5

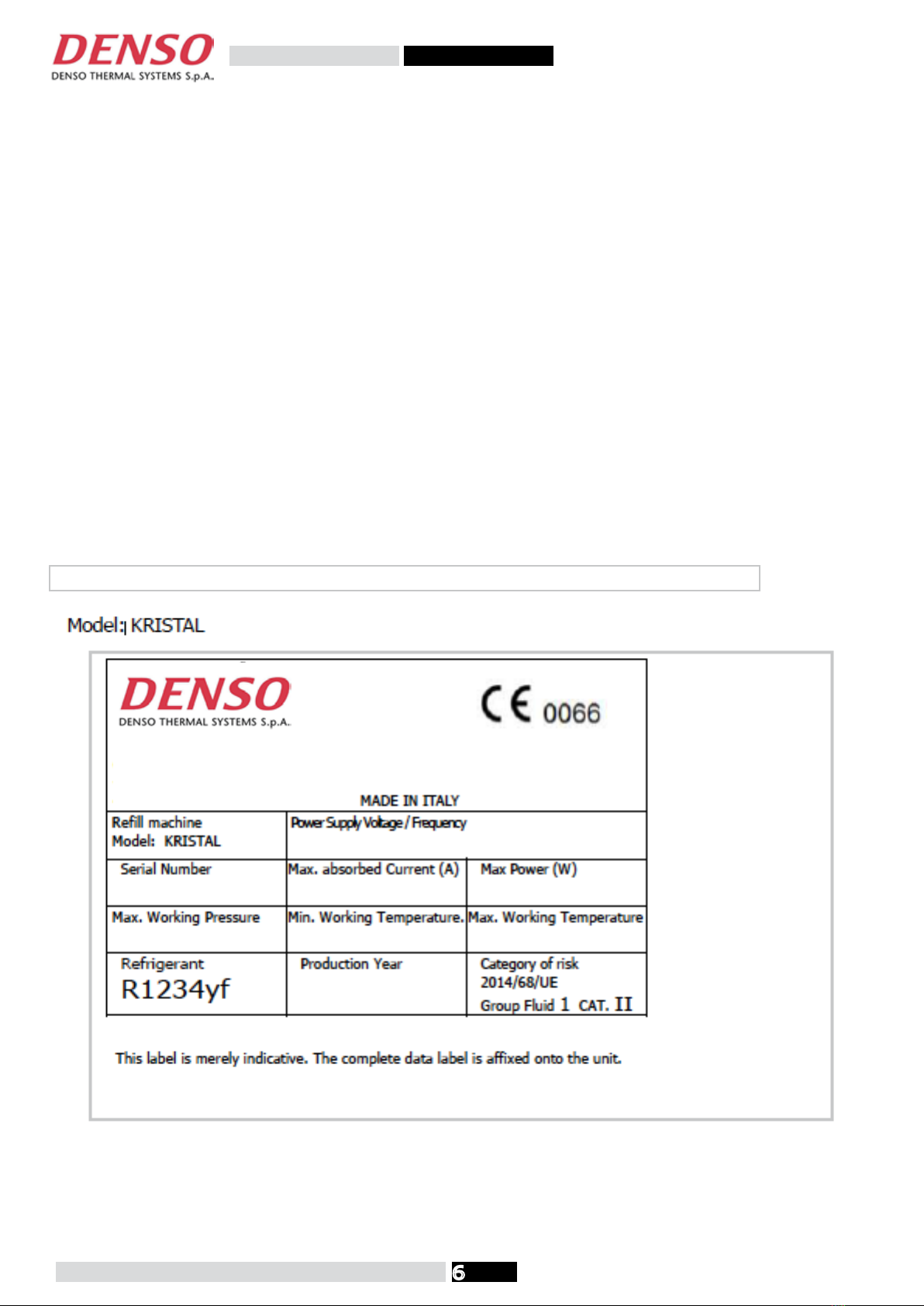

User Manual KRISTAL

Denso Thermal Systems S.p.A. would like to thank you for selecting a product from our range and to encourage you to read

these instructions. They

contain any information required for correct operation of the RRR station you have purchased. Please read this manual

entirely and follow the instructions provided in it thoroughly. This User Manual should be stored in a place where it is not

subject to alterations. The information given in this manual may be changed without prior notice and/or without any additional

obligation in order to add modications and improvements to any shipped units. Reproduction or translation of any part of the

manual is prohibited without the owner’s authorization in writing. Denso Thermal Systems S.p.A. is responsible for manufactu-

ring defects throughout

the entire warranty term, which they will try to x in the shortest time possible.

WARRANTY

The term of the warranty is 12 months from the purchase date. The warranty only entitles the user to the replacement of

defective parts. The warranty is voided if equipment is not operated according to its intended use, if it is tampered with by

unauthorized people or in cases where non-conforming components or procedures are used.

Warranty terms (please read)

1. Warranty details

Denso agrees to repair free-of-charge any defects that may be identied within the warranty term, which have occurred during

normal use in compliance with the precautions laid down in this user manual.

2. Procedure for repairs under warranty

To ask for repairs under warranty following a malfunction during the warranty term, contact the dealer from which the equip-

ment was purchased and give him the purchase document. If this document is not submitted, repairs under warranty may not

be granted.

3. Cases outside the warranty

Even if they are identied during the warranty term, the following defects are not included in the warranty:

(I) defects due to equipment operation in special environments (e.g. potentially explosive environments);

(II) defects resulting from failure to comply with the danger, warning and caution signs and other indications provided in the

user manual of the product in question;

(III) defects resulting from checks, handling, disassembly, etc. which have not been performed by our company or by an

authorized service center;

(IV) defects occurring with the purchased model. These include defects due to environmental factors relating to ageing (paint

dissipation, etc.) or wear linked to equipment use;

(V) defects caused by pets/animals;

(VI) defects resulting from accidents such as re, explosions, etc. lightning, earthquakes,

eruptions, ooding and tsunami, and other types of natural disasters or destruction due to riots, etc.;

(VII) defects originating from problems connected to the electricity supply;

(VIII) defects resulting from use of electricity other than that specied;

(IX) defects originating from use of different spare parts from those specied by Denso Thermal Systems S.p.A.;

(X) defects due to events caused by malfunctioning of other products than this device;

(XI) defects due to electromagnetic disturbance.

4. Denso srl shall not be liable for the resulting costs.

(I) Denso Thermal Systems S.p.A. shall not be liable for additional costs connected to a product defect such as lost working

hours, refrigerant leaks,

refrigerant contamination and unauthorized shipment and/or labor costs.