Dennard 2050 User manual

Type 2050 coax

Index

sheet 1. Introduction & Index,

sheet 2. List of contents

sheet 3. Mounting configurations.

sheet 4. Safety bond.

sheet 5. Standard ceiling mounting.

sheet 6. Bracket mounting.

sheet 7. Tile mounting.

sheet 8. Dome mounting.

sheet 9. Electrical connections.

sheet 10. Address switches.

sheet 11. Control configurations.

sheet 12. Circuit diagrams.

sheet 13. Addendum contents.

addendum 1. 2050/FA dome camera.

addendum 2. 2050/FA connections.

addendum 3. 2050/FA ‘zoom cam’.

Introduction

Congratulations on choosing a Dennard Series 2050 Precision Dome camera.

This operation manual provides detailed information on the extensive mounting

variations available with the Series 2050 surveillance domes.

Models covered in this guide include 2050, 2050drx, 2050wp, 2050drx/WP and

2050/FA

This operation manual will provide all the necessary information to install the

Series 2050 Precision Dome Camera. Please refer to the System manual for

operation and programming features.

1. Type 2050 Menu system manual (supplied)

2. Type 2050 datasheet

Other technical documents available

2050 coax operation manual Sheet. 1

Fig.1 Components supplied

Before installation please remove the components from the packaging and

check that all items listed below have been supplied.

A. 1 x Series 2050 Dome enclosure

B. 1 x Power supply

C. 1 x Safety bond

D. 1 x Flying lead connector

E. 1 x Fixing bag containing the following:

4 x M6x16 Soc cap hd. screws 1 x M6 Plain nut

1 x M6 Spring washer 1 x M6 Plain washer

1 x 5mm A/F Hexagonal socket key 1 x 4mm A/F Hex socket key

In addition to the above components, a type 2050 product guide,

a 2050 menu system manual and a final test procedure are supplied.

List of contents

2050 coax operation manual Sheet. 2

AB

C D E

With appropriate bracketry the Type 2050 dome enclosure can be mounted in any of the

applications as shown above.

1. Wall/Pendant Mount (order suffix /WM) supplied as standard giving pendant or wall mount options

2. Pendant mount bracket (order suffix /PM) with drop length to suit customers requirements.

3. Snowdrop mount bracket (order suffix /SM) for mounting atop a pole or column.

4. Vintage mount bracket (order suffix /VM) for a vintage feel around historical buildings.

5. Ceiling mount bracket (order suffix /CM) for solid or suspended ceilings.

6. Tile mount (order suffix /TM) for suspended ceilings.

7. Side Entry (order suffix /SE) for use when cabling through ceiling is not possible.

8. Corner Bracket (order suffix /CB) for mounting to corners of buildings.

9. Extended corner mount (order suffix /ECM) for mounting to corners of buildings.

10. Extended wall mount (order suffix /EWM) for extending out from a wall.

All bracket variants can be supplied with optional rain shield (order suffix /RS)

All mounting variants are suitable for both weatherproof ( IP66 BS EN 60529 ) & indoor units.

1. 2.

4.

5.

9.

Fig.2 Bracket mounting variants

3.

10.

6.

7.

8.

2050 coax operation manual Sheet. 3

Mounting Configurations

For wall, pendant & snowdrop mounted domes attach the supplied safety bond, as shown in Fig.3, under

existing fixing in (position A) (use M6 plain washer supplied). Clip carbine at other end to eyelet (B) on

bracket to secure.

For standard ceiling mounted domes attach the supplied safety bond, as shown in Fig.4. Fit bond over M6

stud (position B) and secure with M6 nut, plain washer & spring washer supplied. Clip carbine to eyelet (E)

on dome to secure (see sheet 5 ‘Ceiling mounting instructions’ for details on eyelet mounting)

Note: Always support dome with bond prior to mating connector C. Weight of dome should be

supported by bond ensuring no stress is placed on centre connector C at any time.

Fig.3 Safety bond (Bracket mount)

A

B

C

Fig.4 Safety bond (Ceiling mount)

D

E

Safety Bond

2050 coax operation manual Sheet. 4

Cut/drill hole pattern in ceiling as shown in (fig.5) (Note: fixings for hole (A) are not supplied by Dennard

due to the variations of ceiling materials / thicknesses found on site. Please choose suitable fixings, with

countersunk head, for your application.) Attach mounting disc (B) to ceiling with chosen fixings and screw 4

off M6 x 16 soc cap hd. screws supplied into bushes as shown (C). Attach transfer disc (E) to top of dome

enclosure (G) with 4 off M6 dome hd. self tapping trilobular screws (D) pre-fitted (fig.6) (Note: Fit safety

bond bracket (F) as shown) Offer dome enclosure to ceiling mounting disc (fig.7) engaging the screw

heads (C) into keyhole slots (G). Twist to locate and tighten fixings

(C) to secure. Please ensure safety bond is fitted as descibed on sheet 4.

Fig.7

Fig.5 Ceiling hole pattern

Fig.6

B

160mm

160mm

E

F

113mm

113mm

A

4 x Ø15mm

Ø80-120mm

5mm

C

D

G

DG

2050 coax operation manual Sheet. 5

Ceiling Mounting

4 x Ø12mm AB

C

22.5º

Fig.8 Bracket Base Casting

D

Fig.9 Fig.10

EF

Wall Fixing Screws

Outer Trilobular Fixings (M6 x 16)

2050 coax operation manual Sheet. 6

A. Remove bracket base casting by unscrewing outer trilobular fixings, then assuming masonry wall mounting,

mark & drill 4 x Ø12 holes using bracket base casting as pattern, shown above.To assist with orientation

flats are

provided on all 4 axes allowing the use of a spirit level for alignment. (Fig 8) (use goggles when drilling)

B. Insert 4 x M6 Rawlbolts into wall until flush.

C. Offer bracket base casting into position & screw wall fixing screws through into inserts.

D. Tighten fixings to secure. Note: An optional spreader plate (/SP) is recommended when fixing to brickwork

to reduce the ‘pull out’ forces on a single brick.(Available from Dennard on request)

Note: Locating a dome on a corner of a building will give an increased area of surveillance. For this reason

Dennard are able to offer an optional corner bracket (/CB) to adapt the standard wall bracket.

E. Thread cable from bracket through cable entry hole in bottom of bracket base casting, then replace

bracket. (Fig 9)

F. Using supplied trilobular fixings attach bracket to base casting as shown. (Fig 10)

Wall Bracket Mounting

Cut/drill hole pattern in ceiling/tile as shown in (fig.11). Attach the mounting frame to the dome as shown in

fig.12 using 4 off M6 dome hd. self tapping trilobular screws (pre-fitted). Pass dome complete with

attached mounting frame (item A) through ceiling tile from beneath and clamp to tile using clamp ring

(item C) from above. Secure with 4 off M6 fixings (item D) as shown in (fig.13). If not already fitted adhere

Velcro® strips to hemisphere flange and likewise to the inside face of the trim bezel suppled. Simply offer

bezel over hemisphere into position aligning Velcro® strips to ensure a good bond is achieved as shown in

(fig.14). Fit safety bond supplied to attachment point shown in (fig.12).

Fig.14 Bezel mounting

Fig.11 Ceiling hole pattern

Fig.13 Mounting to tile (ceiling)

205mm

205mm

A

4 x Ø7mm

Ø190mm

C E

D

Safety bond

attachment point

Fig.12 Mounting

frame

2050 coax operation manual Sheet. 7

Tile Mounting

Fig.15 Mounting dome to bracket

AB

CD

Dome Mounting

2050 coax operation manual Sheet. 8

A. Secure & hang dome to bracket by attaching safety bond carbine to eyelet, as shown.

B. Mate central connector supplying power & control to dome. (ensure power is off when connecting)

C. Lift dome to bracket flange ensuring head of screws (previously fitted M6x12 Trilobular self tapping screws)

pass through keyhole slots. Twist to locate.

D. Tighten 4 top mounting fixings with 4mm A/F Hexagonal key supplied to secure.

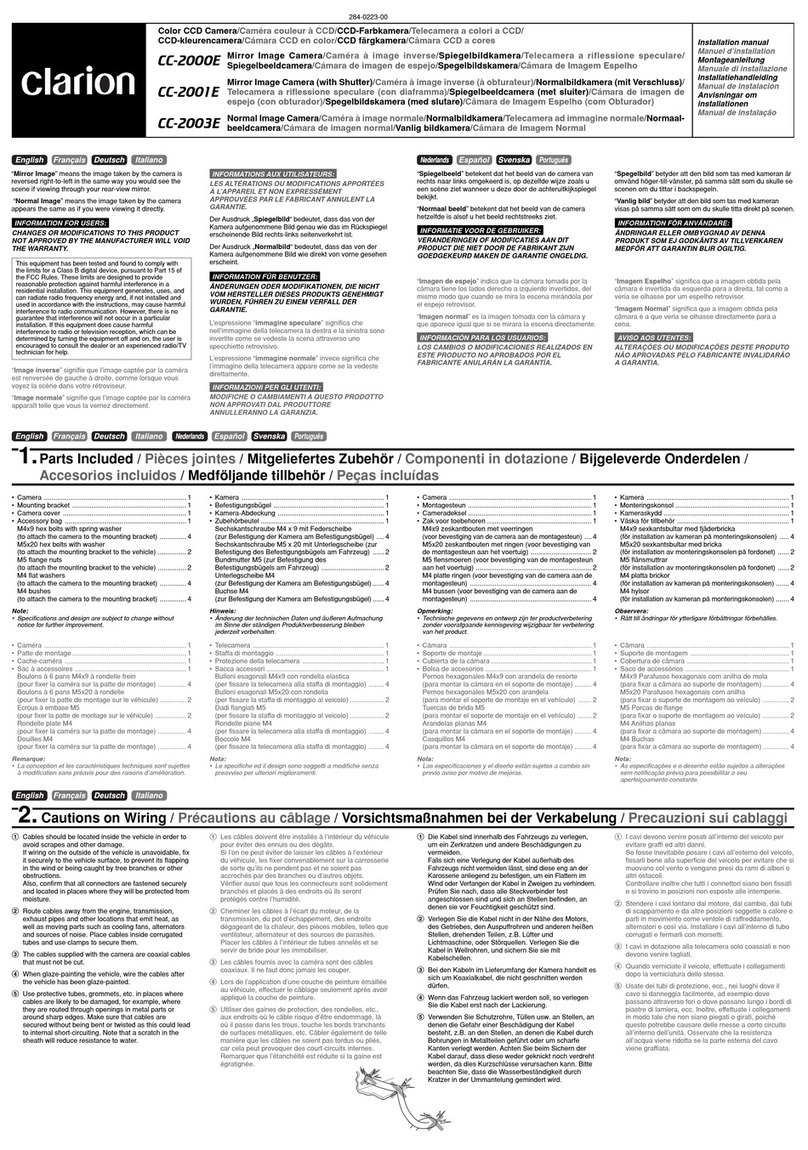

The Type 2050 external connections are via an IP66 Amphenol connector with 3 metre composite cable

flying lead comprising co-ax, power pair & RS485 pair. This lead should be connected to the boxed

P.S.U. supplied with the dome. The connections are as follows:

Fig.16 Electrical connections

Red wire.......24V a.c. live

Blue wire......24V a.c. neutral

The co-ax and power wires are always connected, the RS 485 wires are only connected when an

external protocol converter is fitted or an RS485 controller is being used.

Fig.17 Address chart

Co-ax. (Video)

Multicore cable with

integral Co-ax (Video)

Yellow wire.......R.S. 485 ‘A’

Green wire.......R.S. 485 ‘B’

Co-ax screen........BNC screen

Co-ax signal........BNC centre pin

0123456789101112131415

0123456789ABCDEF

YELLOW

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111

112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127

128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143

144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159

160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175

176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191

192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207

208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223

224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255

BLUE

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

ADDRESS SWITCHES

Electrical Connections

2050 coax operation manual Sheet. 9

Fig.18 Address switches.

B

C

Address switches

The Type 2050 can be controlled via RS 485 com-

mands or ‘up the co-ax’

With RS 485 control each dome has to be individually

addressed using the Blue and Yellow rotary address

switches following the address chart on the previous

page. For ‘up the co-ax’ control using the built in pro-

tocol converter the same address switches are used

to select the protocol format of the controller being

used i.e.

BAX AC PANEL.................Blue.F Yellow.C = 252

For: Baxall a.c. controllers

DEN PANEL.......................Blue.F Yellow.D = 253

For: Dennard, BBV & DM Sprite controllers

BAX DC PANEL................Blue.F Yellow.E = 254

For: Baxall d.c. controllers

For ‘up the co-ax’ control using external protocol con-

verters like the drx 100 or DAX-DEN the address

switches should be set to

Blue.0 Yellow.1 = 1

To access the address switches remove the outer

hemisphere and inner shroud as shown in A & B.

Picture D shows the location. This operation should

be carried out in an office type environment to avoid

ingress of moist air.

A

Address switches

2050 coax operation manual Sheet. 10

Address Switches

PSU PSU

Fig.19 RS485 configuration

1 to 32 Dome Cameras

Video cable

to Controller Video cable

to Controller

Local

230Va.c.

Input

R.S.485

Data Link

(Daisy chain)

Connect to

Controller

The Dennard Type 2050 dome can be

controlled by one of three methods.

Fig.19 RS485

Fig.20 Twisted Pair Configuration

Fig.21 Up the co-ax

The configuration drawings on this page

show the three connection arrangements.

Type 2050 Domes are delivered with address

switches set at ...253 (DEN PANEL)

Type 2050drx Domes are delivered with

address switches set at...1

Local

230Va.c.

Input

drx 100

+ PSU

drx 100

+ PSU

Fig.20 Twisted Pair Configuration

1 to 16 Dome Cameras

Twisted Pair

(20mA)

(current loop)

Video cable

to Controller

Video cable

to Controller

Local

230Va.c.

Input

PSUPSU PSU

Fig.21 Up the co-ax Configuration

1 to 16 Dome Cameras

Video cable

to Controller

Video cable

to Controller

Local

230Va.c.

Input

Local

230Va.c.

Input

4 x local

alarms

Local

230Va.c.

Input

4 x local

alarms

Twisted Pair

(20mA)

(current loop)

Termination Resistor Link

Fitted resistor in (default)

Not fitted resistor out

Yellow

Address

Switch

Blue

Address

Switch

Control Configuration

2050 coax operation manual Sheet. 11

RS485 / Up the Co-Ax Configuration

drx options

Circuit Diagrams

2050 coax operation manual Sheet. 12

ADDENDUM

Addendum.1. Type 2050/FA (Fixed Attitude Dome)

Addendum.2. Type 2050/FA (Electrical Connections)

Addendum.3. Type 2050/FA (‘Zoom Cam’ Set Up)

2050 coax operation manual Sheet. 13

Moving cameras can be positioned remotely, fixed

attitude modules require manual adjustment to position the

camera. Follow the procedure below to set-up your required

picture frame.

1. Unscrew the 6 fixings securing the outer hemisphere to the

casing and remove.

2. To adjust the pan position of the camera, grip the inner hemi-

sphere and rotate. This adjustment provides 180º of pan right &

left movement. Tip. Do not wind more than 180º in one direction

as this will stress the connections to the camera.

3. To adjust the tilt position grip the camera platform (accessible

through the camera viewing slot) as shown and move. This

adjustment provides tilt up/down. See Addendum 3 for ‘zoom

cam’ set-up.

1. Hemisphere removal

2. Camera pan adjustment

6 x fixing screws

Inner hemisphere

3. Camera tilt adjustment

2050 coax operation manual Addendum 1

Type 2050/FA (Fixed Attitude Dome Camera)

The Type 2050/FA Camera Dome is supplied complete with an IP66 ‘Amphenol’ 7 way connector and 3

metre multicore with Co-ax flying lead assembly. The Amphenol connector mates as shown in fig.16 to

the top of the dome. The table below details the flying lead functions.

Electrical connections

Red ..... 24Va.c. live

Blue .....24Va.c. neutral

P.S.U. Connection diagram

Co-ax. (Video)

Multicore cable with

integral Co-ax (Video)

Yellow ..... not used

Green ..... not used

Co-ax Screen ..... BNC screen

Co-ax Signal ..... BNC centre pin

2050 coax operation manual Addendum 2

Type 2050/FA (Fixed Attitude Electrical Connections)

Type 2010ZC/COL & /COLMON are equipped with the ‘zoom cam’ high resolution

camera. See instructions below.

1. Control

Remote zoom control requires a Dennard, BBV or DM telemetry controller. as well as the removal of link ‘A’

(see point 6) if not already disconnected. Depress the zoom buttons or use the joystick pan axis to operate.

If no control is available the camera can function as a ‘fixed lens’ (see point 6)

2. Presets

The ‘zoom cam’ can store up to 8, user definable, zoom presets within memory. Please refer to the relevant

controller instructions for preset programming.

3. Default position

After a period of inactivity (default 1min.) the ‘zoom cam’ will revert to preset 1 (wide angle if no preset

stored). On Dennard & BBV controllers only use the ‘Patrol 2 delay program’ to adjust the time interval.

Intervals are 1,2,3,4,5,6,8 & 10 minutes for keys 1-8.

4. Patrol

The ‘zoom cam’ patrol feature can be used to sequence between the preset positions. Follow the relevant

controller instructions to setup ‘Patrol 1.’ Patrol mode is cancelled with any manual zoom action.

5. Video level adjustment

Video level is factory set, but can be adjusted by turning VR1 located just above the link’A’ on the receiver

board. (see opposite) This adjustment may be required to lighten / darken the picture depending on the dis-

tance of co-ax required.

6. Fixed lens

When no remote control is available the ‘zoom cam’ can function as a ‘fixed lens’ (i.e. the camera can be

manually zoomed (locally) to a preset position)

a. Ensure link ‘A’ (supplied) is fitted, as shown, between pins 9 & 10 on power up

b. Frame the preset picture required by zooming using the buttons provided on the side of the camera.

c. Temporarily remove the link ‘A’ for a few seconds and then refit. (The link must be left in permanently)

Note: to revert back to ‘zoom cam’ operation the link must be removed and power re-applied.

zoom buttons Link ‘A’ (shown fitted) between pins 9 & 10

Left side of camera

Right side of camera

VR1 Video

adjustment

Type 2050/FA ‘Zoom Cam’

2050 coax operation manual Addendum 3

This manual suits for next models

4

Table of contents

Other Dennard Security Camera manuals