Denyo DLW-300LS User manual

No. D48443 02204A

Caution : Do not operate this machine before you

thoroughly read and understand this manual.

Always keep this manual near the machine.

HEAD OFFICE

2-8-5 Nihonbashi-horidomecho, Chuo-ku, Tokyo, 103-8566 Japan

TEL

+81 - 3 - 6861 – 1111

FAX

+81 - 3 - 6861 – 1181

Printed in Japan

Page No.

FOREWORD ----------------------------------------------------------------------- 1

1. SAFETY PRECAUTIONS ----------------------------------------------------------- 2

2. OUTLINE AND PART NAMES -------------------------------------------------------- 5

2-1 Outline Drawing and Name of Instrument ------------------------------------ 5

2-2 Name of Components -------------------------------------------------------- 5

2-3 Control Panel ------------------------------------------------------------- 6

3. TRANSPORTATION AND INSTALLATION ----------------------------------------------- 7

3-1 Caution in Transporting Machine ------------------------------------------ 7

3-2 Operating Angle ---------------------------------------------------------- 7

3-3 Preparations ------------------------------------------------------------- 8

3-4 Battery ------------------------------------------------------------------ 9

3-5 Battery Cable Connection ------------------------------------------------- 10

3-6 Fan Belt ----------------------------------------------------------------- 10

4. LUBRICATING OIL,COOLING WATER AND FUEL ---------------------------------------- 11

4-1 Engine Oil --------------------------------------------------------------- 11

4-2 Engine Cooling Water ----------------------------------------------------- 11

4-3 Fuel --------------------------------------------------------------------- 12

4-4 Fuel Consumption --------------------------------------------------------- 13

5. ENGINE PRESTART CHECKS -------------------------------------------------------- 15

6. STARTING AND OPERATING -------------------------------------------------------- 16

7. STOPPING THE ENGINE ----------------------------------------------------------- 18

7-1 Operating Precautions ---------------------------------------------------- 19

7-2 After Stopping ----------------------------------------------------------- 20

7-3 How to Use Automatic Air Bleeding Unit ----------------------------------- 20

7-4 Protection Device -------------------------------------------------------- 21

8. OPERATION OF THE WELDER ------------------------------------------------------- 23

8-1 Welding Cable and Polarities -------------------------------------------- 23

8-2 Selection of Welding Cable ----------------------------------------------- 24

8-3 Adjustment of Welding Current and Selection of Welding Mode -------------- 24

8-4 e mode Operation -------------------------------------------------------- 26

8-5 In Welding Operation ----------------------------------------------------- 27

8-6 Duty Cycle --------------------------------------------------------------- 27

8-7 Welding Mode Selector Switch and Arc Force Regulator --------------------- 28

8-8 VRD(Voltage Reduction Device) -------------------------------------------- 30

8-9 AC Power Supply ---------------------------------------------------------- 31

8-10 Earth Leakage Relay(Option) --------------------------------------------- 33

9. MAINTENANCE ------------------------------------------------------------------- 35

9-1 Routine Maintenance ---------------------------------------------------- 35

9-2 Engine Oil Filter -------------------------------------------------------- 37

9-3 Fuel Filter Element / Water Separator Element ---------------------------- 37

9-4 Air Cleaner Element ------------------------------------------------------ 38

9-5 Condenser ----------------------------------------------------------------- 38

10.TROUBLESHOOTING --------------------------------------------------------------- 39

11.STORAGE OF MACHINE ------------------------------------------------------------ 41

12.SPECIFICATIONS ---------------------------------------------------------------- 42

13.OUTLINE DRAWING -------------------------------------------------------------- 43

14.GENERATOR WIRING DIAGRAM ------------------------------------------------------ 44

15.ENGINE WIRING DIAGRAM --------------------------------------------------------- 46

16.ATTACHMENT -------------------------------------------------------------------- 48

- 1 -

FOREWORD

FOREWORDFOREWORD

FOREWORD

◆ This “ INSTRUCTION MANUAL ” gives a detailed description of the operation,

routine inspection, maintenance and trouble shooting of the diesel engine driven

DC Welder, and other items required for proper operation.

◆ Please read this manual carefully, especially the items with the caution marks.

◆ While the machine is placed for operation, please keep the instruction manual

near the machine.

◆ For the detailed operation and maintenance of the ENGINE, please refer to the

“Engine Operation Manual”.

Your Machine ; Model No. : DLW-300LS

Serial No. :

[ NOTE ]

[ NOTE ] [ NOTE ]

[ NOTE ] : There may be a difference between the specifications detailed in this

manual and the actual performance of the machine due to modifications

of the machine.

Symbol mark in this Manual

Symbol mark in this ManualSymbol mark in this Manual

Symbol mark in this Manual

DANGER

:

This symbol refers to a hazard or unsafe practice which can result

in severe personal injury or death.

CAUTION

:

This symbol refers to a hazard or unsafe practice which can result

in personal injury or product or property damage.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ]

:

This symbol shows handling precautions for effective operation and

many years of satisfactory operation.

- 2 -

The symbols shown below are used throughout this manual to call attention to and

identify possible hazards. When you see the symbol, watch out, and follow the

related instructions to avoid the hazard. Read and follow all Safety Standards.

Only qualified persons should install, operate, maintain, and repair this machine.

During operation, keep everybody, especially children, away.

DANGER :

ELECTRIC SHOCK CAN KILL.

Do not touch output

terminals

DANGER :

DIESEL FUEL CAN CAUSE FIRE

OR EXPLOSION.

during operation. This is extremely

dangerous when your hands are wet.

Stop the machine before you touch the

terminals for connection and other

purposes.

Fuel and oil are inflammable. Never fail

to keep in flammable material away from

the machine, never smoke while refueling

and never refuel during operation.

DANGER :

ENGINE

EXHAUST GASES CAN

KILL

CAUTION :

HOT PARTS CAN CAUSE SEVERE

BURNS.

Exhaust from the engine contains

substances harmful to the human body.

Sufficient change of air is necessary

when the machine is used in places

with poor ventilation, such as in a

tunnel or indoors. Do not direct exhaust

to passers-by or houses.

Do not touch, while operating the unit,

the engine cooling fan and other places

of high temperature like the exhaust

pipe, engine and radiator.

Even when the machine is stopped, take

care that the machine has cooled down

enough before touching the engine and

the like.

DANGER : NO CONNECTION TO HOUSE

WIRING

Connecting to house wiring is very

dangerous because it may cause electric

shocks and damage the machine.

CAUTION :

Do not touch moving parts

inside the machine. Stop the

engine when you do

maintenance.

DANGER : CONFIRM CONNECTION

Damaged cables and insufficient

tightening of connection screws may

cause damage to the machine and

electric shocks. Repair damaged

cables and ensure connections are tight.

- 3 -

CAUTION :

BATTERY ECTROLYTE CAN CAUSE

EXPLOSIONS OR BURNS.

CAUTION :

In case the battery liquid

(dilute sulfur acid)

happens to come in contact

Battery contains acid and generates

explosive gases. Handle battery carefully.

Stop engine before connecting or

disconnecting battery cables, and confirm

for correct polarity for connection on

battery. Do not allow tools to cause

short circuit accident due to contacting

to terminals. Flush eyes, skin and clothes

immediately with much water if battery

acid is attached.

with clothing or skin, you must immediately

rinse it out by using a lot of water.

If the battery liquid comes into contact

with your eyes, wash it out with lot's of

water and seek medical attention immediately.

CAUTION :

HOT COOLANT CAN CAUSE

SEVERE BURNS.

CAUTION :

ARC RAYS CAN BURN EYES AND

SKIN

Do not open the radiator cap, cooling

water drain plug, or engine oil drain

plug while engine is still hot. Hot

coolant or oil can burn face, eyes, and

hand.

When welding or watching, use a hand

shield or welding helmet fitted with

proper shade of filter. Wear protective

clothing and foot protection.

CAUTION :

Read the manual and use the

machine safely and properly.

CAUTION :

Overloading shortens the life

of the machine. Use the

machine

When you rent it to others or let others

use it, explain the instruction manual

in detail and advise users to read the

manual in advance.

with appropriate AC and DC current and

appropriate duty cycle.

CAUTION :

FALLING EQUIPMENT CAN CAUSE

DEATH ACCIDENT

CAUTION :

HIGH CURRENT CAN AFFECT

PACEMAKER

Take caution in transporting the

machine. Use a lifting equipment of

enough capacity.

Pacemaker wearers should not go near

arc welding operation before consulting

their doctor

- 4 -

CAUTION :

WELDING CAN CAUSE FIRE OR

EXPLOSION.

CAUTION :

Low voltage and frequency can

damage electrical equipment

such as Motors.

①

Remove all flammables where flying

sparks can strike. If this is not

possible, tightly cover them with

approved covers.

②

Watch for fire, and keep a fire

extinguisher nearby.

Take caution or disconnect AC loads when

engine is starting or running with idle

control switch in "ON".

CAUTION :

FLYING PIECES OF METAL or DIRT

can injure eyes.

Wear safety glasses with side shields

or face shield

- 5 -

2-1 Outline Drawing and Name of Instrument

① Control panel ⑥ Air intake ⑪ Oil drain

② Fuel tank inlet ⑦ Exhaust ⑫ Radiator inlet

③ Lifting hook ⑧ Ventilation ⑬ Lock

④ Door latch ⑨ Fuel drain ⑭ Ground Terminal

⑤ Bar(for rope) ⑩ Water drain ⑮ Wheel(option)

2-2 Name of Components

① Generator ⑥ Water Separator ⑪ Reserve Tank

② Diesel Engine ⑦ Oil Inlet ⑫ Battery

③ Air Cleaner ⑧ Oil Filter ⑬ Voltage Reduction Switch

④ Fuel Tank ⑨ Oil Level Gauge ⑭ Fuse

⑤ Fuel Filter ⑩ Radiator ⑮ Fuel Priming Lever

- 6 -

2-3 Control Panel

①

AC Voltmeter ⑩

e-Mode Selector Switch

②

Welding Mode Selector Switch (VARIABLE, LOW/HIGH, HIGH)

③

Current Regulator ⑪

※ 1-Phase AC output Receptacle

④

AC Circuit Breaker ⑫

※ Earth Leakage Relay

⑤

Arc Force Regulator ⑬

※ 1-Phase AC output Terminal

⑥

Starter Switch ⑭

※ Ground terminal(for ELR)

⑦

DC Welding Output Terminal (+,-) ⑮

※ Remote Control Switch

⑧

3-Phase AC output Terminal ⑯

※ Remote Control Receptacle

⑨

Engine Monitor ※ Option

Warning Lamp Unit

(Oil Press./Water Temp./Control Unit temp./Charging/Preheat)

Frequency Lamp

Hour MeterFuel Meter

- 7 -

3-1 Caution in Transporting Machine

Caution : When transporting and lifting the machine, lift it at the lifting hook which is

located at the center of gravity on the top panel.

3-2 Operating Angle

Make sure the machine is placed on level foundation or ground. Do not operate the machine on

place with inclination of more than 5 degrees, or engine damage will occur.

- 8 -

3-3 Preparations

This machine has undergone stringent factory tests and inspections to ensure the

machine performs in accordance with its specifications, before been shipped

to the end user.

As with any piece of motorized machinery, excessive use of a brand new machine

may shorten the life of the machine. Therefore, it is recommended for the initial

50 hours of machine usage, special care is required for this break-

in period.

Upon receipt of the machine, please perform a maintenance check of the machine

BEFORE USE, so as to further ensure there are no major malfunctions or damage

to the machine that occurred during transit.

We recommend the machine be placed upon a level surface, where there is not

excessive dust or moisture.

When using the machine in places where there is inadequate ventilation, make sure

the following care is taken:

Notice for Installation.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Avoid using the machine in places of high humidity.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Avoid using the machine in places where the surrounding

temperature is likely to rise over 40 degrees Celsius.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Avoid using the machine in places where there is excessive

dust, noxious gases and explosive gases.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Provide adequate space for machine inspection and maintenance.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Do not have any obstacles within a 1 meter from the machine.

Failing to do so, may cause the machine to overheat.

- 9 -

3-4 Battery

Proper maintenance of the battery is extremely important to ensure smooth

starting and long service life. Check the specific gravity, level of electrolyte

and output voltage every 50 hours or once every month.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : The electrolyte must always cover the plates. If the plates are

exposed to air for a long time, damage will result.

(1) Battery Check

◆ Always ensure the level of electrolyte is always maintained above the

low level mark. If the electrolyte level is low, distilled water should

be immediately supplied to the battery.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Do not refill the battery over the upper level mark. Always

remember to tighten the battery cap properly after refilling

the battery.

◆ Measure the battery gravity if there is a suspicion that battery leakage

has occurred especially where there have been instances where the

machine would not start.

◆ The relationship between Battery Gravity and Battery Charging at 20 ℃.

Battery Gravity

Battery Charging

over 1.28 over charged(need adjustment)

1.25 - 1.28 optimal charging

1.24 - 1.25 average

below 1.24 low charged(need adjustment)

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : In determining the specific gravity at a temperature other

than 20 ℃, use the following formula:

.

Where : is the calculated specific gravity at 20 ℃.

: is the measured specific gravity

: is the battery solution temperature reading.

- 10 -

3-5 Battery Cable Connection

◆ Make sure the battery cables are properly connected to battery terminal

(+) and (-).

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : If the cable is connected incorrectly, damage to the electrical

parts will result soon.

◆ See the starter switch is “OFF” before connecting the battery cables.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Do not connect the cables to the battery terminal when the

starter switch is“ON”, because electric sparks will be produced.

This may injure the operator and cause damage to the machine's

electrical components.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : It is recommended that a thin film of grease be applied to the

battery terminals to ensure a good connection and the prevention

of corrosion of the battery terminals. An insufficient sufficient

or poor connection may cause poor starting of the machine and

other malfunctions to occur.

◆

Connect (-) Cable Last.

3-6 Fan Belt

Check the belt for tension and looseness and adjust them as

required. Also, check that the belt has not been damaged and

immediately replace it if any abnormality is noted on the belt.

Perform the adjustment and replacement as directed in

the “Instruction Manual” provided by the Engine

Manufacturer.

Fan Belt : Parts No. Y 060 20 152 90

- 11 -

4-1 Engine Oil

Open air temp.(℃

)

-30 -20 -10 0 10 20 30

◆ The lubricating o

il used influences engine

performance, starting characteristic and

ultimately the life of the engine.

We recommend that the appropriate, good

quality, lubricating oil be used.

(1) We recommend that “CD class”

lubricating

oil be used ( API service grade ).

(2) We recommend the use of SAE10W-30 all season type of engine oil

viscosity. The viscosity of the oil to be used is dependent on the

external temperature. Refer to the table to select oil.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Do not pour in different kinds of oil as it will change the oil

quality which will have a detrimental effect on engine performance.

If you want to add in a different type of oil, you must first drain

the oil already in the engine completely.

(3) The total oil change capacity is 3.5 litters.

4-2 Engine Cooling Water

(1) Use only soft water for cooling water. For example, tap water that is

of good quality can be used.

(2) If the machine is to be used in cold areas, especially where there is a

risk of freezing, long-life, anti-freeze, coolant ( LLC ) should be used.

( This machine when delivered ex-factory, the radiator cooling water

contains 30 % long life coolant. )

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : The recommended ratio of LLC to be used is between 30 % - 50 %

range.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : The following is the recommended of LLC to be used for below

mentioned temperature:

- 30 % : down to -10 ℃

- 40 % : down to -20 ℃

- 50 % : down to -30 ℃

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : The LLC should be changed at least every 2 years.

(3) The total cooling water capacity is 3.15 litters.

( This does not include the cooling water reserve tank. )

① For the proper use of LLC carefully follow the instructions given by

the LLC manufacturer.

② During cold periods and LLC is not used, the cooling water should be

drained, including the reserve tank cooling water before adding in the

LLC at the appropriate ratio in relation to the prevailing temperature.

- 12 -

4-3 Fuel

(1) Use ASTM No.2 Diesel Fuel

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : If other than the recommended type of fuel is used, it can

bring about a undesirable result to engine for its output

performance, length of life, etc.

(2) Use JIS special No.3 diesel fuel.

JIS No.2 Diesel Fuel : down to - 5 ℃

JIS Special No.3 Diesel Fuel : down to -25 ℃

(3) The Fuel tank capacity is 36 litters.

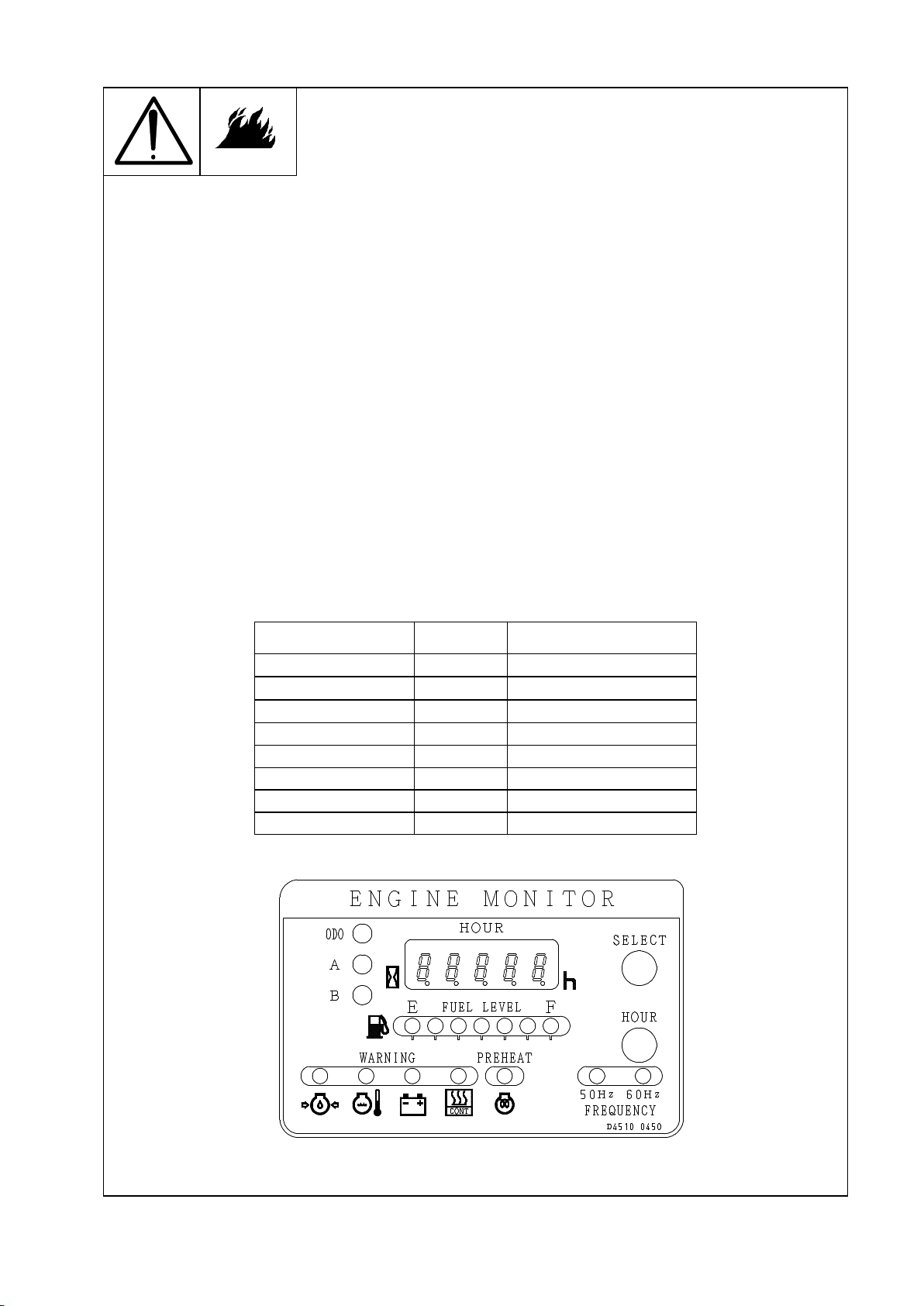

(1) Before starting the machine, check to see that fuel is sufficient by the engine

monitor.

(2) While fuel is full in the installed tank, all of green lamps are on. Numbers of lamps

decrease as remaining fuel amount decrease. Color of lamps also change from green

to red following decrease of remaining fuel amount. Fill fuel when only one lighting

lamp is left. A cor

relation between numbers of lighting lamps and remaining fuel amount

is roughly like the below chart.

The number of lamp

Lamp color

Fuel residual quantity

7 Green 32Full

6 Green 2832

5 Green 2428

4 Green 2024

3 Green 1620

2 Green 1316

1 Green 1013

1 Red 010

- 13 -

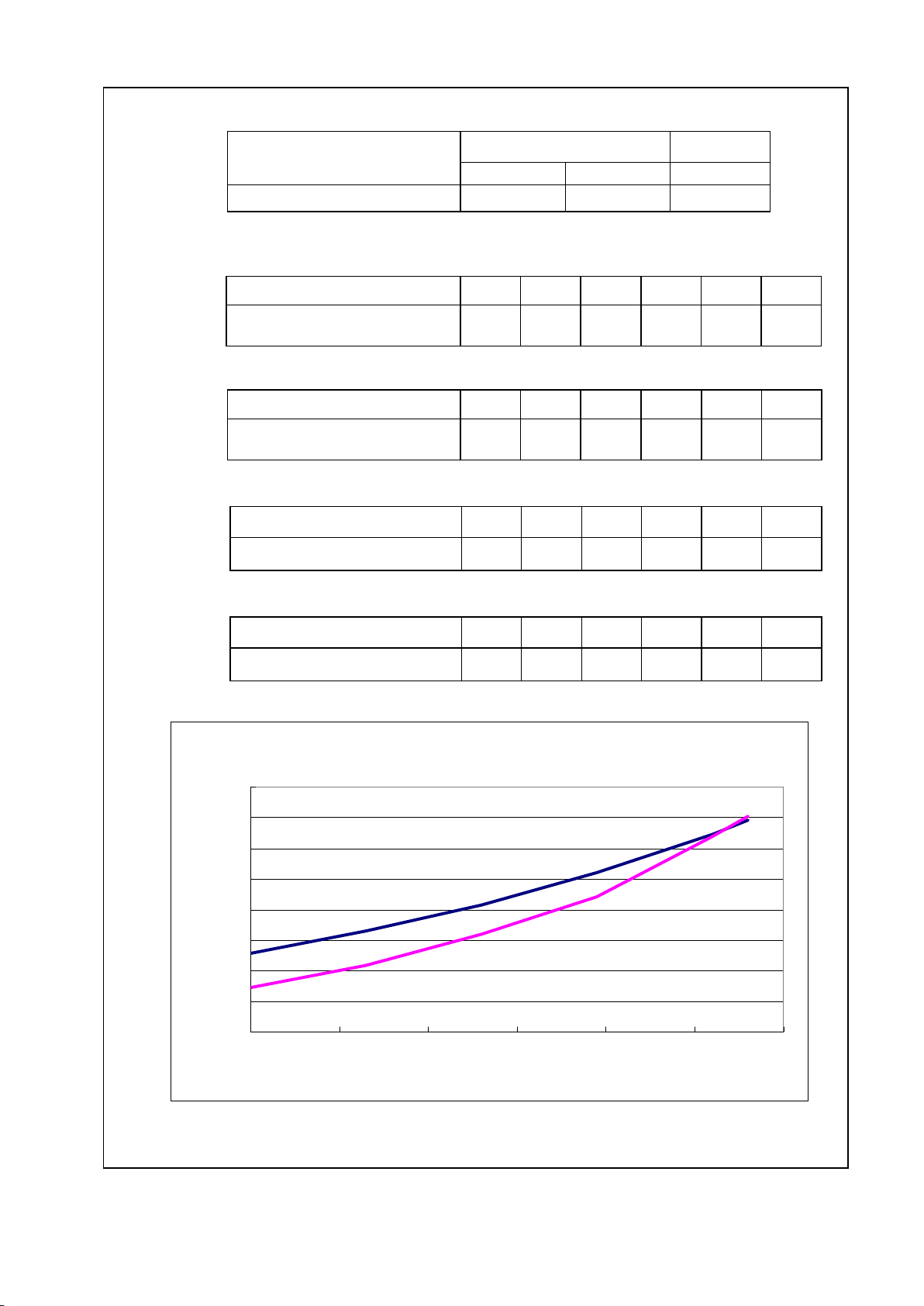

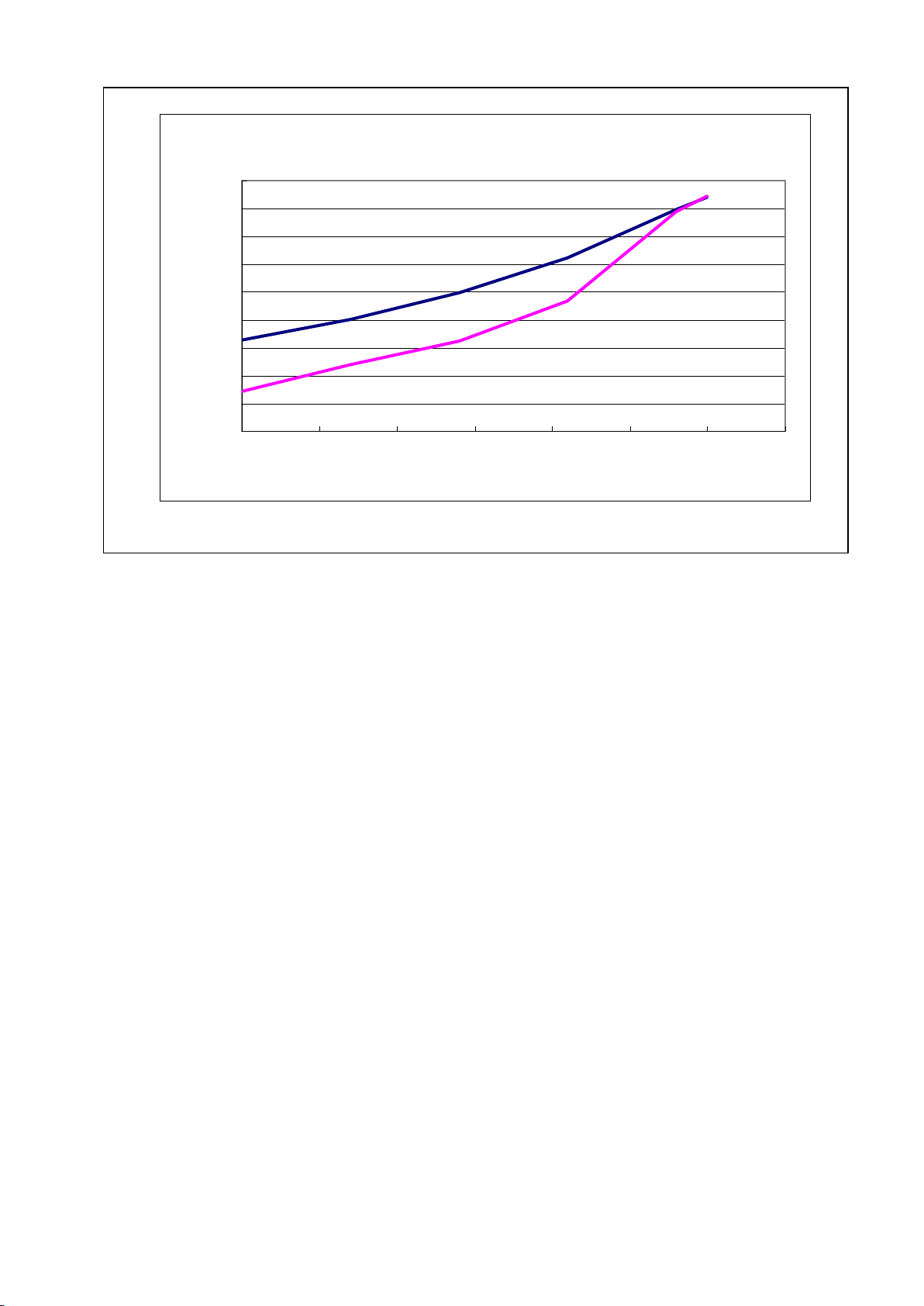

4-4 Fuel Consumption

(1) No Load

High Low

No Load

(3000min

-1

) (3600min

-1

) (2000min

-1

)

Fuel Consumption (L/h) 1.28 1.65 0.72

(2) Load

High[50Hz]

Amperes (A) 0 65 130 195 260 280

Fuel Consumption (L/h) 1.28 1.64 2.07 2.60 3.23 3.45

High[60Hz]

Amperes (A) 0 70 140 210 280 300

Fuel Consumption (L/h) 1.65 2.01 2.49 3.12 3.98 4.21

Variable[50Hz]

Amperes (A) 0 65 130 195 260 280

Fuel Consumption (L/h) 0.72 1.19 1.59 2.21 3.20 3.52

Variable[60Hz]

Amperes (A) 0 70 140 210 280 300

Fuel Consumption (L/h) 0.72 1.20 1.63 2.34 3.95 4.22

Fuel Consumption (50Hz)

Fuel Consumption (50Hz)Fuel Consumption (50Hz)

Fuel Consumption (50Hz)

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

0 50 100 150 200 250 300

DCWeld Amperes at 100% duty cycle [A]

Fuel Consumption [L/h]

High

HighHigh

High

Variable

VariableVariable

Variable

- 14 -

Fuel Consumption (60Hz)

Fuel Consumption (60Hz)Fuel Consumption (60Hz)

Fuel Consumption (60Hz)

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

0 50 100 150 200 250 300 350

DCWeld Amperes at 100% duty cycle [A]

Fuel Consumption [L/h]

High

HighHigh

High

Variable

VariableVariable

Variable

- 15 -

◆ Check the positions shown under before starting.

- 16 -

◆ Before starting the machine, the pre-starting safety checks must be completed.

In addition, do a general survey of the area surrounding the machine making

sure the area is safe, air vents of the machine are not blocked and the exhaust

can freely be discharged.

The machine can be started, once the people surrounding the machine have been

notified that the machine is going to be used.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : In cold operating conditions, use suitable cooling water and

lubricating oil for improved starting and prevention of any

troubles. The battery must always be maintained at full

charging level.

(1) Check whether the breaker is at the “OFF” position.

(2) Turn the “e Mode Selector Switch” to select VARIABLE or HIGH/LOW.

(3) Insert the key into the “Starter Switch”. When turn the key to

the "RUN-Heat" position, the indicator lamp acts as a

"Oil indicator" and "Charge indicator". If the indicator lamp

don't come on, inspect the electric bulb of indicator lamp or

the fuse.

(4) Turn the key to the“Start”position to start the engine.

As soon as the engine starts, release the key where by the

key will automatically return to the “Run”position.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : Key switch will automatically return to “Run-Heat” position

after the engine has started.

If the key switch did not return automatically, return it

manually to prevent damage to the starter.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : During winter or when the surrounding air temperature is cold, in

situations where a load start is required, turn the key to the

“Pre-heat position”, you must wait until the engine indicator

lamp goes off.

(5) In situations where the sounds of the engine turning over cannot be heard in trying

to start the machine, repeat the starting procedure from the beginning in accordance

with the Operation Manual, after about 30 seconds.

If the machine fails to start despite repeating the starting procedure, there is obviously

some problem with the machine.

Therefore a thorough check is required ( e.g.: Fuel has run out, forgetting to turn

the fuel cock to the open position, excessive air in the fuel system and battery leakage )

- 17 -

(6) After the engine starts, let the machine idle 510 minutes to warm-up.

And the engine rotates high speed for a few seconds immediately after the engine starts,

if the “e Mode Selector Switch” is in VARIABLE or HIGH/LOW.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : While the engine is operating, do not turn the starter switch on.

(7) Carefully check the engine for abnormal vibration ( noise ), oil leakage,

fuel leakage, cooling water leakage and air leakage. If the machine is operating

normally, set the “Circuit breaker”to the ON position in order to supply

electricity to the load.

(8) Do not have any of the doors of the machine open while operating. The main problems

with leaving the doors of the machine open during operating, are the effect on the internal

cooling air-flow of the machine and alien substances ( e.g. dust and dirt ) will be

drawn into the machine.

(9) After the engine in started, check to see that the oil pressure lamp and battery

charging lamp are off. If one of these lamps are on, check the machine after the engine

is turned off. (Refer to the Operation Manual for details)

(10) While the engine is operating, check the Hour Meter operating. When turn the key to

the “Start” position, the Hour Meter operating.

- 18 -

(1) Turn the load side's circuit breaker to the“OFF”position.

(2) Turn the circuit breaker on the machine to the“OFF”position and let

the engine idle for five minutes, so as to allow the engine to cool

down. After the five minutes idling period is over, turn the key to the

“OFF”position.

(3) Remove the key out of the starter switch. Make sure the key, when the

machine is not use, is kept in safe.

(4) Turn the fuel filter cock to the “Close”position.

(5) Disconnect the wiring and plug(s) from the AC Power connections.

(6) Make sure the machine is not exposed to moisture. It is important that

the machine be kept dry when not in use.

(7) To keep the machine in good working order, do not leave the machine

exposed to the elements and cover it using a sheet, when the machine

is not been used.

[ NOTE ]

[ NOTE ][ NOTE ]

[ NOTE ] : In the unlikely occurrence of the engine not stopping when the

key is turned to the “OFF”position, there is a way of

stopping the machine. Please refer to the following diagram

and explanation.

Turn the fuel filter cock to the “Close”position.

Closing the fuel filter cock cuts the supply of fuel to the

engine and the engine will take a few minutes to come to a stop.

This should only be done in case of an emergency.

Table of contents

Other Denyo Welding System manuals

Popular Welding System manuals by other brands

Lampert

Lampert PUK 3s professional operating instructions

SHARKS

SHARKS Super power IGBT 190A Instruction for operation and maintenance

widos

widos HRG 10 Working Instructions Translation

GYS

GYS KRONOS 250M manual

Kemppi

Kemppi MASTER MLS 1600 Operation instructions

Hobart Welding Products

Hobart Welding Products Champion Elite owner's manual