Deramp Altair 8800c User manual

Page 1

Altair 8800c Front Panel Board Set

Ver 1.2, Feb 2019

Introduction

The Altair 8800c front panel

board set is a drop-in re-

placement for the original Al-

tair 8800 front panel board.

The ne board set as creat-

ed for the follo ing reasons:

1) Availability

Finding an original front panel board to restore

or build an Altair is nearly impossible. The ne

board set provides a drop-in equivalent that is

readily available.

2) Elimination of the Hand Wired Harness

The original front panel board picked up bus sig-

nals and connected to the CPU board through a

large hand- ired harness. This harness as te-

dious to build and as often a reliability issue –

especially if you had to remove and ork on the

front panel board. The 8800c board set replaces

the hand- ired harness ith a 50 pin ribbon ca-

ble that connects to a bus interface board (sho n here) to pick up and drive the required bus signals.

3) Mechanical Compatibility with the Altair 8800 Clone Cabinet

The original Altair 8800 cabinet made by Optima is no longer manufactured, and like the original

front panel board, finding an original cabinet by itself is nearly impossible. As an alternative, the cab-

inet for the Altair 8800 Clone is still available, ho ever, the original front panel board covers mount-

ing points in the Clone cabinet’s front panel bracket. This ne front panel board is designed to fit

properly in the Clone cabinet’s mounting bracket. The ne front panel board also fits in an original

Altair cabinet.

4) Compatible with the 8800b CPU Board

The original front panel board does not ork ith an Altair 8800b CPU board and vice-versa. This is

due to a change in ho the 8800b front panel injects data into the CPU and ho it stops the CPU. For

increased flexibility, the ne front panel set orks ith both the original and the 8800b CPU boards.

5) Logic Error Fixes

The original front panel board had a fe logic problems that are fixed in the ne front panel board

set. These same problems ere also fixed by MITS hen they designed the 8800b computer.

CPU “Stop” Timing Error

The Stop s itch is designed to put the 8080 into a ait state on an instruction fetch bounda-

ry (the M1 cycle). Ho ever, due to a timing issue in the run/stop circuit, the front panel

doesn’t al ays stop on an M1 cycle.

Page 2

Indeterminate Power On State

On po er-on, the run/stop flip-flop on the front panel board is not initialized and the 8080

processor is not given a reset signal. These omissions tend to leave the 8080 in an invalid

state on po er-on. This is hy the “STOP/RESET” s itch sequence is required to put the

computer into a valid state. This fix can be optionally enabled or left like the original.

Reset not Synchronized with phi2

An undocumented 8080 reset timing requirement is that reset be released a minimum of

about 200ns prior to the rising edge of phi2. This is implemented in the Intel 8224 clock gen-

erator that as used on the 8800b CPU board, but this chip is not used on the original Altair

CPU board. The ne front panel board enforces this timing for resets generated by the front

panel.

Front Panel PRDY Output is not Open Collector

Clients on the bus should drive the PRDY signal ith an open collector driver. The signal is

terminated on the CPU board ith a 1K pull-up resistor. Ho ever, the original front panel

board actively drives this signal high. Therefore, hen any bus client drives PRDY lo to in-

sert ait states, its output driver is sinking the active high drive of the front panel’s PRDY

driver.

6) Enhancements

In addition to duplicating the functionality of the original front panel board, the 8800c front panel

board set offers several enhancements that can be optionally enabled:

• An output latch at I/O address 0FFh that can display on the data LEDs (similar to IMSAI 8080)

• Auto repeat single-step at selectable rate from 1hz-8hz, similar to the 8800b

• Code snippet injection: Common Altair bootstrap loaders, port echo routines, Kill-the-Bit, etc.

can be injected into RAM by selecting the desired code snippet on the lo er eight address

s itches, then depressing the AUX-Left s itch.

• Auto jump on po er-on (can be independent of reset operation)

• Auto jump on reset (can be independent of po er-on operation)

Page 3

Front Panel Board Assembly

Assembly of the front panel board is not a beginner’s project and these instructions on’t teach you

ho to solder components on a PCB, solder connectors, or sho you the difference bet een a resistor

and a diode. If you have any concerns about building this board, please contact me first.

Many assembly details are illustrated in photographs that follo . Rather than print this manual, you

may ant to vie this document on your tablet hile you ork. A tablet makes it especially easy to

zoom into the photos to see the details you may need.

Parts List

Designator Description Part Number Distributor

C1-C5 0.1uf, 50v 2146302 Jameco

C6 100uf, 16v electrolytic 647-TVX1C101MAD Mouser

D1-D36 Red LED Everlite HLMPD150A Digi-Key 1080-1064-ND

J1 50 pin, dual ro IDC straight header 517-D3433-6302-AR Mouser

J2 5-pin, 0.156 locking header B5P-VH-B-LFSN Digi-Key 455-1642-ND

Female Housing VHR-5N Digi-Key 455-1186-ND

Crimp Pins SVH-21T-P1.1 Digi-Key 455-1133-1-ND

IC-A,B,C,D,E 74LS165 Parallel In Shift Register 595-SN74LS165AN Mouser

R1-R36 2K, 1/4 , 5% 291-2K-RC Mouser

R37-R52 4.3K,1/4 , 5% 291-4.3K-RC Mouser

S1 Toggle S itch On-None-On (Silver) APEM 5236AB Search for best deal

S10-S25 Toggle S itch On-None-On (Gold) APEM 5236CDB Search for best deal

S2-S9 Toggle S itch (On)-Off-(On) (Gold) APEM 5237CDB Search for best deal

Switches

If at all possible, do not use C&K switches for the front panel. The C&K s itches have an erratic and stiff

feel – especially the momentary s itches – compared to the American S itch brand used in the original

Altair. In addition, I’ve had several C&K s itches break hile gently tightening the bushing nut as ell as

during normal use. The APEM s itch part numbers listed above are much closer to the original American

S itch brand. In fact, APEM purchased American S itch a number of years ago.

The po er s itch must have silver contacts as noted for S1. Ideally, use gold contacts for all remaining

s itches. Do not mix s itch brands as most have slightly different body heights and this causes prob-

lems hen mounting the front panel to the mounting plate/bracket.

The APEM s itches can be expensive. I may be able to help ith a bulk buy. Contact me if interested.

Additional Part Notes

Use only LS-TTL parts. Some IC inputs are tied directly to Vcc. Multi-emitter TTL inputs do not tolerate

this ell (e.g., 74xxx and 74Sxxx).

The specified LEDs provide an appropriate brightness ith the 2K resistors specified for R1-R36. You may

need to choose a different resistor value if a different LED is used.

Page 4

Front Panel Assembly Steps

First, insert and solder lo -profile parts

1) Insert and solder R1-R52.

2) Insert and solder IC-A through IC-E (or sockets).

3) Insert and solder C1-C6. Note polarity on C6.

The follo ing instructions for installation of the s itches and LEDs assume you have an Altair Clone cab-

inet. If you’re installing in an original Altair cabinet, follo the instructions in the original manual for me-

chanically aligning the s itches and LEDs hile soldering into the PCB.

Use the front panel mounting bracket from the Altair Clone cabinet as a jig to help install the front panel

s itches, S1 through S25. Do not attempt to solder the switches without usin a ji .

Note: The follo ing pictures are from the Altair Clone assembly manual, so the PCB looks a bit different

than the 8800c front panel board. I nore the LED orientation/polarity shown in the pictures.

1) Prop the front panel bracket an inch or t o above your ork surface and orient the bracket as

sho n in the picture belo . Note, the APEM switches are blue, not red as show in the picture.

2) Place the po er s itch, S1 (toggle s itch ith silver terminals) in the bracket (far left corner as

pictured). Notice that each s itch has a slot in the threaded bushing. Orient the slot of all s itches

a ay from your vie as you place them in the bracket.

3) Place S2-S9 (momentary s itches ith gold terminals) in the eight holes across the bottom of the

bracket (ro furthest a ay from your vie ). Again, orient the slot of all s itches a ay from your

vie as you place them in the bracket.

4) Place S10-S25 (toggle s itches ith gold terminals) in the 16 holes above the eight momentary

s itches. Again, orient the slot of all s itches a ay from your vie .

Page 5

5) Check that all s itches are as squarely aligned as possible, then carefully lo er the circuit board,

component side do n, onto the s itches. Don’t let o of the board after you have it settled on

the s itches as the board ill tend to rock to ards you and fall off the s itches.

6) To solder the s itches, keep pressure on the board ith your “spare” fingers placed in bet een

the t o ro s of s itches and near here you are soldering. This keeps the board level and square

on the s itches.

The next step is to install the front panel LEDs. In order to hold the LEDs at the proper and consistent

height above the board, use the front

dress panel as a jig. Do not cut or prep LED

leads until after soldering is complete!

1) Insert D1-D36 fully into the circuit

board. The anode of the LED is indi-

cated by the longer lead and the

cathode by the flat spot on flange

(for the specific LED in the parts list).

The cathode is closer to the top side

of the circuit board and the anode is

closer to the bottom of the circuit

board. You may ant to prop the

PCB off the ork surface as sho n

to accommodate the long LED leads.

Page 6

2) Work the front dress panel over the s itches and then do n the s itch bushings slightly. You

don’t need to push the panel all the ay do n to the s itch body.

3) Turn the PCB/front panel over as sho n belo and let the LEDs fall into the front panel LED holes.

If the front panel sags a bit in the middle, add a third support point near the middle of the panel.

4) Carefully adjust the spacing bet een the PCB and the front panel in order to accommodate the

four 5/8” spacers provided*. The goal is to make the PCB and front panel as parallel as possible.

The spacers are used only for this step – they do not remain in the assembly. (Note that once an

LED is soldered, it can then serve as a “spacer”) See the pictures on the next pa e.

5) Push each LED all the ay do n into its corresponding front panel hole. Re-verify that the front

panel and PCB look perfectly parallel to each other and are resting directly on all of the hite

spacers. See the pictures on the next pa e.

6) Solder the LEDs: Press do n gently on the PCB ith your “spare” fingers as you solder the LEDs to

the PCB. You may ant to slide the hite spacers near the area you are orking as you proceed

through the LEDs. Note that once an LED is soldered, it can then serve as a “spacer.”

* The spacer height determines ho far the LEDs ill protrude through the front panel after final as-

sembly. With APEM s itches in the Altair Clone case, a spacer height of 5/8” to 11/16” gives a good

LED position after final assembly. At 5/8”, the LEDs protrude just slightly through the front panel. At

11/16”, the LEDs protrude a bit further. You can add something thin under each 5/8” spacer to raise it

to ards 11/16” depending on your LED position preference. The spacin requirement is different if

you use a different s itch brand since s itch body height varies slightly bet een brands.

Page 7

Lastly, install J1 and J2 on the back side of the circuit board.

J1 – Note the orientation of the keying slot before soldering the connector onto the board. Again, the

connector goes on the back side of the board.

J2 – Though not a requirement, I’d recommend pulling the center pin out of the J2 connector. If you

leave the pin in place, note that its hole on the PCB is not plated and should not be soldered.

Page 8

Final Assembly (using an Altair Clone cabinet)

Mount the circuit board to the front panel support bracket.

1) Set all toggle s itches in the

do n position. Feed the

s itch batons into the holes

through the rear of the sup-

port bracket. Be sure the

bracket is fully seated

against the body of every

s itch. You may have to

squeeze/push the panel

firmly around a fe of the

s itches to free those spots

here the support bracket

may be caught on the

s itch threads.

2) Install a lock asher and nut (finger tighten only) on the po er s itch, all eight momentary

s itches, and every other address s itch (A14, A12, A10,… do n to A0) as highlighted belo .

3) Incrementally tighten nuts – one on the far left, then one on the far right, orking back to the

middle, then repeat tightening each nut a bit more. A 5/16” deep socket makes this job much

easier. Do not over-tighten the nuts – trust the lock asher.

Page 9

Mount the front dress panel to the front panel sup-

port bracket.

1) Slide a 0.150 hite spacer over each of the six

studs on the back of the front dress panel.

2) Insert the batons from the s itches into the

front panel and ork the studs into the holes on

the front panel support bracket until the front

panel and support bracket have fully sand-

iched the spacers.

3) Work the front panel do n around the s itch

bushings as needed until the front panel is flat

and even over all 25 s itches. When properly

assembled, the bushings generally protrude just

slightly above the surface of the front panel.

4) Install a #6 nut over each of the studs on the back side of the support bracket(do not tighten). A

shallo 5/16” nut driver makes this job easier.

5) Incrementally tighten the nuts – one on the far left, then one on the far right, orking back to the

middle, then repeat tightening each nut a bit more.

Page 10

Install the Front Panel Assembly into the Case.

1) Slide the front panel assembly in from the front of the case. The front panel may be snug as it goes

into the case bezel. If this is the case, ork the panel in bit-by-bit, keeping the amount of insertion

on all four sides approximately equal as you ork the panel back ards into place ( here the

mounting bracket’s threaded holes line up ith the four holes in the bottom of the case).

2) Attach the front panel support bracket using four of the #6 scre s you set aside during disassem-

bly of the case. Lock ashers go under the t o scre s closest to the rear the panel. The

lock ashers ensure an electrical connection bet een the chassis and the front mounting bracket

for better static protection.

Page 11

Interface Board Assembly

Assembly of the interface board is fairly straight for ard, ho ever, these instructions on’t teach you

ho to solder components on a PCB, solder connectors, or sho you the difference bet een a resistor

and a diode. If you have any concerns about building this board, please contact me first.

Parts List (interface board)

Designator Description Part Number Distributor

C1 10uf, 25v tantalum 80-T350E106K025AT Mouser

C2-C17 0.1uf, 50v 2146302 Jameco

D1* 1N5817 Schottky Diode 511-1N5817 Mouser

J1 50 pin, dual ro IDC right-angle header 517-D3433-5302-AR (3M) Mouser

50 pin IDC socket (x2) MKC50A-ND DigiKey

50 pin IDC strain relief (x2) MKSR50-ND DigiKey

50 conductor ribbon cable MC50G-1-ND DigiKey

J2 8 pin, right-angle Molex header 538-26-60-3080 Mouser

Female Housing (x2) 09-50-7081 Mouser

Crimp Pins (x16) 08-50-0106 Mouser

J3* Not stuffed

IC-A PIC16F1828 Processor 579-PIC16F1828IP Provided

IC-B 74LS30 Single 8-Input NAND 595-SN74LS30N Mouser

IC-C 74LS164 Parallel Out Shift Register 595-SN74LS164N Mouser

IC-D,I 74LS374 Octal Latch 595-SN74LS374N Mouser

IC-E,F 74LS109 Dual J-K* Flip Flop 595-SN74LS109AN Mouser

IC-G,L 74LS02 Quad 2-Input NOR 595-SN74LS02N Mouser

IC-H 74LS00 Quad 2-Input NAND 595-SN74LS00N Mouser

IC-M 74LS04 Hex Inverter 595-SN74LS04N Mouser

IC-J 74LS244 Octal Bus Driver 595-SN74LS244N Mouser

IC-K 74LS10 Triple 3-Input NAND 595-SN74LS10N Mouser

IC-N 74LS368 Hex Inverting Bus Driver 595-SN74LS368AN Mouser

R1,R2,R4,R6 4.3K, 1/4 , 5% 291-4.3K-RC Mouser

R3,R5 1K, 1/4 , 5% 291-1K-RC Mouser

T1-T3 2N4401 Transistor 610-2N4401 Mouser

VR1 7805 Regulator 511-L7805ACV Mouser

Heatsink 129242 Jameco

4/40 x 3/8" scre

#4 internal tooth lock asher

4/40 nut

* J3 is not stuffed and a jumper ire can be substituted for D1 if this board ill never be attached to a Microchip

PIC programmer. Since firm are updates can be applied ithout using a programmer, these parts are most like-

ly not needed.

Part Notes

Use only LS-TTL parts. Some IC inputs are tied directly to Vcc. Multi-emitter TTL inputs do not tolerate

this ell (e.g., 74xxx and 74Sxxx).

Page 12

Interface Board Assembly Steps

Insert and solder parts orking from shortest to tallest:

1) Insert and solder R1-R6 and D1 (or ire jumper – see * above)

2) Insert and solder VR1. Bend the leads such that the hole in the mounting tab lines up ith hole in

the circuit board. You may ant to temporarily slide the heat sink under the regulator before sol-

dering to make sure the part is the right height off the surface of the board.

3) Insert and solder IC-A through IC-N (or sockets).

4) Insert and solder C1-C17. Note polarity on C1.

5) Insert and solder J1

6) Insert and solder J2

7) Insert and solder T1-T3

Install the heat sink under VR1 and fully tighten ith the #4 hard are listed in the parts list. Do not use

a mica insulator. Thermal grease is not required.

J1 Cable Assembly

A 50 pin ribbon cable connects the front panel board to the interface board in the bus. One ay to route

this cable is sho n in the picture belo . Here the cable exits to ards the back side of the board, takes a

45/90⁰ bend, and then runs along the side of the cards to reach the front panel connector. The cable

could also come for ard over the CPU board, then take a 45/90⁰ bend to go left, and then straight into

the front panel connector. This latter routing could be employed if a card cage is used that prevents

running the ribbon cable out the side. The parts for this cable are listed under J1 in the parts list.

J2 Cable Assembly

A straight-through, eight ire cable assembly connects J2 on the interface board to the data connector

on the CPU board. In the picture belo , this assembly consists of red and black ires ith a hite con-

nector at each end. The parts for this assembly are listed under J2 in the parts list.

Page 13

Altair 8800c Computer Assembly Hints

Grounding

For maximum resistance to static shock, make sure all sections of the metal cabinet are in electrical con-

tact ith each and ith the po er supply enclosures. Then also ensure the po er cord ground ire is

connected to the chassis ground terminal on each of the po er supplies.

As shipped, the Altair Clone case has lock ashers that bite through the paint here the front panel

bracket attaches to the bottom pan and here the rear panel attaches to the bottom pan. This provides

an electrical connection bet een these pieces. If you drill holes and use scre s to mount the po er

supplies, the po er supply chassis ill most likely have good electrical contact ith the bottom case

pan. If not, use lock ashers under the po er supply mounting scre s.

Unless connected else here, connect the DC terminal used for signal ground to the chassis ground ter-

minal on at least one po er supply. This ensures DC ground is at the same potential as chassis ground.

Motherboards ith plated mounting holes that are connected to DC ground may make this connection

to chassis ground for you as ell.

If putting scre s through pre-drilled holes in the cabinet, paint may prevent electrical contact ith the

scre . You can slightly ream the holes or use a lock asher to bite through the paint to ensure electrical

connection to the bottom case pan.

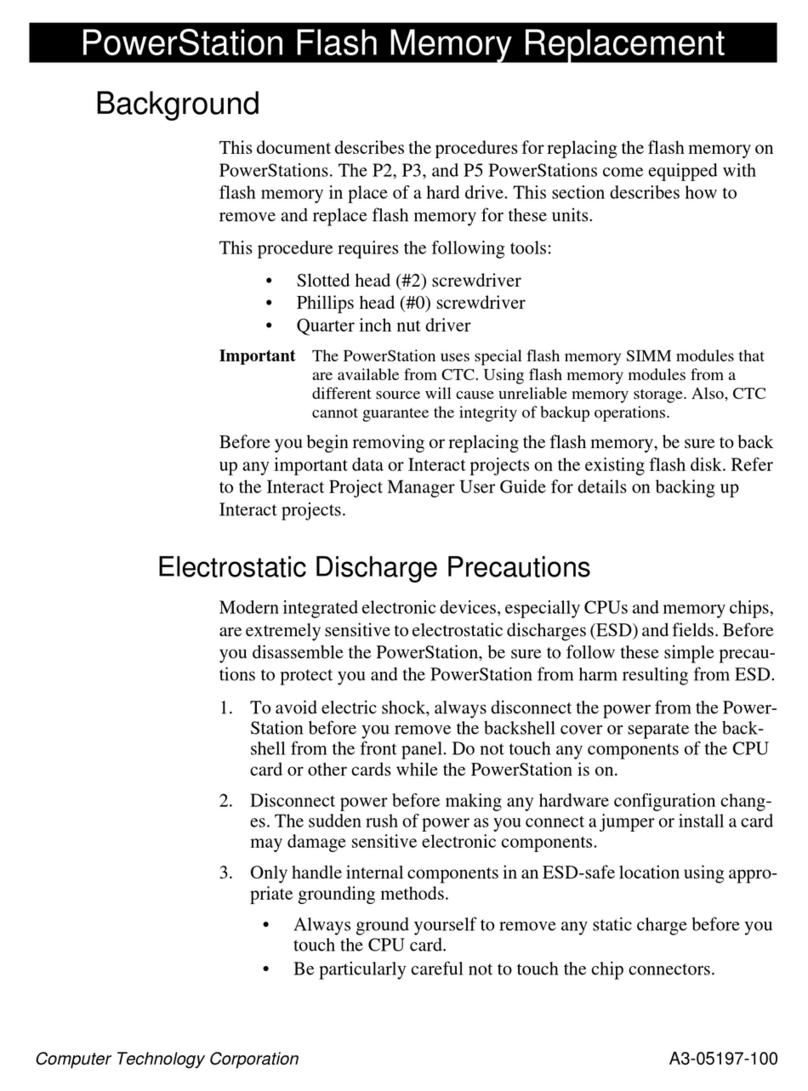

Power Supply Note

An internal lead can accidentally short against a mounting

scre in the small Mean ell RS-15 po er supplies as

sho n belo . Make sure your mounting scre s do not

reach in far enough to touch the exposed lead. You can

push the lead a bit to the left ith a small scre driver if

needed.

High Voltage Wiring

The incoming AC hot ire should be routed to an outside

pin on the J2 mating connector. On the opposite outside

position on the J2 mating connector ( ill be s itched AC

hot), run a ire back to the AC line terminal on each po er

supply.

Since modern s itching po er supplies are typically very

ell self-protected and contain an internal fuse as a back-

up, an external line fuse is typically not necessary. Ho ev-

er, if you’re concerned about the AC hot path through the

s itch prior to the po er supplies, an in-line fuse can be

added there.

Page 14

Front Panel Operation

In its default configuration, the 8800c Front Panel board set duplicates the operation of the original Al-

tair front panel. In addition, the follo ing features can be selectively enabled as desired:

• Po er-on to a valid reset state

• An output latch at I/O address 0FFh that can display on the data LEDs

• Auto repeat single-step at selectable rate from 1hz-8hz, similar to the 8800b

• Code snippet injection: Common Altair bootstrap loaders, port echo routines, Kill-the-Bit, etc.

can be injected into RAM by selecting the desired code snippet on the lo er eight address

s itches, then depressing the AUX-Left s itch.

• Auto jump on po er-on (can be independent of reset operation)

• Auto jump on reset (can be independent of po er-on operation)

These features are configured using three 8-bit “virtual” DIP s itches (VDIPs). The follo ing paragraphs

define the VDIP settings for each option. The process of setting the value of the virtual DIP s itches is

covered in the “Updating Virtual DIP S itches” section further do n in this manual.

7

6

5

4

3

2

1

0

VDIP #1 P r Reset FF Latch Code Inj ---- ---- Auto-Steps/sec (zero disables)

VDIP #2 MSB of Po er-On Jump Address (zero disables)

VDIP #3 MSB of Reset Jump Address (zero disables)

Power On Reset

By default, and to behave like the original Altair 8800 front panel, the run state of the 8800c Front Panel

is indeterminate at po er-on and the 8080 is not given a RESET. This, in turn, tends to leave the 8080

processor in an invalid state as ell. This is the reason for the manual STOP/RESET that must be per-

formed on the Altair front panel after po er on.

To get around this problem, the 8800c Front Panel can be configured to automatically perform a

STOP/RESET during po er-up. To enable this feature, set bit 7 of VDIP #1 to 1. To disable automatic re-

set, set the bit to 0.

Output Latch at 0FFh

An output latch can be enabled at I/O address 0FFh. The latch content can be displayed on the eight da-

ta LEDs on the front panel. The AUX-Right s itch is used to choose bet een displaying the output latch

or normal output on the data LEDs.

While the computer is running, pressing the AUX-Right s itch do n displays the output latch on the da-

ta LEDs. Conversely, raising the AUX-Right s itch restores normal display on the data LEDs.

Behavior hile the computer is stopped is slightly different. When stopped, the normal LED display is

important for virtually every operation performed. Therefore normal data is automatically sho n hen-

Page 15

ever the computer is stopped. The output latch is displayed only hile the AUX-Right s itch is held

do n – normal display is restored as soon as the s itch is released.

The output latch feature is controlled by VDIP #1, bit 6. A value of 1 turns on the output latch, a value of

0 turns off the output latch.

Auto Repeat Single Step

The 8800b provides an auto-repeat single step feature hen the SINGLE-STEP s itch is held do n. This

same feature can be enabled on the 8800c Front Panel board. The lo er three bits of VDIP #1 specify

the approximate auto-repeat rate in steps per second. A value of zero disables the auto-repeat feature.

Code Snippet Injection

A number of code snippets can be injected into RAM by entering the octal identifier for the desired code

snippet on s itches A7-A0 (see belo ) and then depressing AUX-Left. After injection, an “examine” of

the start address is automatically performed, so simply depressing run starts the loaded code.

The code injection feature is enabled by VDIP #1, bit 5. A value of 1 enables code injection, a value of 0

disables code injection.

Bootstrap Loaders for BASIC

BASIC 1.0

000 2SIO

002 SIO

003 ACR

4K BASIC 3.2

004 2SIO

006 SIO

007 ACR

8K BASIC 3.2

010 2SIO

012 SIO

013 ACR

4K BASIC 4.0

014 2SIO

016 SIO

017 ACR

8K BASIC 4.0

020 2SIO

022 SIO

023 ACR

Extended BASIC 4.0

024 2SIO

026 SIO

027 ACR

Other Routines

ACR Leader Detector

030 For BASIC 3.2

031 For BASIC 4.0

Port Echo Routines

034 2SIO (1

st

port)

035 2SIO (2

nd

port)

036 SIO

037 ACR (SIO at 6/7)

Miscellaneous

040 Kill the Bit

041 Pong

044* Intel Hex Loader 2SIO (1

st

port)

045* Intel Hex Loader 2SIO (2

nd

port)

046 Memory Test (2SIO console)

*Relocatable – Set s itches A15-A8 to the MSB of the desired load address before depressing AUX-Left

Page 16

Bootstrap Loaders

The BASIC Version 3.2 and 4.0 bootstrap loaders are straight from the Altair BASIC manuals. Refer to the

appropriate BASIC manual for ho to load these versions of BASIC.

The Version 1.0 bootstrap loader runs at 1800h (014000 octal). Once BASIC is loaded, STOP/RESET the

machine and then depress RUN to get the startup dialog.

ACR Leader Detector

This is the code from the 88-ACR manual that looks for a valid leader byte before jumping to the boot-

strap loader. To use the leader detector, first inject the required bootstrap loader, then inject and run

the appropriate leader detector. As you’ll notice, the leader detector loads and runs at 100h (400 octal).

Kill the Bit

Kill the Bit game by Dean McDaniel, May 15, 1975. Object: Kill the rotating bit. If you miss the lit bit, an-

other bit turns on leaving t o bits to destroy. Quickly toggle the s itch, don't leave the s itch in the up

position. Before starting, make sure all the s itches are in the do n position.

See http://deramp.com/do nloads/altair/soft are/miscellaneous/

Pong

PONG for Altair front panel. Left player quickly toggles A15 to hit the "ball." Right player toggles A8.

Score is kept in memory locations 80h and 81h (left and right). Score is missed balls, so the lo er num-

ber ins.

See http://deramp.com/do nloads/altair/soft are/miscellaneous/

Intel Hex Loader

Loads an Intel hex file through the chosen 2SIO serial port. The program is relocatable: Set s itches A15-

A8 to the MSB of the desired load address before depressing AUX-Left. The program prompts the opera-

tor to send the hex file. Once the complete hex file is received, the program pauses in an endless loop.

At this point, STOP/RESET to regain front panel control.

Memory Test

At the "*" prompt, key in four hex characters for the starting address follo ed by four hex characters for

the ending address. Press ESC to restart entry if a mistake is made. The test begins immediately hen

the last digit of the ending address is typed (RETURN not required).

The starting address is typically 0100h (the program is on page zero). If RAM ends at DFFF (for example),

specify an end address of E000. This ill cause the program to print an "error" for E000 at the comple-

tion of each test cycle as an indicator of activity.

The test runs continuously until reset. The program generates a pseudo-random number sequence,

rites a portion of it into RAM, and then regenerates the sequence from the same point to compare

ith hat is read from memory. If the pass is correct, a ne portion of the sequence is ritten to a ne

section of memory and the process repeats. Errors are printed out ith the address, hat as ritten

follo ed by hat as read.

Page 17

Power On and Reset Auto Jump

The front panel can force an auto-jump upon po er-on and/or reset. The auto-jump address can be dif-

ferent for po er-on than for reset. This is unlike many auto-jump circuits hich perform the same ac-

tion for po er-on and for reset. For Altair BASIC and Altair DOS, duplicate auto-jump addresses can be

problematic. For example, the RESET s itch is normally used to regain control from an executing or

hung program and return to the BASIC or DOS prompt. Ho ever, if the RESET s itch instead forces an

auto-jump to the cold boot code in PROM, then the entire initialization process for BASIC or DOS – in-

cluding the slo process of mounting each disk – must be performed. For these programs, it is best to

have a po er-on auto-jump ithout a reset auto-jump.

Power On Auto Jump

The MSB of the po er-on auto-jump address is specified on VDIP #2. If a non-zero value is specified,

then upon po er-on, the front panel forces a clean reset, an “examine” of the auto-jump address, and

then lets the 8080 processor run. If a value of zero is specified, po er-on auto-jump is disabled.

Reset Auto Jump

Whenever RESET is released, the front panel can force an “examine” of an address you specify. This sets

the 8080 program counter to this address and therefore performs an auto-jump to the specified address

if the computer is running. Note that if the computer is not running hen RESET is actuated (or a

STOP/RESET is performed), this has the effect of examining the auto-jump address upon reset ith the

computer remaining in a stopped state.

The MSB of the reset auto-jump address is specified on VDIP #3. If a value of zero is specified, the reset

auto-jump is disabled.

Updating Virtual DIP Switches

The virtual DIP s itch (VDIP) values are stored in EEPROM. The VDIP values can be examined and updat-

ed from the front panel. The AUX-Right s itch is used like the “Ctrl” key on a keyboard to give each

front panel s itch an additional function. While holding AUX-Right in the UP position, the front panel

s itches provide the follo ing functions hen actuated:

EXAMINE ( ith AUX-Right held up) places the value of VDIPs 1-3 into Altair RAM locations 1-3. The

firm are version is placed into RAM location zero. This allo s you to “examine” the virtual DIP

s itch values.

DEPOSIT ( ith AUX-Right held up) “deposits” the values from Altair memory locations 1-3 into VDIPs

1-3 in EEPROM.

RESET ( ith AUX-Right held up) resets the front panel into safe mode. See the “Firm are Updates”

section for more information about safe mode.

Once VDIP values are placed into Altair RAM using AUX-Right/EXAMINE, the values can be vie ed and

changed in Altair memory using normal front panel examine and deposit operations. Once the VDIP val-

ues are as you ant them, rite them back to EEPROM using the AUX-Right/DEPOSIT sequence.

Page 18

Firmware Updates

The logic on the front panel and interface boards is controlled by a state machine in a PIC16F1828 pro-

cessor. The firm are in the processor can be updated hile the board set is installed in a orking Altair

computer. The computer must have at least 8K of RAM and a functional 2SIO port at the standard I/O

address (10h/11h).

To update firm are, the front panel must be placed into “safe mode” by holding the AUX-Right s itch in

the UP position hile po ering on the Altair computer. Safe mode is a fully functional version of the

firm are in a protected area of flash memory. Safe mode provides all the functions of the original Altair

front panel and also the ability to program the “normal mode” area of flash memory. Safe mode does

not rely on parameters from EEPROM and provides none of the enhanced features available in the nor-

mal mode firm are. This allo s safe mode to serve as a fail-safe backup to ensure front panel function-

ality even if the normal mode code is missing, corrupted, or has a fatal bug.

To update firm are, connect a PC running a terminal emulator to the 2SIO port in the Altair. The emula-

tor should be set for 8N1 ith the baud rate determined by the 2SIO board. With the front panel already

in safe mode, raise and hold AUX-Right in the up position, then raise and release AUX-Left to start the

firm are update process. A prompt from the Altair should appear on the terminal emulator indo .

Follo the prompt to send the .hex file that contains the firm are update from the PC. Once the .hex

file is received, the update is automatically programmed into flash and the front panel restarts into the

updated normal mode code.

When firm are is updated, the EEPROM containing the virtual DIP s itch parameters is erased to zero.

You ill need to re-configure the VDIP s itches to match your feature preferences.

Helpful Hints

When the firm are update mode is entered, you should notice the WAIT light turn off (or go very dim)

since the Altair is no running a small program that as injected into memory by the front panel. If the

WAIT light stays bright, this indicates the 8080 is still stopped and the injected code failed to run. This is

typically because the front panel asn’t actually in safe mode or there is a problem ith RAM in the first

8K of address space.

If the Altair is running the injected program, but you don’t have terminal response, try typing a ctrl-c on

the terminal and see if an abort message appears. If not, perform a RESET on the front panel hich re-

turns the front panel to normal operation, then attempt the AUX-Right/AUX-Left entry sequence again.

Additional Notes about Safe Mode and Normal Mode

Safe mode is entered in three conditions:

1) AUX-Right is held up hen the computer is po ered on

2) The normal mode area of flash is erased

3) While in normal mode, RESET is raised and released hile AUX-Right is held up

Note that if normal mode is functional, safe mode can be entered from normal mode by performing

item #3 above.

Table of contents

Popular Desktop manuals by other brands

CTC Union

CTC Union PowerStations P3 Replacement manual

Dell EMC

Dell EMC OptiPlex 3090 Ultra Setup and specifications guide

Advantech

Advantech IPC-690 user manual

Lenovo

Lenovo C205 Hardware Maintenance Manual

HP

HP Pavilion t100 - Desktop PC Getting started guide

Lenovo

Lenovo IdeaCentre B310 Hardware Maintenance Manual