_04

1

3EN

INDEX

1 - GENERAL INFORMATION

1.1 Manual's purpose............................................................6

1.2 Glossary and Definitions................................................6

1.3 Emission...........................................................................6

1.4 Service request ...............................................................6

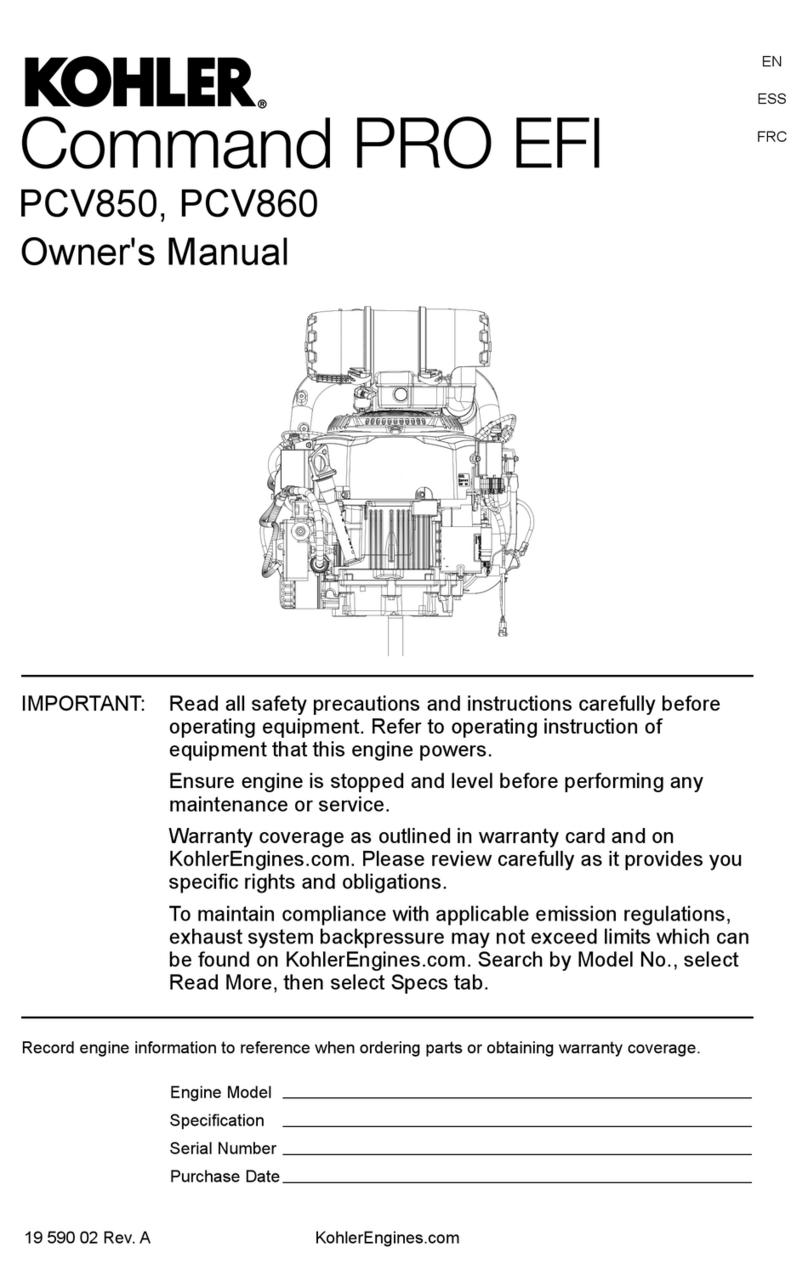

1.5 Engine component identification..................................7

1.6 Manufacturer and motor identification data ...............8

2 - TECHNICAL INFORMATION

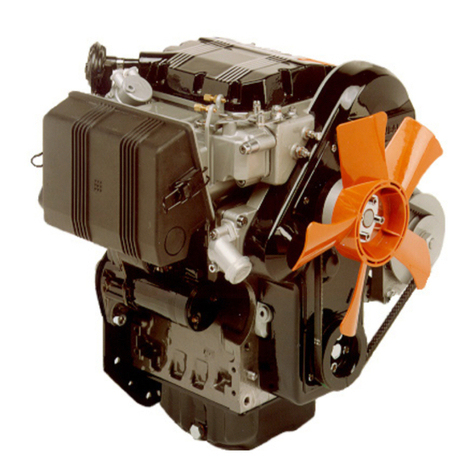

2.1 General description of the engine ................................9

2.2 Engine specifications.....................................................9

2.3 Engine dimensions (mm) - with TMC 260 reversing gear ... 9

2.4 Oil....................................................................................10

2.4.1 SAE oil classification .................................................10

2.5 Fuel .................................................................................11

2.5.1 Fuel for low temperatures.........................................11

2.5.2 Biodiesel fuel .............................................................11

2.5.3 Synthetic fuels: GTL, CTL, BTL, HV.........................11

2.5.4 Non-Road Fuels .........................................................12

2.5.5 Emission-Related Installation Instructions ............12

2.6 Coolant recommendation ............................................12

2.7 Battery recommendation.............................................12

2.8 Control panel.................................................................13

3 - SAFETY INFORMATION

3.1 Safety information ........................................................14

3.2 General remarks ...........................................................14

3.2.1 Note for OEM/installer ..............................................14

3.2.2 Note for end user.......................................................14

3.3 Safety signal description .............................................16

3.3.1 Adhesive safety plates ..............................................16

3.3.2 Safety guards.............................................................16

3.3.3 Warnings.....................................................................16

3.4 Information and safety signals....................................17

3.5 Safety and environmental impact...............................17

3.6 Location of safety labels on engine ............................18

4 - INFORMATION ABOUT USE

4.1 Pre-start check .............................................................19

4.2 Break-in running...........................................................19

4.3 Starting and turning off ...............................................19

4.3 .1 Starting .......................................................................19

4.3.2 After starting..............................................................19

4.3.3 Turning off ..................................................................19

4.4 Refuelling.......................................................................20

4.5 Engine oil filling.............................................................20

4.6 Reversing gear oil top-up ............................................21

4.7 Coolant filling ................................................................22

5 - INFORMATION ABOUT MAINTENANCE

5.1 Useful information about maintenance......................23

5.2 Periodic maintenance ..................................................23

5.3 Oil level check ...............................................................24

5.4 Rubber hoses check.....................................................25

5.5 Check coolant level ......................................................26

5.6 Zinc anode, intercooler and radiator check ..............26

5.7 Check and setting alternator standard belt tension.31

5.8 Control water filter cartridge fuel ...............................31

5.9 Product preservation ...................................................32

5.10 Engine storage (up to 6 months) ...............................32

5.11 Engine storage (over 6 months).................................32

5.12 Engine starting after storage.....................................32

5.13 Unused machine .........................................................33

5.13.1 Operations for the engine .......................................33

6 - INFORMATION ABOUT REPLACEMENTS

6.1 Engine oil replacement ................................................34

6.2 Oil filter cartridge replacement...................................35

6.3 Fuel filter cartridge replacement................................36

6.4 Water pump impeller replacement .............................36

6.5 Alternator belt replacement ........................................37

6.6 Coolant replacement....................................................38

6.7 Air cleaner replacement...............................................38

6.8 Disposal and scrapping ...............................................38

ED0053032450