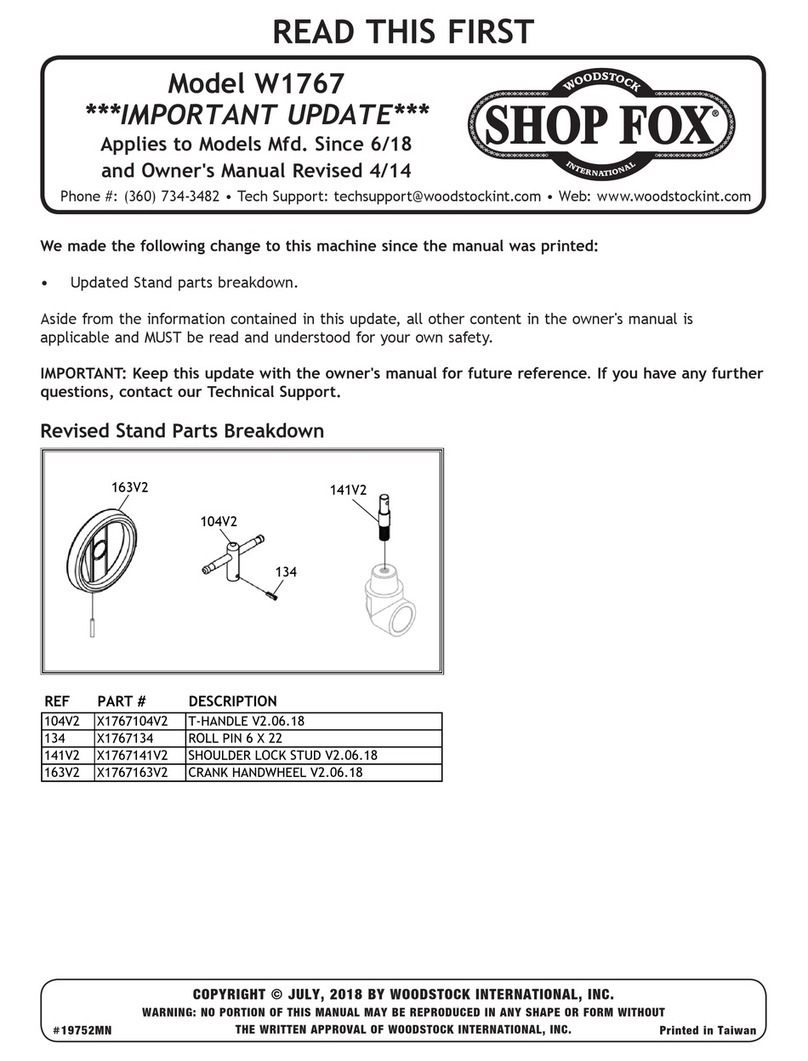

Denray 3648G User manual

OPERATING INSTRUCTIONS

3648G

WARRANTY

This Machine is covered with a 12 month warranty. The warranty covers replacement parts, except filters

and wooden top (if applicable). The only way Denray will cover the labor is the work must be done by

Denray at Denray's Facility. The shipping must be provided by the customer (owner of the machine) both

ways. You may contact the dealer you purchased the machine from, and discuss with them, the

possibility of their assistance in helping to solve the problem in your facility. Denray assumes or accepts

no responsibility more than the cost of the machine. In the case of repair Denray will determine either to

fix or replace the product. Denray reserves the right to modify or change the design of this and any model

of their machines, without changing or updating any previous manufactured machine.

The warranty will not cover any damage done by fire or any other act of nature or if abuse or improper

maintenance was or was not performed.

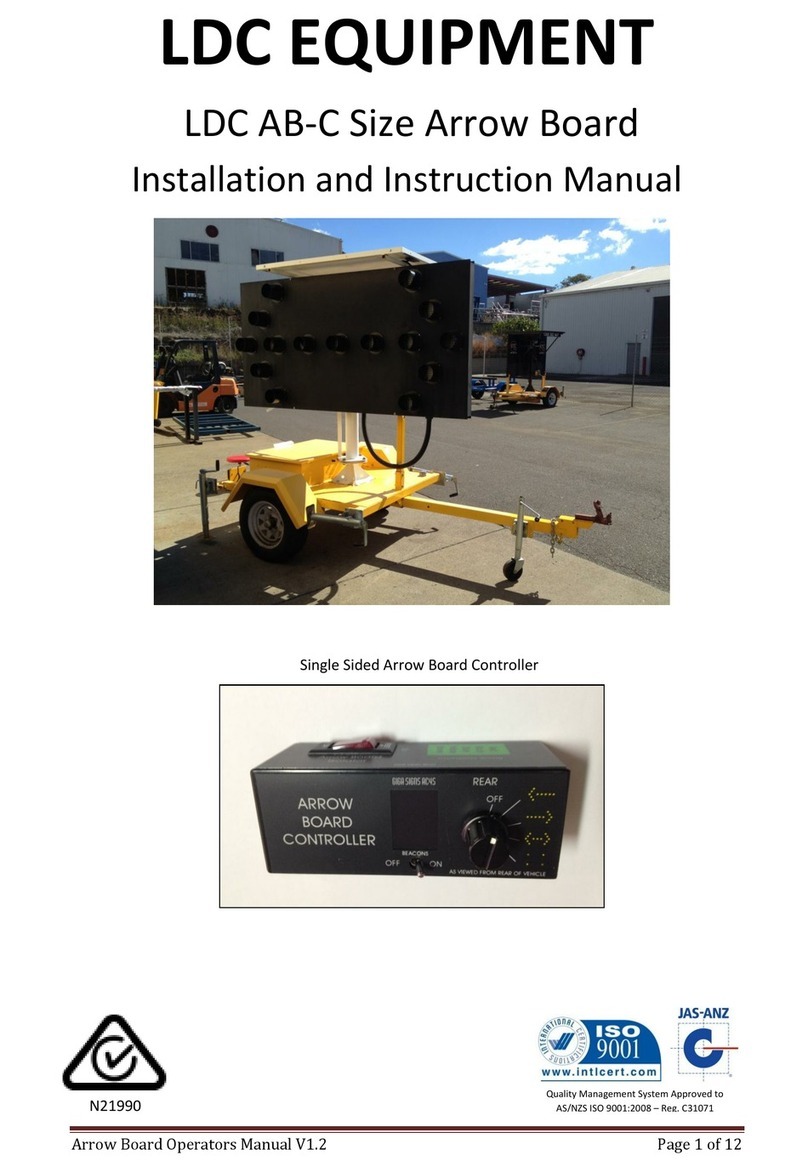

To find YOUR tables pertinent information please locate the table sticker on your table.

**Please note the image above is a "generic" table sticker for visual purposes only! The table sticker

on your machine reflects how it left the manufacturer and does not reflect any after-market changes

made by previous owners. If you have questions please call Denray Machine at (800) 766-8263.

Never Allow Any Unauthorized or Untrained Person To Operate

This Machine

Lockout and tagout any time maintenance is performed on this

machine

WARNING

NEVER GRIND OR SAND ANY ALUMINUM OR MAGNESIUM, OR ANY

SPARK CREATING PRODUCT ON THIS MACHINE

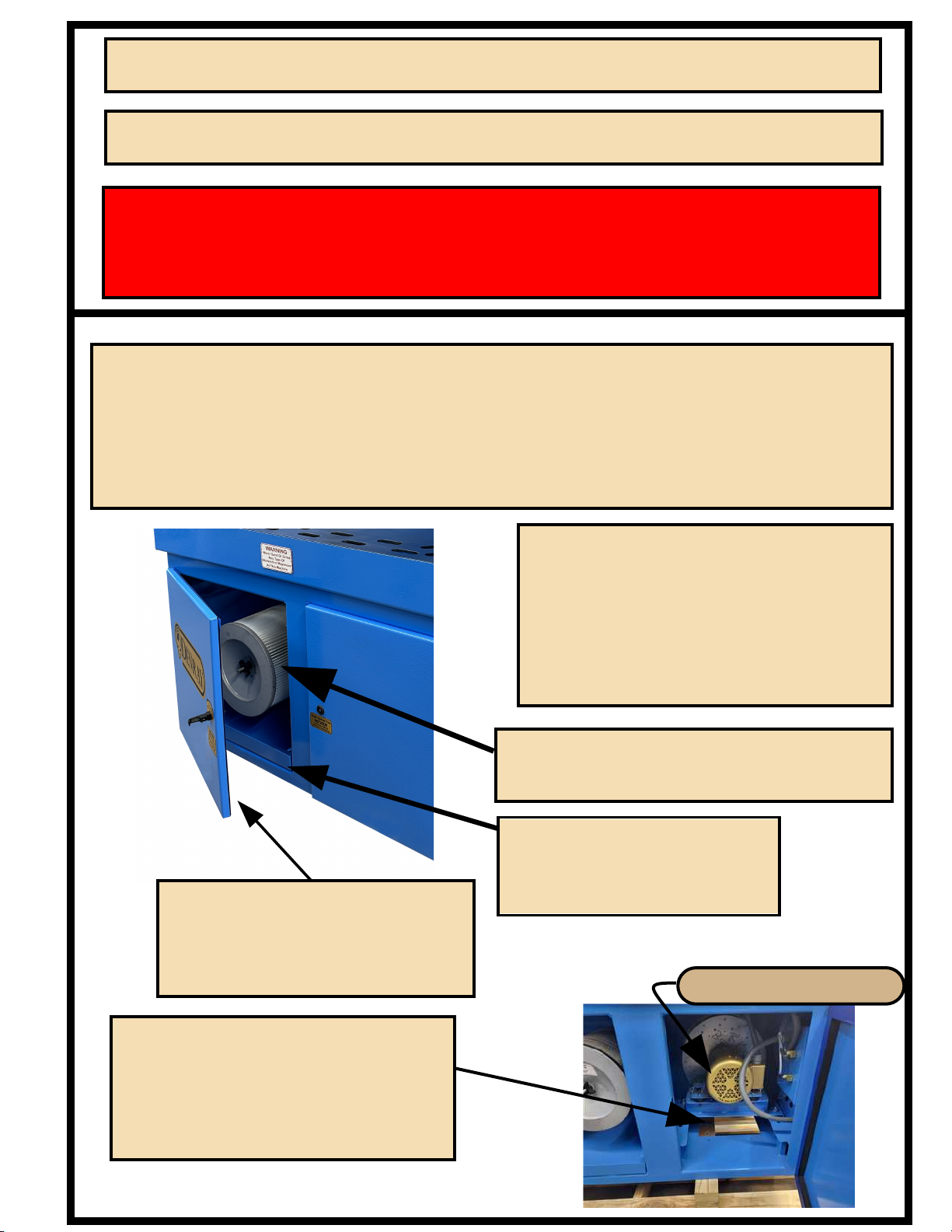

Filters are the main need of maintenance, the cleaner the filters are kept the better the machine will

perform. This machine is equipped with timers to clean the filters, every so many minutes a pulse of

air will be released into one of the filters, and a few minutes later the other filter will be pulsed, the

time is needed to refill the tank. The time between pulses are adjustable, refer to the electrical

diagram. Warning if the time is reduced between pulses the filter may plug up reducing the

machines performance. The filters can also be pulsed with the machine off, it may blow dust back

into the work area, so caution should be used here, pulse the machine then turn machine on to pull

dust back into the filters.

The filters will clean better with machine off,

you may shut machine off and before it slows

down to a complete stop, pulse the filter and

allow the fan to prevent the dust from exiting

the filter compartment.

Filter replacement number is on the inside of

the filter door.Be sure to replace with same

type of filter or a filter made of polyester

media.

Cartridge Filters 99.95% efficeincy

down to .5 micron

The exhaust air will exit through

opening to the floor, if muffler

is added the plate on the end will

be located here to force the air

through the muffler

Motor compartment

Dust Drawer Clean

regularly, as needed Filter replacement number

Is on inside of this door.

MUST replace with the

proper fire retardant filter

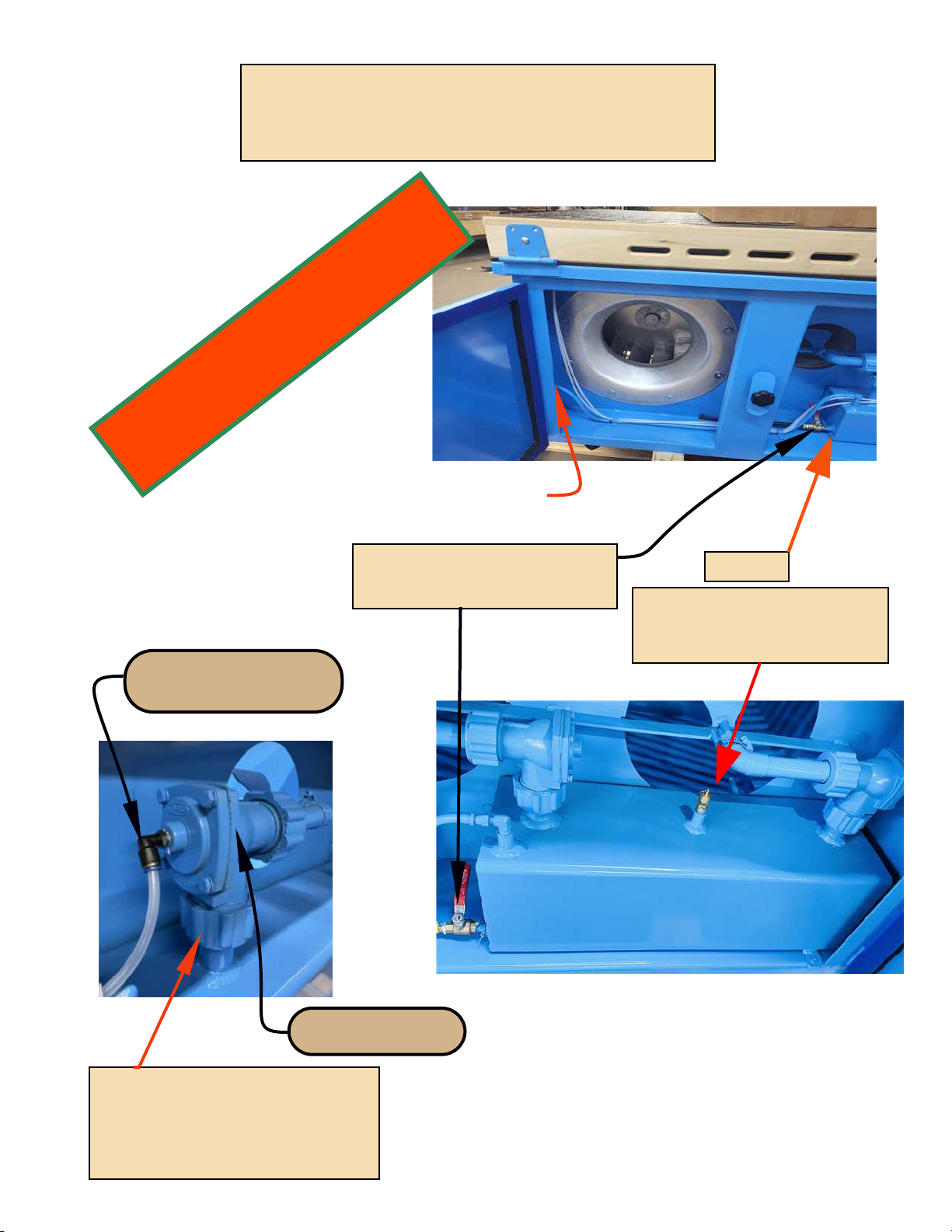

Air Tank View (Generic)

Incoming airline

90-120 psi

150 PSI Pressure relief valve, 1/4"

NPT Male, if you have air leaking

from the tank area, this is the

1st place to check.

Compression nut that holds valve

to the tank. Always apply a small

amount of either grease or oil to

the threads when reassemling to

the tank.

Never Open Any Door

While Machine Is Running

Label text

Air Tank

Drain Moisture from tank

daily, and provide clean dry

air from factory compressed air

Valve to release air into

the filters to clean them

Push on air line

if you hear a fog horn noise

check each fitting for leaks

Air Tank

to clean filters

Valves to clean Filters

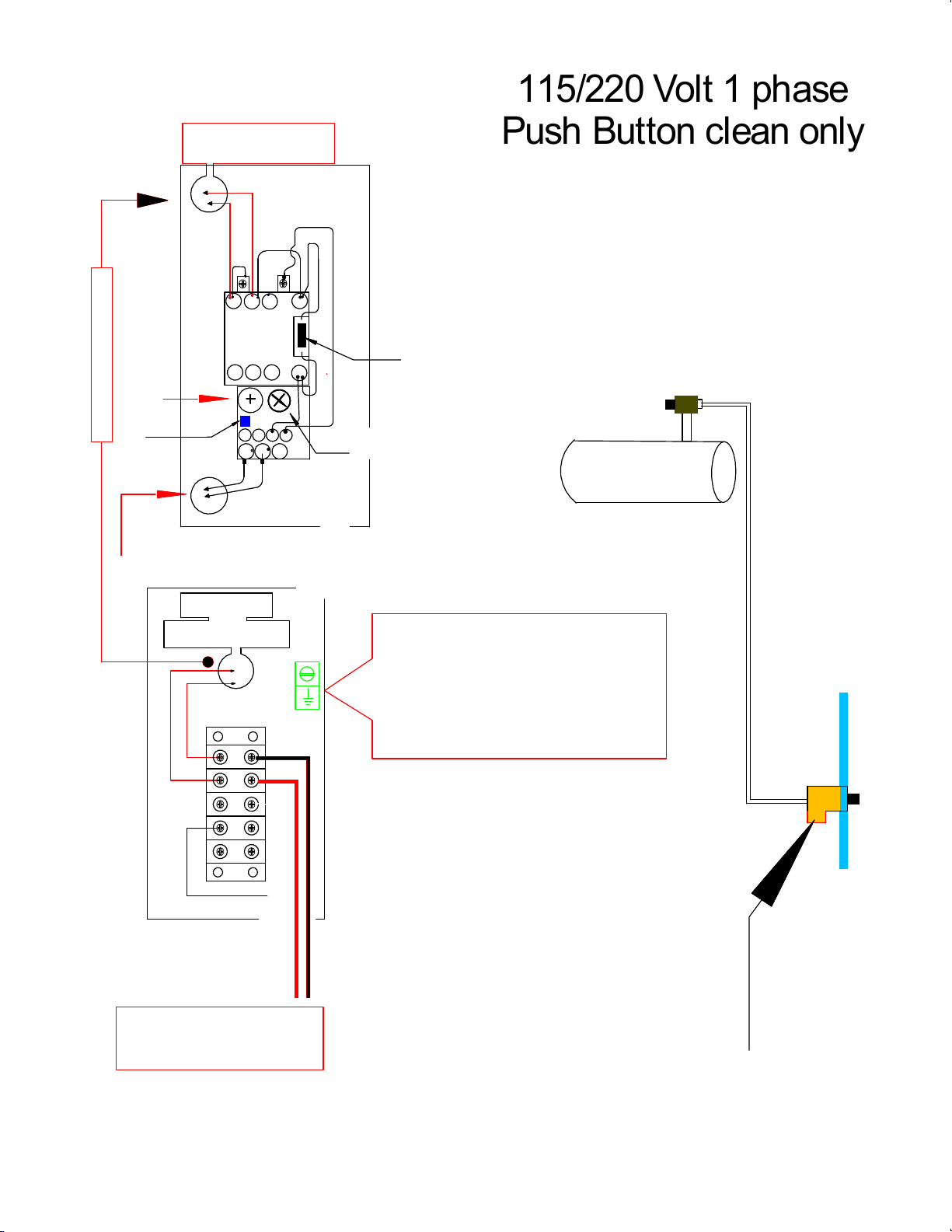

Out Going Power

incoming

power

115/220 1Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

24 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 59 6

Stop button

Start Button

To Magnetic Starter

Wires Through

Hole into next Box

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

115/220 Volt 1 phase

Push Button clean only

Push Button

To Clean filter/s

Box on outside

of machine for

easy wire hook up

Conduit with wire to this box

ELECTIC SOLENOID

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

23456789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valve to clean Filters

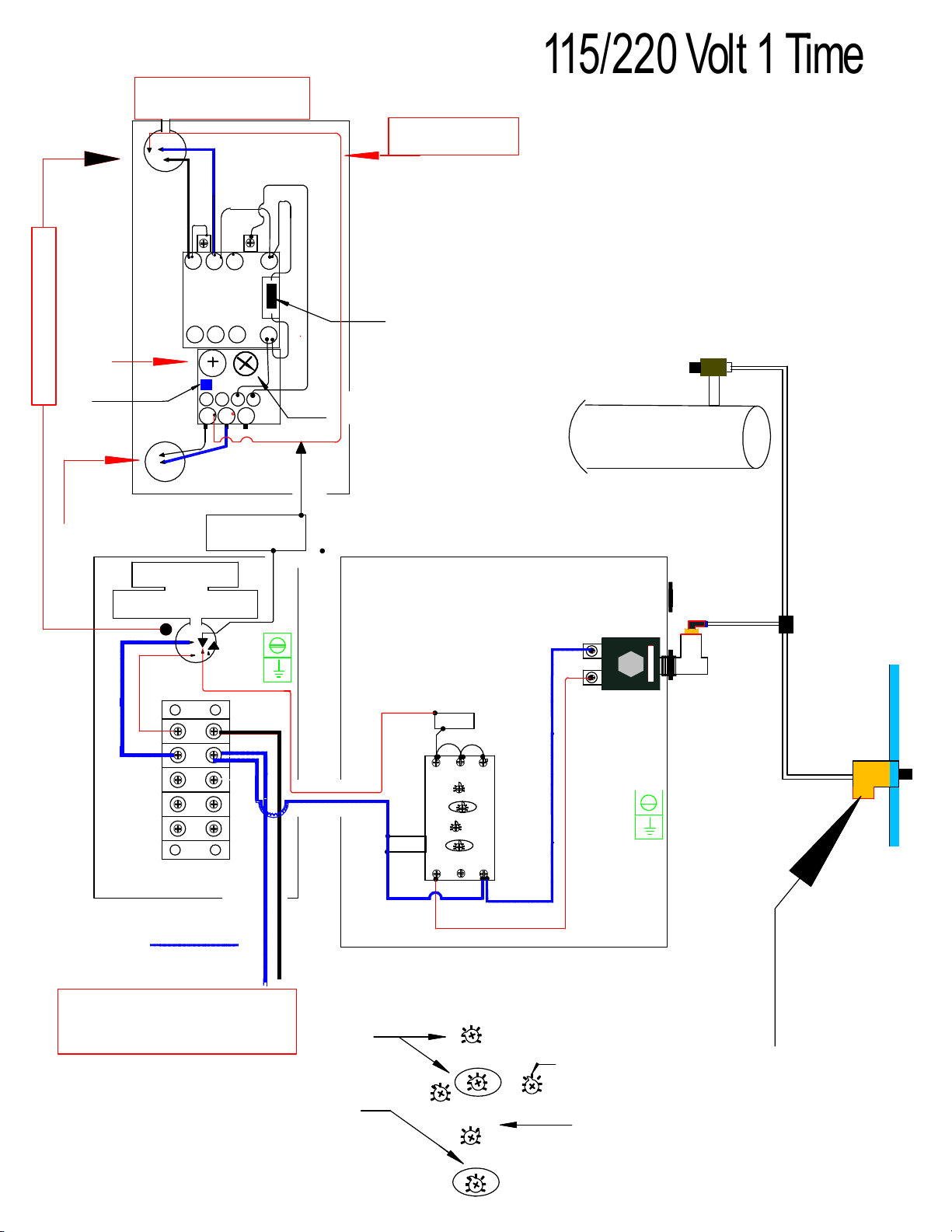

From T1

Out Going Power

incoming

power

115/220 Volt

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

M A N

AUT

2 4 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 59 6

Stop button

Start Button

power wire

to Transformer

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Push Button

To Clean filter/s

Power

115/220 Volt 1 Timer

So The timers only

work when machine is running

Power to timers come

from T1

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

A1 15 Y1

18 16 A2

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valves to clean Filters

ELECTIC SOLENOID

ELECTIC SOLENOID

From T1

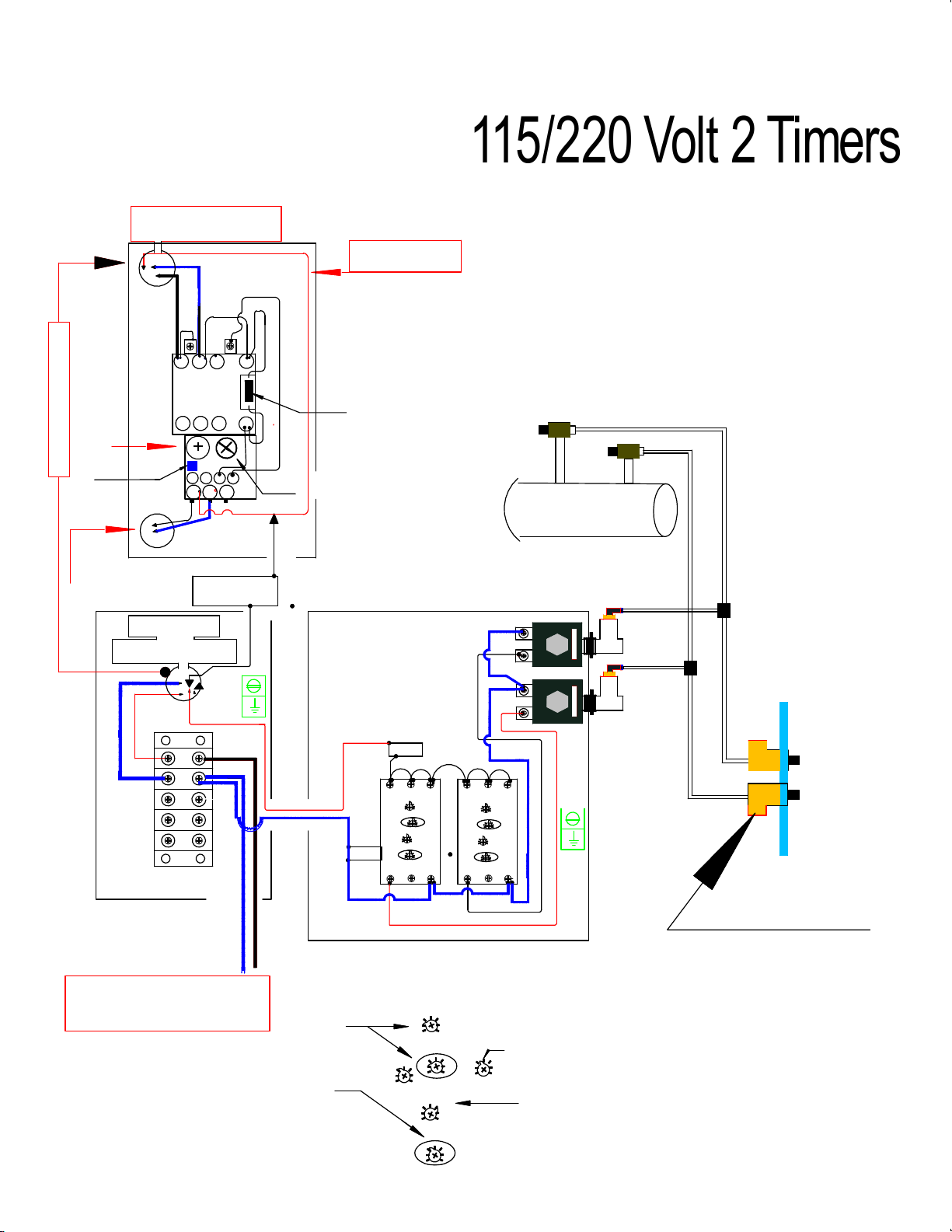

Out Going Power

incoming

power

115/220 Volt

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

2 4 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 5

9 6

Stop button

Start Button

power wire

to Transformer

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Push Buttons

Power

115/220 Volt 2 Timers

So The timers only

work when machine is running

Power to timers come

from T1

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

Air Tank

to clean filters

Valves to clean Filters

Out Going Power

incoming power

230 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

2 4 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 5

9 6

Stop button

Start Button

To Magnetic Starter

Wires Through

Hole into next Box

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

230 Volt 3 phase push

Button clean only

Push Button

To Clean filter/s

Box on outside

of machine for

easy wire hook up

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valves to clean Filters

ELECTIC SOLENOID

230 Volt

230 Volt

Fuse 2

Fuse 1

Fuse 3

From T1

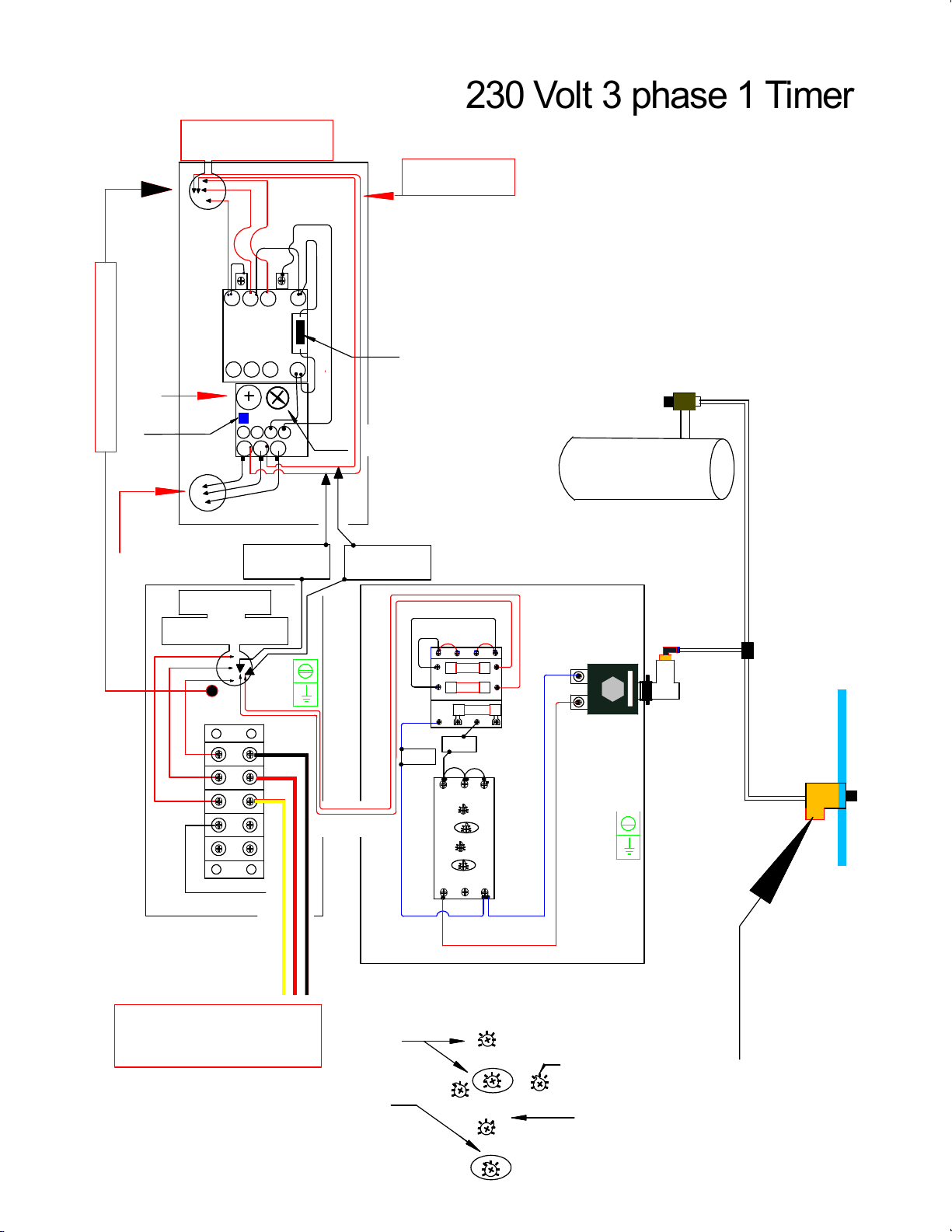

Out Going Power

incoming power

230 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

24 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 59 6

Stop button

Start Button

power wire

to Transformer

From T2

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Power

230 Volt 3 phase 1 Timer

Push Button

To Clean filter/s

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

A1 15 Y1

18 16 A2

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valves to clean Filters

ELECTIC SOLENOID

ELECTIC SOLENOID

230 Volt

230 Volt

Fuse 2

Fuse 1

Fuse 3

From T1

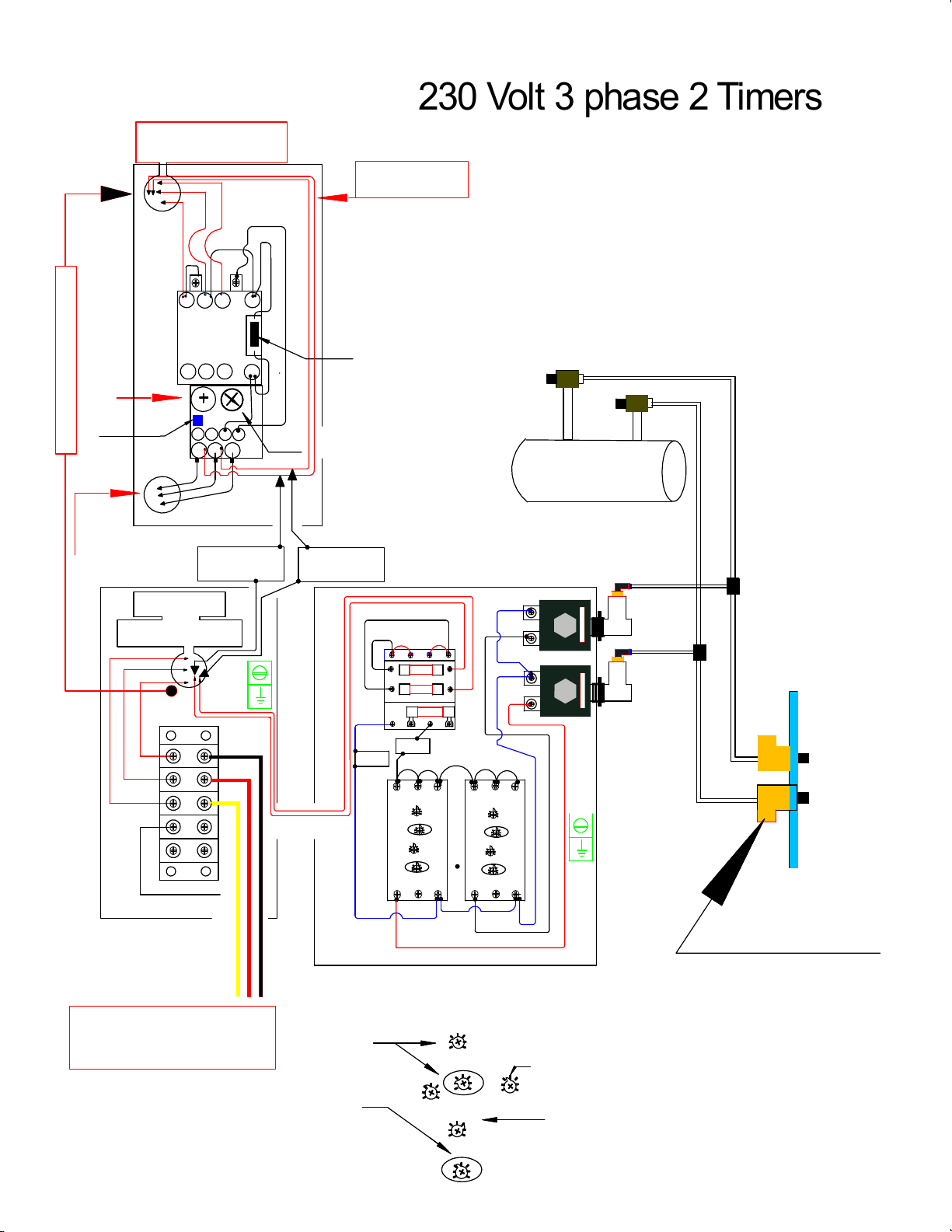

Out Going Power

incoming power

230 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MA N

A U T

24 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 59 6

Stop button

Start Button

power wire

to Transformer

From T2

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Push Buttons

Power

230 Volt 3 phase 2 Timers

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

Air Tank

to clean filters

Valves to clean Filters

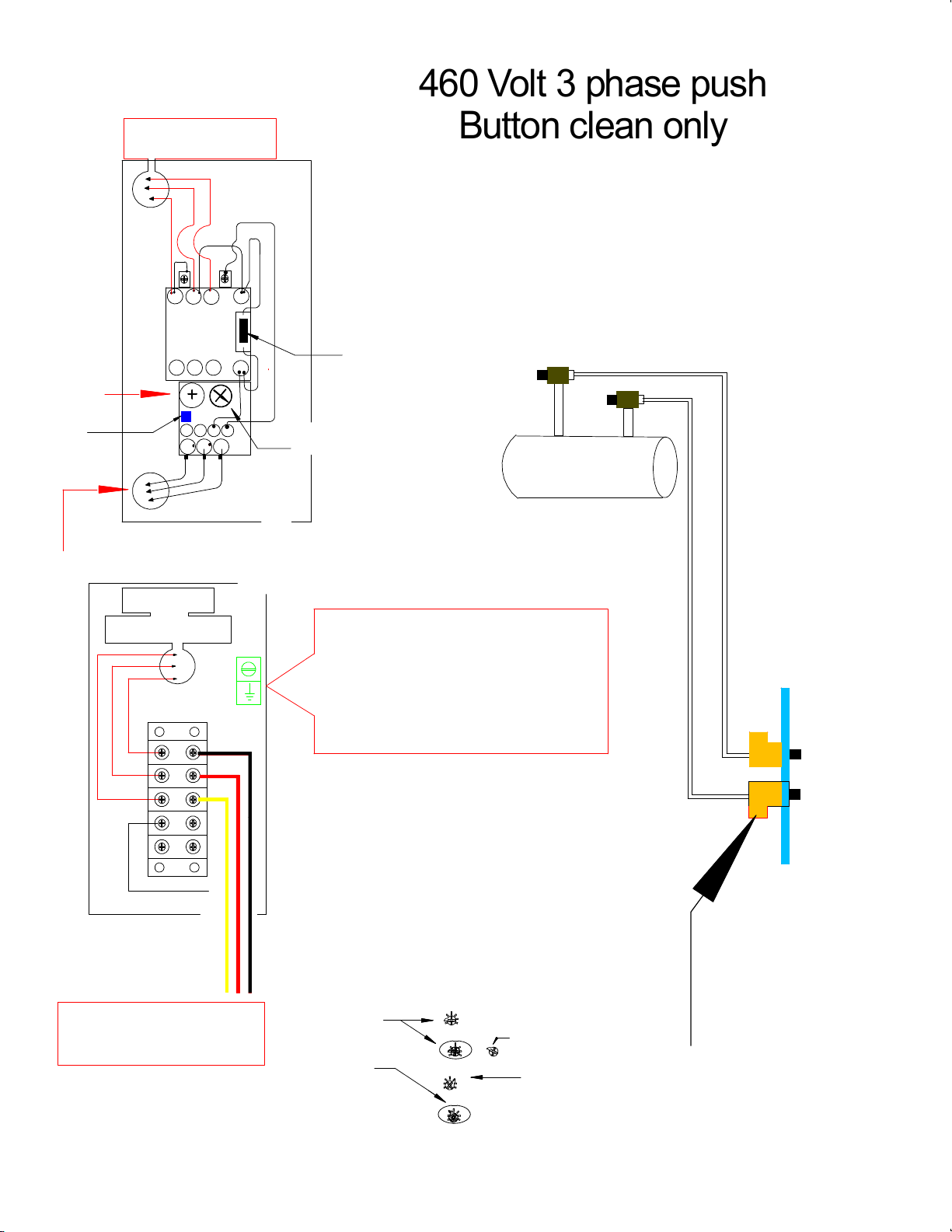

Out Going Power

incoming power

460 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

2 4 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 5

9 6

Stop button

Start Button

To Magnetic Starter

Wires Through

Hole into next Box

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

460 Volt 3 phase push

Button clean only

Push Button

To Clean filter/s

Box on outside

of machine for

easy wire hook up

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valves to clean Filters

ELECTIC SOLENOID

Fuse 2

Fuse 1

Fuse 3

From T1

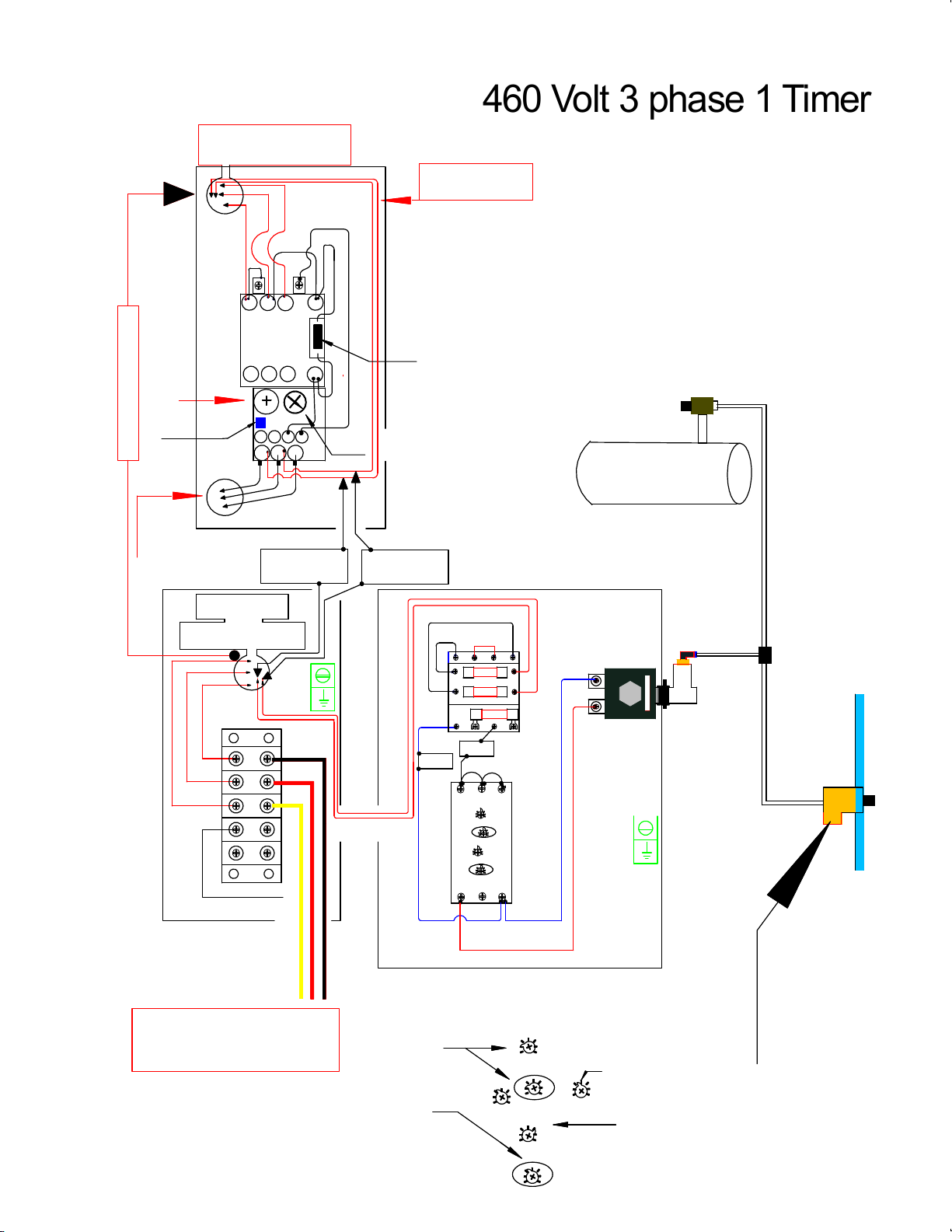

Out Going Power

incoming power

230 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

24 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 5

9 6

Stop button

Start Button

power wire

to Transformer

From T2

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Power

460 Volt 3 phase 1 Timer

Push Button

To Clean filter/s

460 Volt

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

A1 15 Y1

18 16 A2

A1 15 Y1

18 16 A2

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

Air Tank

to clean filters

Valves to clean Filters

ELECTIC SOLENOID

ELECTIC SOLENOID

460 Volt

Fuse 2

Fuse 1

Fuse 3

From T1

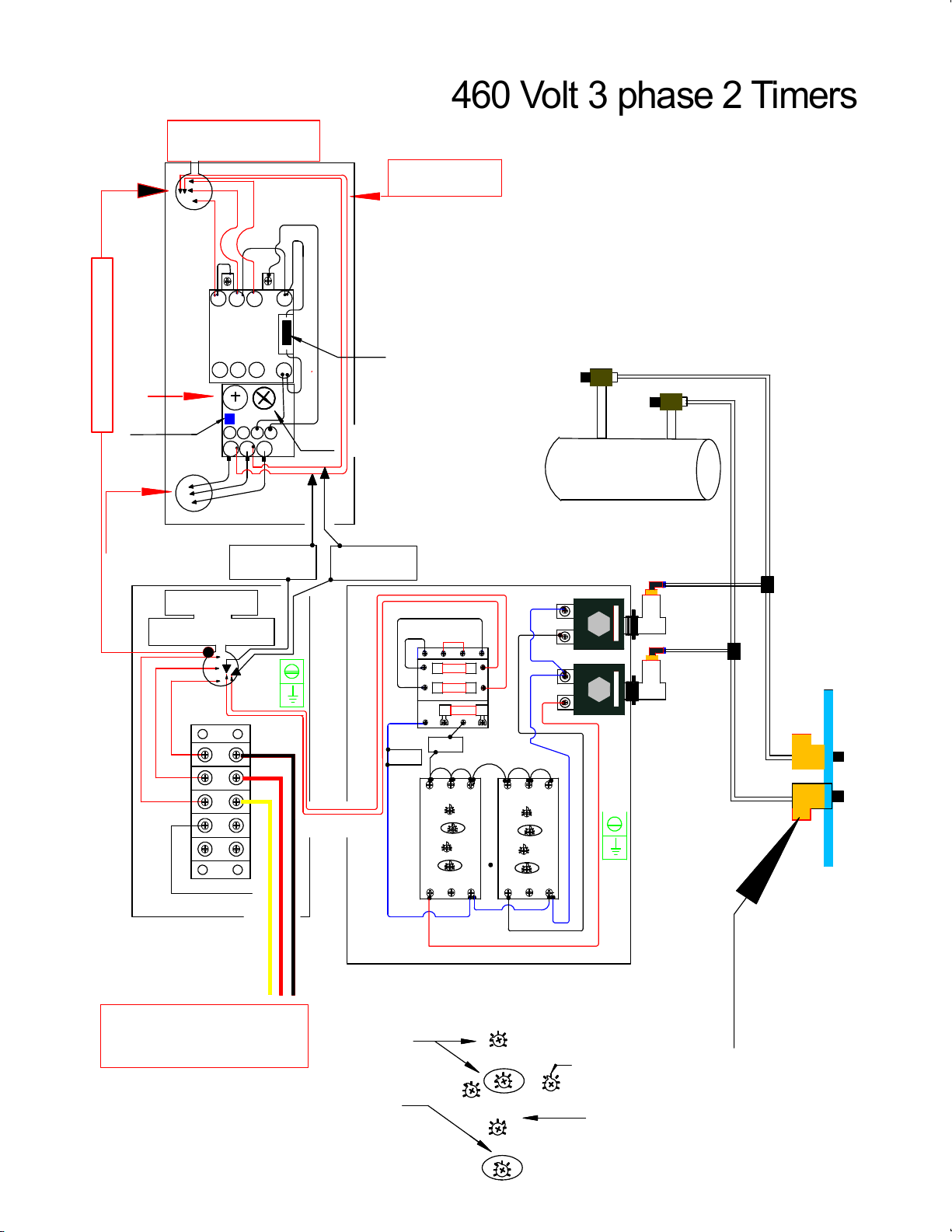

Out Going Power

incoming power

230 3Ph -

6

incoming power from

junction box

L 1 L 2 L 3 1 3

T 2T 1 T 3

9 7

9 8

MAN

AUT

24 1 4

MOTOR

MAG. STARTER

4

56

7

Overload dial set

just above motor

amps

TO

MOTOR

set on Auto

9 59 6

Stop button

Start Button

power wire

to Transformer

From T2

To Magnetic Starter

Wires Through

Hole into next Box

Neutral

The clear Hose only carry about 5 PSI The push

button drains the air from the hose causing the

valve to pulse thus cleaning the filters. No Electrical

power needed or incoming air needed, air comes

from the air tank

Power

460 Volt 3 phase 2 Timers

Push Button

To Clean filter/s

Conduit with wire to this box

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time on

1-10min

6-60min

1-10h

10-100h

0.1-1

1-10

6-60

1

2345 6 789

10

Time off

Time the pulse

is on We use 2 seconds

Set on these

Set Here for 6-60min.

1=6min

2=12min

3=18min

4=24min

5=30min

6=36min

7=42min

8=48min

9=54min

10=60min

Time between

pulses

Dial with Pointer

set pointer to

proper number

6x4=24

TIMER SETTINGS

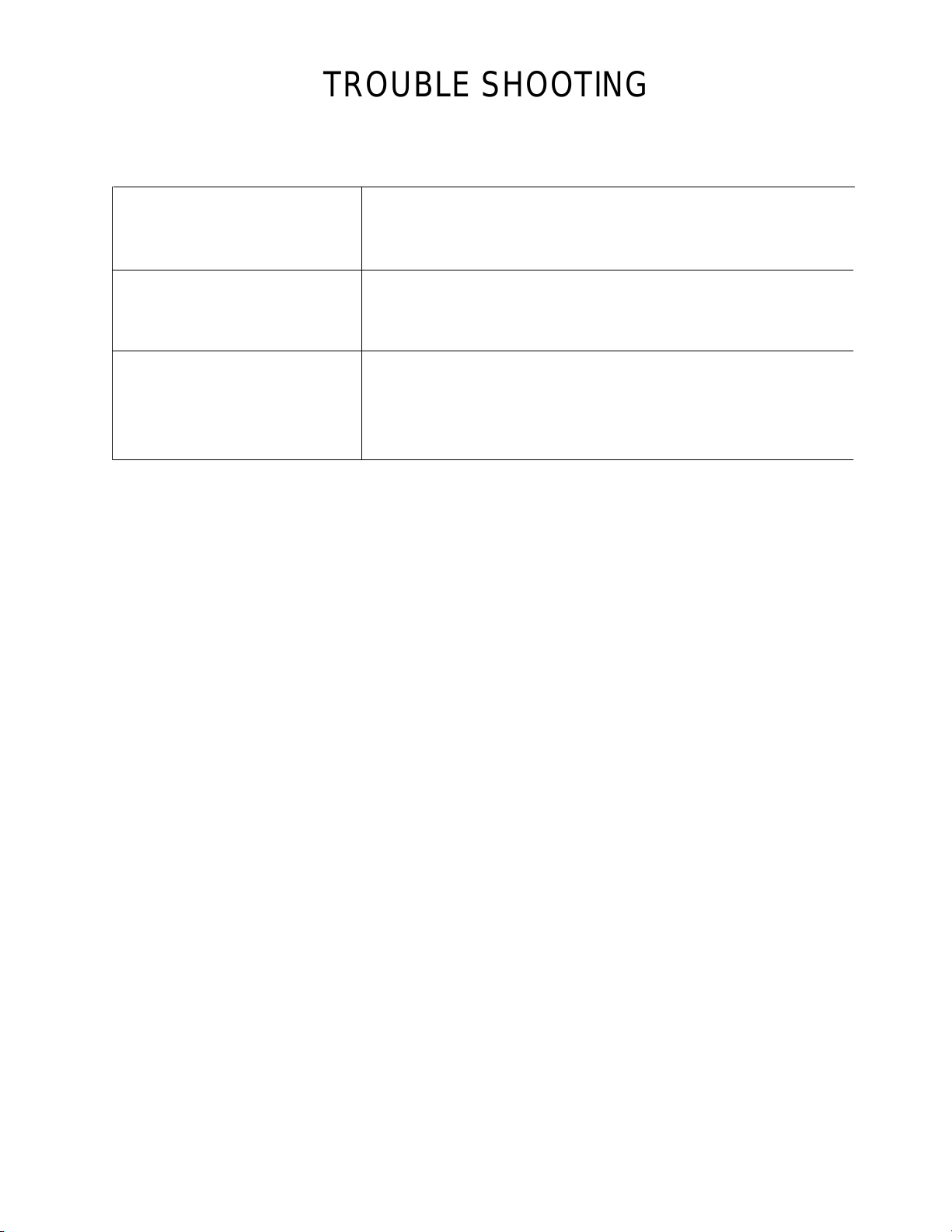

TROUBLE SHOOTING

Motor not running Look to see if L1- L2 -L3

wires are in and secured

and proper voltage is there

Check if wires at bottom of

mag starter to the motor are

in bottom and secured.

The above checks OK In center of the contactor is a rectangle post that is

hooked to coil below. With screwdriver push in and see

if motor will run. If motor will run something is wrong

with the push buttons, That activates the starter.

Motor runs when center

post is held in, but not

by the switches

Make sure every wire is secured on starter if

still no results call Denray for further assistance

If center post is held in

and nothing happens

hook power leads to motor

leads at bottom of mag

starter if motor runs the

problem is the starter.

Call factory for switch replacement

If on switch closes mag

starter and motor does

not run.

FIRST take tester and check see if there is the

proper voltage at bottom of starter

If proper voltage is at

bottom of starter Check to see wiring at motor is properly

hooked together

All the below solutions are meant to be done

only by a qualified technician

Mag starter works

and motor only hums Check for proper voltage

check all wire connections to be tight

check wiring diagram and motor leads to be correct

Filter Cleaning valve will

not pulse Check the three 1 amp fuses on

top of the transformer in the

switch box.

Fuses OK Check wiring in front of and behind the fuses

Fuses and wiring checks

out OK With it being quiet activate the switch and listen

to hear a clicking sound from the valve or valves.

You hear it clicking Make sure air is hooked up to tank

Air is hooked up

and it still clicks Call Denray Replace valve

1

2

3

4

5

6

7

8

9

10

11

12

Motor runs for a

few minutes and

shuts off

Turn the amp dial on overload to increase the

number. Increase only 1 amp at a time

Never increase more than 2 amps above motor

full load amps

13

TROUBLE SHOOTING

Loss of suction on top

of table Dirty filters :: Refer to above

All the below solutions are meant to be done

only by a qualified technician

Excessive exhaust air

on the floor

Rotate filters two times a week 1/4 turn

Timer not working

Machines with timers Check fuses:: Check wiring between mag starter

and timer. Any loose connection,

secure the connection

Filters need to be

cleaned more often Turn dial on timer to a lesser number set at

factory at approx. every 20 minutes.

Lots of dirt remaining on

filters after being cleaned Decrease time between cleanings. Check air

pressure going into machine.

Keep between 100-140 psi

Filter never completely

cleans all dirt off Not supposed to:: Machine designed to operate at

30% filter blockage. The cleaner a filter is the better

the machine will perform.

Any air that is sucked into the table top must come

out in exhaust somewhere. Look into adding Muffler

to machine

Dirt packed in top 1/3 of

filters

Inside of filters are

rusty colored Blowing water from air tank inside of filter. Drain

air tank more often ( daily if possible) Installation

of a dryer or water trap may be necessary

Filters will not come

clean Pull filters out of machine and take blow gun and

from inside blowing out give filters a deep cleaning

How often do I need

to do the above Some companies do it daily and some weekly

and some monthly. You must determine that

for yourself

Moisture blowed in filters

will make filters harder

to clean

14

15

16

17

18

19

20

21

22

23

24

25

26

Refer to 22

Are filters washable? Spun-bond filters in the grind tables can be washed only

a couple times and must let thoroughly dry.

Filter cleaning service companies may be available in

your area.

Green light on timer

does not work See above

Bad timer needs replacement

All fans are factory balanced from fan company,

fans checked and rebalanced at table MFG, if

table has vibration, fan weights may need to be

moved to another blade.

TROUBLE SHOOTING

All the below solutions are meant to be done

only by a qualified technician

27

28

29

Fan making a loud roar Fan rotation backwards, on three phase,switch

wires on L1 and L2

Lack of proper suction Fan running backwards will produce 2/3rds less

suction check fan rotation

Verify Correct Fan Direction on your Machine

Machine vibration on

direct drive systems

Table of contents

Other Denray Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

EASTMAN

EASTMAN Kodak X-Omat 180 LP Service manual

KSB

KSB AmaDrainer Box Box Z2 B Installation & operating manual

Volvo

Volvo REMU user manual

Stober

Stober RB 5022 Commissioning instructions

schmersal

schmersal AZM400Z-ST-1P2P-BOW manual

Grundfos

Grundfos TPE 1000 Series Installation and operating instructions