Denison Hydraulics Goldcup Series User manual

DENISON HYDRAULICS

SERVICE LITERATURE

Axial Piston Motor

Variable Displacement

Goldcup Series M6H-Model C

Goldcup Series M7H-Model A

INSTALLATION

&

OVERHAUL INSTRUCTIONS

SVM-M6/M7-GRevised 4/04

“The product information specifications and descriptions contained in this catalog have been compiled for the use

and convenience of our customers from information furnished by the manufacturer, and we cannot and do not

accept any responsibility for the accuracy or correctness of any description, calculation, specification or

information contained herein. No such description, calculated, specified or information regarding the products

being sold has been made part of the basis of the bargain nor has same created or amounted to an express

warranty that the products would conform thereto. We are selling the goods and merchandise illustrated and

described in this catalog on an “as is” basis and disclaim any implied warranty, including any warranty of

merchantability or warranty of fitness for any particular purposes whatsoever, with respect to the goods and

merchandise sold. All manufacturer warranties shall be passed on to our customers, but we shall not be

responsible for special, indirect, incidental or consequential damages resulting from the use of any of the products

or information containe d or described in this catalog.

TABLE OF CONTENTS

SECTION 1 INTRODUCTION PAGE

General------------------------------------------------------------------------- 3

Description-------------------------------------------------------------------- 3

Table 1 Characteristics---------------------------------------------------- 3

SECTION II INSTALLATION

Mounting---------------------------------------------------------------------- 4

Piping-------------------------------------------------------------------------- 4

Service Information--------------------------------------------------------- 4

Start Up------------------------------------------------------------------------ 4

Table II Trouble Shooting------------------------------------------------- 5

SECTION III DISASSEMBLY

Controls------------------------------------------------------------------------ 7

Barrel Holddown------------------------------------------------------------- 7

Port Block--------------------------------------------------------------------- 7

Barrel & Holddown Shaft-------------------------------------------------- 7

Drive Shaft-------------------------------------------------------------------- 7

Housing------------------------------------------------------------------------ 7

Cam & Cradle Assembly-------------------------------------------------- 7

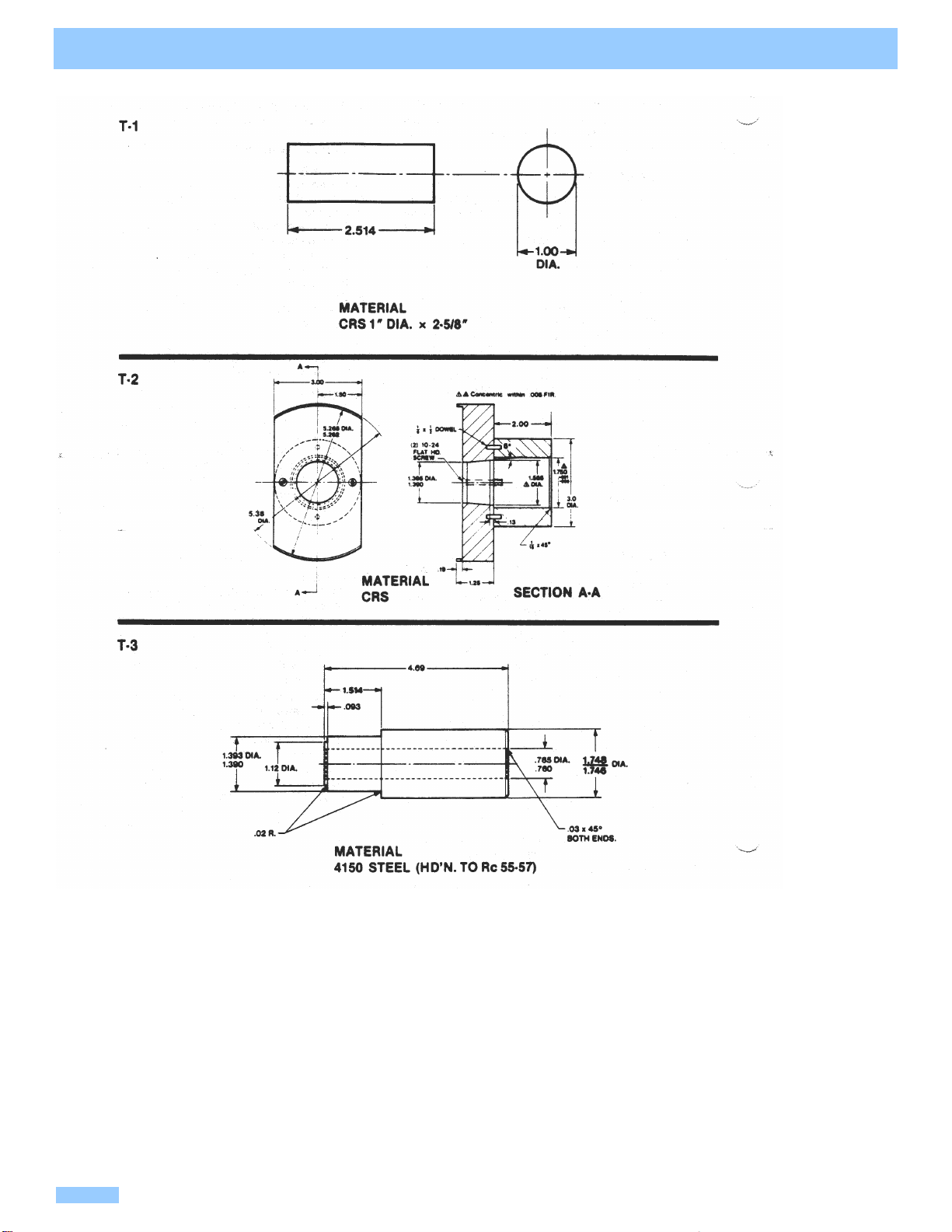

SECTION IV ASSEMBLY TOOL DRAWINGS

T1, T2 & T3------------------------------------------------------------------- 8

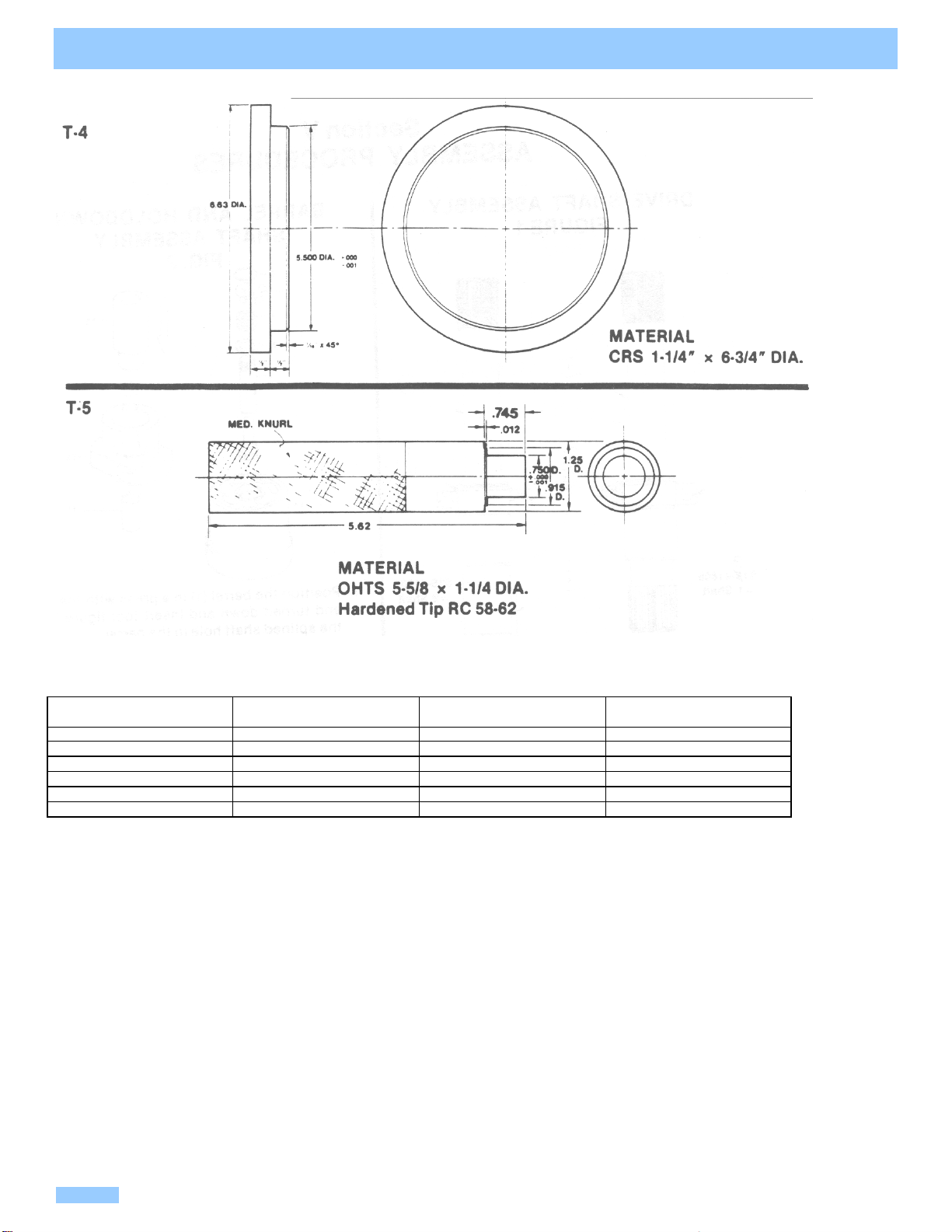

T4 & T5------------------------------------------------------------------------ 9

Rework Limits---------------------------------------------------------------- 9

SECTION V ASSEMBLY PROCEDURES

Drive Shaft Assembly------------------------------------------------------ 10

Barrel & Holddown Shaft-------------------------------------------------- 10

Rocker Cam & Stroking Assembly-------------------------------------- 11

Barrel & Stroking Assembly to Mounting Flange-------------------- 14

Housing Assembly and Installation------------------------------------- 15

Mounting Port Block Assembly------------------------------------------ 16

Barrel Holddown------------------------------------------------------------- 17

Shaft & Shaft Seal----------------------------------------------------------- 18

Counter Balance Control-------------------------------------------------- 18

Control Cover Assemblies------------------------------------------------- 18

Shuttle Valve Assembly---------------------------------------------------- 21

Seal Kits

Shaft Seal----------------------------------------------------------------------S13-44302

Basic Motor--------------------------------------------------------------------S13-44308

Control Seals------------------------------------------------------------------S13-44309

2

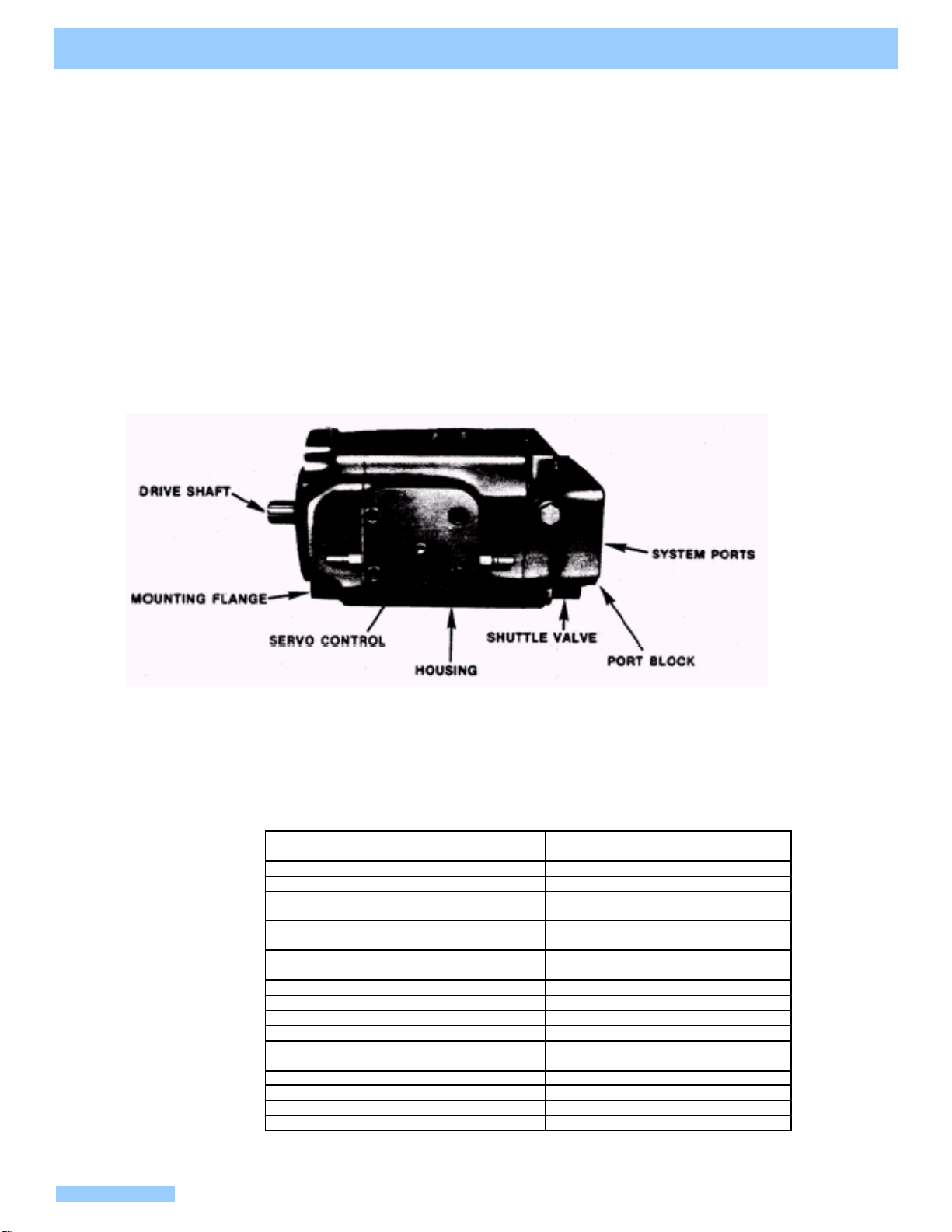

SECTION 1 -INTRODUCTION

General The Denison Goldcup 6 and 7 axial piston motors feature advanced design concepts which

are time proven and provide for smooth controlled power. The instructions contained in this

manual cover complete disassembly and reassembly of the unit. Before proceeding with

the disassembly or reassembly of any unit, this manual should be studied in order to

become familiar with proper order and parts nomenclature.

Description The use of a rocker cam to control the motor displacement provides a small package size,

reduces wear, and speeds control response. The control vane actuator eliminates linkage

and backlash inherent in typical stroking cylinder designs.

Standard control for the units is cylinder control with adjustable maximum and minimum

displacement stops. Additional optional controls are also available. This unit is bi-

directional.

Table 1

TYPICALCHARACTERISTICS

Specification Term Goldcup 6 Goldcup 7

Displacement at max. angle In.3/rev 6.00 7.25

Pressure Ports A or B max. continuous PSI 5000 5000

Intermittent (not to exceed 6 sec/min) PSI 6000 6000

Mounting Standard SAE 2-Bolt

fluid connections, Ports A & B

SAE-C

SAE-C

4-Bolt Pad for 6000 PSI Split Flange SAE-1 1/2” SAE –1

1/2”

Speed, max. continuous @ full displacement RPM 3000 3000

Speed, max. continuous @ 50% displacement RPM 3600 3600

Flow, Theor. max. @ 100 RPM GPM 2.6 3.14

Flow. Theor. max. @ 3000 RPM GPM 77.9 94.2

Torque Theor. max. per 100 PSI IN# 95.5 115.4

Torque Theor. max. @ 5000 PSI IN# 4774 5769

Torque Theor. max. @ 6000 PSI IN# 5729 6923

Power Theor. max. @ 5000 PSI per 100 RPM HP 7.57 9.15

Power Theor. max. @ 6000 PSI @ 3000 RPM HP 227 274.3

Efficiency Torque approx.-Stalled % theor. 81 81

-Running 93 93

Pkg. motor variable displ. 2AO control Lbs. 155 155

3

SECTION II –INSTALLATION

MOUNTING This motor is designed to operate in any position. The mounting hub and two bolt mounting

flange are in full conformance with SAE standard. The motor shaft must be in alignment

with the shaft of the driven load and should be checked with a dial indicator. The mounting

pad or adaptor into which the fluid motor pilots must be concentric with the motor shaft

within 0.010 TIR to prevent bearing failure. This concentricity is particularly important if the

fluid if rigidly connected to the driven load without a flexible coupling.

PIPING Connect inlet and outlet lines to the port block of the motor. It is recommended that the

case leakage line be connected to the top of the motor, but it may be connected to the

bottom or to the port block between the inlet and outlet ports. The case leakage line must

be of sufficient size to prevent back pressure in excess of 75 PSI and returned to the

reservoir below the surface of the oil as far from the supply suction a possible. All fluid

lines, whether pipe, tubing or hose must be adequate size and strength to assure free flow

through the motor. An undersize inlet line will prevent the motor from reaching full speed

and torque. An undersize outlet line will create back pressure in the motor from reaching

full speed and toque. An undersize outlet line will create back pressure in the motor and

cause improper operation. Flexible hose lines are recommended. If rigid piping is used,

the workmanship must be accurate to eliminate strain on the motor port block or to the

fluid connections. Sharp bends in the lines must be eliminated wherever possible. All

system piping must be cleaned with solvent or equivalent before installing motor. Make

sure the entire hydraulic system is free of dirt, lint, scale and other foreign material.

CAUTION: Do not use galvanized pipe. Galvanized coating can flake off with

continueduse.

SERVICE INFORMATION These hydraulic products are designed to give lone dependable service when properly

applied and their systems properly maintained. These general instructions apply to typical

systems. Specific instructions for particular equipment can be developed from them.

START UP PROCEDURE FOR 1. Read and understand the instruction manual. Identify components and their function.

NEW INSTALLATION 2. Visually inspect components and lines for possible damage.

3. Check reservoir for cleanliness and drain and clean as required.

4. Check fluid level and fill as required with filtered fluid at least as clean as that

recommended. Fill motor case as necessary.

5. Check alignment of drive.

6. Check oil cooler and activate it, if included in circuit. Check fluid temperature.

7. Reduce pressure settings of relief valve. Make sure accurate pressure readings can be

made at appropriate places.

8. If solenoids in system, check for actuation.

9. Start pump drive. Make sure pump and motor fill properly.

10. Bleed system of air. Recheck fluid level.

11. Cycle unloaded machine at low pressure and observe actuation (at low speed if

possible).

12. Increase pressure settings gradually steps. Check for leaks in all lines, especially in

pump and motor inlet lines.

13. Make correct pressure adjustments.

14. Gradually increase speed. Be alert for trouble as indicated by changes in sounds,

system shocks and air in fluid.

15. Equipment is operational.

FLUID It is recommended that a hydraulic fluid be used as specified in Denison Bulletin 1107.

MAINTENANCE This motor is self lubricating and preventive maintenance is limed to keeping the system

fluid clean by changing filters frequently. Fluid cleanliness level per NAS 1638, Class 8

above 15 micron or Class 9 under 15 micron must be maintained. This usually can be

accomplished by effective use of 10 micron filters. Do not allow dirt to accumulate on the

motor especially around the shaft seal. Keep all fittings and screws tight. Do not operate

the motor at pressures and speeds in excess of the recommended limit. If the motor does

not operate properly, check the Trouble Shooting Chart before attempting to overhaul the

unit. Overhaul is relatively simple and may be accomplished by referring to the procedures

in Section III.

4

TROUBLESHOOTING

TROUBLESHOOTING Component problems and circuit problems are often interrelated. An improper circuit may

operate with apparent success but will cause failure of a particular component within it.

The component failure is the effect, not the cause of the problem.

This general guide is offered to help in locating and eliminating the cause of problems by

studying their effects.

EffectofTrouble Possible Cause Fault which needs remedy

Air influid Leak at suction line of pump

Leak at shaft seal of pump

Low fluid level in reservoir

Turbulent fluid

Return lines above fluid level in reservoir

Gas leak from accumulator

Excessive pressure drop in the inlet line from a

pressurized reservoir

Suction line strainer acting as air trap

Cavitation in

Motor rotating

group

Fluid too cold

Fluid too viscous

Fluid too heavy

Shaft speed too high

Suction line too small

Suction line collapsed

Suction strainer too small

Suction strainer dirty

Operating altitude too high

Boost or replenishment pressure too low

Replenishment flow too small for dynamic

conditions

Misaligned shaft Faulty installation

Distortion in mounting

Axial interference

Faulty coupling

Excessive overhung loads

Noisy pump

Mechanical fault

in pump/motor Piston and shoe looseness or failure

Bearing failure

Incorrect port plate selection

Eroded or worn parts in the

displacement control

Air in fluid See aboveErosion on barrel

ports and port plate Cavitation See above

Excessive loads Reduce pressure settings

Reduce speeds

High wear in motor

Contaminant

particles in fluid Improper filter maintenance

Filters too coarse

Introduction of dirty fluid to system

reservoir openings

Reservoir breather

Improper line replacement

Improper fluid Fluid too thin or thick for operating

temperature range

Breakdown of fluid with time/temperature/

shearing effects

Incorrect additives in new fluid

Destruction of additive effectiveness

with chemical aging

5

TROUBLESHOOTING

TROUBLESHOOTING

(continued) EffectofTrouble Possible Cause Fault which needs remedy

Improper repair Incorrect parts

Incorrect procedures, dimensions, finishes

High wear in motor

(continued) Unwantedwater

In fluid Condensation

Faulty breather/strainer

Heat exchanger leakage

Faulty clean-up practice

Water in make-up fluid

Cogging load Mechanical considerations

Worn relief valve Needed repairs

Worn

compensator

Show response in

checkvalves

Needed repairs

Replace or relocate

Servo pressure to

low to maintain

firm control

Increase pressure and check

pressure drop through servo filter

Excessive de-

Compression

energyrates

Improve decompression control

Excessive line

capacitance

(line volume,

line stretch,

accumulator

effects)

Reduce line size or lengths

Eliminate hose

Bleed air

Pressureshocks

Barrel blow-off Re-check pump hold-down, rotating group,

drain pressure

Excessive motor

leakage Recheck case drain flow and repair as required

Fluid too thin

Improper assembly, port timing

Relief Valve Set too low (compared to load or to

compensator)

Instability caused by back pressure, worn parts

Compensator Set too high (compared to relief)

Worn parts

Pump too large

for fluid needs Select smaller pump displacement

Heat exchanger Water turned off or too little flow

Water too hot

Fan clogged or restricted

Efficiency reduced by mud or scale deposits

Intermittent hydraulic fluid flow

Heating of fluid

Reservoir Too little fluid

Entrained air in fluid

Improper baffles

Insulating air blanket that prevents heat rejection

Heat pick-up from adjacent equipment

6

SECTION III –UNIT DISASSEMBLY

The instructions contained in this section cover a complete teardown of the subject motor. Disassemble only as far as necessary to replace or repair

any worn parts.

DISASSEMBLY Position motor unit so the shuttle valve assembly is on the bottom. A bench or similar

suitable surface capable of supporting unit should be used. Disassembly area should be

clean.

CONTROLS 1. Remove the four screws (14) from the side (16) and remove the input shear seal

(See Figure 9)assembly.

2. Remove the four screws (14) from the side cover (15) and remove the counter balance

shear seal assembly.

3. Remove the two screws (12) and spacers (11). Remove the servo stem (9) and

plate (10).

BARREL HOLD-DOWN 1. Remove snap ring (8), end cover (6) and O-ring (7).

(See Figure 8) 2. Remove cotter pin (5), hold-down nut (4), thrust washers (1), bearing (2) and

seal ring (3).

PORT BLOCK 1. Remove four screws (5) that secure the port block (1) to the housing (9).

(See Figure 7) 2. Remove port block (1) and gasket (8). Remove port plate (7) and port plate

pins (6).

CAUTION: When removing port block, the port plate can cling to the face plate

because of oil film. Make sure it does not fall and become damaged.

BARREL AND HOLD-DOWN Remove the barrel assembly by grasping the hold-down shaft and lifting the complete

SHAFT assembly out of the housing.

DRIVE SHAFT REMOVAL 1. Remove the four screws (8) and gaskets (7).

(See Figure 9) 2. Remove seal retainer (6), and gasket (5). See view of item 4.

3. Carefully remove the carbon ring and the remainder of the shaft seal from the shaft.

Do not scratch seal area of the shaft.

4. Remove snap ring (3) and the shaft and bearing assembly (1). Remove spacer or

ring (2).

HOUSING REMOVAL After shaft assembly has been removed, position the unit on end with the mounting

(See Figure 6) flange turned down.

1. Push the ends of the small tube lines (5) away from the housing (4).

2. Lift the housing from the mounting flange, remove the gasket (3), and dowel pins (7)

from the mounting flange.

3. Do not remove the roll pins and the bearing from the housing unless the bearing is

damaged and must be replaced.

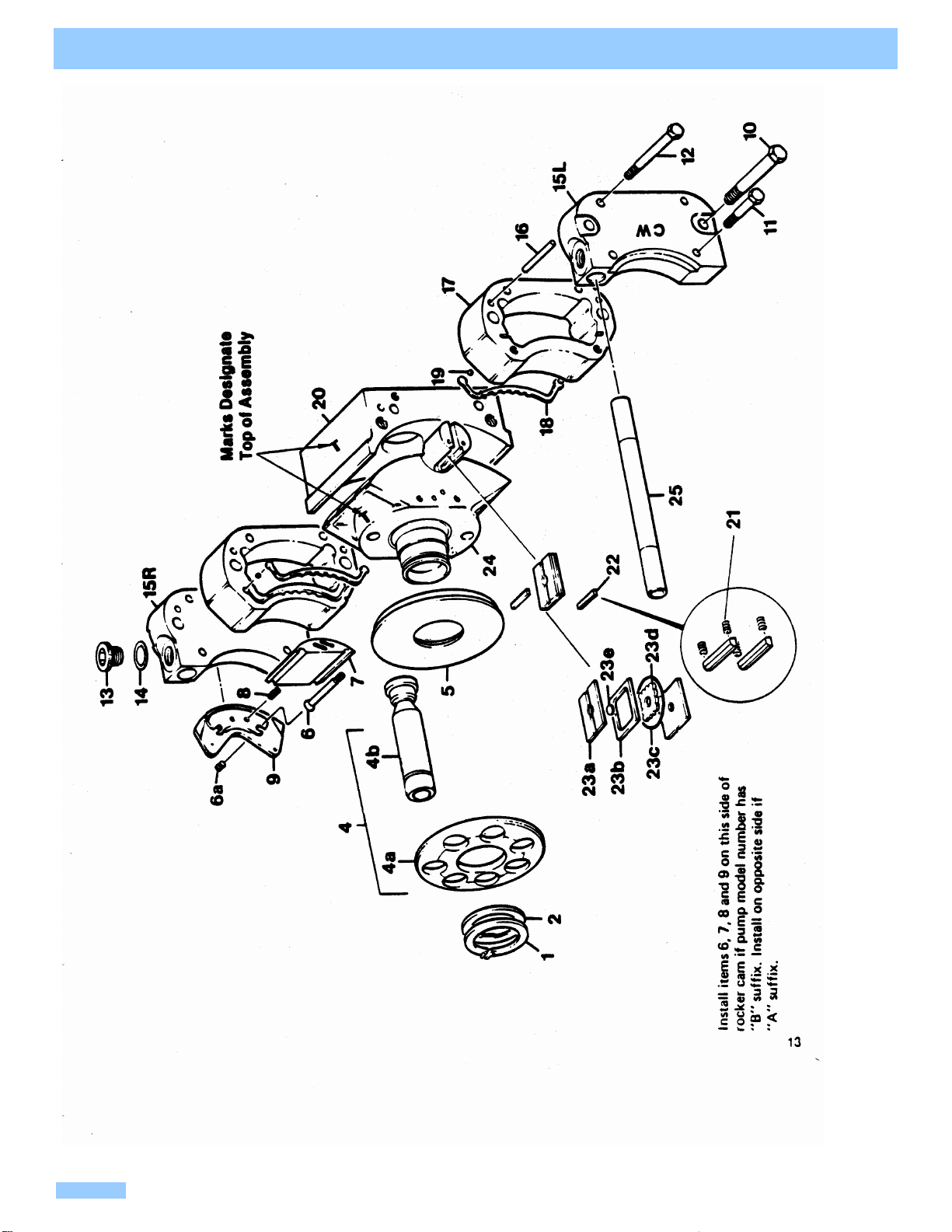

ROCKER CAM AND CONTROL 1. Remove the complete assembly from the mounting flange and position on a clean

STROKING ASSEMBLY flat surface with the two tubes (2) in a horizontal position and located at the top. Mark

(See Figure 4) the cam (24) and cradle (20) as indicated in Figure 3. These marks will determine

positioning of parts during reassembly.

Caution: Do not bend these lines.

(See Figure 3) 1. Position the assembly in an upright position on the flat surface on the cradle (20).

Remove the retaining ring (1) and thrust washer (2).

2. Remove the piston and shoe assembly (4) and the creep plate (5) from the cam (24).

Carefully remove the screws (6a) and (6) that secure the servo input parts (7, 8 and) to

the cam (24).

3. Remove the four 7/16” screws (10) and eight 1/4” screws (11) and (12) from the control

covers (15R) and (15L).

4. Remove the four dowel pins (16) and remove the two chambers (17). Remove the two

special seats (18) and the four steel balls (19).

5. Remove the two vane seal cartridge assemblies (23), vane springs (21) and the four

hold-down vanes (22) from the rocker cam (24).

6. Remove the rocker cam (24) from the cradle (20).

7

SECTION IV –ASSEMBLY TOOL DRAWINGS

8

SECTION IV –ASSEMBLY TOOL DRAWINGS

REWORK LIMITS OF WEAR PARTS

6 and 7.25 In.3 Original

Dimension Max. Rework from

Original Dimension Min. Dimension

After Rework

Port plate face .315/.305” .010” .295”

Cylinder barrel face 4.480” .010” 4.470”

Shoe retainer face .314/.312” .005” .307”

Piston shoe face (pocket) .019/.014” .011/.006” .281”

Creep plate face .293/.291” .010” .281”

Face plate None Replace

9

SECTION V –ASSEMBLY PROCEDURES

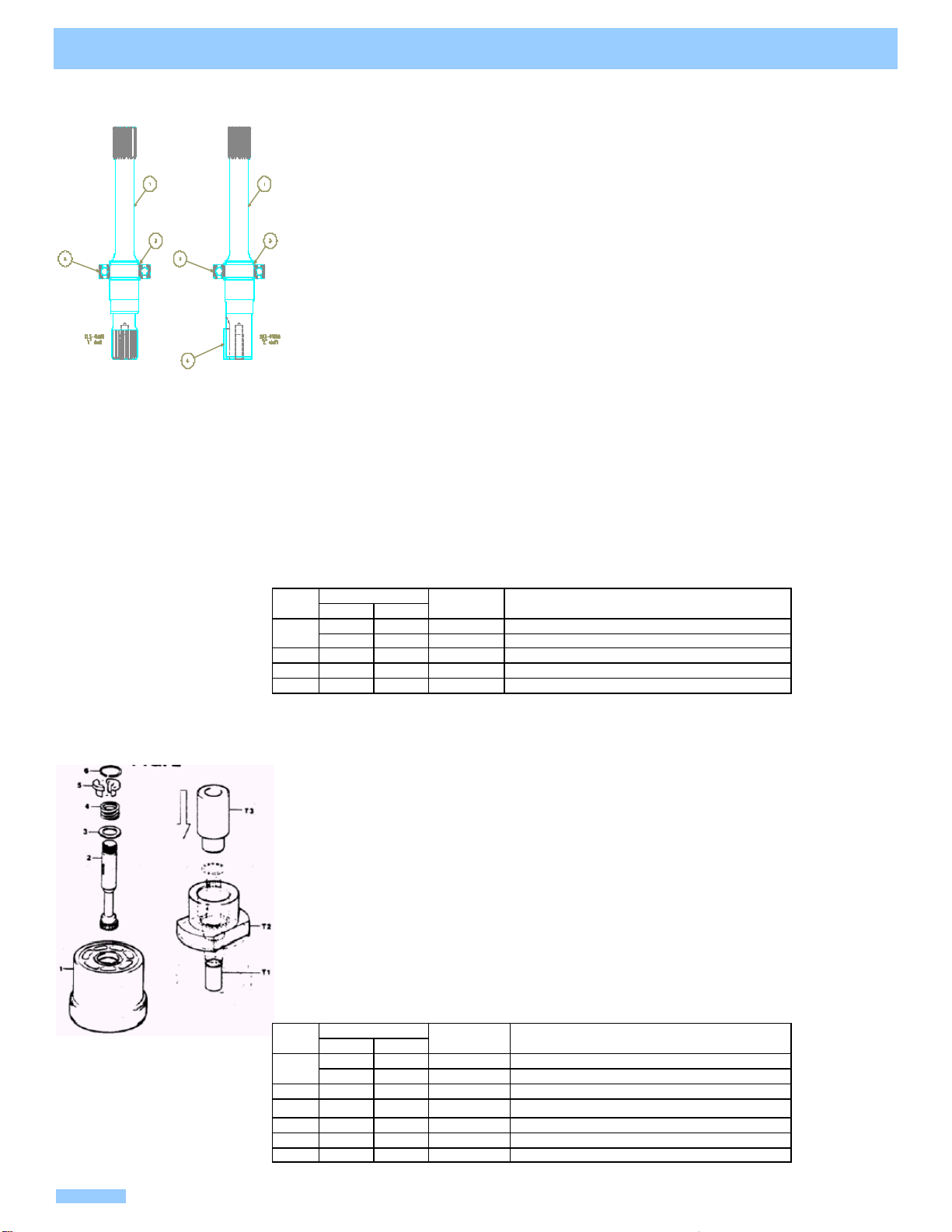

DRIVESHAFT ASSEMBLY 1. Pass one retaining ring (3) over the internal end of drive shaft (1) and install in the

Figure 1 groove near the shaft seal surface.

DO NOT PASS THE RING OVER THE SEAL SURFACE.

2. Slide the bearing (2) over the same end of the shaft andseat against the ring.

Support only the inner race of the bearing and press on the coupling end of the

shaft.

DO NOT USE EXCESSIVE FORCE AND DISTORT OR DAMAGE THE RETAINING

PIN.

3. Install the other retaining ring (3) in the other retaining ring groove. Be sure that both

rings are fully seated.

PARTS LIST FOR FIGURE 1

S13-41805 #1 Drive Shaft Assembly (Splined)

S13-41806 #2 Drive Shaft Assembly (W/Key-way)

QUANTITYITEM #1 #2 PART

NUMBER DESCRIPTION

2-- 033-70567 #1 (Splined) Drive Shaft1-- 1033-70579 #2 (W/ 5/16 KW) Drive Shaft

211230-82140 Shaft bearing MRC-107KS

322033-70817 Retaining Ring

4-- 1035-71348 Square Key 5/16 x 1 1/4

BARREL AND HOLD-DOWN 1. Position the barrel (1) in a press with the large end turned down and insert tool figure

SHAFT ASSEMBLY T-1 in the splined shaft hole in the barrel.

Figure 2

2. Place thrust washer (3) and spring (4) over shaft (2) in the same sequence as shown.

3. Insert shaft (2) in barrel (1) and rest on tool figure T-1. Position the two spring retainers

(5) around the shaft (2) and inside of spring (4).

4. Carefully place tool figure T-2, with the large end of the tapered hole up, over the shaft

(2) and against the barrel (1) face. Insert ring (6) around the shaft (2) and in the tool.

5. Position the ring with the gap within 5/8” of the notch in the barrel for easy removal.

6. Place tool figure T-3 over the shaft (2) with the small end against ring (6). Press on the

end of the assembly tool and seat the ring (6) in the groove in the barrel (1).

7. Remove the assembly tools. Check to be sure that the ring is properly seated. Check

barrel face to be certain it is not marred.

PARTS LIST FOR FIGURE 2

QUANTITYITEM #1 #2 PART

NUMBER DESCRIPTION

1-- S13-43657 Barrel & Sleeve Assy. M6 Only1-- 1S13-47511 Barrel & Sleeve Assy. M7 Only

211033-70583 Hold-down Shaft

311350-10069 Thrust Washer TRA-1220

411033-70493 Barrel Hold-down Spring

522033-70483 Spring Retainer

611033-70494 Retaining Ring

10

SECTION V –ASSEMBLY PROCEDURES

ROCKER CAM ASSEMBLY Position the rocker cam (24) on the cradle (20). Note the marks made previously on the

See Figure 3 cradle and cam to indicate top. (See marks in Figure 3.) Marks will be used for assembly

reference.

VANE SEAL CARTRIDGES 1. Install O-ring (23c) around spacer (23d) and insert in the seal vane (23b).

2. Install check valve (23e) inside of spacer (23d) and assemble between the two backup

plates (23a) with the notched V’s exposed.

3. Install assembled cartridge in slot in cam as indicated in Figure 3. Repeat steps 1, 2,

and 3 on other side of cam.

4. Install the four hold-down vanes (22) and springs (21) in the slots on each side of the

control vanes (23).

CONTROL CHAMBER 1. Position both control chambers (17) on a clean flat surface with seal grooves turned up.

Drop the four steel balls (19) in the four counter-bored holes at each end of the seal

grooves.

2. Lubricate seals (18) and insert in seal grooves in control chamber (17).

3. The tapered side of the seals must be pushed into the grooves and the ends must cover

the steel balls.

4. Install the control chamber (17) with seal (18) and steel balls (19) assembled over the

control vane (23). The seal must be against the cam. Rotate the chamber until it

passes over the control vane assembly, then rotate in the opposite direction until the

1/4” dowel pins (16) can be pushed through the chamber (17) and into the cradle (20).

Install chamber in the same manner on the other side of the cam.

NOTE: Two sets of chamber covers are available. The set marked CW must be

installed in the right hand rotation pump and the set marked CCW must be used

in the left hand rotation pump. (Rotation is determined facing the shaft end of

pump.) The covers must be installed with the tubing holes and the tapped holes

at the top of the unit.

5. Install chamber covers (15r) and (15l) on the control chambers (17) over the dowel pins

(16). The tapped holes must be at the top. Refer to the“T” marked on the rocker

cam (24) and cradle (20).

6. Install four 1/4 –20 screws, two (11) and two (12), in each side and torque to 10 ft. lbs.

7. Install two 7/16-14 screws (10) in each side and torque to 45 ft. lbs.

8. Install O-ring 914) and plug (13) in each cover.

9. Install tubes (25) in reamed holes in each cover. These tubes must be a tight fit. If

tubes are loose, the ends can be expanded with a tapered punch.

10. Tap the tubes in place with a plastic mallet.

SERVO ASSEMBLY 1. Install two orifice screws (8) in the servo stem (7).

2. Install servo plate with the screws through the servo stem. The orifice screw end of the

servo stem must be against the servo plate.

3. Position the stem and plate on the rocker cam input side (at 9 o’clock on “B” model or

3 o’clock on “A” models) with the screws positioned over the 10-24 tapped holes. Hold

the assembly against the cam and alternately turn the screws 1/2 turn each until the

stem and plate are firmly attached to the cam. Torque the screws (6) to 40 in. lbs.

Install set-screws (6a) over the screws (6) and torque to 5 ft. lbs.

CAUTION: The screws must not protrudefromtheservoplate.

PISTON AND SHOE ASSEMBLY 1. Install creep plate (5) over center post on rocker cam. Small O.D. of plate must face the

cam.

2. Install the seven piston and shoes (4b) in the shoe retainer (4a). Position the assembly

(4). Position the assembly (4) over the center post and against the creep plate.

3. Install thrust washer (2) over center post.

4. Five different retaining rings (1) are available for the hold-down assembly. Install the

thickest ring (1) with the dot up, that will fit in the groove on the center post and allow a

clearance of .002 to .004 between the shoe and creep plate. Grasp one piston and lift

tightly against shoe retainer to measure this clearance.

5. The piston and shoe assembly (4) should be free to rotate by hand. (5 ft. lbs. or less).

See Figure 4.

11

SECTION V –ASSEMBLY PROCEDURES

PARTS LIST FOR FIGURE 3

NO. QTY. PART

NUMBER DESCRIPTION

Retaining ring –USE ONE ONLY

033-72175 .086 w/white dot

033-72176 .084 w/blue dot

033-70484 .083 thick w/yellow dot

033-70488 .081 thick w/green dot

11

033-70490 .079 thick w/red dot

21033-72249 Thrustwasher

3-- --------------- NOT USED

4-- See below Piston & shoe assy. w/retainer

51033-71261 Creep plate

62353-25041 Screw

6a 2312-09032 Setscrew

71033-71312 Servostem

82033-70819 Orificescrew

91033-53874 Servo plate

10 4306-40183 Hex hd. screws 7/16-14 x 2 1/2

11 4306-40188 Hex hd. screws 1/4-20 x 1 1/4

12 4306-40187 Hex hd. screws 1/4-20 x 2 1/4

13 2488-35001 Hex socket plug SAE-4

14 2691-00904 O-ring 90-6290-4

1033-70572 Right side chamber cover CW Rot.15R

15L 1033-70571 Left side chamber cover CW Rot.

16 4324-21624 Dowel pin 1/4 x 1 1/2

17 2033-70570 Chamber

18 2606-25036 Seal

19 4201-06001 Steel Ball 3/16 H & G

20 1033-53951 Rocker Cradle

21 8033-72233 Vane hold-downspring

22 4033-72232 Hold-downvane

23 NOT USED

23a 4033-70802 Seal back-up plate

23b 2033-70501 Vaneseal

23c 2691-00120 O-ring 90-914-20

23d 2033-70519 Spacer

23e 2033-70803 Check valve

24 1S23-12104 Rocker camand plug assembly

25 2033-70524 Pressure tube

NO. QTY. M6 M7 DESCRIPTION

41S13-43655 S13-42308 Piston & shoe assy.w/retainer

4a 1033-54290 033-54290 Shoe retainer

4b 7S13-45680 S13-46040 Piston & shoe assy. only

12

SECTION V –ASSEMBLY PROCEDURES

13

SECTION V –ASSEMBLY PROCEDURES

BARREL, ROCKER CAM

AND FLANGE ASSEMBLY

See Figure 4

1. Install tube line assemblies (3) and (4) in the holes provided in cradle.

2. Install two dowel pins (6) in the cradle mounting surface of the flange

and two dowel pins (6) in the outer edge of the flange.

3. Install rocker cam and cradle assembly over the two dowel pins (6)

in the mounting flange. Be certain that cradle is seated over the

pins and against the flange with the tube lines (3) and (4) in the

grooves in the flange.

4. Install two or more 1/4-20 x 1 1/4 screws through the seal retainer

area into the cradle. Be certain the cradle is fully seated in flange.

These screws are required to hold the rocker cam assembly in

and will be removed later.

5. Tilt the rocker cam to either extreme position in the cradle and position

the barrel assembly with auxiliary shaft (1) directly over the pistons.

Start with the upper-most piston and guide them one at a time into

the barrel. Return the rocker cam to a level position in the cradle.

NOTE: Tube assemblies (3 & 4) must be a snug fit into holes in

cradle. Expand end of tubes with a pointed tool to assure fit.

PARTS LIST FOR FIGURE 4

NO.

QTY. PART NO. DESCRIPTION

11See Fig. 2 Barrel and Hold-down Shaft Assy.

22033-70524 Pressure Tube

31S13-42402 Tubing Assy. (right side)

41S13-42403 Tubing Assy. (left side)

51See Fig. 3 Rocker Cam and Stroking Assembly

64324-22412 Dowel Pin 3/8 x 3/4

71033-70604 Mounting Flange

FIG. 5 s15-42335 HOUSING ASSEMBLY

NO.

QTY. PART NO. DESCRIPTION

11033-71284 Housing

21033-70580 Bearing

34324-21608 Dowel Pin

42325-16280 Roll Pin

51691-00912 O-ring 90-6290-12

61488-35014 Hollow Hex Plug SAE-12

14

SECTION V –ASSEMBLY PROCEDURES

HOUSING ASSEMBLY

See Figure 5

1. Position housing (1) on a clean flat surface with the large open

end up.

2. Install bearing (2) in the housing bore. Insert pressing plug

tool (figure T-4) in the bearing. With a smooth and steady

force, press the bearing into the housing bore until seated.

DO NOT HAMMER OR BEAT INTO PLACE.

3. Turn housing (1) on side and install roll pin (4) in the 1/4”

through hole in the control cover pad. The pin must be

3/8” below the pad surface.

NOTE: The pin end must not interfere with the internal

bearing cage.

4. Install two dowel pins (3) in the blind holes in the same pad.

5. Repeat operation 3 on the opposite side of the housing.

6. Install O-ring (5) on plug (6) and install the hollow hex plug

in bottom of housing (1). Roll pins (4) are in bottom half

of housing.

HOUSING INSTALLATION

See Figure 6

1. Install the three face plate pins (1) in the holes provided in

the holes provided in the barrel face.

2. Apply heavy grease to the face of the barrel and install the

face plate (2) over the pins (1) in the barrel.

CAUTION: Make certain the plate is properly seated on

the barrel and pins.

3. Install gasket (3) over the two dowel pins (item 7, fig. 4) in the

mounting flange.

4. Install the housing assembly (4) over the barrel and auxiliary

shaft assembly and carefully guide the pressure tubes and

tube lines (items 3, 4 and 5, fig. 4) through the housing

assembly (4, fig. 6).

PARTS LIST FOR FIGURE 6

NO.

QTY. PART NO. DESCRIPTION

13033-49825 Face Plate Pins

21033-71530 Barrel Face Plate 6 in.3 only

1033-72532 Barrel Face Plate 7.25 in.3 only

31033-70576 Housing Gasket

41See Fig. 4 Housing Assembly

15

SECTION V –ASSEMBLY PROCEDURES

MOUNTING PORT BLOCK 1. Thread socket pipe plugs (2) into port block.

ASSEMBLY 2. Install O-ring (4) on hollow hex plug (3) and thread the tapped hole in tope of the

See Figure 7 port block.

3. Install gasket (8) on the housing assembly (9).

4. Install the two port plate pins (6) in the face of the port block assembly. Apply petroleum

jelly or heavy grease to the port plate (7) and position port plate over the pins (6) on the

port block.

5. Install the port block assembly and port plate over the end of the auxiliary shaft. Be

certain that tubes 2, 3 and 4 as shown on Fig. 4 are seated and that the port plate (7) is

still on the pins (6).

6. Install the four bolts (5), and torque to 150 ft. lbs.

PARTS LIST FOR FIGURE 7

NO.

QTY. PART NO. DESCRIPTION

11033-71297 Port block

22431-90404 1/4” Soc. Pipe Plugs

31488-35041 Hollow hex plug SAE-6

41691-00906 O-ring 90-6290-6

54306-40182 Hex head cap screw 5/8-11 x 9

62033-49825 Port plate pins

71033-71531 Port plate M6 only

1033-71267 Port plate M7 only

81033-70577 Housing gasket

91033-71284 Housing

16

SECTION V –ASSEMBLY PROCEDURES

BARREL HOLD-DOWN 1. Install seal ring (3) on hold-down shaft. Position bearing (2) between the two thrust

Figure 8 washers (1) and install around the seal ring.

2. Install hold-down nut (4) on the shaft and tighten no more than 10 ft. lbs. max. Back off

the nut until second slot is aligned with cotter pin hole in the shaft. Install cotter pin (5)

through nut and shaft and bend one tang over the end of the shaft.

3. Place O-ring (7) on end cover (6) and lubricate. Install end cover over hold-down nut

(4).

4. Depress cover and install snap ring (8). Make certain that snap ring is properly seated

in groove.

PARTS LIST FOR FIGURE 8

NO.

QTY. PART NO. DESCRIPTION

12350-10065 Thrust Washer

21230-82131 Bearing NTA-1625

31033-70510 Seal Ring

41033-53922 Hold-down nut

51322-03324 Cotter pin 3/32 x 1

61033-70537 End cover

71671-00138 O-ring

81356-65095 Internal Snap Ring

17

SECTION V –ASSEMBLY PROCEDURES

SHAFT AND SEAL 1. Stand the motor in an upright position with the port block inlet and outlet pads turned

INSTALLATION down.

See Figure 9 2. Remove the two 1/4-20 x 1 1/4” screws that were temporarilyused to hold the cradle in

the mounting flange. Install the shaft and bearing assembly (1) in the mounting flange

and cradle. Be certain that there are no burrs or sharp edges on shaft seal area of the

shaft.

3. For a rigid shaft application use the shim (2) that resultsin least clearance around the

shaft bearing. Do not use a shim with a floating shaft.

4. Install the snap ring (3) in the mounting flange to retain the shaft assembly. Make sure

that the ring is fully seated in the groove. Use the ring that results in the tightest fit.

SEAL ASSEMBLY The seal assembly (4) is available as a complete unit only.

CAUTION: Before installing the seal assembly, examine all the parts. The lapped

seal seat and the carbon ring have a precision finish that must be handled with care.

Be certain that both parts are free of scratches, marks and cracks.

1. Install the spring retainer (e) over the shaft and against the retaining ring on the shaft

assembly. Place the spring (d) against the retainer (e). Apply oil to the inner surface

of the rubber friction ring (f) and position the shell containing the rubber friction ring (f)

and carbon ring (c) over the shaft with the carbon ring exposed. Apply heavy grease to

the square section rubber seal (a) and install on the cast iron seat (b).

2. Install the seat and seal in the seal retainer (6) with the lapped side of the seat in

position to contact the carbon ring. Place the seal retainer assembly and gasket (5)

over the shaft with the lapped surface against the carbon face.

3. Install the four gaskets (7) on the four screws (8) and insert in the seal retainer (6).

Depress the seal retainer only far enough to start the four screws and tighten evenly.

Torque to 10 ft. lbs.

COUNTER-BALANCE SERVO 1. Install the two spacers (11) on the two screws (12) and insert through the balance plate

STEM ASSEMBLY (10) and the servo stem (9).

2. Insert these parts through the opening in the side of the housing assembly and position

the screws over the two 10-24 tapped holes in the rocker cam.

3. Hold these parts against the cam and alternately tighten screws (12) to hold the

assembly firmly in place. Torque screws to (5) ft. lbs.

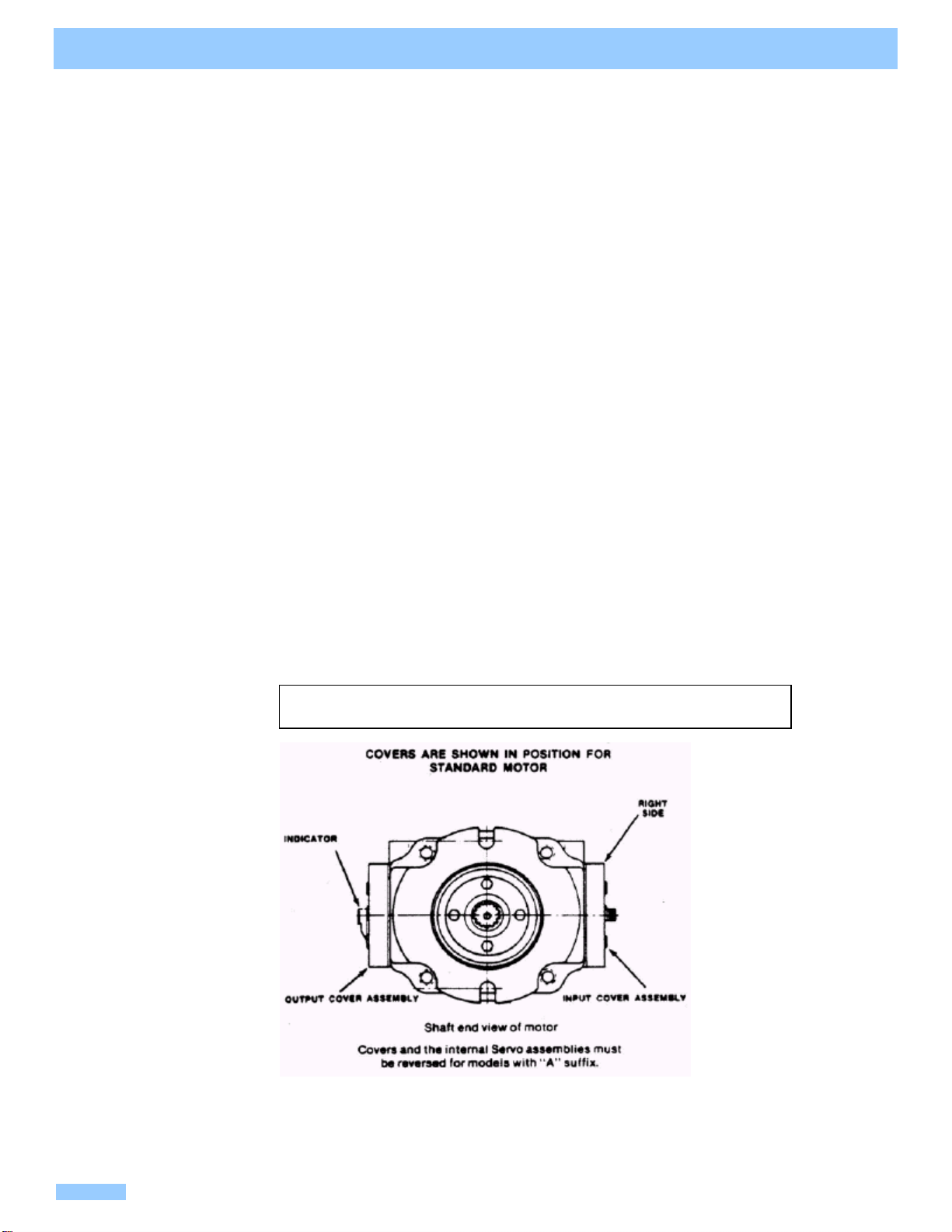

CONTROL COVER ASSEMBLIES 1. Lubricate O-rings (21 & 22) and install in counter-bore and groove in covers.

Figure 9 2. Position the cover assemblies (15 & 16) over the two dowel pins on the housing pads

and secure with seals (13) and screws (14). Torque to 45 ft. lbs.

The input cover assembly must be installed on the right hand side of the motor

with a “B” suffix. Install the output cover assembly on the right hand side on

modelswiththe“A”suffix.

18

SECTION V –ASSEMBLY PROCEDURES

PARTS LIST FOR FIGURE 9

NO. QTY. PART

NUMBER DESCRIPTION

1S13-41805 No. 1 Splined Shaft Assy. (See Fig. 1)11S13-41806 No. 2 Keyed Shaft Assy. (See Fig. 1)

1033-53948 Shim21033-53949 Shim

1033-53901 Retaining Ring

1033-53902 Retaining Ring

3

1033-53903 Retaining Ring

41623-00006 Shaft Seal

51033-70549 Seal Retainer Gasket

61033-70516 Seal Retainer

74631-45003 Nylite Gasket

84306-40144 Screw

91033-71312 Servo Stem

10 1033-70546 Balance Plate

11 2033-71247 Spacer

12 2358-10300 10-24 x 2 3/4 Soc. HD. Cap Screw

13 8631-45007 Nylite Washer

14 8353-25018 3/8-16 x 1 1/4 Hex Washer Head Screw

15 1S13-42064 Output Balance Control Assembly

16 1S13-42068 Input Servo Control Assembly

17 3691-10016 Tetraseal

18 1S23-00181 Cover Plate (not shown-optional to item 20)

19 3306-40106 Hex Head Cap Screw

20 Optional –See Fig. 10

21 1671-00017 O-Ring*

22 1671-00048 O-Ring 4-3/4 x 4-7/8*

*Some controls use gasket #033-53575 in lieu of O-rings.

19

Other manuals for Goldcup Series

3

This manual suits for next models

4

Table of contents

Other Denison Hydraulics Engine manuals