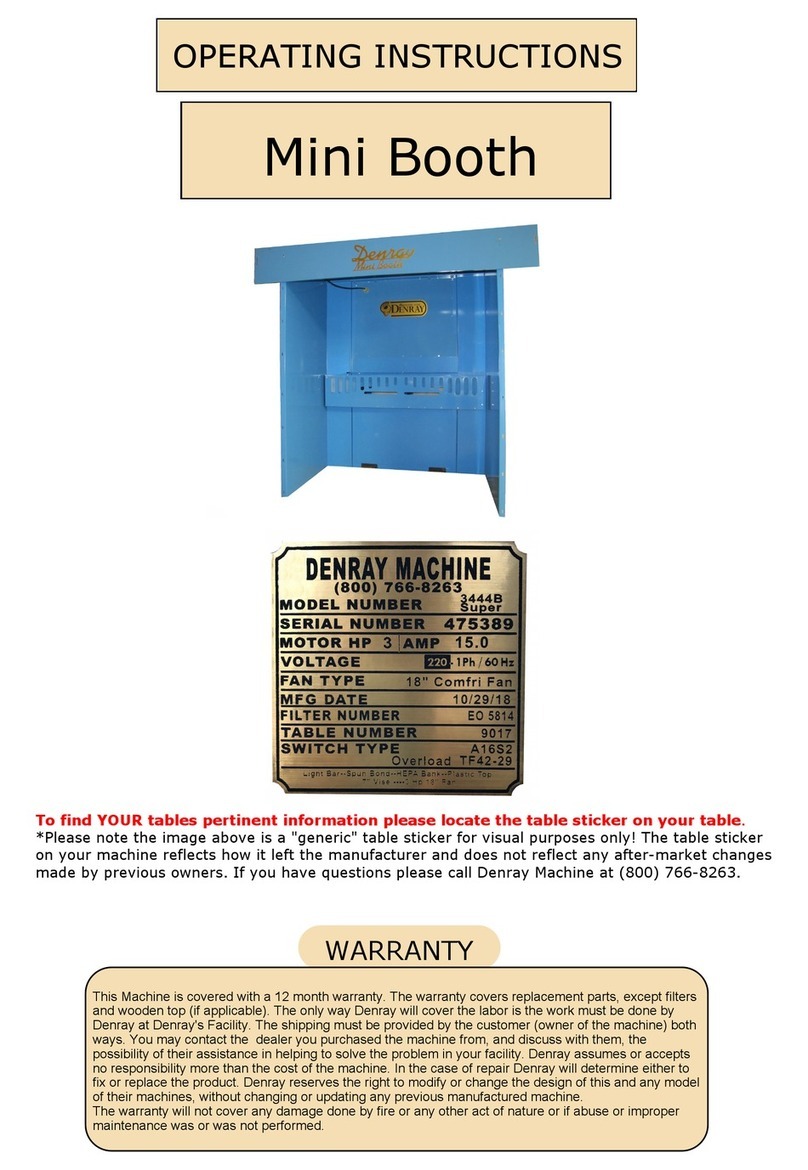

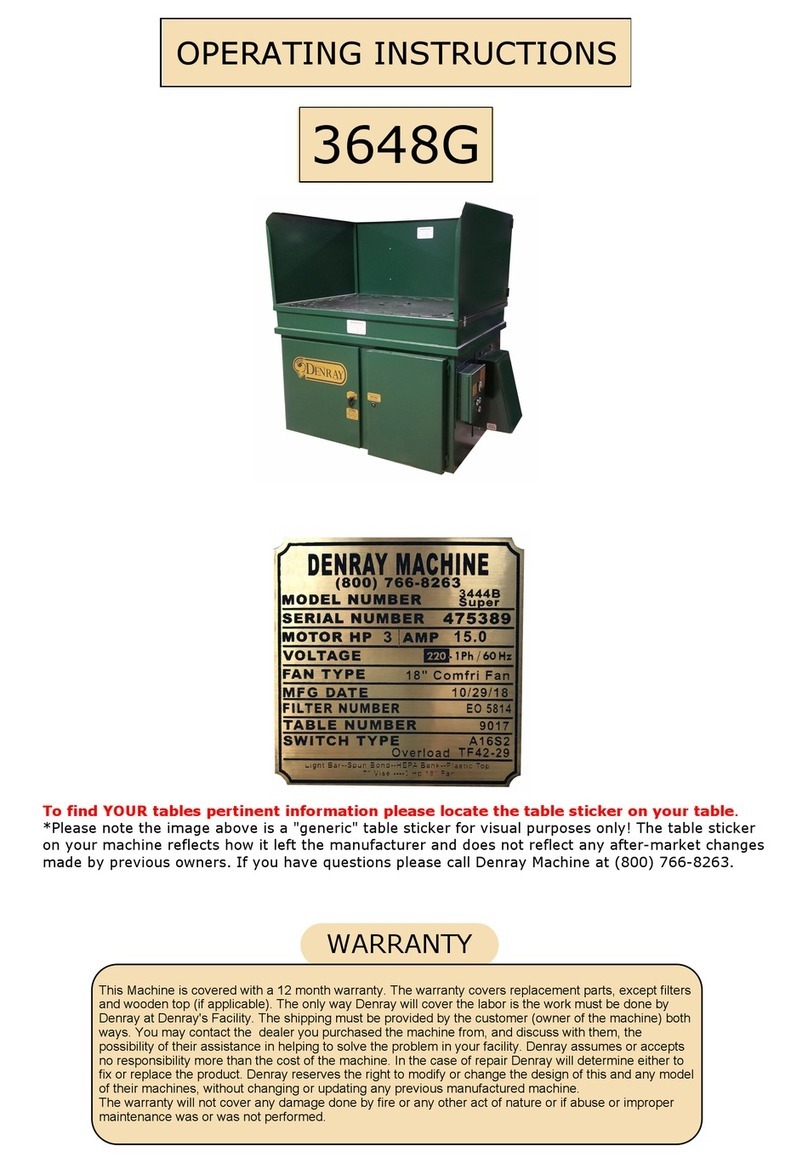

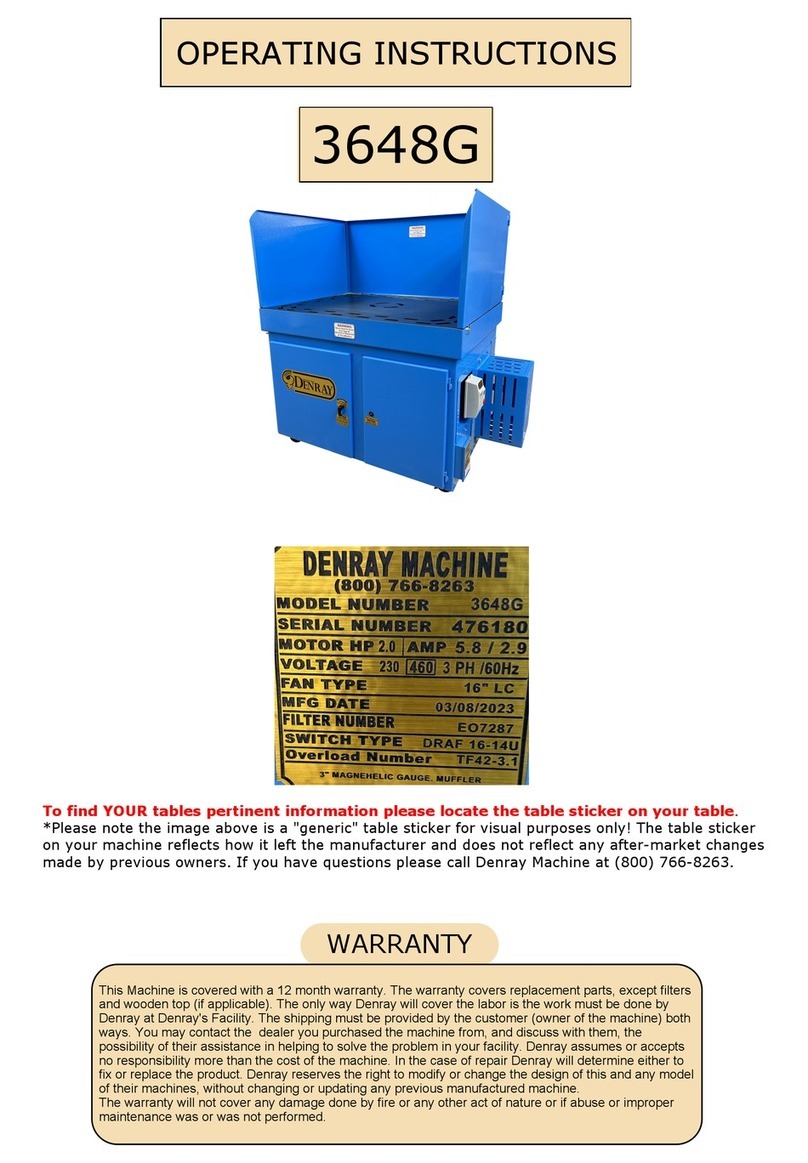

Denray 2872B User manual

Other Denray Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Panduit

Panduit Smartzone PViQ Connectivity System user manual

morse

morse 310 Series Operator's manual

Idex

Idex KNIGHT SINK MATE PLUS instruction manual

Veeder-Root

Veeder-Root TLS-4 Series Programming and troubleshooting

SCHUNK

SCHUNK VERO-S NSE3-A3 138 Assembly and operating manual

Southwire

Southwire HB5A-12X5 operating instructions

matev

matev CLS-SE operating manual

Festo

Festo EHPS LK Series operating instructions

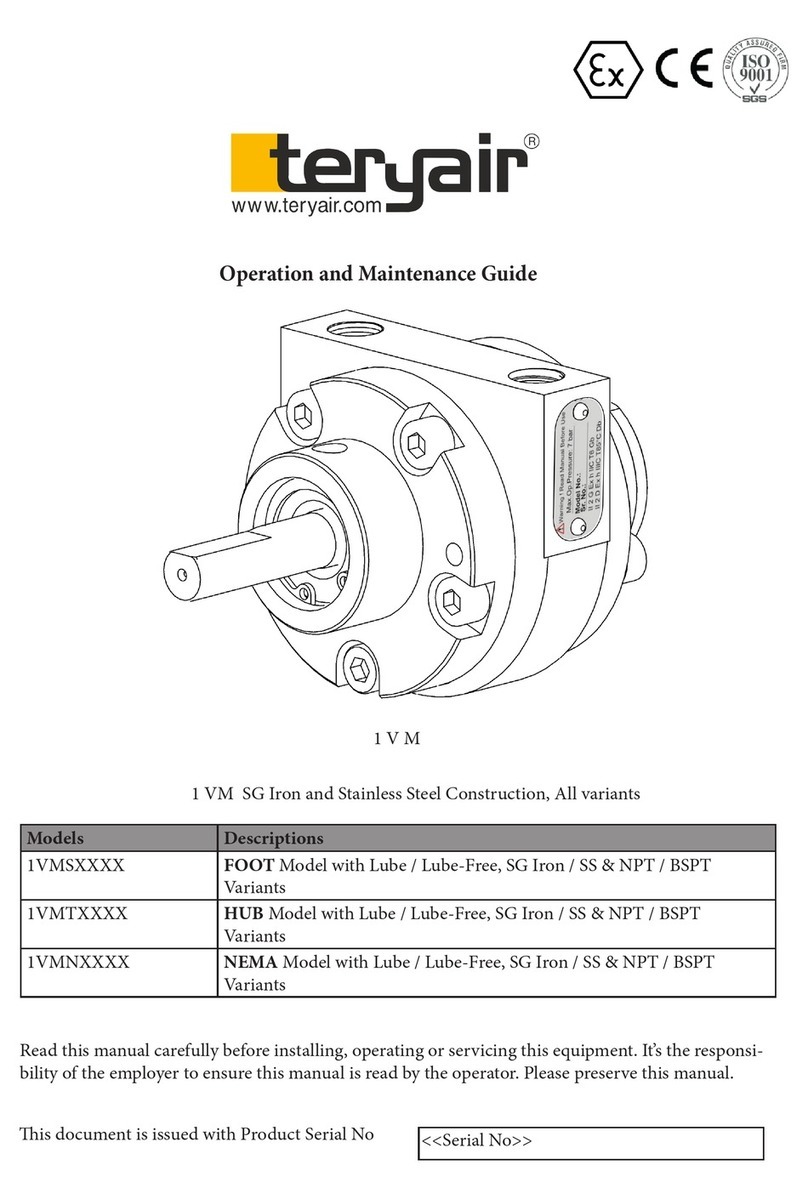

Teryair

Teryair 1VMS Series Operation and maintenance guide

Regulus

Regulus HSK PV Installation and operation instruction

Wacker Neuson

Wacker Neuson DPU 130Le Machine configuration manual

Afag

Afag RA-40-2F Series Assembly and operating instructions

GW Instek

GW Instek PEL-2000 Series Programming manual

Samoa

Samoa LARIUS PNEUMATIC HOIST 200 operating instructions

Land Instruments International

Land Instruments International NIR Borescope installation guide

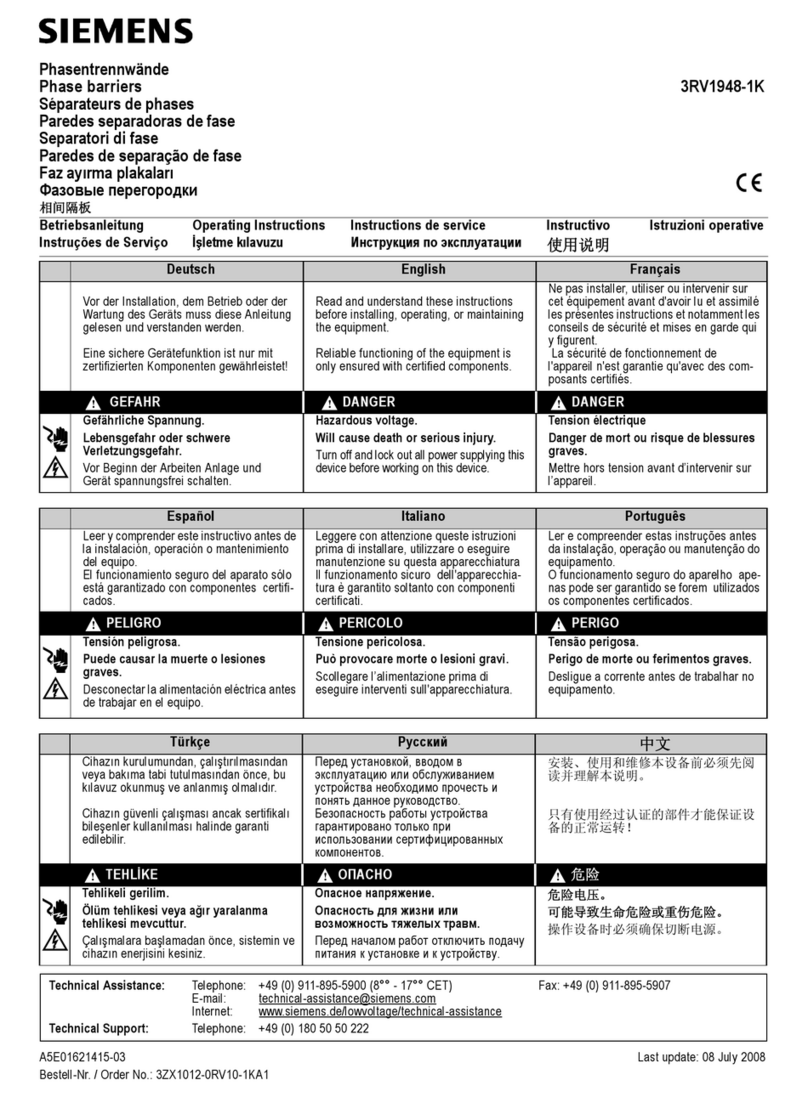

Siemens

Siemens 3RV1948-1K operating instructions

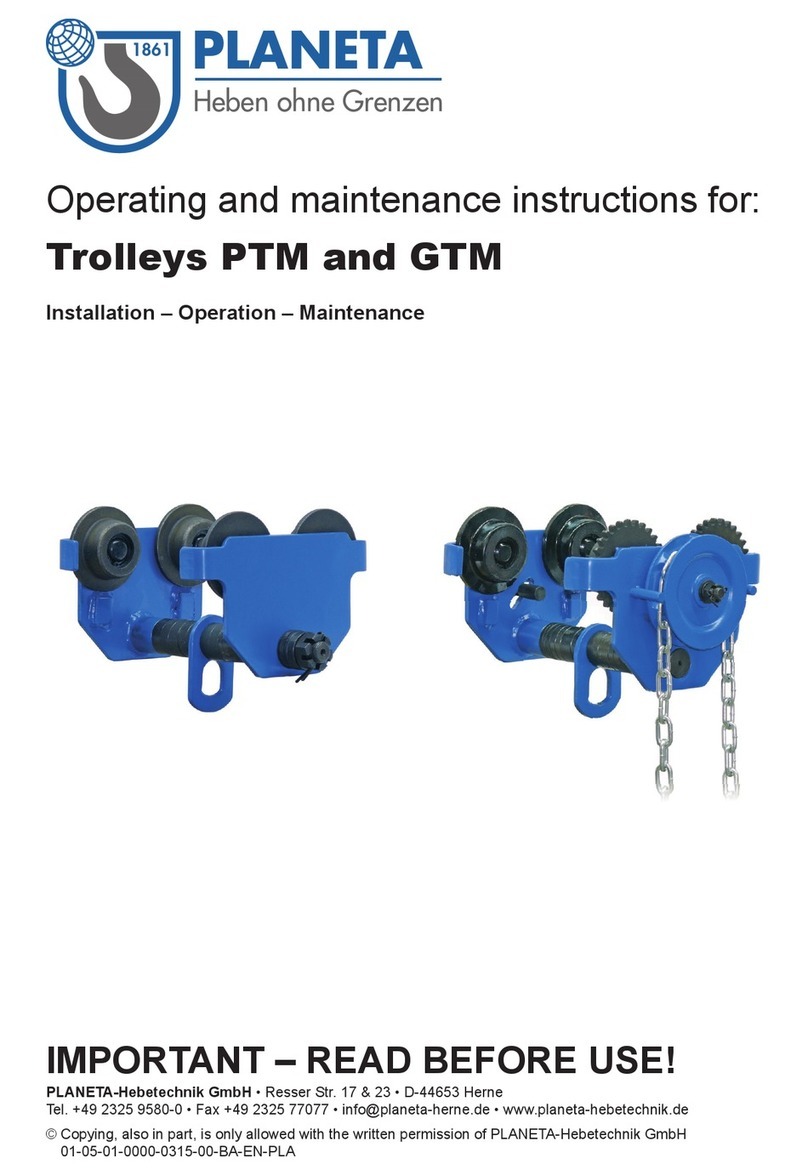

Planeta

Planeta PTM Operating and maintenance instructions

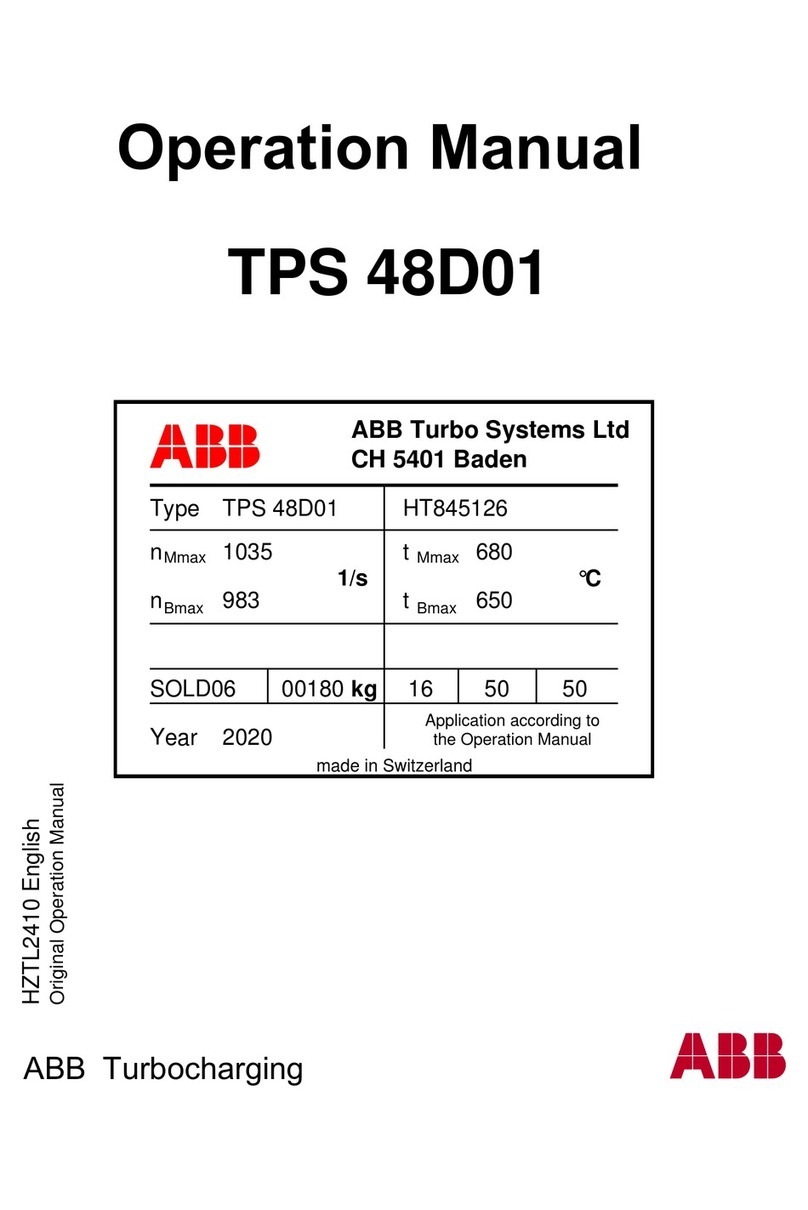

ABB

ABB HT845126 Operation manual