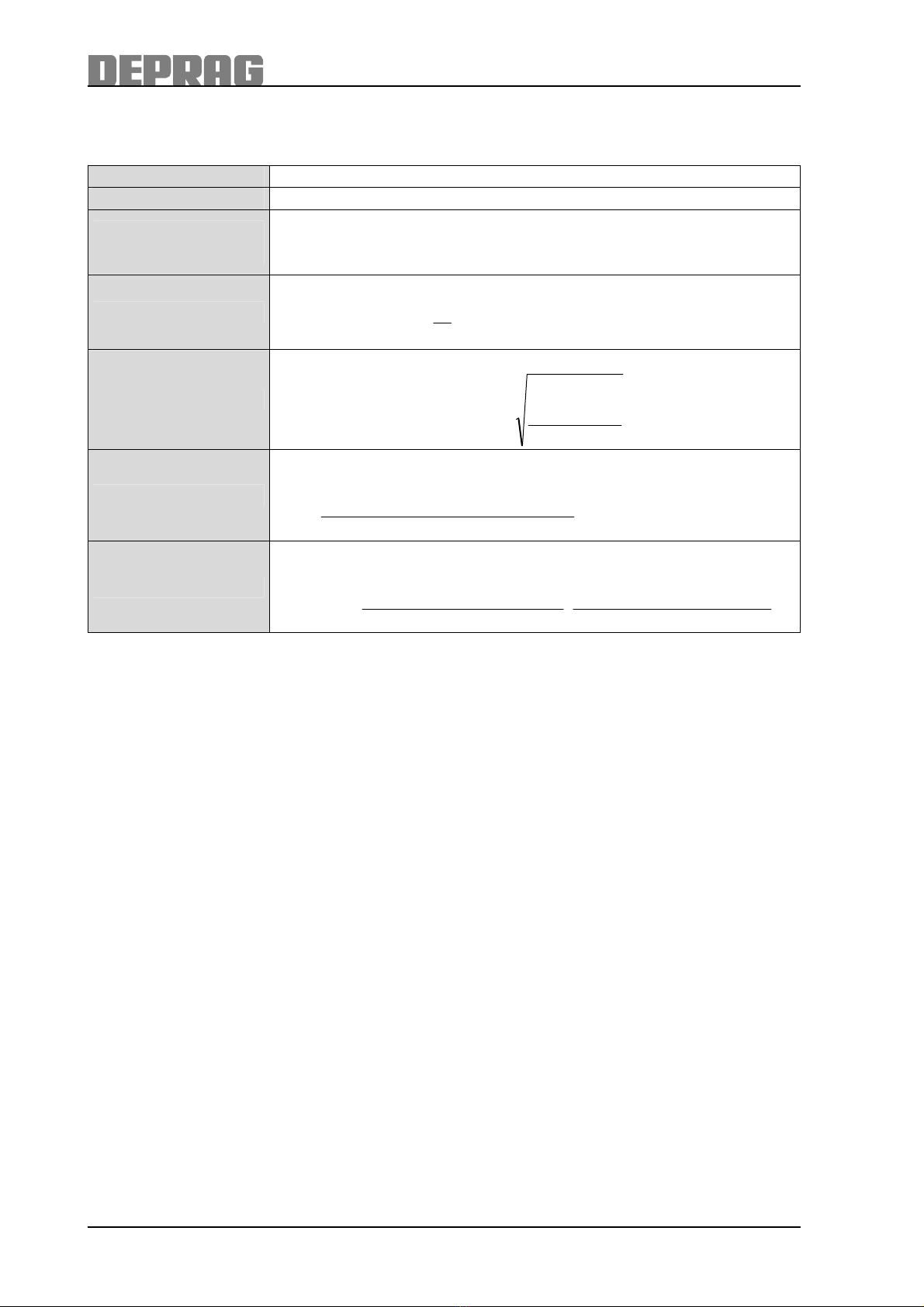

4

Table of Figures

Picture 1: Top view of the ME6000............................................................................................9

Picture 2: Front view with LEDs...............................................................................................10

Picture 3: Rear view with connectors ......................................................................................11

Picture 4: Main program ..........................................................................................................20

Picture 5: Settings for DMS sensor .........................................................................................21

Picture 6: Settings for a different manufacturer’s DMS sensor................................................21

Picture 7: Settings for piezo sensor.........................................................................................21

Picture 8: Settings for external transducer ..............................................................................22

Picture 9: Settings for a different manufacturer’s external transducer.....................................22

Picture 10: Graph with default settings..................................................................................23

Picture 11: Graph with delay = 5 ...........................................................................................23

Picture 12: Graph with delay = 5 and trigger = 25%..............................................................24

Picture 13: Example of measurement with limit value monitoring .........................................25

Picture 14: Choose the measurement unit ............................................................................25

Picture 15: Dropdown menu to choose the measurement unit..............................................25

Picture 16: Choosing measurement by START and STOP ...................................................26

Picture 17: Choosing automatic measurement......................................................................26

Picture 18: popup-window for setting the limit values............................................................27

Picture 19: Choosing series measurement............................................................................27

Picture 20: Setting the amount of measurements within a series..........................................27

Picture 21: Series measurement ...........................................................................................28

Picture 22: Minimise ME6000 program .................................................................................28

Picture 23: Minimised ME6000 program ...............................................................................28

Picture 24: Maximise ME6000 program ................................................................................29

Picture 25: Graph display ......................................................................................................30

Picture 26: Magnify tool .........................................................................................................30

Picture 27: Marking an area to enlarge .................................................................................31

Picture 28: Magnified graph display ......................................................................................31

Picture 29: Display graph in original size...............................................................................32

Picture 30: Display scale .......................................................................................................32

Picture 31: Graph display with scale displayed .....................................................................32

Picture 32: Mark point on the graph ......................................................................................32

Picture 33: Graph display with three markers set..................................................................33

Picture 34: Delete last set marker from the graph .................................................................33

Picture 35: Open a saved graph............................................................................................33

Picture 36: Choosing a graph ................................................................................................34

Picture 37: Saving a Graph ...................................................................................................34

Picture 38: Choose where to save graph ..............................................................................35

Picture 39: Save the graph display........................................................................................35

Picture 40: Choosing where to save the graph display..........................................................35

Picture 41: Print the graph display.........................................................................................36

Picture 42: Copy the graph display into the clipboard ...........................................................36

Picture 43: Statistics ..............................................................................................................38

Picture 44: CMK settings .......................................................................................................39

Picture 45: Absolute value for upper and lower limits............................................................39

Picture 46: Deviation from average for upper and lower limits in percentage .......................39

Picture 47: Delete individual measurement values................................................................40

Picture 48: Choosing where to save measurement results ...................................................41

Picture 49: Instantaneous value display ................................................................................42

Picture 50: Select Language, Limit and other settings ..........................................................43

Picture 51: Setting the calibration values ..............................................................................45