Densei-Lambda ZWS150PAF Series User manual

- 2 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

1-2. ZWS150PAF/J

1 L: AC Input terminal (pin 1 of CN1)

Live line (fuse in line)

2 N: AC input terminal (pin 3 of CN1)

Neutral line

3 FG: Input terminal FG (pin 5 of CN1)

Safety earth (Frame Ground)

Connect to safety ground of apparatus

or equipment.

4 FG: Frame Ground (Connected to pin 5

of CN1)

Must be connected to electrically safety

ground of apparatus or equipment by

electrically conductive spacers. The

mounting surface of the spacer should be

within MAX 8mm.

5 CN2: ON/OFF control terminal (primary circuit)

See NOTE A

6 +: +Output terminal

7 - : - Output terminal

8 V.ADJ: Output voltage adjust trimmer (VR51)

The output voltage rises when a trimmer is

turned clockwise.

9 CN52: ON/OFF control terminal (secondary circuit)

(For power supply output on and off control

with an external signal.)

*Input & Output connector ( J.S.T )

(also for option model /JL,/JA)

Connector Housing Terminal Pin

Input (CN1) B3P-5-VH VHR-5N SVH-21T-P1.1

Output (CN51) B6P-VH VHR-6N SVH-21T-P1.1

*Output Current of each connector pin must be less than 5A.

*Hand Crimping Tool : YC-160R ( J.S.T )

*CN2 is normally shorted by JM-2W-96 ( J.S.T )

See NOTE A

Connector Housing Terminal Pin

B2B - XH - AM XHP - 2 BXH - 001T - P0.6

or SXH - 001T - P0.6

N

OTE A: For COVER & CHASSIS type (MODEL: ZWS150PAF/JA), remote ON/OFF control cannot be used.

*Connector for Remote ON/OFF control: CN2

,

CN52

*Hand Crimping Tool: YC-110R (J.S.T) or YRS-110 (J.S.T)

(J.S.T)

- 3 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

1-3. ZWS150PAF/T

1 L: AC Input terminal L (M4 screw)

Live line (fuse in line)

2 N: AC input terminal N (M4 screw)

Neutral line

3 FG: Input terminal FG (M4 screw)

Safety earth (Frame Ground)

Connect to safety ground of apparatus

or equipment.

4 FG: Frame Ground

Must be connected to electrically safety

ground of apparatus or equipment by

electrically conductive spacers. The

mounting surface of the spacer should be

within MAX 8mm.

5 CN2: ON/OFF control terminal (primary circuit)

See NOTE A

6 +: +Output terminal (M4 screw)

7 - : - Output terminal (M4 screw)

8 V.ADJ: Output voltage adjust trimmer (VR51)

The output voltage rises when a trimmer is

turned clockwise.

9 CN52: ON/OFF control terminal (secondary circuit)

(For power supply output on and off control

with an external signal.)

See NOTE A

* Input & Output connector ( EMUDEN )

(also for option model /TL,/TA)

*CN2 is normally shorted by JM-2W-96 ( J.S.T )

Connector

Input (CN1) T6957-A

Output (CN51) T7094-A

Connector Housing Terminal Pin

B2B - XH - AM XHP - 2 BXH - 001T - P0.6

or SXH - 001T - P0.6

N

OTE A: For COVER & CHASSIS type (MODEL: ZWS150PAF/TA), remote ON/OFF control cannot be used.

*Hand Crimping Tool: YC-110R (J.S.T) or YRS-110 (J.S.T)

*Connector for Remote ON/OFF control: CN2

,

CN52(J.S.T)

- 4 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

1-4. ZWS150PAF/S

1 L: AC Input terminal L (M4 screw)

Live line (fuse in line)

2 N: AC input terminal N (M4 screw)

Neutral line

3 FG: Input terminal FG (M4 screw)

Safety earth (Frame Ground)

Connect to safety ground of apparatus

or equipment.

4 FG: Frame Ground

Must be connected to electrically safety

ground of apparatus or equipment by

electrically conductive spacers. The

mounting surface of the spacer should be

within MAX 8mm.

5 CN2: ON/OFF control terminal (primary circuit)

See NOTE A

6 +: +Output terminal (M4 screw)

7 - : - Output terminal (M4 screw)

8 V.ADJ: Output voltage adjust trimmer (VR51)

The output voltage rises when a trimmer is

turned clockwise.

9 CN52: ON/OFF control terminal (secondary circuit)

(For power supply output on and off control

with an external signal.)

See NOTE A

*Input & Output connector ( EMUDEN )

(also for option model /SL,/SA)

*CN2 is normally shorted by JM-2W-96 ( J.S.T )

Connector

Input (CN1) T6969-A

Output (CN51) T7093-A

Connector Housing Terminal Pin

B2B - XH - AM XHP - 2 BXH - 001T - P0.6

or SXH - 001T - P0.6

N

OTE A: For COVER & CHASSIS type (MODEL: ZWS150PAF/SA), remote ON/OFF control cannot be used.

*Hand Crimping Tool: YC-110R (J.S.T) or YRS-110 (J.S.T)

*Connector for Remote ON/OFF control: CN2

,

CN52(J.S.T)

- 5 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

2. Terminal Connecting Method

Pay attention to the input wiring. If it is connected to

wrong terminal, the power supply will be damaged.

• Input must be off when making connections.

• Connect FG terminal of input connector and mount-

able FG to ground terminal of the equipment.

• Output current of each connector pin must be less

than 5A. ( Except /T, /S models which M4 screw is

used. )

• The output load line and input line shall be separated

and twisted to improve noise sensitivity.

• Remote ON/OFF control lines shall be twisted or use

shielded wire.

• Use the input/output connector housing, terminal pin

as specified in outline drawing. Also, use recom-

mended crimping tool.

Connector housing and terminal pin is not included

with this product.

• When connecting or removing connector, do not ap-

ply stress to PCB.

ZWS150PAF

ZWS150PAF/J

- 6 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

ZWS150PAF/T

ZWS150PAF/S

- 7 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

3. Explanation of Functions and Precautions

3-1. Input Voltage Range

Input voltage range is single phase 85 ~ 265VAC ( 47 ~

63Hz ) or 120 ~ 370VDC. Input voltage which is out of

specification may cause unit damage. For cases where con-

formance to various safety specs(UL,CSA,EN) are re-

quired, input voltage range will be 100 ~ 240VAC

( 50/60Hz ).

3-2. Output Voltage Range

V.ADJ trimmer(VR51) that is nearby to output connector

is for output voltage adjustment within the range of speci-

fications. To turn the trimmer clockwise, the output volt-

age will be increased. Note over voltage protection (OVP)

function may trigger if the output voltage is increased ex-

cessively.

3-3. Inrush Current

This series has used Power Thermistor to protect the cir-

cuit from Inrush Current. Please carefully select input

switch and fuse in cases of the high temperature and re-

input the power.

3-4. Over Voltage Protection ( OVP )

The OVP function ( Inverter shut down method, manual

reset type ) is provided. OVP function operates within the

range of OVP specification.When OVP triggers, the out-

put will be shut down. The input shall be removed for a

few minutes, and then re-input for recovery of the output.

OVP setting is fixed and not to be adjusted externally.

3-5. Over Current Protection ( OCP )

Constant current limiting, automatic recovery. OCP func-

tion operates when the output current exceeds OCP speci-

fication. The output will be automatically recovered when

the overload condition is cancelled. Do not operate over-

load or dead short conditions for more than 30 seconds,

which could result in damage or insulation failure.

3-6. Over Temperature Protection ( OTP )

For /OTP, /JOTP, /TOTP, /SOTP models, OTP circuit is

built into the power supply to prevent power supply from

damage when ambient temperature over the specification.

3-7. Output Ripple & Noise

The standard specification for maximum ripple value is

measured according to measurement circuit specified by

JEITA-RC9131. When load lines are longer, ripple be-

comes larger. In this case, electrolytic capacitor, film ca-

pacitor, etc. might be necessary to use across the load ter-

minal. The output ripple cannot be measured accurately if

the probe ground lead of oscilloscope is too long.

Oscilloscope

Bandwidth : 100MHz

INPUT

L +

-

P.S. C2 C3

Load

1.5m 50ΩCable

150m

m

R : 50

Ω

C1 : 4700pF Film Capacitor

C2 : 100uF Electrolytic Capacitor

C3 : 0.1uF Film Capacitor

+

FG R

C1

N

3-8. Series Operation

For series operation, either method (A) or (B) is possible.

Method ( A )

Output

Terminal

Output

Terminal

Power

Supply

Load

Method ( B )

Output

Terminal

Output

Terminal

Power

Supply

Loa

d

Loa

d

3-9. Parallel Operation

(A) To increase the output current is not possible.

- 8 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

Load

Output

Terminal

Output

Terminal

Power

Supply

(B) To use as Back-up Power Supply

1. Set power supply output voltage higher by the for-

ward voltage drop(VF) of diode

2. Adjust the output voltage of each power supply to

be the same.

3. Use within the specifications for output voltage and

output power.

Output

Terminal

Output

Terminal

Load

Power

Supply

3-10. Peak Output Current

For ZWS150PAF series, the peak output current should

satisfy the conditions below:

1)Should not exceed the rated peak current in the

specifications.(eg. 12A for ZWS150PAF-24)

2)Duty cycle of the peak output current should be < 35%,

and operating time of peak output current is less than 10

seconds. If the power supply is operated under convec-

tion cooling, and ambient exceeds 50oC, the following

operating period for peak current is recommended.

Ambient Temperature ( C) Peak current operating time

-10 ~ +50 C within 10 seconds

+50 C onwards within 5 seconds

3)The relation between peak output current with maximum

average output current is defined as below:

Ip

0A

Im

Ip = Peak output current

Im = Minimum output current

D = Duty cycle, τ/T

τ= Peak output current operating time

T = Period

Io = Maximum allowable average output current of speci-

fications (Io should be average load after derating at

various mounting and ambient temperature)

Formula:

ZWS150PAF: 1.4 Io2> Ip2D + Im2(1-D)

Example I : For ZWS150PAF-24 at Ta =60 C,Mounting A,

Max Io =4.41A (after 70% Derating)

1.4 Io2> Ip2 D + Im2(1-D)

(A): In case of Im =0, Ip =12A,

D<18.9%

(B): In case of Im =2A, Ip =12A,

D<16.6%

Example II : Following table illustrate some peak load op-

eration examples for ZWS150PAF-24.

Please note that the actual Io in peak load operation is low .

3-11. Remote ON/OFF Control

Remote ON/OFF control (CN2,CN52) function is avail-

able. Using this function allows the user to turn the output

on and off without having to turn the AC input on and off.

Remote ON/OFF control can be used by following 2 modes.

However, for Cover and Chassis type (eg. ZWS150PAF/A,

/JA, /TA, /SA) cannot be used.

Max allowable

average load after

derating by various

Mounting and Ta :

Examples of peak load

derating, calculated by

above formula

Actual

Io

Average Load(%) Io(A) Ip (A)max D max Im (A) Io(A)

100% 6.3

90% 5.67

80% 5.04

70% 4.41

60% 3.78

50% 3.15

40% 2.52

30% 1.89

20% 1.26

10% 0.63

12 35.0% 2.83

12 31.3% 0

12 24.7% 0

12 18.9% 0

12 13.9% 0

12 9.7% 0

12 6.2% 0

12 3.5% 0

12 1.5% 0

12 0.4% 0

6.04

3.75

2.96

2.27

1.67

1.16

0.74

0.42

0.18

0.05

o

o

o

T

τ

o

- 9 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

Using CN2

It is controlled by short or open between +R & -R of CN2.

CN2 is provided in the primary circuit for ON/OFF control

by means of a switch or other device. When using this con-

nector, which is considered to be electrically connected to

the mains input voltage, all the requirements of EN60950

must be met with respect to the connector, wiring and

switch etc.

In particular:

1) Basic insulation must be provided between the

ON/OFF control circuit and earth.

2) Reinforced insulation must be provided between the

ON/OFF control circuit and any secondary circuit or

accessible part.

3) Wiring must be routed such that damage to the insula-

tion of the wire or additional sleeving cannot occur.

4) The switch must meet requirements for reinforced in-

sulation from the ON/OFF control circuit to actua-

tor/ac-cessible parts.

[CN2] The control mode is shown below.

+R & -R Terminal condition Output condition

Short ON

Open OFF

*Using CN52

At first, remove short piece of CN2.

It is controlled by the voltage applied to +R and –R. This

circuit is in the Secondary ( output ) side of the power sup-

ply unit. Do not connect in the Primary ( input ) side. And

this circuit is isolated from the output by a photo-coupler.

Power

Supply

1kΩ

-R

+R

R

SW

E

CN52

[CN52] The control mode is shown below.

+R & -R terminal condition Output condition

SW ON (Higher than 4.5V) ON

SW OFF (Lower than 0.8V) OFF

External voltage level: E External resistance: R

4.5 ~ 12.5VDC No required

12.5 ~24.5VDC 1.5kΩ

3-12. Isolation Test

Isolation resistance between output and FG (Chassis) shall

be more than 100MΩat 500VDC. For safety operation,

voltage setting of DC isolation tester must be done before

the test. Ensure that the it is fully discharged after the test.

Output – FG (Chassis)

500VDC 100MΩor more

AC(L)

AC(N)

+R(CN52)

-R(CN52)FG

+

-

Isolation

Tester

3-13. Withstand Voltage

This series is designed to withstand 3.0kVAC between in-

put and output, 2.0kVAC between input and FG (Chassis)

and 500VAC between output and the FG (Chassis) each

for 1 minute. When testing withstand voltage, set current

limit of the withstand voltage test equipment to 20mA

( Output - FG (Chassis) : 100mA ). The applied voltage

must be gradually increased from zero to the testing value

and then gradually decreased for shut down. When timer is

used, the power supply may be damaged by high impulse

voltage at timer switch on and off. Connect input and out-

put as follows.

Input ~ Output (dotted line )

3kVAC 1min. ( 20mA )

Input ~ FG (Chassis) (solid line )

2kVAC 1min. ( 20mA )

AC(L)

AC(N)

+R(CN52)

-R(CN52)

FG

+

-

Withstand

Voltage

Tester

- 10 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

Output ~ FG (Chassis)

500VAC 1min. ( 100mA )

AC(L)

AC(N)

+R(CN52)

-R(CN52)

FG

+

-

Withstand

Voltage

Tester

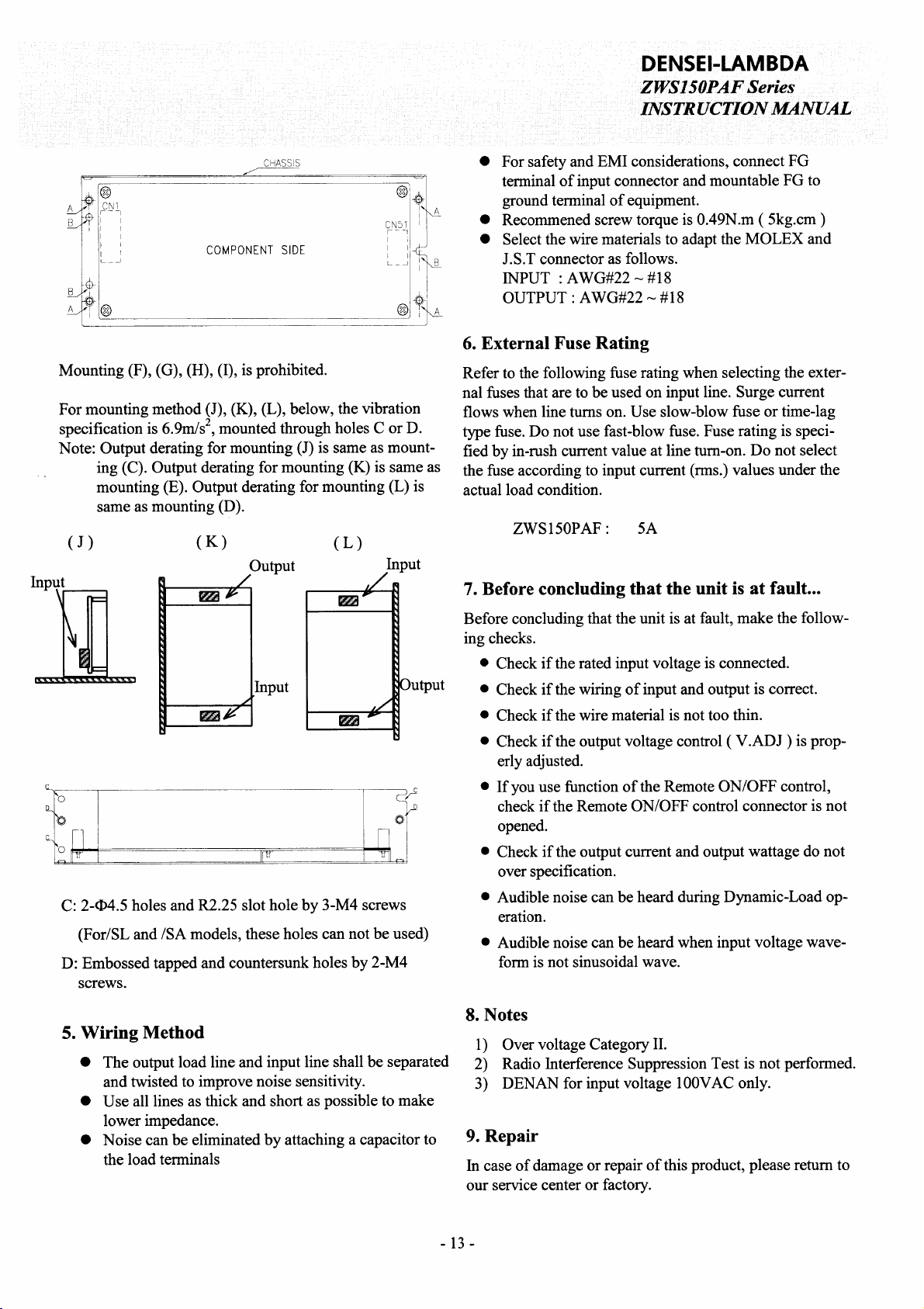

4. Mounting Directions

4-1. Output Derating according to the Mounting Di-

rections

Recommended standard mounting method is ( A ). Method

( B ), ( C ), ( D ), ( E ) are also possible. Mounting (F), (G)

are prohibited. Please do not use installation method ( F ),

where the PCB will be on the top side and heat will be

trapped inside the unit. Refer to the derating below. In the

following derating curve, average load(%) is percent of

maximum output load (both Maximum Output Current and

Maximum Output Power in specifications). Do not exceed

the load deratings.

PCB type

( A )

With chassis, with chassis&cover type

( B )

( C )

( F )

Prohibit

Standard Mounting

( D )

( E )

( A )

Standard Mounting ( B )

( C ) ( D )

( E ) ( F )

Prohibit

( G )

Prohibit

Co

m

po

n

e

n

t

Input

In

p

ut

Input

Output

Out

p

ut

In

p

ut

Com

p

onent

Input

Input In

p

ut

Output

Out

p

ut

In

p

ut

( H )

Prohibit

( I )

Prohibit

- 11 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

Output Derating

• Convection cooling

PCB type and with chassis type

0

20

40

60

80

100

-10 0 10 20 30 40 50 60

Ambient Temperature (°C)

Average Load (%)

Convection Average Load (%)

Mounting

Ta A B C D E

-10~ 40°C 100 100 100 100 100

50°C 100 100 80 80 80

55°C 85 85 70 70 70

60°C 70 70 60 60 60

With chassis and cover type

0

20

40

60

80

100

-10 0 10 20 30 40 50

Ambient Temperature (°C)

Average Load (%)

Convection Average Load (%)

Mounting

Ta A B C D E

-10~ 15°C 100 100 100 100 100

20°C 100 100 95 100 95

30°C 100 80 80 80 80

40°C 80 65 65 65 65

50°C 65 50 56 50 56

• Forced air cooling

PCB type and with chassis type

0

20

40

60

80

100

-10 0 10 20 30 40 50 60 70

Ambient Temperature (°C)

Average Load (%)

Forcedair Average Load (%)

Mounting

Ta A,B,C,D,E

-10~ 60°C 100

70°C 70

With chassis and cover type

0

20

40

60

80

100

-10 0 10 20 30 40 50 60

Ambient Temperature (°C)

Average Load (%)

Forcedair Average Load (%)

Mounting

Ta A,B,C,D,E

-10~ 50°C 100

60°C 70

*Recommended minimum air velocity : 0.7m/s ( Measured

at component side of PCB, air must flow through compo-

nent side).As a reference for forced Air Cooling, let air flow

so that the transformer T1 core temperature is lower than

85°C.

Mounting (A),(B)

Mounting (C),(D),(E)

Mounting

(A),(B),(C),(D),(E)

Mounting (A)

Mounting (B),(D)

Mounting (C),(E)

Mounting

(A),(B),(C),(D),(E)

- 12 -

DENSEI-LAMBDA

ZWS150PAF Series

INSTRUCTION MANUAL

Test point T1

PCB

(CORE)

R7

4-2. Mounting Method

PCB type

Please use the mounting hole (4 holes of φ3.5) and insert

the spacer (MAXφ8.0)of height over 8mm to lift the unit.

Also use all 4 mounting holes for the unit installation. The

vibration spec is the value taken when the unit is raised by

8mm spacers.

Note: For cases where the unit is often under vibration

condition, fix with isolated spacer (non conductive), at the

5th hole, near C6 on the PCB.

The 5th hole diameter: Φ3.5mm

PCB thickness: 1.6mm

Maximum spacer outer diameter: Φ7mm

Example:

Please leave 4mm space from the surfaces and leave

4mm space from the sides of PCB, especially from the

solder surface, 8mm space is necessary. If the space is

not enough, the specification of insulation and withstand

voltage will not be satisfied.

FG should be connected to the earth terminal of the appa-

ratus. If not, the EMI noise and output noise will increase.

Hatching area is maximum permissible area of metal part

for mounting.(9mm from each PCB corners)

For chassis option /L, chassis & cover option /A

Recommended mounting by following holes A or B, to

meet 19.6m/s2 vibration specification.Mounting direction

(F) & (G) is prohibited as shown in section 4-1. The power

supply can be mounted through holes A or B.

A: Embossed tapped and countersunk holes by 4-M4

screws

B: Φ4.5 holes and R2.25 slot hole by 3-M4 screws (For

/SL and /SA models, these holes can not be used)

This manual suits for next models

8

Table of contents