORT BLOCK INSTALLATION (Figure 7)

1. Position the motor with the unplugged hole in the housing assembly (6) facing up. Install gasket (5)

on the housing.

2. Install two dowel pins (3) in the face of the port block assembly (2).

3. Apply heavy grease to the rear of the port plate (4) and install over the dowel pins. Port plate must

be fully seated on the pins.

4. Install the port block assembly over the hold-down shaft. Make sure that tubes (2, 5 and 6, Figure 4)

are fully seated and port plate remains firmly secured on the pins.

5.Install the four bolts (1). Do not drop the bolts in place as the threads may be damaged. Torque

bolts evenly in 50 lb. increments to 350 ft.-lbs.

BARREL HOLD-DOWN (Figure 8)

1. Position the motor in the horizontal position.

2. Install seal ring (6) on hold-down shaft. Place bearing (7) between the two thrust washers (8) and

install around the seal ring.

3. Install hold-down nut (4) on auxiliary shaft and tighten until snug (10 ft.-lbs. maximum). Back hold-

down nut off until second slot in nut is aligned with the cotter pin hole in shaft.

4. Install cotter pin (5) through hold-down nut and auxiliary shaft. Bend one tang over end of shaft.

NOTE: DO NOT RE-USE COTTER PIN. DO NOT BEND TANG OVER MORE THAN ONCE.

5. Install O-ring (2) on end cover. Lubricate O-ring and install cover over hold-down nut.

6. Depress end cover and install retaining ring (1)

PARTS LIST FOR FIGURE 7

No. Qty. Part No. Description

14306-40112 Hex head cap screw

21033-71521 Port block

32324-21610 Dowel pin

1033-71916 Port plate M11 only41033-71551 Port plate M14 only

51033-71579 Port block gasket

61488-35041 Plug

71691-00906 O-ring

84488-35001 Plug

94691-00904 O-ring

PARTS LIST FOR FIGURE 8

No. Qty. Part No. Description

11356-65095 Retaining ring

21671-00138 O-ring

31033-70537 End cover

41033-72026 Hold-down nut

51322-03324 Cotter pin

61033-72101 Seat ring

71230-82164 Thrust bearing

82350-10081 Thrust washer

19

www.comoso.com

ASSEMBLY PROCEDURES

20 www.comoso.com

This manual suits for next models

1

Table of contents

Other Denison Hydraulics Engine manuals

Popular Engine manuals by other brands

BONFIGLIOLI

BONFIGLIOLI AS Series manual

Kohler

Kohler K91 Service manual

Bayliner

Bayliner MCM 7.4L Service manual

Briggs & Stratton

Briggs & Stratton 11A600 Operating & maintenance instructions

Performance

Performance ZZ454 Specifications

Idex

Idex MICROPUMP EagleDrive MS Installation, operation and warranty information