Denray 3444B Super User manual

OPERATING INSTRUCTIONS

Mini Booth

WARRANTY

This Machine is covered with a 12 month warranty. The warranty covers replacement parts, except filters

and wooden top (if applicable). The only way Denray will cover the labor is the work must be done by

Denray at Denray's Facility. The shipping must be provided by the customer (owner of the machine) both

ways. You may contact the dealer you purchased the machine from, and discuss with them, the

possibility of their assistance in helping to solve the problem in your facility. Denray assumes or accepts

no responsibility more than the cost of the machine. In the case of repair Denray will determine either to

fix or replace the product. Denray reserves the right to modify or change the design of this and any model

of their machines, without changing or updating any previous manufactured machine.

The warranty will not cover any damage done by fire or any other act of nature or if abuse or improper

maintenance was or was not performed.

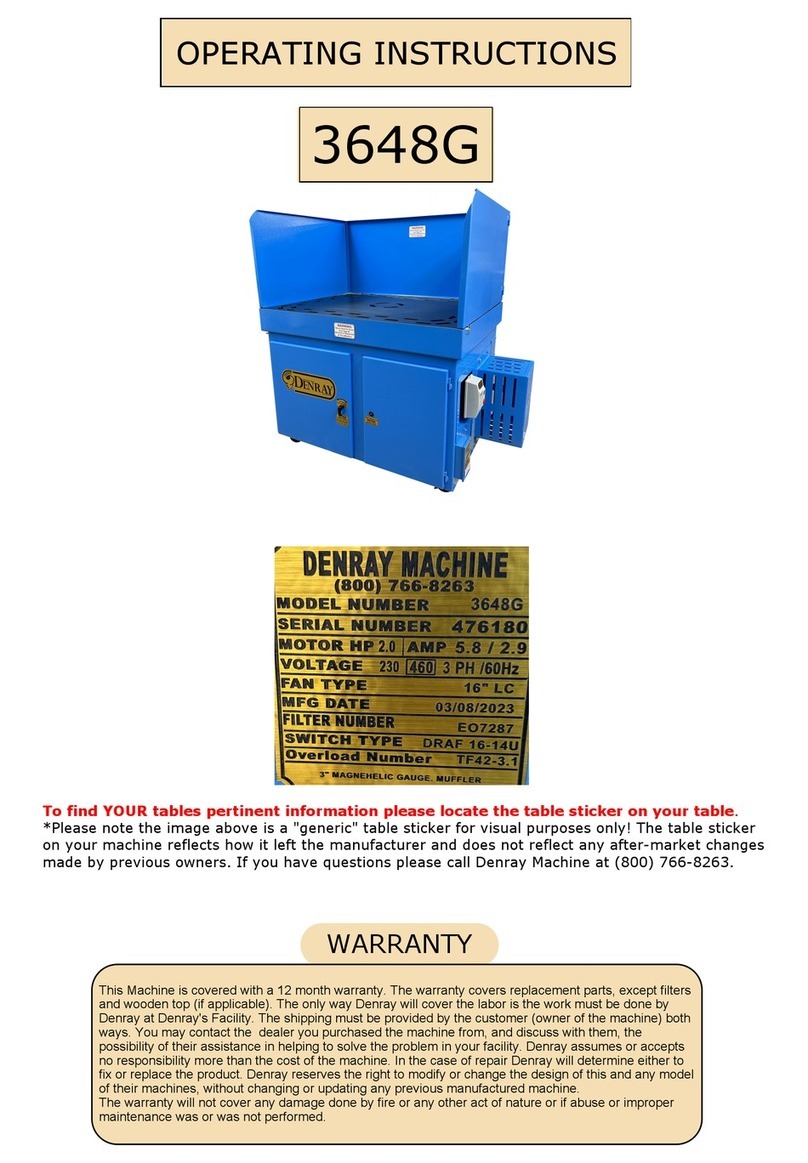

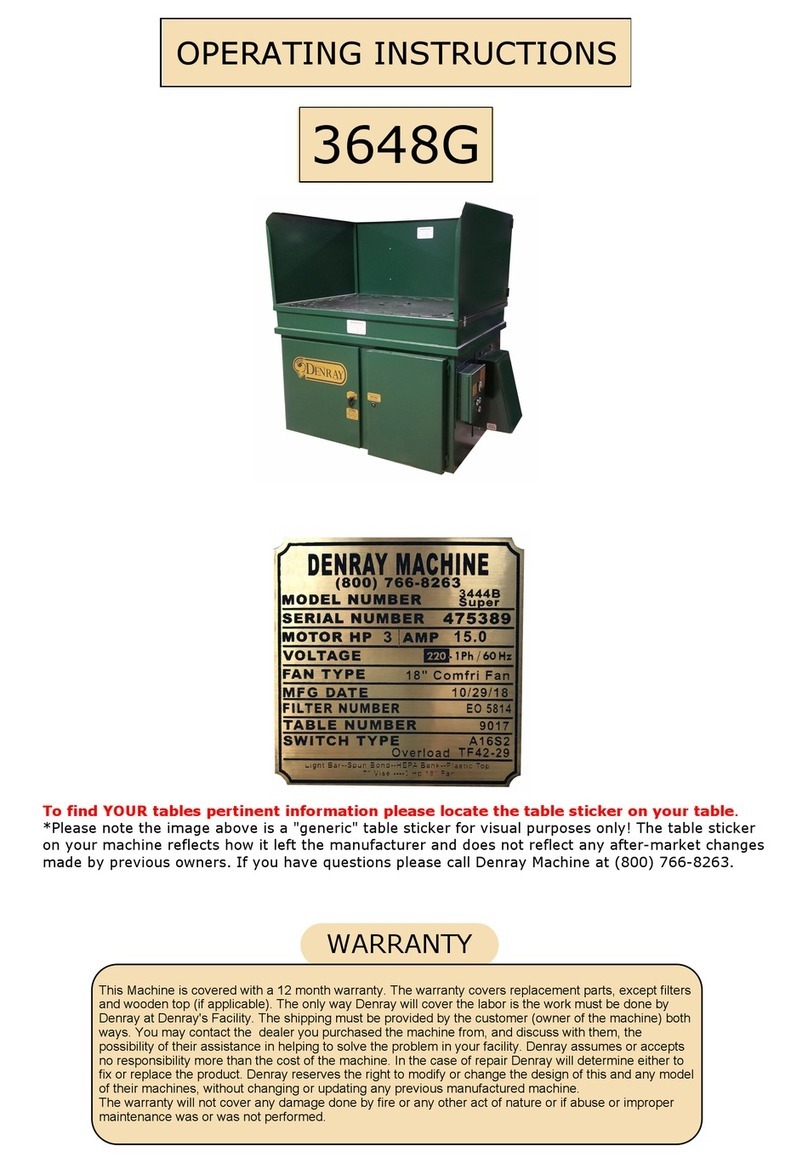

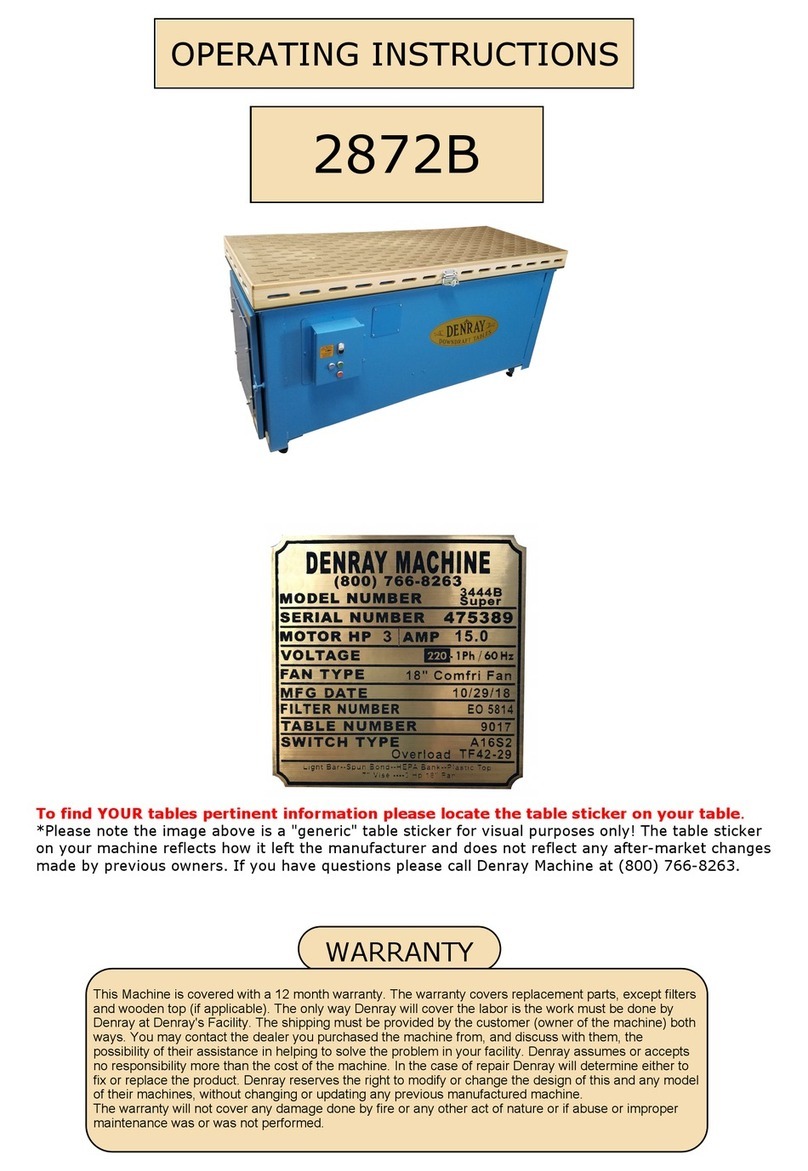

To find YOUR tables pertinent information please locate the table sticker on your table.

**Please note the image above is a "generic" table sticker for visual purposes only! The table sticker

on your machine reflects how it left the manufacturer and does not reflect any after-market changes

made by previous owners. If you have questions please call Denray Machine at (800) 766-8263.

Never Allow Any Unauthorized or Untrained Person To Operate This

Machine

Lockout and tagout any time maintenance is performed on this

machine

WARNING

NEVER GRIND OR SAND ANY ALUMINUM OR MAGNESIUM, OR ANY

SPARK CREATING PRODUCT ON THIS MACHINE

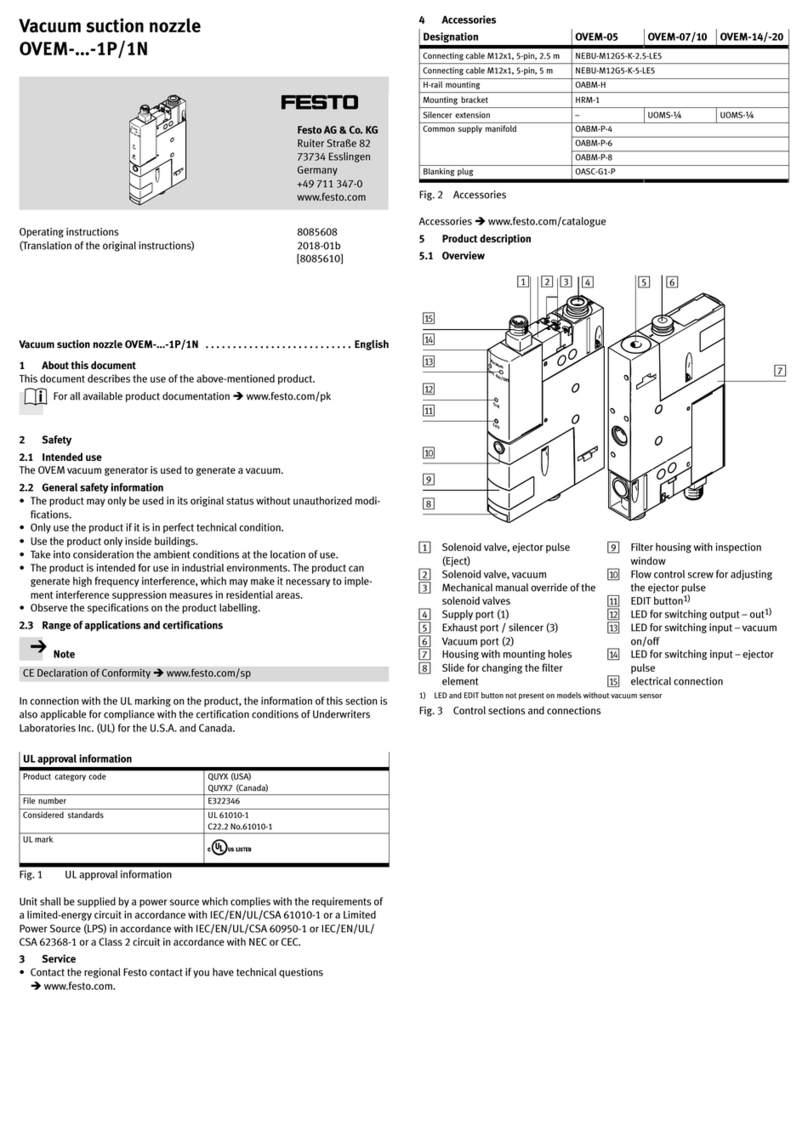

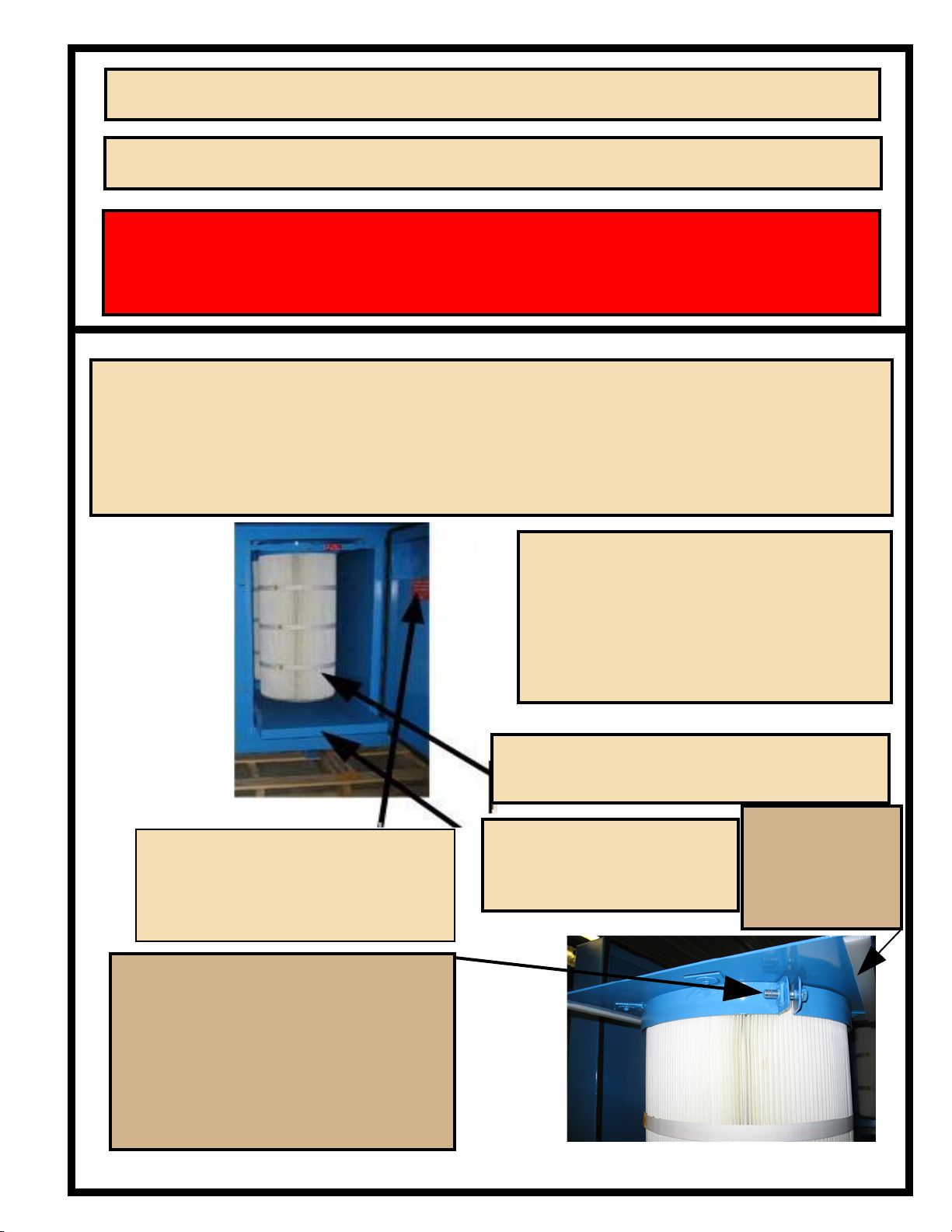

Filters are the main need of maintenance, the cleaner the filters are kept the better the machine will

perform. This machine is equipped with timers to clean the filters, every so many minutes a pulse of

air will be released into one of the filters, and a few minutes later the other filter will be pulsed, the

time is needed to refill the tank. The time between pulses are adjustable, refer to the electrical

diagram. Warning if the time is reduced between pulses the filter may plug up reducing the

machines performance. The filters can also be pulsed with the machine off, it may blow dust back

into the work area, so caution should be used here, pulse the machine then turn machine on to pull

dust back into the filters.

The filters will clean better with machine off,

you may shut machine off and before it slows

down to a complete stop, pulse the filter and

allow the fan to prevent the dust from exiting

the filter compartment.

Filter replacement number is on the inside of

the filter door.Be sure to replace with same

type of filter or a filter made of polyester

media.

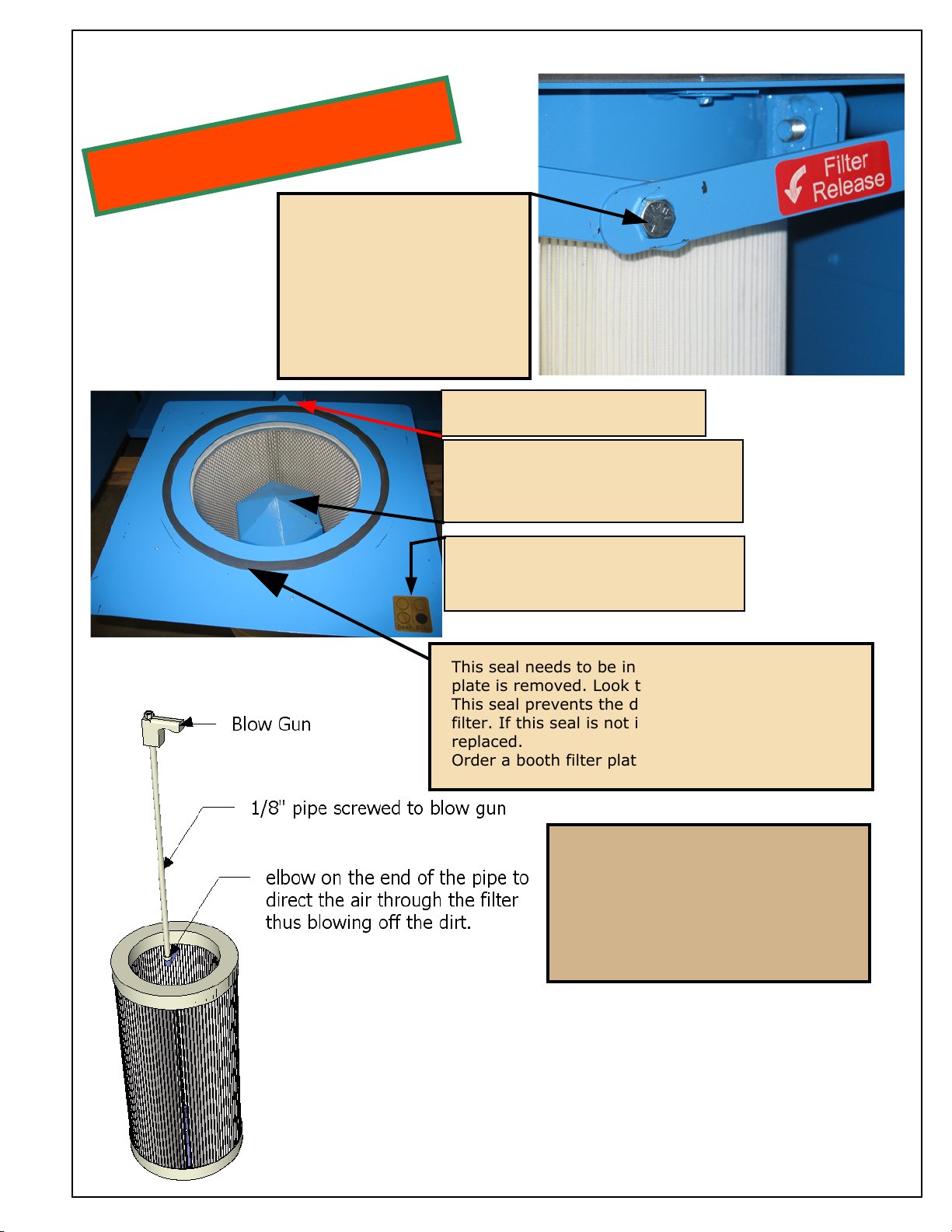

Bolt that holds the band that

secures the filter to the steel plate

that slides in the filter unit.

This makes removing filters from

the plate very easy, Allowing filter

deep cleaning a much easier task,

thus allowing the filters

to be cleaned better and easier.

Filter replacement number

Is on inside of this door.

MUST replace with the

prop

er fire retardant filter

Cartridge Filters 99.95% efficeincy

down to .5 micron

Dust Drawer Clean

regularly, as needed

UMHW Plastic

strips for ease

of sliding the

filters. Must be

in place

This Vee will align into the filter

placed in first

Never Open Any Door

While Machine Is Running

This bolt holds the

levers that raise and lowers

the filters. Once the machine

is in place, remove the nut

from this bolt, once the

bolt is in the hole pull down

on the levers to lock the

bolt in place.

looks like the picture

The cone on the inside of the filters

enhances the cleaning process. It is

bolted into the bottom of the filter.

This shows the location of the four

filters, the black circle shows this

filter is the front right filter.

This seal needs to be inspected everytime the steel

plate is removed. Look to see if any missing rubber,

This seal prevents the dust from by passing the

filter. If this seal is not intact it needs to be

replaced.

Order a booth filter plate seal

Harbor Freight Catalog outlet

sells a blow gun with a long

stem that will reach into all

the filters.

Filter Cleaning is almost the only thing

that has to be done to maintain these

machines. No lubrication to maintain

The cleaner the filters are kept the

better the machine will perform.

The dirtier the filters the harder it is

to pull air through them.

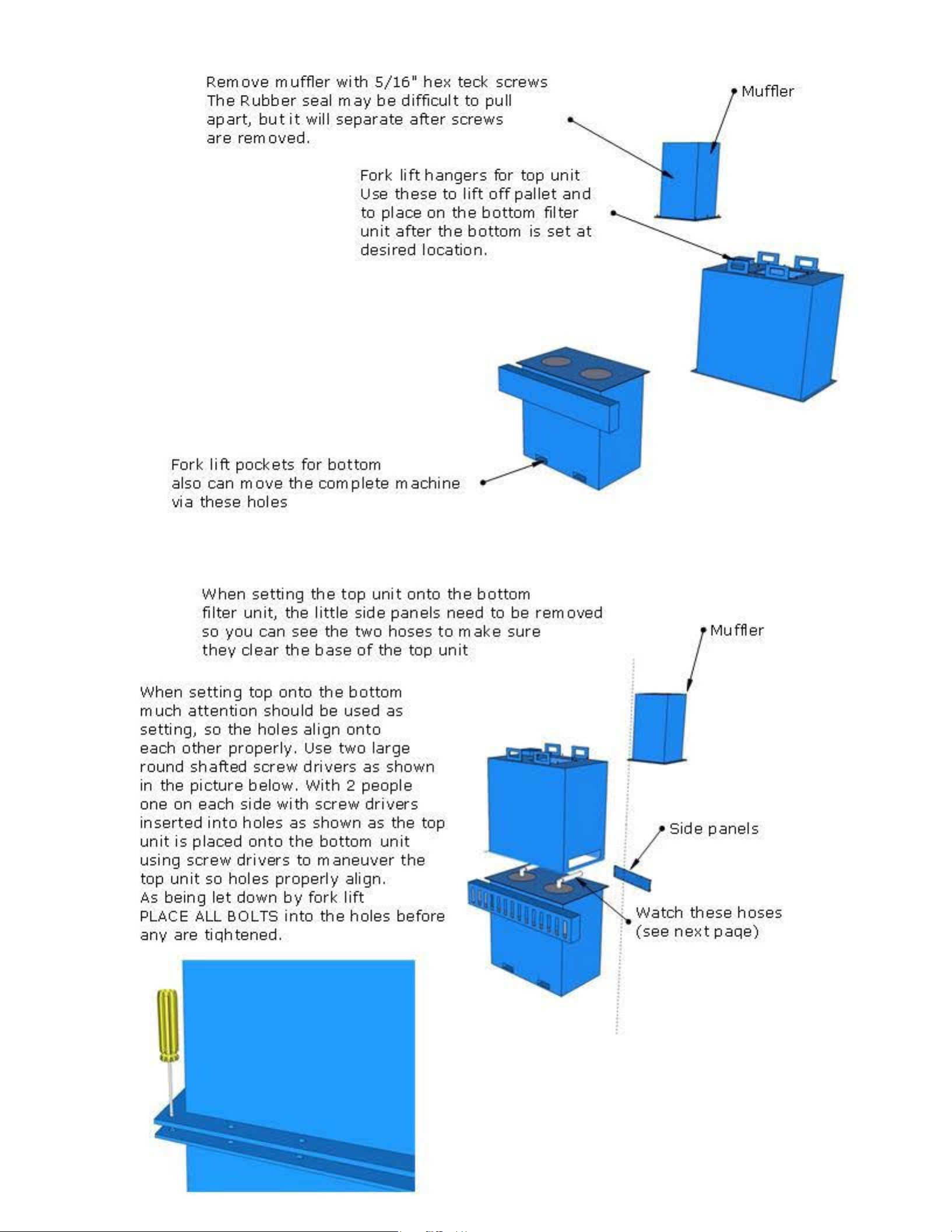

Rem

ave

muffler

with

5/16"

hex

teck screws

The

Rubber

seal

may

be

difficult

to

pu

II

apart,

but

it

wilI separate

after

screws

are

removed.

Fork

Ii

ft

hangers

for top

unit

Use

these

to

I

ift

off

pal

let

and

to

place on

the

bottom

filter

unit

after

the

bottom

is

set

at

desired Iocation.

Fork

lift

pockets

for

bottom

also can m

ave

the

complete

machine

vi

a these holes

When

setting

the

top

unit

onto

the

bottom

filter

unit,

the I

ittle

side panels need to be

removed

so you can see the

two

hoses

to

make

sure

they

cl

ear

the base

of

the top

unit

When

setting

top onto the

bottom

much

attention

shou

Id

be used as

setting, so the holes align

onto

each

other

properly.

Use

two

large

round shafted

screw

drivers

as shown

in the

picture

below. With 2 people

one on each side

with

screw

drivers

inserted

into

holes as shown as the top

unit

is

placed

onto

the

bottom

unit

using

screw

drivers

to

maneuver

the

top

unit

so holes

properly

align.

As

being

let

down

by

fork

I

ift

PLACE

ALL

BOLTS

into

the

holes before

any

are

ti

qhtened.

/

Muffler

kSide panels

Watch

these

hoses

(see

next

paqe)

The

two

sides

are

to

be

mounted

to

the

unit

Muffler

to

be

mounted

and

screwed

on

Now

the top

bracket

paqe

3

On each end

/side

there

is a

sm

alI panel

held on

with

the

5/16"

hex

headed screws

that

opens

to

the

hoses th

at

leads

to

the

air tank, remave the panel and you

wi

II

see

the

hose

that

fits on the hosebib.

placing

the

hose

over

the bib and tightening

the

hose clamp

to

secure the hose, so

the

filters

can be pulsed cleaned.

hose

not

on

Hose placed

over

the bib

and

the clamp

in

place.

Top is

in

location

now

the

sides

are

ready

to

Iocate and place

left

side

.

.

.

.

iri

to

position

'

'

.

Riqht

side

Weld on

hinge

is

what

secures

the

sides,

just

slide

the pin in

to

the hole. Lubrication

Ii

ke

WD

40

wilI help

all

ow

the

side

to

slide

into

hole

better.

left

side

Top coming in

next

after

sides are

into

place.

Riqht side

.

'

.

'

'

•

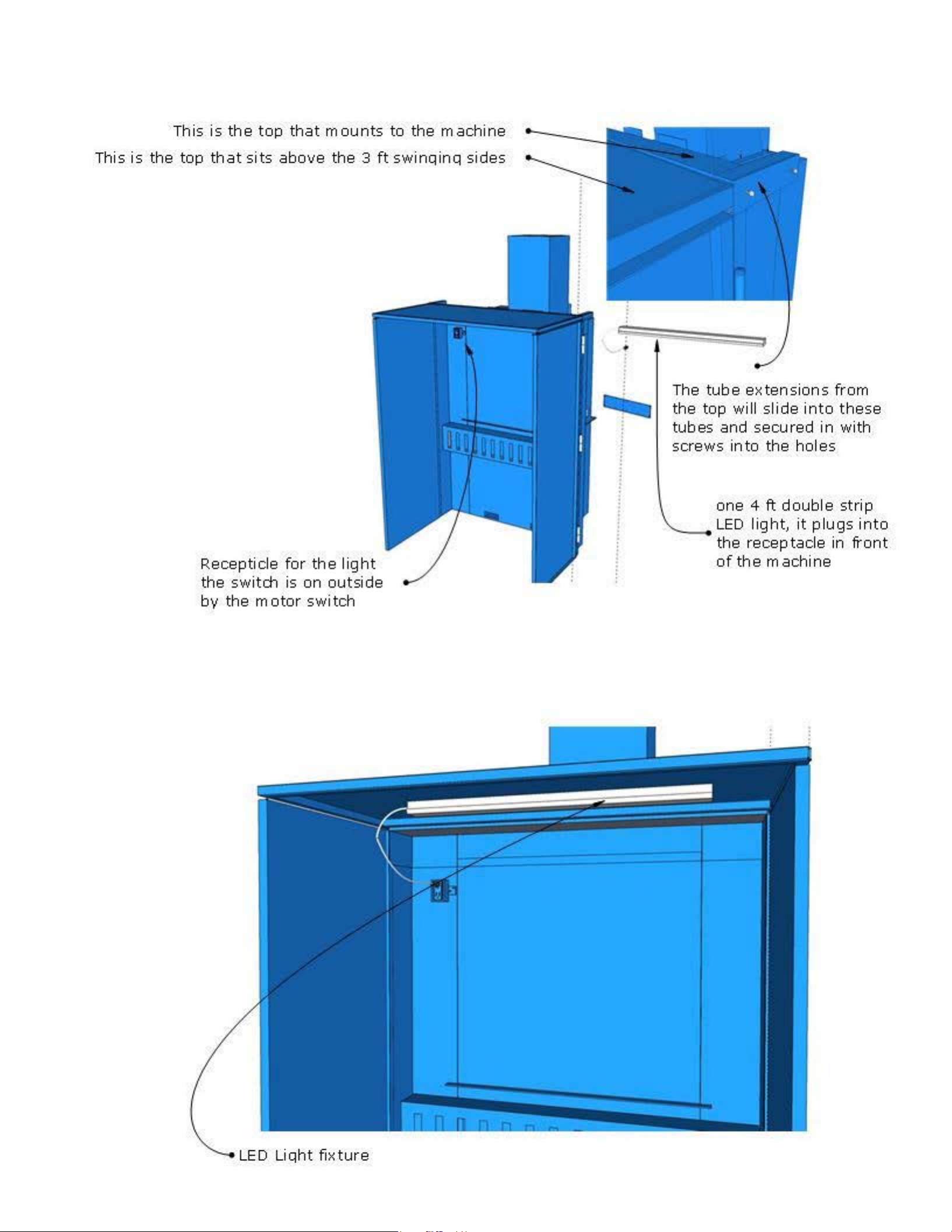

Th

is

is

the top

that

mounts

to

the

machine

This

is

the top

th

at

sits above the 3

ft

swinqinq sides

Recepticle

for

the Iig

ht

the switch is on outside

by

the

motor

switch

LED

Li

qht

fixture

'

,::::

•

'

'

=

The

tube

extensions

from

the top wi

II

slide

into

these

tub

es

and secured

in

with

screws in

to

the holes

one 4 ft

double

strip

...__

LED

Iig

ht,

it

plugs

into

the receptacle in

rront

of

them

achine

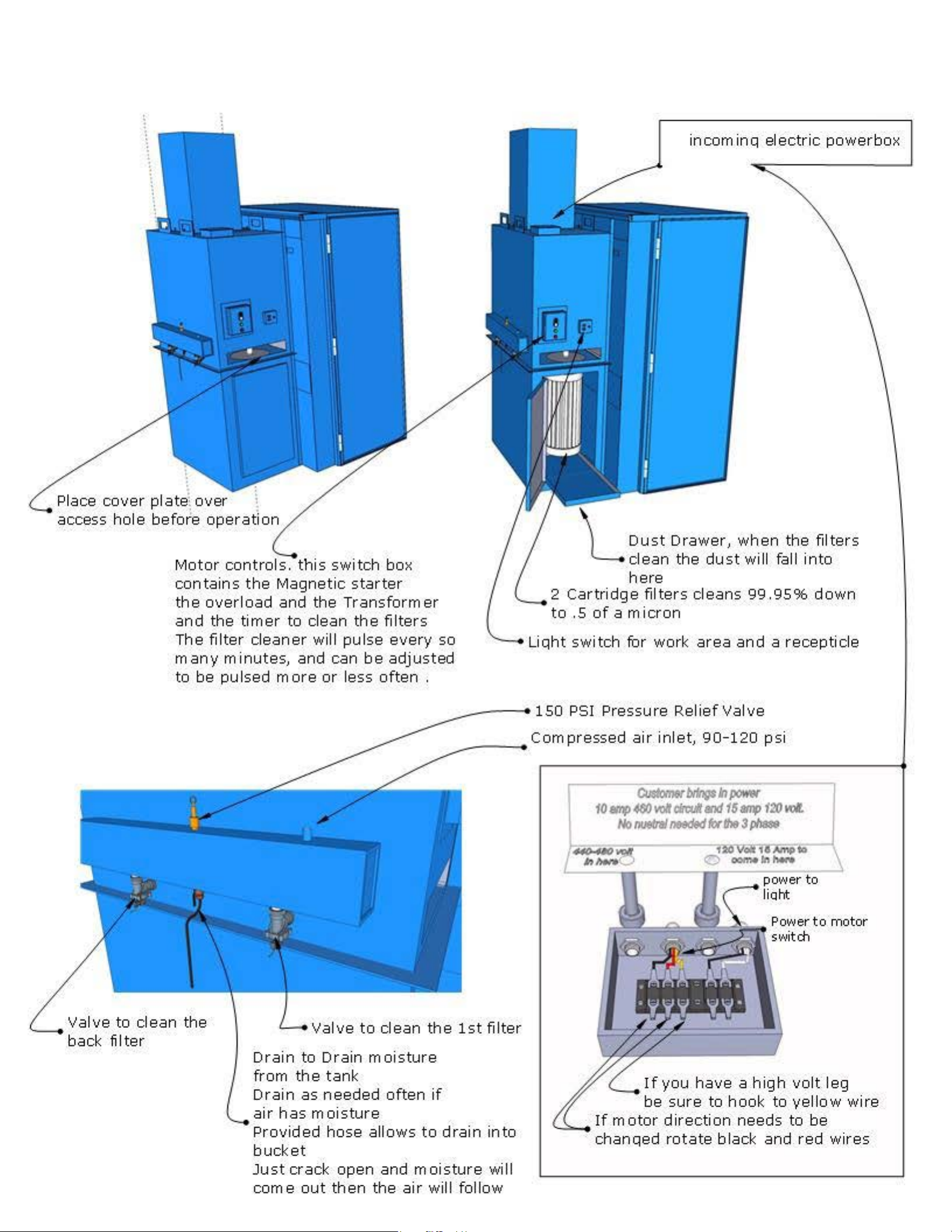

Place

cover

pl

ate

\

over

.

access

hole

befo

re

operation

incom inq electric

powerbox

\

Dust

Drawer,

when

the

filters

L clean the du

st

wi

II

falI

into

here

Motor

controls.

this

switch

box

contains

the

Magnetic

starter

the

overload

and the Transform

er

and

the

timer

to

clean

the

filters

The

filter

clean

er

wilI pulse

every

so

many

minutes,

and can

be

adjusted

to

be pulsed

more

or

less

often

.

.___2

Cartridge

filters

cleans

99.

95%

down

to

.5

of

am

icron

Valve

to

clean the

- - back

fi

I

ter

----

Li

qht

switch

for work

area

and

a recepticle

.----

---150

PSI Pressure

Relief

Valve

com

pressed

air

inlet,

9

0-120

psi

------

-

Valve

to

clean

the

1st

filter

Drain

to

Drain

moisture

from the

tank

Drain

as

needed

often

if

air

has

moisture

Provided hose allows

to

drain

in

to

bucket

Ju

st

erack open and

moisture

wi

11

come

out

th

en the

air

wilI follow

Cudomarblfngan

powi;r

10

_,.,

WI

Vil/I

c/mil

and

16

IJITfJ

12/J

Vil/I.

Ho-...,Jedfortho3pt,-

12i0Voi11M,jto

<D

oom,ef,\

,-.

power

to

,,-

-lioht

If

you

have

a

high

volt

leg

be sure

to

hoak

to

yellow

wire

If

motor

direction

needs

to

be

,___,

_ chanqed

rotate

black and

red

wires

Si

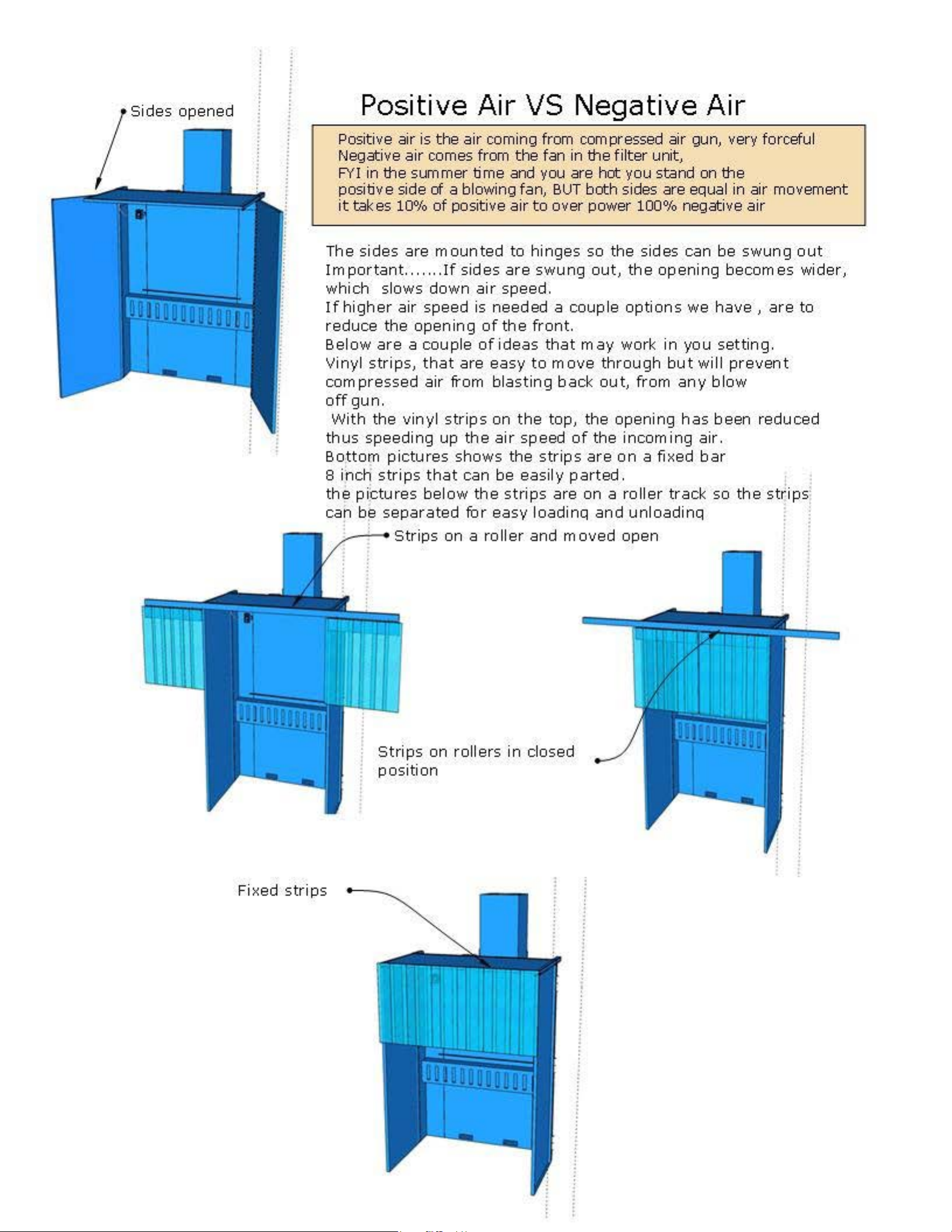

des opened Positive Air VS Negative Air

Positive air is the air coming

from

compressed air gun, very forceful

Negative air

comes

from the fan in thefilter unit,

FYI

in the summer time

and

you

are hot you stand

on

the

positive side of a blowingfan,

BUT

both sides are equal in air movement

it takes 10%

of

positive air

to

over power 100% negative air

The sides are

mounted

to

hinges so the sides can be swung

out

Important.

......

If

sides

are

swung

out,

the

opening becomes wider,

which slows down

air

speed.

If

high

er

air speed is needed a couple

options

we have ,

are

to

reduce the opening

of

the

front.

Bel

ow

are

a coupie

of

ideas

that

may

work

in

you setting.

Vinyl strips,

that

are easy

tom

ave through

but

will

prevent

com pressed air rrom blasting back

out,

from

any

blow

off

gun.

With the vinyl

strips

on the top, the opening

has

been reduced

th

us speeding up

the

air

speed

of

the incoming air.

Bo.

ttom

pictures shows the

strips

are

on

a fixed

bar

B ihc

ti

strips

that

can be easily

parted.

:

th

e

pi

'ctures below

the

strips

are on a

roller

track so

the

st

~ips:

can b~ separated

for

easy Ioadinq

and

unloadinq ,

· ' Strips on a ro

II

er

and

moved

open '

Fixed

strips

Strips on rollers

in

closed

position

,0q{Alrolcid*',dlS@rfrril-

,&ffitffituilDgPrE

Fco-nlrruceowe!

Fu$'l&2$oteds

th€ tBsftrffi and

tu* 3 prdeds the

Overload dial sd

just above motor

And Two \falves

Boxon top

of machine

120 Volt in here

44G4B0Volt 3PH in here

'l'ie red into orle valve

Tie Uue into other vah,e

rnake sure the wire frorn

tlle tirnerand the rnanual

$r/itch are both positive

Valve 1

On two valves bring

nuetral from one to the other

--oY*:

Light Switch

Valve 2

Generalsettings

\ bod taBs 24 minutes

Grind taHes 18 minutes

\ Hd srnoketab[es 12 minutes

s=sorin-----\ u$o-;ffi*n setHerefor6$omin.

6=36min -\ r-ro.iKa-3r-ron

Ii3ffi gg-*"*-*ffi;=

9-54min 7-.q- \s_^

1o+omin \ffi_--i "

TROUBLE SHOOTING

Motor not running Look to see if L1- L2 -L3

wires are in and secured

and proper voltage is there

Check if wires at bottom of

mag starter to the motor are

in bottom and secured.

The above checks OK In center of the contactor is a rectangle post that is

hooked to coil below. With screwdriver push in and see

if motor will run. If motor will run something is wrong

with the push buttons, That activates the starter.

Motor runs when center

post is held in, but not

by the switches

Make sure every wire is secured on starter if

still no results call Denray for further assistance

If center post is held in

and nothing happens

hook power leads to motor

leads at bottom of mag

starter if motor runs the

problem is the starter.

Call factory for switch replacement

If on switch closes mag

starter and motor does

not run.

FIRST take tester and check see if there is the

proper voltage at bottom of starter

If proper voltage is at

bottom of starter Check to see wiring at motor is properly

hooked together

All the below solutions are meant to be done

only by a qualified technician

Mag starter works

and motor only hums Check for proper voltage

check all wire connections to be tight

check wiring diagram and motor leads to be correct

Filter Cleaning valve will

not pulse Check the three 1 amp fuses on

top of the transformer in the

switch box.

Fuses OK Check wiring in front of and behind the fuses

Fuses and wiring checks

out OK With it being quiet activate the switch and listen

to hear a clicking sound from the valve or valves.

You hear it clicking Make sure air is hooked up to tank

Air is hooked up

and it still clicks Call Denray Replace valve

1

2

3

4

5

6

7

8

9

10

11

12

Motor runs for a

few minutes and

shuts off

Turn the amp dial on overload to increase the

number. Increase only 1 amp at a time

Never increase more than 2 amps above motor

full load amps

13

TROUBLE SHOOTING

Loss of suction on top

of table Dirty filters :: Refer to above

All the below solutions are meant to be done

only by a qualified technician

Excessive exhaust air

on the floor

Rotate filters two times a week 1/4 turn

Timer not working

Machines with timers Check fuses:: Check wiring between mag starter

and timer. Any loose connection,

secure the connection

Filters need to be

cleaned more often Turn dial on timer to a lesser number set at

factory at approx. every 20 minutes.

Lots of dirt remaining on

filters after being cleaned Decrease time between cleanings. Check air

pressure going into machine.

Keep between 100-140 psi

Filter never completely

cleans all dirt off Not supposed to:: Machine designed to operate at

30% filter blockage. The cleaner a filter is the better

the machine will perform.

Any air that is sucked into the table top must come

out in exhaust somewhere. Look into adding Muffler

to machine

Dirt packed in top 1/3 of

filters

Inside of filters are

rusty colored Blowing water from air tank inside of filter. Drain

air tank more often ( daily if possible) Installation

of a dryer or water trap may be necessary

Filters will not come

clean Pull filters out of machine and take blow gun and

from inside blowing out give filters a deep cleaning

How often do I need

to do the above Some companies do it daily and some weekly

and some monthly. You must determine that

for yourself

Moisture blowed in filters

will make filters harder

to clean

14

15

16

17

18

19

20

21

22

23

24

25

26

Refer to 22

Are filters washable? Spun-bond filters in the grind tables can be washed only

a couple times and must let thoroughly dry.

Filter cleaning service companies may be available in

your area.

Green light on timer

does not work See above

Bad timer needs replacement

All fans are factory balanced from fan company,

fans checked and rebalanced at table MFG, if

table has vibration, fan weights may need to be

moved to another blade.

TROUBLE SHOOTING

All the below solutions are meant to be done

only by a qualified technician

27

28

29

Fan making a loud roar Fan rotation backwards, on three phase,switch

wires on L1 and L2

Lack of proper suction Fan running backwards will produce 2/3rds less

suction check fan rotation

See Drawing Fan

Rotation

Machine vibration on

direct drive systems

Other manuals for 3444B Super

1

This manual suits for next models

1

Table of contents

Other Denray Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Noble House Home Furnishings

Noble House Home Furnishings Chair Assembly instructions

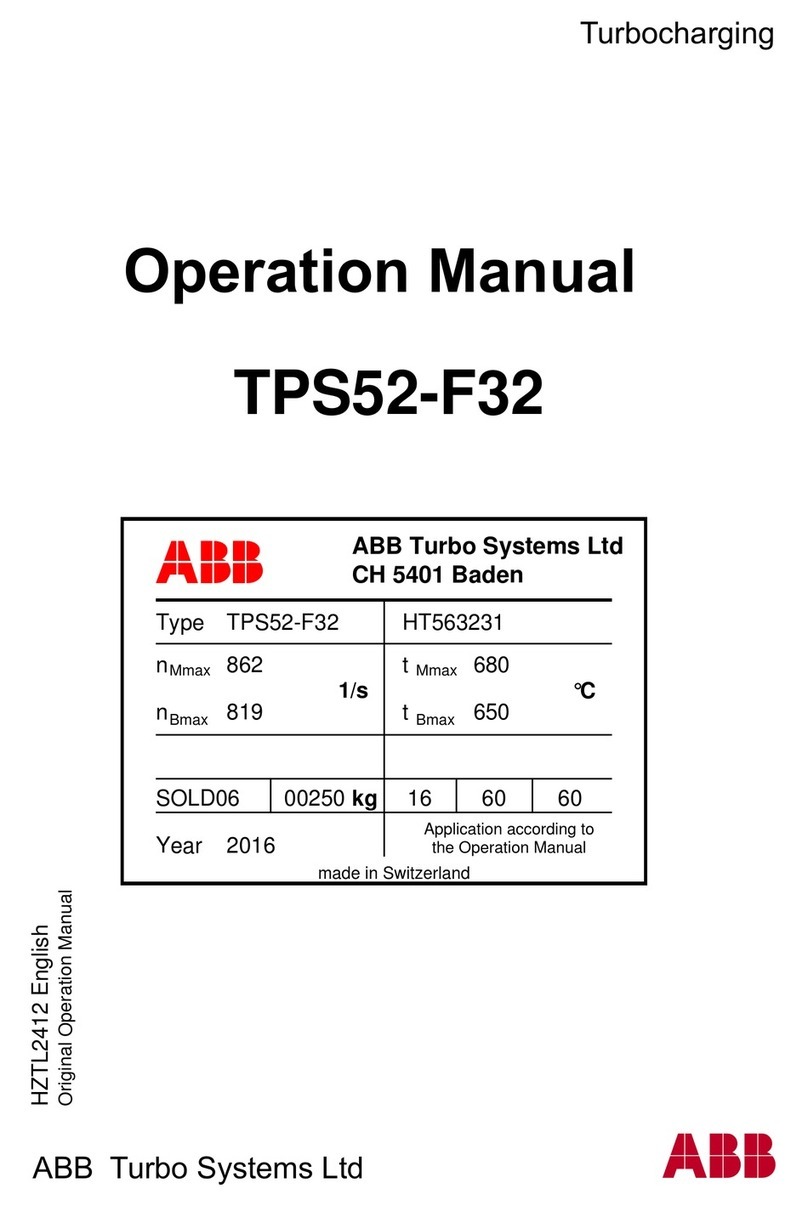

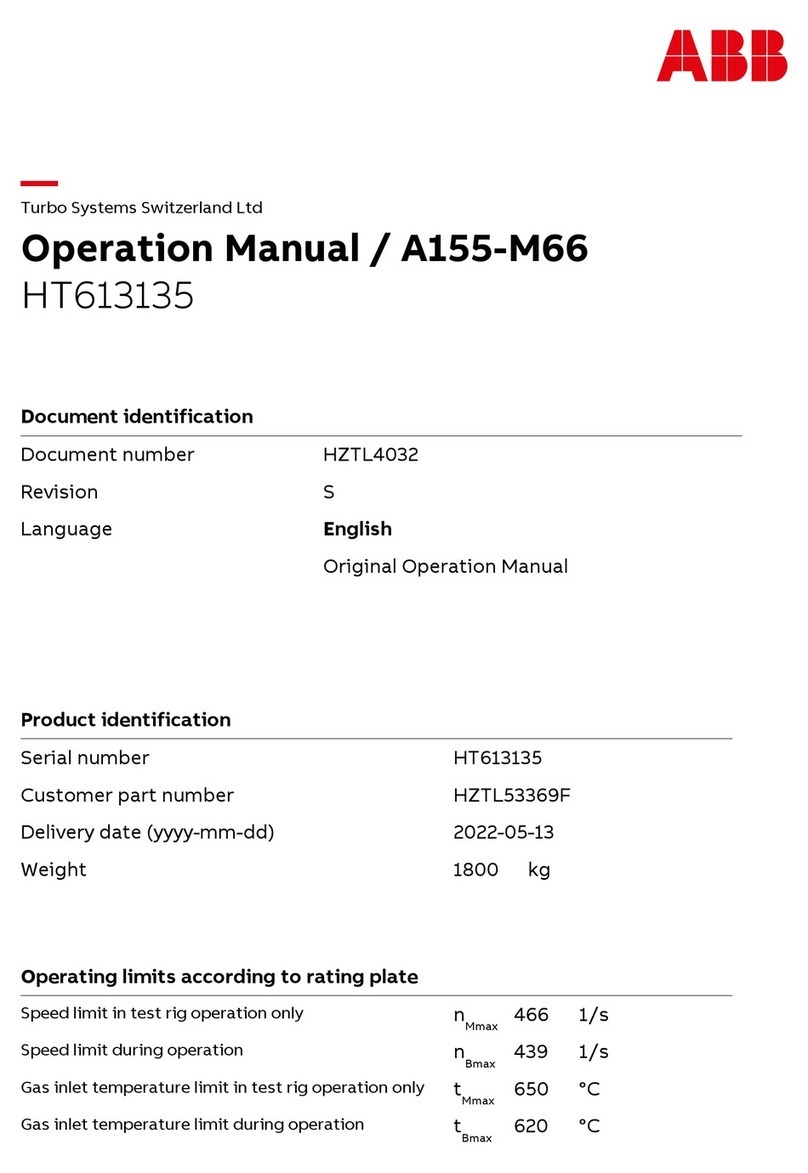

ABB

ABB HT613135 Operation manual

Venmar

Venmar K7 ERV User's and installer's manual

GRUNDFOS ALLDOS

GRUNDFOS ALLDOS Oxiperm C 164 Series Operation and service manual

ABB

ABB HT604072 Operation manual

Neopost

Neopost RENA XPS-ProMail 3.0 user guide