Cramaro GALOPPINO Parts list manual

CRAMARO TS S.r.l. / COLOGNAV.TA(VR) VIAQUARI DESTRA71 TEL. 0442/411688 / FAX 0442/411690

E-MAIL info@cramaro.com WEB : http://www.cramaro.com

Pag 1

TS

S.r.l.

CRAMARO TS S.r.l. COLOGNAV.TA(VR)VIAQUARI DESTRA71 TEL. +39-0442/411688 / FAX +39-0442/411690

E-MAIL info@cramaro.com WEB :

http://www.cramaro.com

“ GALOPPINO “

TECHNICAL SPECIFICATIONS FOR UTILISATATION and ASSEMBLY

FOR HANDLING SYSTEM WITH DRIVIING ARC

COLOGNA VENETA ( VR )

SISTEMI DI COPERTURA BREVETTATI

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 2/31

This document is the property ofCRAMAROTS s.r.l. and cannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 2

CERTIFICATION

The abovementioned plant conforms to the “Machine” 2006/42 EC Directive, as amended, as well as Directive

2006/28 relating to the electro-magnetic compatibility (for its variation to electrical handling) and is subject to EC

branding.

STRUCTURE OF THE MANUAL

The customer should read the information shown in this manual very carefully, as the correct utilisation and

maintenance constitute the basis of the Customer - Manufacturer relationship.

CRAMARO ITALI S.r.l. shall not consider itself responsible for snags, breakages or accidents due to a lack of

compliance or non-application of the indications contained in this manual.

PURPOSE AND CONTENT

The purpose of this manual is to provide the necessary information to the Customer in order that, other than

appropriate utilisation of the plant, they are able to operate it in the most autonomous and safe manner possible.

The manual includes inherent information, such as the technical aspect, maintenance, spare parts and safety.

Before conducting any operation on the machine, the operators and Qualified

Personnel must read the instructions contained in this manual carefully.

In the case of doubts about the correct interpretation of the instructions, kindly call your nearest assistance

centre to obtain the necessary clarifications.

Any operative methodology of the plant not included in this instruction manual is to be considered as incorrect or

improper.

RECIPIENTS

The abovementioned manual is directed at: the Operator and Qualified Personnel appointed to maintain the

plant.

It is specified that “OPERATOR” means the personnel assigned to make the plant function and carry out the

ongoing maintenance.

“QUALIFIED PERSONNEL or QUALIFIED OPERATOR” means those persons who have attended

specialisation and training courses, etc., and have experience in connection with the installation,

commissioning, maintenance and repairs of the plant.

CONSERVATION

This instruction booklet and all the publications attached thereto must be kept in an accessible place, known to

all the operators and personnel authorised for maintenance.

ASSISTANCE CENTRES

The Customer is kindly requested to refer directly to the manufacturer for any needs relating to the use of the

plant, maintenance or to request spare parts, specifying the identifying data of the machine.

CRAMARO TS

S.r.l.

Registered and operational office 37044 Cologna Veneta ( VR ) ITALY via Quari Destra 71

Tel

0039 – 0442 –

411688

-------

Fax

0039 – 0442 –

411690

CRAMARO TS S.r.l. reserves the right to change the documentation without updating that issued, if

necessary.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 3/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 3

DESCRIPTION OF THE PRODUCT

Officially created in 2007, the GALOPPINO handling system does not set out to be a substitute but rather as

an ALTERNATIVE to the innumerablevariants of the well-known CABRIOLE’ tarpaulin.

The new CRAMARO tarpaulin, called “GALOPPINO“, groups together the best characteristics of the well-

known CABRIOLE’ tarpaulin from which it inherits both the supporting structure of the canvas, or rather the

SLIDING ARCHS that allow simplicity of assemblyand maintenance.

Nevertheless, differing from the CABRIOLE’ tarpaulin, it neither has the tarpaulin pulling system, to be fixed in

front of the box structure with the consequent bulk problems that are sometimes irresolvable, if not resorting to

using complex deviation systems of the pulling cables, and not even the double pulling cables with ring

closures, that are classic with a CABRIOLE’tarpaulin.

In fact the last arc of the GALOPPINO tarpaulin also incorporates its own motorisation

The great advantages of the GALOPPINO tarpaulin are mainly:

Easy assembly of the tarpaulin as it does not require laborious transformations of the box on

which the tarpaulin must be applied;

Very rapid assembly given the demands of the pieces that make it up;

Very rapid replacement of anypieces damaged during use;

Possibility of removing the tarpaulin completely from the vehicle by only uncoupling the two

lateral cables that are anchored to the box bytwo simple hooks with rear couplings;

No mechanical bulk in the front of the vehicle seeing that the pulling element is integrated in

the rear arc of the tarpaulin itself;

extremely adaptable to the various boxes on the market by virtue of the GREAT width

adjustability of the various elements that make it up;

Compacted bulk of the tarpaulin, almost equivalent to the other tarpaulins of the same type;

Ease and rapidity of replacement of the main pulling element of the tarpaulin in the event of a

fault or damage. (it will be sufficient to keep an assembled arc in stock so as to immediately

replace a tarpaulin that is not functioning, meanwhile the non-functioning piece can be serviced

at a CRAMARO assistance centre);

Ease and rapidity of replacement of the intermediate elements of the tarpaulin, which usually

can be replaced without having to remove the tarpaulin from the vehicle.

DIAGRAM OF THE FRONT ASSEMBLY

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 4/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 4

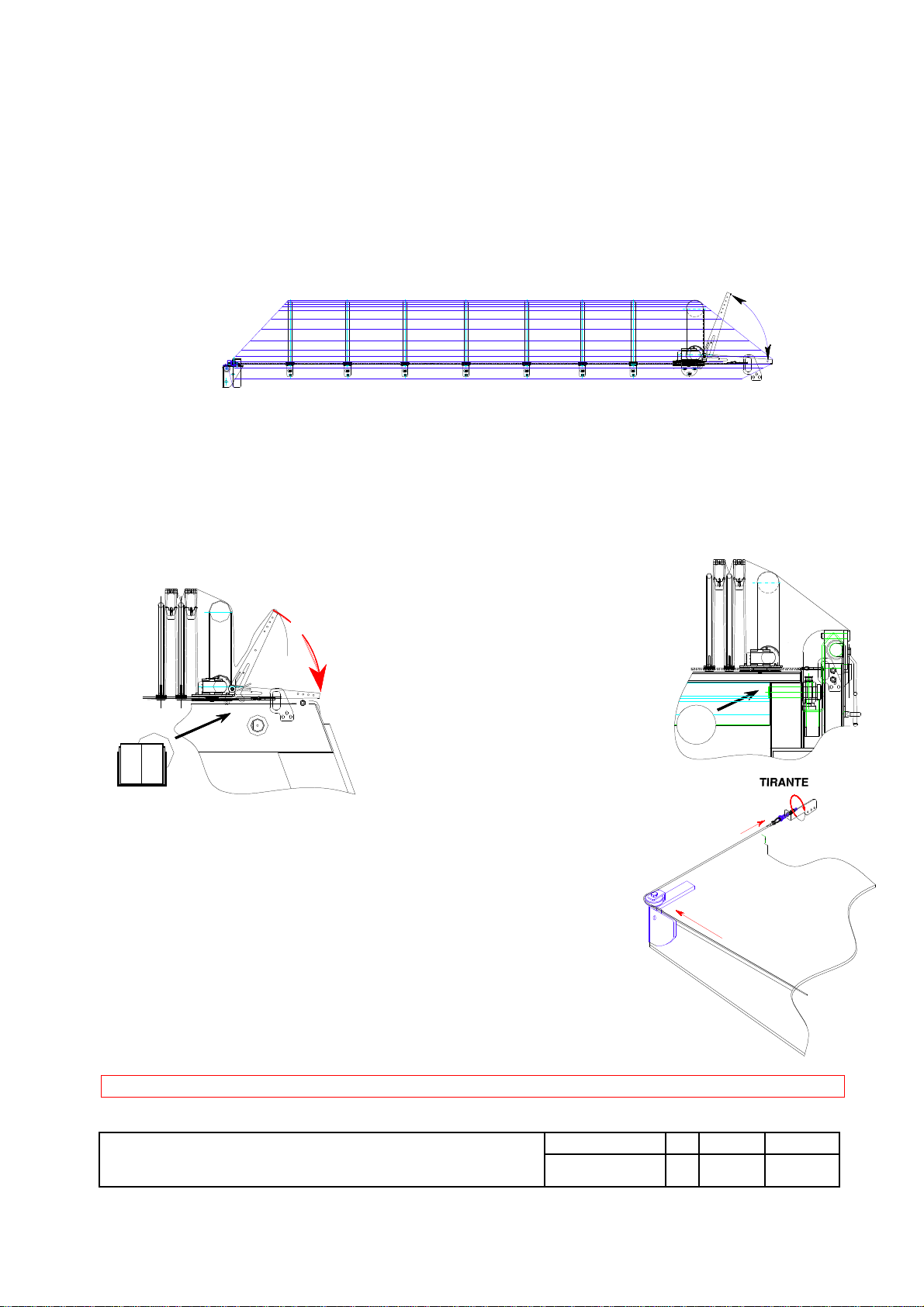

ADJUSTABILITY OF THE CONTROL ELEMENTS OF THE TARPAULIN

FRONT ANCHORAGE ASSEMBLY OF THE CANVAS

MOTORISED PULLING ARC

INDICATIONS FOR THE ASSEMBLY OF THE SYSTEM

There are few operations to be carried out before application of the system on a common box (which confirms

the minimum APPLICABILITY characteristics shown above) but these are essential to ensure that the work is

successfully done.

1 ) Check that the front face of the cab is not sloping or contoured in a manner such as to not permit a flat

support and therefore secure mounting of the FRONT RETURN SYSTEM.

N.B. always check before drilling, by placing assembled system close to the point where the hole for the various

fixings must be drilled and that there are no electrical wires near the holes or the point of union between the

various elements that make up the box.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 5/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 5

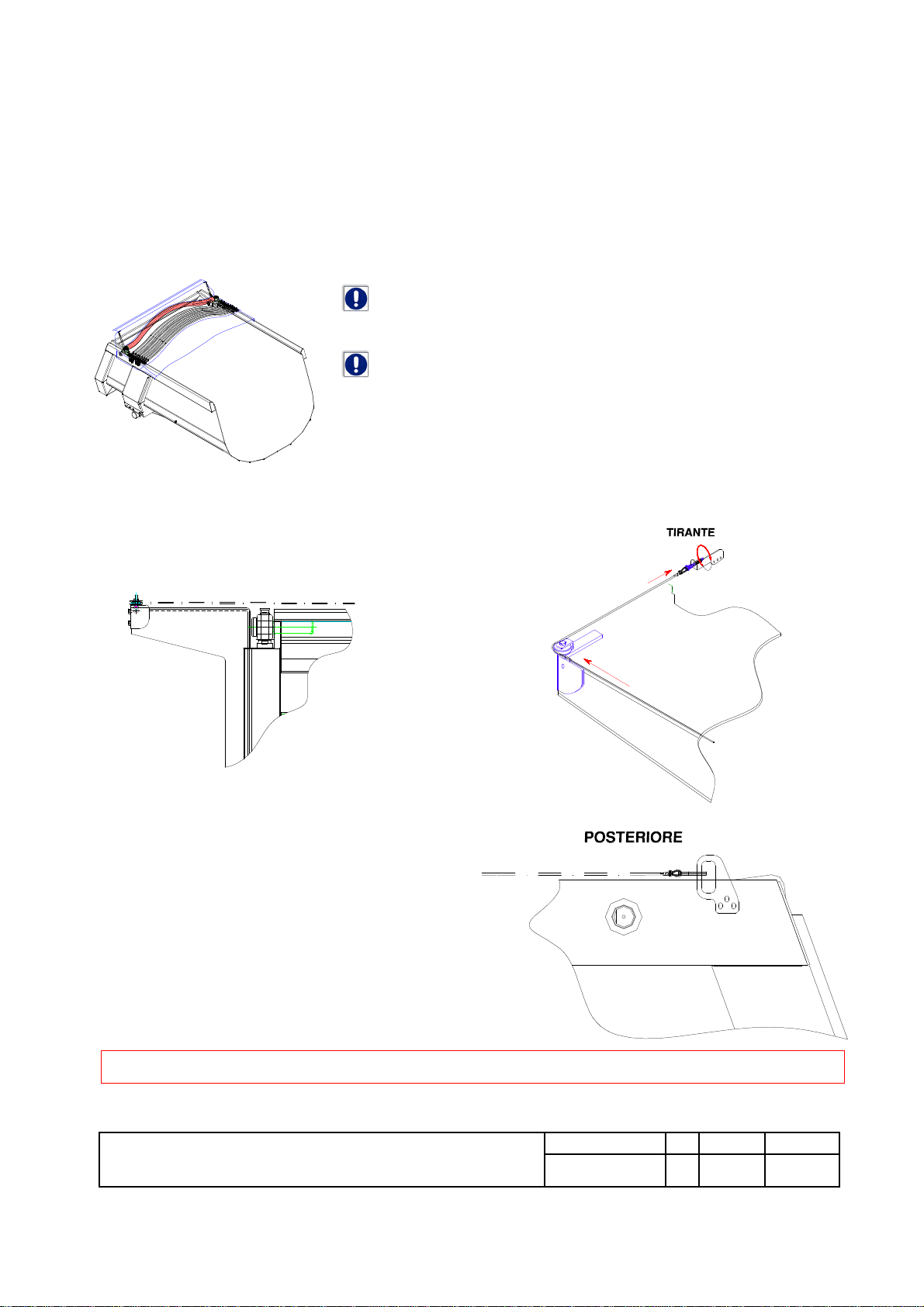

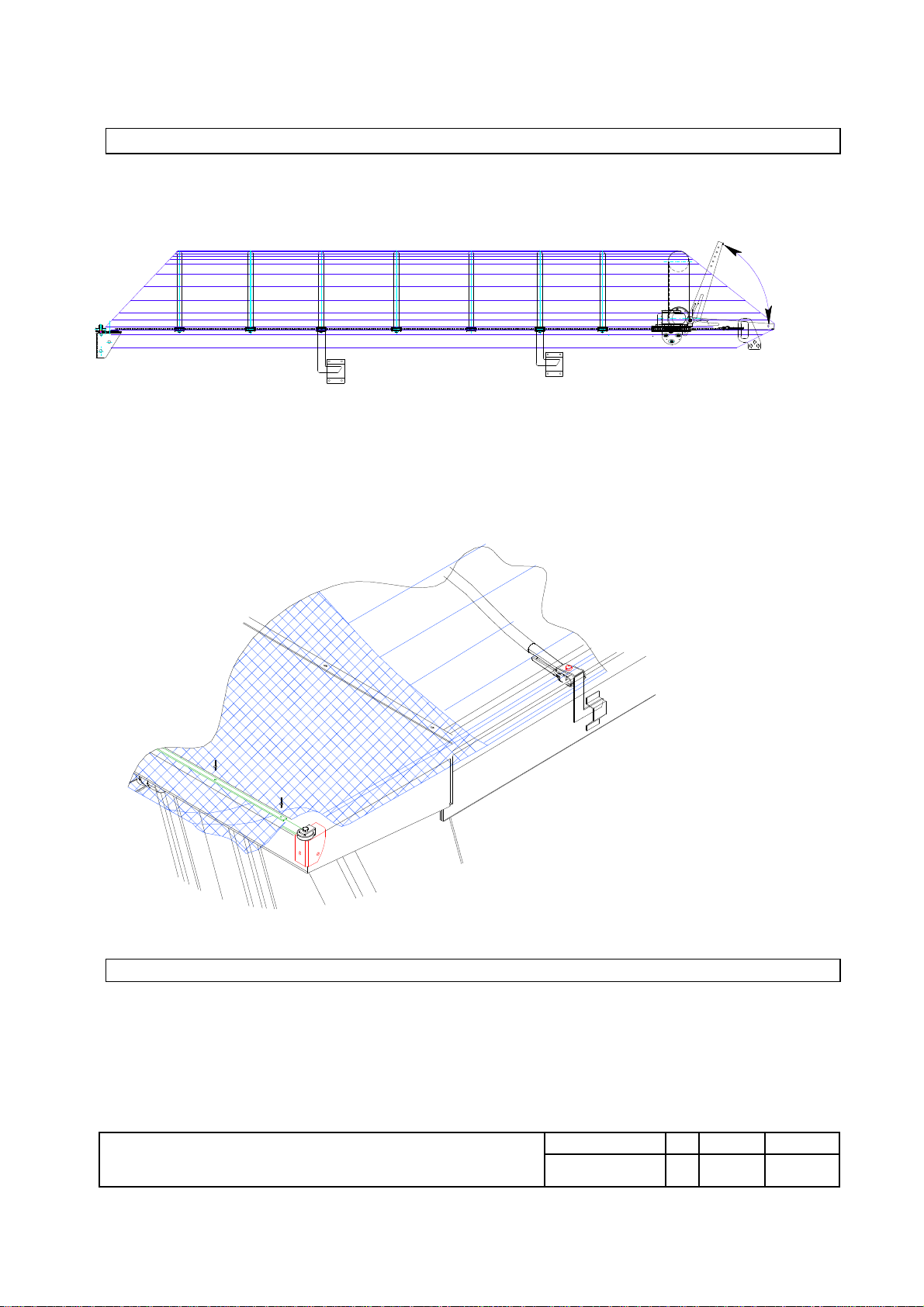

POSITIONING OF THE CANVAS AND ASSEMBLY WITH THE ACCESSORIES

The tarpaulin is normally supplied PRE-ASSEMBLED, or rather with the arcs already inserted

in the canvas, electrical connections already incorporated, the power supply cable already

inserted in the appropriate pocketwithin the tarpaulin andwith the various lateral anchorage

systems already assembled and ready to be fitted on the box.

DIAGRAM OF

CANVAS

POSITIONING PACKAGED ON THE BOX

Bind the canvas pack and arcs with a cord at the centre to avoid it

coming loose during the subsequent operations.

Turn the canvas pack over and position it on the box placing the

FLAP with the springs towards the rear edge.

Then proceed with attaching the front return systems and the rear

hooking kit.

(see diagrams)

FRONT

TENSIONROD

REAR

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 6/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 6

FF

The height of the front cables is automatically determined by the fixed position of the front return

pulleys, while in the rear part of the box, the cable supports must be positioned so that the cable

remains more or less at the height of the higherwire on the edges.

In this way, when the tarpaulin is completely compacted the cables both remain slightly below the

higher profile of the edges, thus becoming less subject to damage during the loading and unloading

phases of the vehicle.

After having fixed the cables in the rear hooks unravel the tarpaulin completely by supplying

current to the system and taking the motorised arc near to the rear of the box.

Spread the canvas thus assembled over the box by cautiously activating the (electric) movement until the last

arc of the tarpaulin is sent to the rear rebate ( 1) ( 2)

( 1) Check the rotation of the FLAP so that it falls exactly in line with the rear door.

( 2) If instead the tarpaulin has a “STANDARD REAR TAIL“ then position the motorised arc in the rearmost

position.

Assembly Assembly

with FLAP without FLAP

Then tighten the cables by using the system

of the front stays.

Check that the tensioning of the lateral cables is equal on both of the cables.

The check is conducted operatively by activating the opening and closing

movement of the tarpaulin itself; during this first test check that the

pulling cables do not slip on the central pulleys of the arc motor and that

these move in a uniform manner.

ATTENTION: THE CABLES MUST NOT BE TOO TIGHT AS

OTHERWISE MOVEMENT WOULD BE DIFFICULT AND THE

CABLES WOULD DETERIORATE QUICKLY.

Once the SLIDING cables of the tarpaulin have been provisionally tightened, one can

proceed with the complete assembly of the electrical system and the control unit of the tarpaulin.

TENSION ROD

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 7/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 7

1

2

3

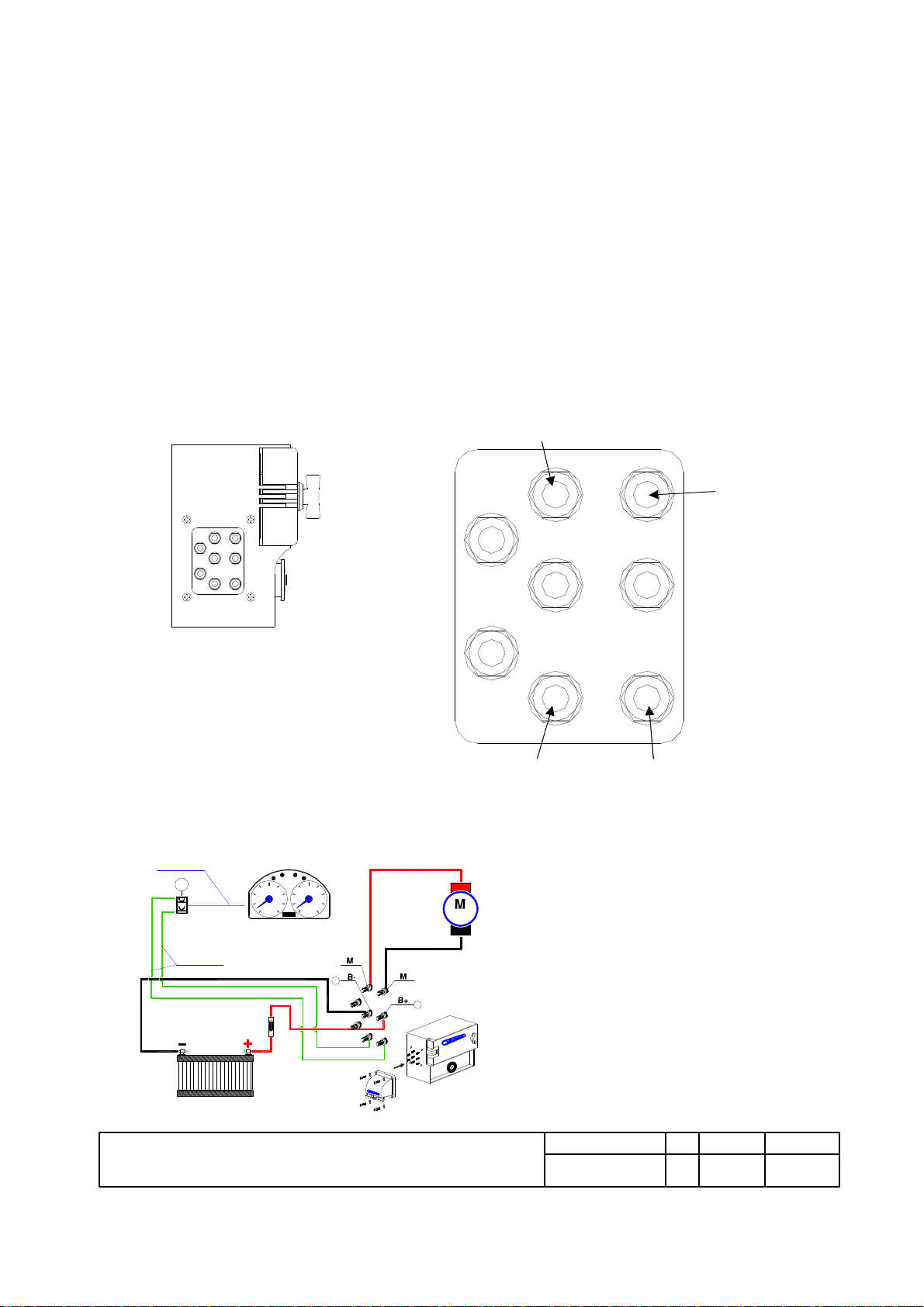

STD. CONTROL UNIT CODE 4WCE4C03031A

CONNECTION DIAGRAM

TO THE MOTOR

TO THE MOTOR

TO THE CONTROL

UNIT

1) CONTROL UNIT

2) BATTERY POWER SUPPLY CONNECTOR 3 ) ELECTRIC CONTACTS UNIT

CONTROL UNIT ELECTRICAL CONNECTION DIAGRAM

The control unit has 4 connection elements, 2 for the motor

and 2 for the battery. The connection must be carried out with two

electric cables, one of which is directed to the tarpaulin's motor,

while the other one is to the power supply circuit. Both cables are

tightened with cable glands inserted in a plastic boss with

a water-repellent gasket.

CONNECTION DIAGRAM

– CONNECTION:

Staple the FASTON cables with eyelet

on the cable whose insulation

has been removed beforehand.

Insert the FASTON cables

as shown in the figure and tighten the nuts.

Attach the plastic boss

with the 4 screws supplied and

tighten the CABLE-GLANDS.

12V 24V

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 8/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 8

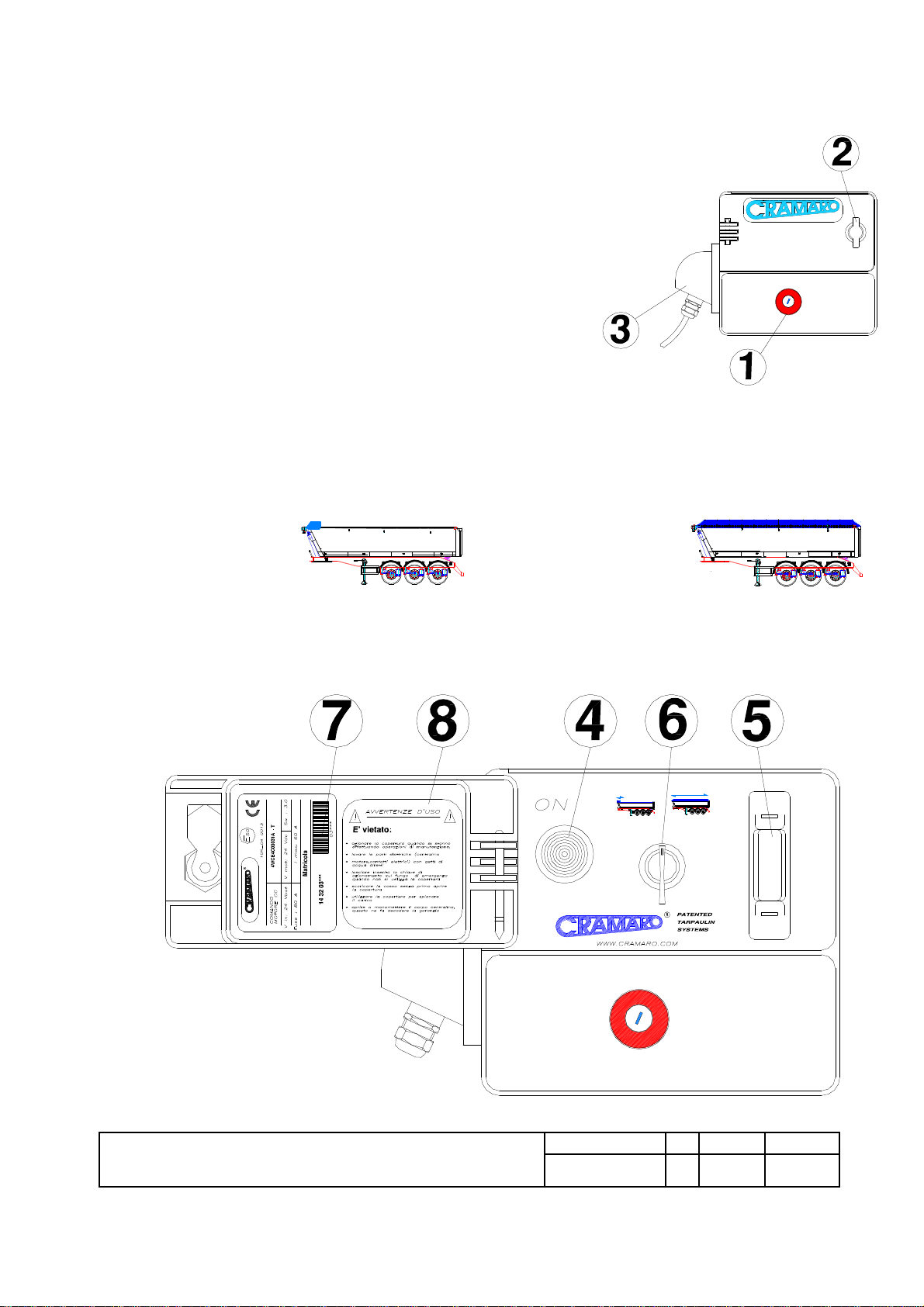

The control unit contains the following:

1emergency “MUSHROOM-SHAPED“ button

also used to start the control unit

( with REMOVABLE keys )

2Knob to open the door

that protects the control panel

3 Boss to protect electrical connections

Inside the cover of the control unit, instead, the control panel contains the following :

4Red warning light, on when the tarpaulin is moving

580 A fuse

6Spring-loaded operating switch:

- OPENING -

- CLOSING -

INTERNAL VIEW OF THE CONTROL PANEL

CRAMAR

RCRAMA

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 9/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 9

7Identification plate for the

control unit featuring the SERIAL NUMBER

(to be reported to Customer Service).

OPERATING WARNINGS

It is forbidden:

•to activate the cover when maintenance is

being performed.

•to wash electrical parts (control unit, motor,

electrical contacts) with direct jets of

water.

•to leave the activation key on the

emergency button when the cover is not

being used.

•to unload the box without first opening the

cover.

•to use the cover to smoothen the load.

•to open or tamper with the control unit

body, this renders the warranty null and

void.

8 Plate reporting the WARNINGS

.

indicating all of the most important instructions on using the

tarpaulin

N.B.

Thenewcontrolunit code

4WCE4C03031A

only works with the new transmitter code

405330211220

.

A

D

TRANSMITTER CODE

405330211220

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 10/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 10

TEST FUNCTIONS

The test function is useful to verify and diagnose the operation of the control unit

and the connection of the wiring during installation, even with the motor

disconnected. After having powered the control unit, having implemented the

learning process of the remote control and accessed the test function, you can

check the operation by selecting the button (or selector) that opens or closes the

cover; if the red LED inside the cover is on, the control unit and all the wiring is

working correctly.

For the control unit to be made active and operative, it is MANDATORY to switch

off and on by pressing the (red) mushroom-shaped emergency button.

The procedure to perform this kind of test is:

1.Press the (red) mushroom-shaped emergency button to switch the device off and wait at

least 1 second

2.Release the (red) mushroom-shaped emergency button to switch the device on again

3.Within 3 seconds after start-up, press buttons A and D on the remote control

simultaneously until the LED will light up for about 100 ms (wait for about 3 s). This

means that the control unit has is entered the learning mode.

4.Release buttons A and D on the remote control and wait at least 1 second; within 10

seconds, in the control unit learning mode, activate the test function.

5.Activate the test function as follows: press and hold the D button on the remote control

until the LED will be activated with two consecutive pulses of about 100 ms to indicate

that the control unit has successfully performed the function and exited the learning

mode

6.Select the cover opening or closing button (or selector) to verify operation. If the red

LED inside the cover is on, the control unit is running.

7.Switch the control unit off and on to make it active and operative by pressing the

(red) mushroom-shaped emergency button.

In the learning mode, the control unit can only perform one function at a time. The test

function cannot be enabled unless the remote control code is first saved.

Once you enter the learning mode, the control unit, will wait 10 seconds for a function to be

executed (learning-test-deletion). If no action is launched, once the 10 seconds elapse, the

LED will be activated with two consecutive pulses of about 100 ms and the control unit

will automatically exit the learning mode. When the control unit exits the learning mode, it

is automatically operational.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 11/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 11

Identify the new control unit CODE 4WCE4C03031A by looking at the label inside the

cover. The serial number is written in the lower left part and only a barcode is present

compared to the previous version

NEW LABEL

OLD LABEL

The control unit learning procedures are compatible with the 4-button remote control as

well as the 2-button remote control.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 12/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 12

FULL OPTIONAL CONTROL UNIT CODE 4WCE4C03032A

The controller unit called "FULL OPTIONAL" integrates the STD with the following additional

commands:

-PARTIAL OPENING (timed)

-CONTROL IN CABIN

-PARTIAL OPENING + CABIN CONTROL

-CONTROL FOR VIBRATOR

The FULL OPTIONAL control unit is only available with the 24V version

WIRING CONNECTION DIAGRAM

M

M

M=motor

AUX B=battery

CC=cabin control

B- B+ AP=partialopening

AUX=vibratorcontrol

+AP

CC CC

WIRING CONNECTION CONTROL DIAGRAM IN CABIN FOR DRIVING

IC= switch in the cabin, normally open and

with the positive connected in power (e.g.

on the dashboard)

FUSE

24 V dc

IC

MOTOR

MOTOR

MOTOR

BATTERY

+

BATTERY

−

2 x 2 mm2

2 x 2 mm2

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 13/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 13

WIRING CONNECTION CONTROL DIAGRAM IN CABIN FOR SEMI-TRAILER

IC= switch in the

cabin, normally

open and with the

positive

connected in

power (e.g. on the

dashboard)

WIRING

CONNECTION DIAGRAM FOR PARTIAL OPENING (TIMED 7 s)

IC = command from

PTOs with positive

connected in power

(e.g. on the

dashboard)

−

+

BATTERY

MOTOR

BATTERY

MOTOR

FUSE

24 V dc

IC

MOTOR

2 x 2 mm2

2 x 2 mm2

FUSE

24 V dc

IC

MOTOR

MOTOR

MOTOR

BATTERY

+

BATTERY

−

+

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 14/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 14

FUSE

24 V dc

MOTOR

MOTOR

MOTOR

BATTERY

+

BATTERY

−

WIRING CONNECTION DIAGRAM FOR VIBRATOR CONTROL

RELAY

The RELAY to be used to control the vibrator is the E T106A2 model of RAVIOLI

A 4-CHANNEL TRANSMITTER must be used to use the VIBRATOR CONTROL

B

A

D

C

Button A : cover activation - OPENING function

Button B : cover activation - CLOSING function

Button C : VIBRATOR activation

Button D : cover activation - CLOSING function (same function as button B)

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 15/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 15

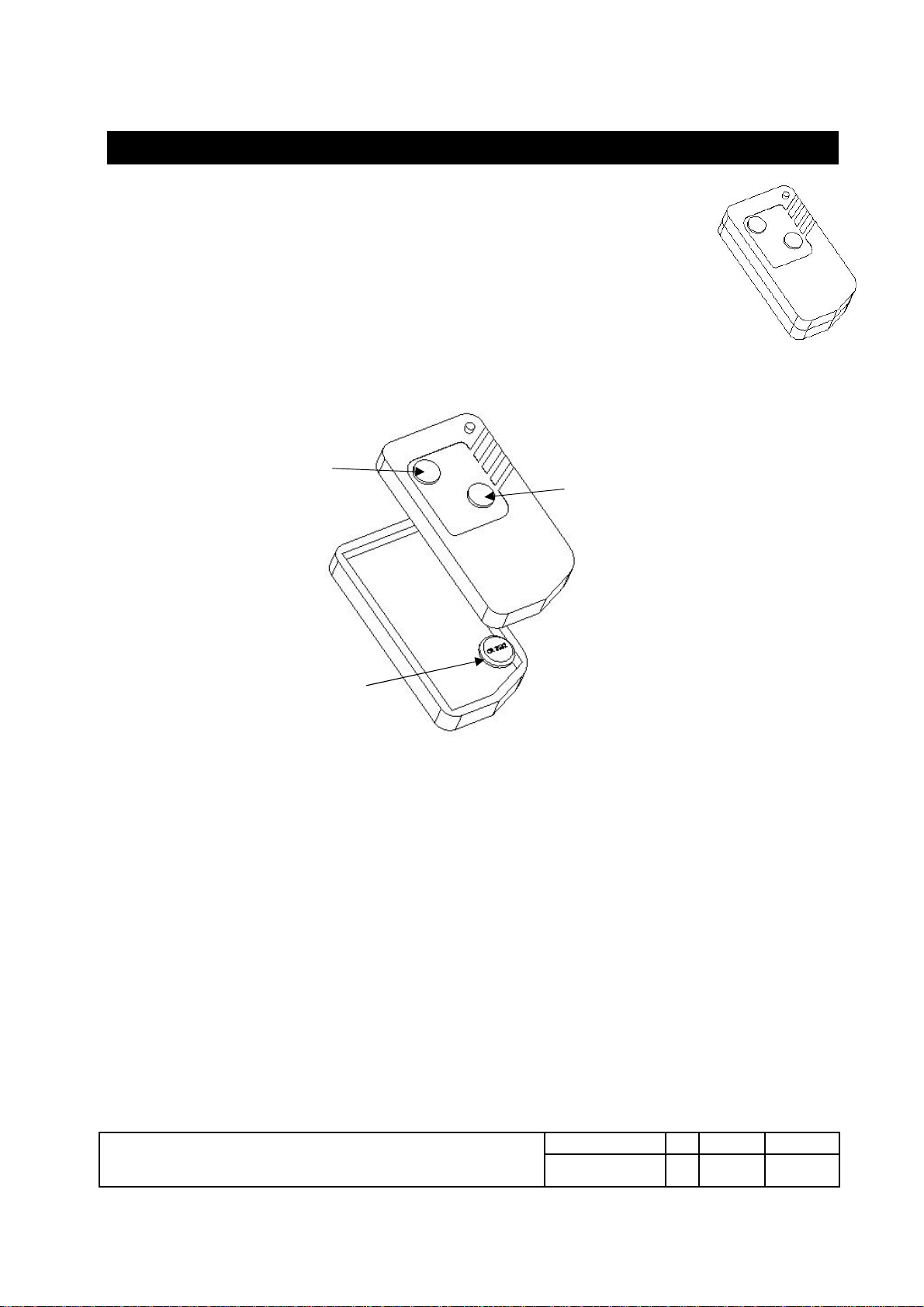

RADIO CONTROL (optional)

The control unit must be configured correctly to be able to use the radio

control. Below are the steps to recognise and save one or several radio

controls.

Learning how to use the Remote Control

The control unit can learn, i.e. it can recognise and save, a new remote

control. The control unit can associate up to 5 remote controls. When an

additional remote control is recognised and saved the oldest one is deleted.

A

D

1

Button A : cover activation - OPENING function

Button D : cover activation - CLOSING function

1 – battery CR 2032

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 16/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 16

Proceed as follows to recognise and save a new remote control:

1. Press the (red) mushroom-shaped emergency button to switch the device off and

wait at least 1 second

2. Release the (red) mushroom-shaped emergency button to switch the device on

again

3. Within 3 seconds after start-up, press buttons A and D on the remote control

simultaneously until the LED will light up for about 100 ms (wait for about 3 s). This

means that the control unit has is entered the learning mode.

4. Release buttons A and D of the remote control and wait at least 1 second;

within 10 seconds, in the control unit learning mode, activate the save function

of the remote control.

5. Save the remote control code: press and hold the A button on the remote control

until the LED will be activated with two consecutive pulses of about 100 ms to

indicate that the control unit has successfully performed the function and exited the

learning mode.

Repeat the steps above to recognise and save a new remote control..

IMPORTANT NOTE : You can only add one remote control at a time.

Deleting from the Control Unit Memory

The control unit's memory, used to recognise the remote controls, can be erased at any time.

Proceed as follows to erase the control unit's memory:

1. Press the (red) mushroom-shaped emergency button to switch the device off and

wait at least 1 second

2. Release the (red) mushroom-shaped emergency button to switch the device on

again

3. Within 3 seconds after start-up, press buttons A and D on the remote control

simultaneously until the LED will light up for about 100 ms (wait for about 3 s). This

means that the control unit has is entered the learning mode.

4. Release buttons A and D of the remote control and wait at least 1 second;

within 10 seconds, in the control unit learning mode, activate the code delete

function.

5. Deleting codes from the memory : press and hold the A and D buttons on the

remote control simultaneously until the LED will be activated with two consecutive

pulses of about 100 ms to indicate that the control unit has successfully performed

the function and exited the learning mode.

Replacing the operating battery

Replace the battery by opening the remote control and removing the fastening screw at the back with a

screwdriver. The battery model is CR 2032

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 17/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 17

+

−

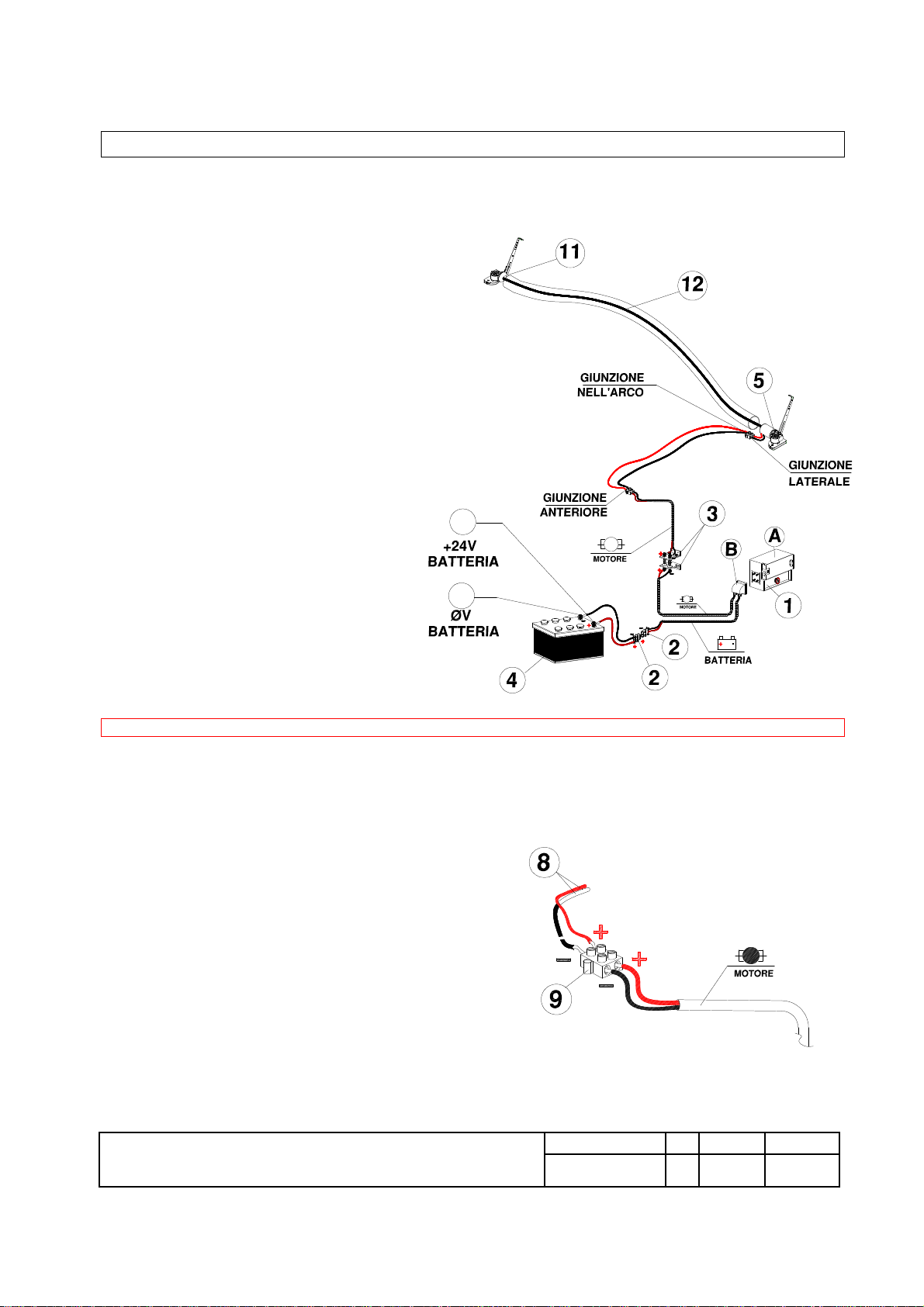

STD ELECTRICAL SYSTEM DIAGRAM

1 ) CONTROL UNIT

2 ) CONNECTION SOCKET + PLUG

3 ) ELECTRICAL CONTACTS

4 ) VEHICLE BATTERY

5 ) MOTOR REDUCTOR

6 ) LATERAL JUNCTION

8 ) 2 CABLES THAT PASS THROUGH THE ARC AND

IN THE LOWER POCKET OF THE TARPAULIN

9 ) FRONT JUNCTION

10 ) CONTROL UNIT CONNECTIONS COVER

11) REDUCER

12) ELEMENT OF TRANSMISSION REDUCERS

JUNCTIONIN ARC – LATERAL JUNCTION – FRONT JUNCTION – 24V BATTERY - MOTOR

The electrical cables (8) are inserted in the appropriate internal pocket of the tarpaulin, pas within the rear of the

arc and connected with the wires ( these also pass within the finalarc) that come from the motor placed at the

extremity of the same arc.The connection takes place through a multi-point terminal.

The control unit is usually positioned

on the side at the front of the chassis

(driver’s side) but may also be positioned

within the cab, in this case an express

request must be made in the order and the appropriate supplementary connection plugs will be provided in an

additional assemblykit.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 18/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 18

Cod 405260201010 = PLUG

Cod 405260201020 = SOCKET - HANDLE

Cod 405260202200 = ( SM ) MALE PIN (small)

Cod 405260202300 = ( SM ) FEMALE PIN (small)

CANVAS FIXING FRONT PART

Spread the tarpaulin completely above the box.

Spread, pulling the front part of the canvas gently, until it rests on the front edge of the box corresponding to the

furthestforward point possible. Fix the lateral parts of the canvas with the Teflon reinforcement (phed plate) with

the screws in the lateral supports of return mechanism; during this operation also position the pulleys protection

guard.

Finally rivet the remaining part of the canvas to the appropriate perforated aluminium plate and cut off the

excess part of the canvas.

PARTICULARS of the FRONT FIXING of the CANVAS

PHED PLATE

GUARD

PERFOIRATED ALUMINIUM PLATE

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 19/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 19

ASSEMBLY OF THE LATERAL RAPID HOOKS

Laterally the “GALOPPINO’“ tarpaulin in the – A – C – versions is anchored to the box by a certain number of

automatically activating metallic fixings.

These FIXNGS called “RAPID HOOKS“ are supplied with a further safety system or else cables and lateral

elastics.

RAPID LATERAL ANCHORAGES OF THE BAYONET TYPE

The rapid hooks for the GALOPPINO tarpaulin are of the BAYONET type, and the number provided is:

2 rapid hooks per

side: A LONG and a MEDIUM hook

FINISHING OPERATIONS AND PRE-UTILISATION CHECK

When all the operations indicated on the previous pages have been completed check that the entire system is

functioning well.

•The tarpaulin must slide when opening and closing without any particular effort or sticking in its

movement.

GALOPPINO

USAGE AND MAINTANENCE MANUAL

Manual n

o.

Ed. Date Pag.

MCA1001-EN-ED05 05 12/09/14 20/31

This document is the property ofCRAMAROTS s.r.l. andcannot be reproduced, even if only partially, without the written authorisation

of the company

Pag 20

•If the tarpaulin tends to stick and/or place itself transversely on the sides it means that the RH and LH

pulling cables do not have the same tension, consequently it is indispensable to adjust the tensioners of the

cables themselves.

REPLACEMENT OF THE PULLING MOTOR OF THE TARPAULIN

The replacement of the tarpaulin motor requires a fewsimple operations and can be done without removing the

tarpaulin from the vehicle.

I. Unhook the cable from the side of the motor to be replaced and remove it from the pulleys of the motor.

II. Lock the final arc to the box so that it cannot fall off and cause accidents to the operator.

III. Remove the screws holding the motor fixed to the final arc.

IV. Extract the motor from the final arc.

V. Remove the screws keeping the motor wires connected to the cable that passes within the arc, noting

the polarity (colour of the wires)

VI. Replace the motor with a new (or reconditioned) motor

VII. Reconnect the wires to the cable that passes within the arc, paying attention to the polarity (colour of

the wires)

VIII. Replace the motor in its housing within the final arc

IX. Check the distance of the lateral mountings of the motor from the lateral sides of the box and adjust it to

the original measure (if necessary)

X. Definitively tighten the screws that hold the motor attached to the final arc.

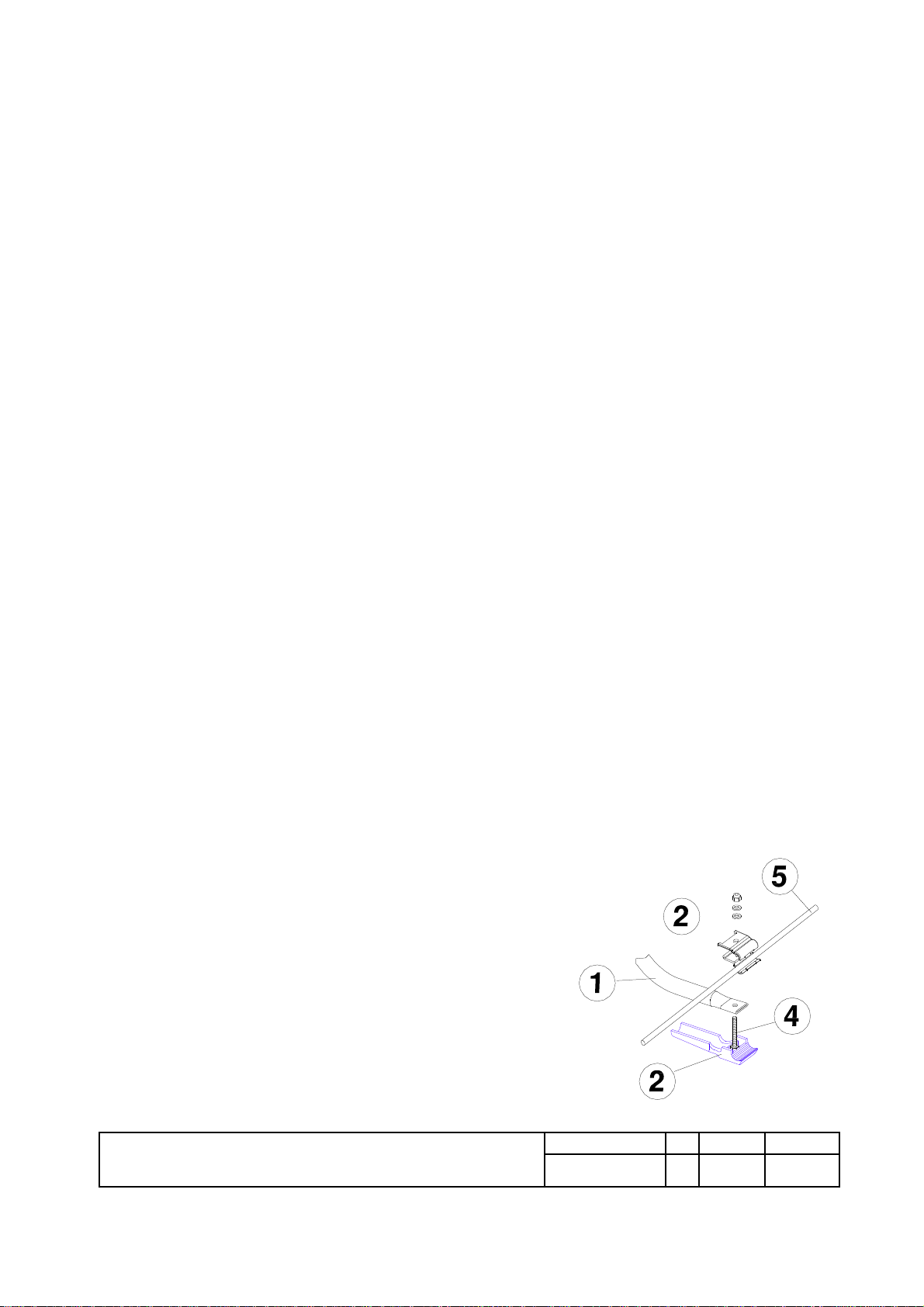

REPLACEMENT OF DAMAGED ARCS

The replacement of damaged arcs can also be carried out without having to remove the tarpaulin from the

vehicle.

If the terminal part of the arc is not damaged it is not even necessaryto remove the cables from the tarpaulin, it

will suffice once the arc to be substituted is identified to:

I. Remove the screws holding the arc fixed to the extremities equipped with a sliding shoe.

II. Undo the shoe and extract the arc from the lower pocket of the tarpaulin that normallyholds it.

III. Insert the new arc in the pocket of the tarpaulin paying

attention not to tear the tarpaulin.

IV. Refit the cables between the two elements of the

dismountable plug, fitting together the elements thereof,

and reassemble the shoe, plug and arc.

V. Check the distance of the lateral mountings of the arc from

the lateralsides of the box and adjust it to the original

measure (if necessary)

VI.

Definitively tighten the screws that hold the

shoe and

dismountable plug

attached to the arc

Table of contents

Other Cramaro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction