2.5 In

ut ca

acitor:C1

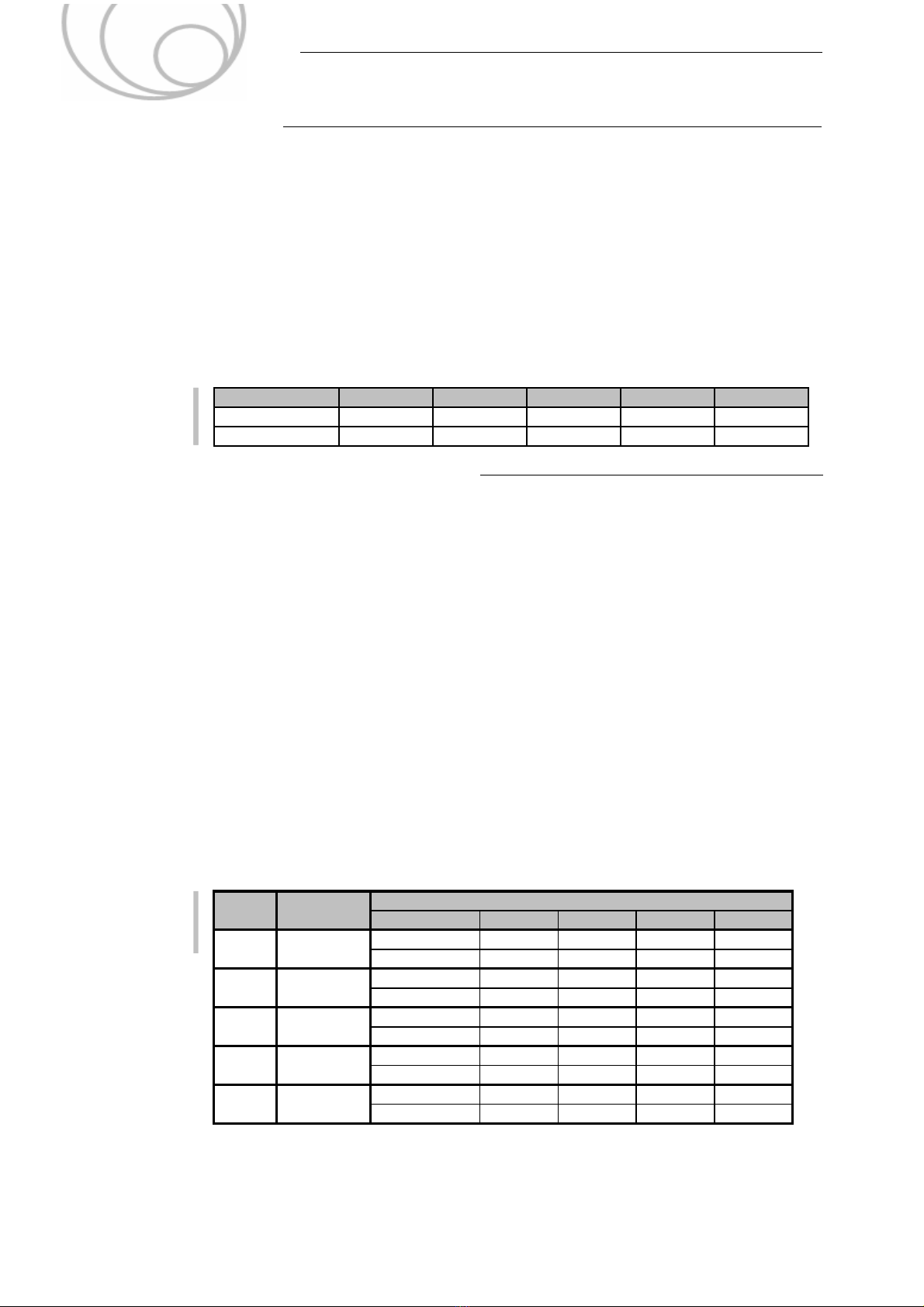

TUHS25

■To comply with conducterd noise CISPR22-B, EN55022-B, connect capacitor C1 which is 0.1μF

between AC input terminals.

■Use a capacitor with a rated voltage of AC250V which complies with the safety standards.

■If 0.11μF or more capacitor is connected, the discharge resistor is necessary in order to

comply UL60950-1. Please connect the discharge

esistor which satisfy the following formula.

2.6 Varistor:SK1

■In order to comply with IEC61000-4-5 Level 3 (surge immunity), coonnect a surge protective device.

■Overvoltage category changes depending on the location for installing the power supply.

Recommended components is complying to the overvoltage category II.

For example, home electronics and information equipment corresponds the installation category II.

And they are installed the primary part of the equipment which is connected to outlet by power cable.

If installation category III (required to connect distribution panel directly) is required, the varistor

must be bigger than recommended varistor.

Please confirm whether the components comply the standards.

2.7 Out

ut ca

acitor:Co

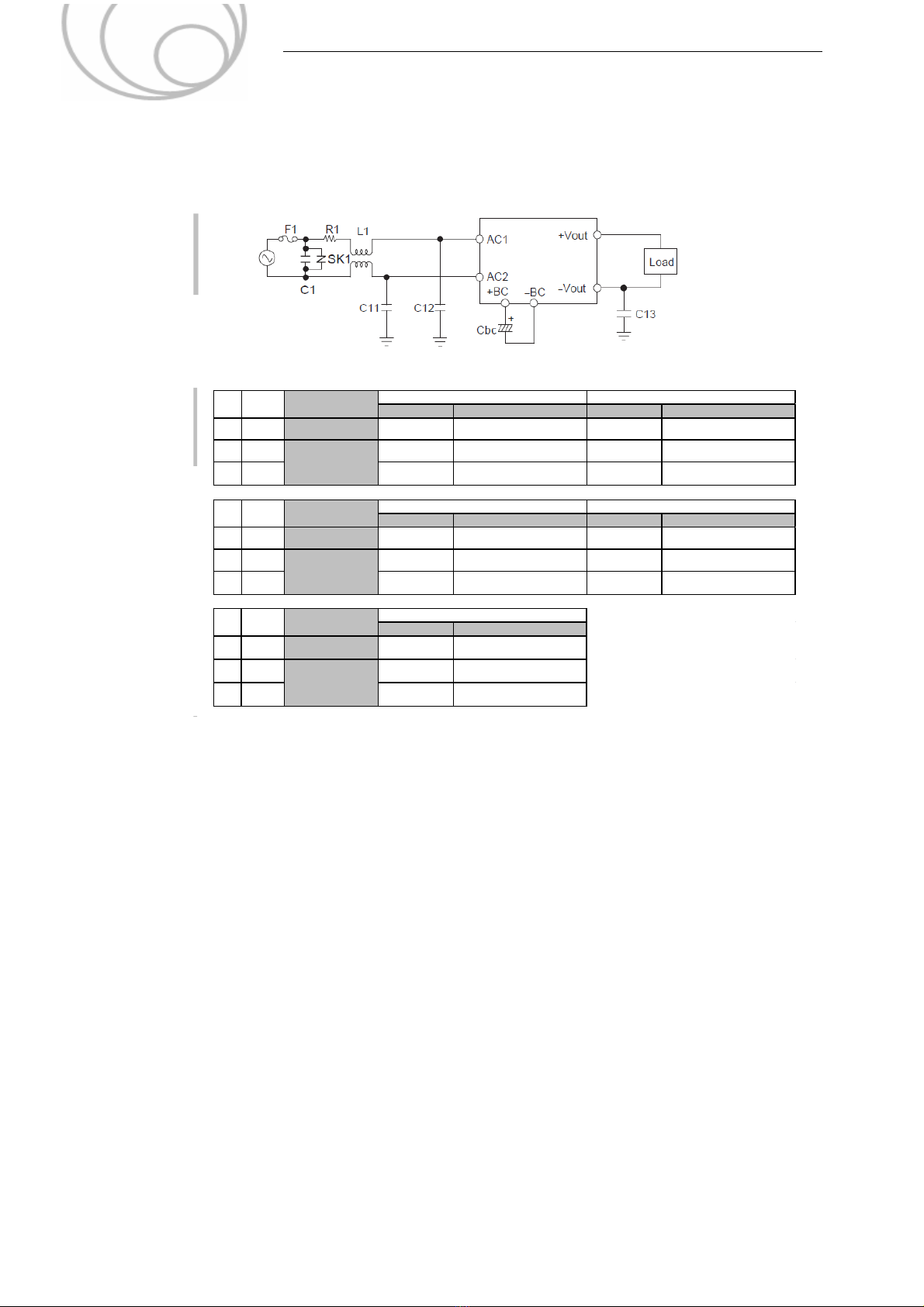

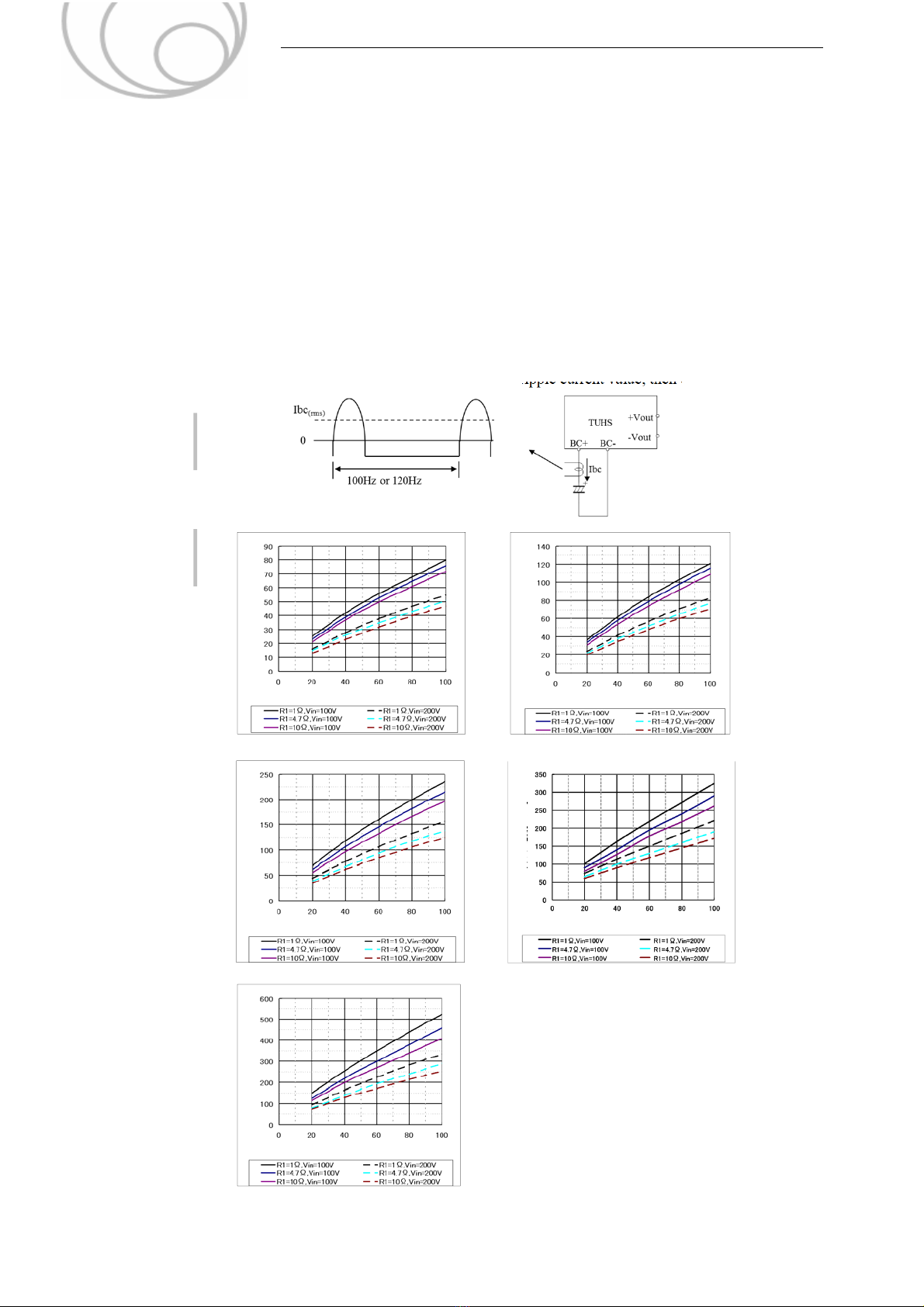

■In the TUHS series, the output capacitor is basically unnecessary. Reduce the ripple voltage or suppress

fluctuation in an output voltage by connecting the output electorolytic capacitor or ceramic capacitor.

The connection example is shown in Fig 2.7.

■When the pulse load is connected, the output voltage will change transiently.

Please check the level of the fluctuation in your situation.

And if the transient output voltage change is not acceptable, please connect the output capacitor Co

Fig.2.7

Connecting Example of

an External Capacitor

to the Output Side

Table 2.5

Recommended

capacitance

Co

2.8 AC line filter:L1

■The commom mode choke coil should be selected with confirmation because there are wire grade

and rated temperature of bobbin.

2.9 Y Ca

acitors:C11

C12

C13

■Please choose safety certified capacitor (Y1, Y2 class approved) to C11 and C12

However,

if secondary circuit is shorted to FG, not connected by capacitor, please choose Y1 class capacitor

as C11 and C12.

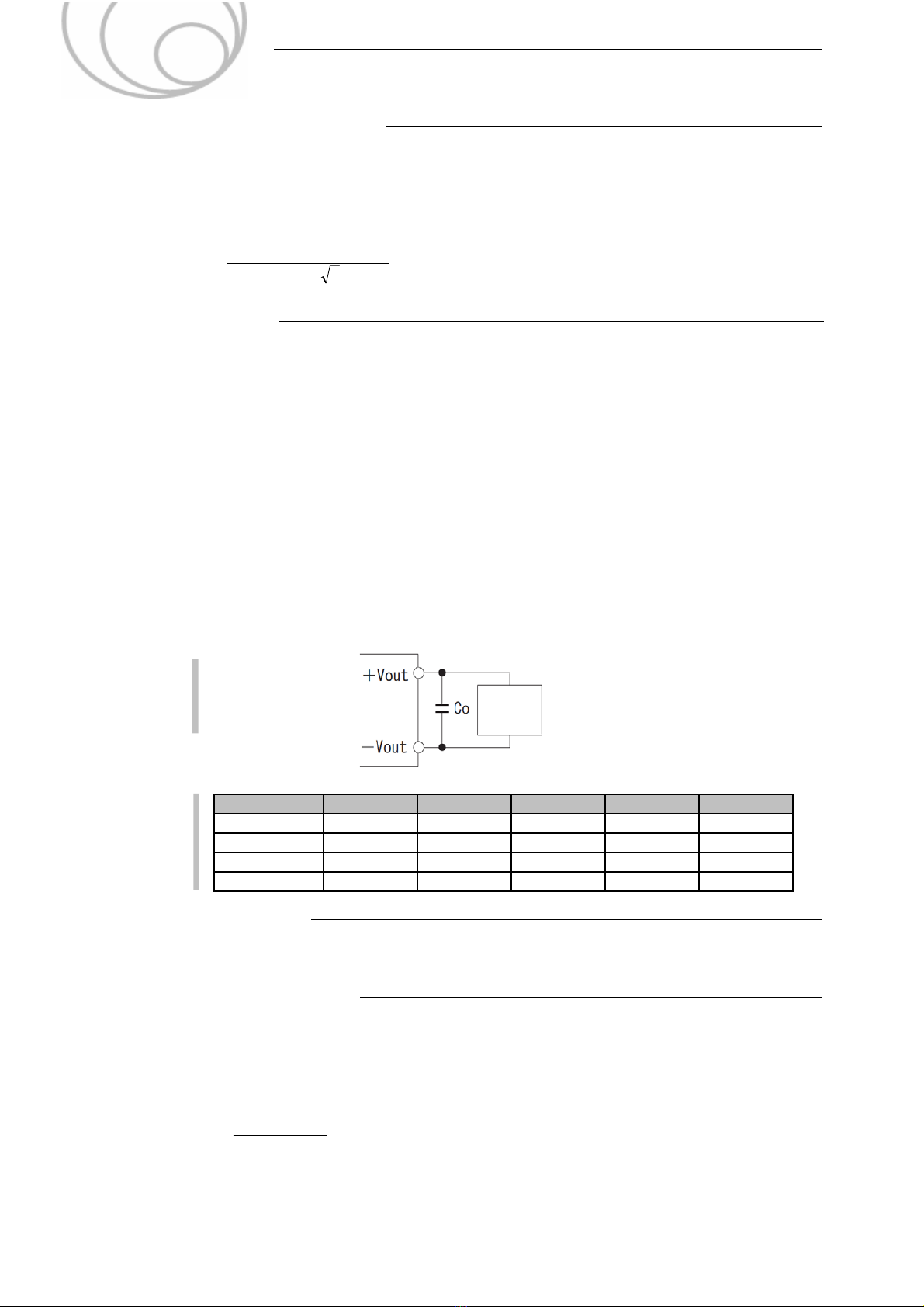

■During high voltage test, the voltage applied to C13 is determined by the value of C11, C12 and C13.

Please note the rated voltage of the capacitor. Fomula of the voltage applied to C13 is shown below.

■The noise reduction level depends on the location of the grounding capacitor.

Please connect the capacitor as close as possible to the power supply.

0~330μF

TUHS5 TUHS10 TUHS15

0~47μF 0~150μF

5V 0~100μF 0~100μF

TUHS25

-

A-7

12V 0~470μF0~47μF

Output voltage TUHS3

0~68μF 0~68μF

0~150μF

24V 0~22μF 0~22μF

15V 0~47μF 0~47μF 0~120μF 0~120μF 0~390μF

0~1000μF

0~220μF

42.4)2(Vlog

1

ine1

/

≦

uuC

R

test

CCC CC VV

312111

1211

C13

u

VC13 :Voltage applied to C12

C11,C12 :Y capacitor on the primary side

C13 :Y capacitor on the secondary side

Vtest :Test voltage

R :Discharge resistor

C1:Input capacitance

Vin:Input voltage 120V or 240V[rms]

Load

Applications Manual

TUHS series