DERNASEER TF 220s User manual

MACHINE TYPE / MODEL

TF220 S

SERIAL NO. 21020181-01

YEAR OF MANUFACTURE 2012

OPERATION, MAINTENANCE & SPARE PARTS MANUAL

TF 220s

TF220s

1

BLANK PAGE

TF220s

2

Important

These operating and maintenance instructions should be read and observed

carefully prior to transport, installation, commissioning, maintenance and

servicing of the machine!

Authorized personnel only, that is familiar with the operating and maintenance

instructions and the appropriate instructions with regard to safety at work and

accident prevention, is allowed to use, maintain and repair this machine.

This instruction manual contains important information on how to operate the

machine safely, properly and most efficiently. Observing these instructions

helps to avoid danger, to reduce repair costs and downtimes and to increase

the reliability and life of the machine.

The operating instructions must always be available wherever the machine is

in use.

DERNASEER ENGINEERING reserve the right to change specification without

prior notice.

TF220s

3

BLANK PAGE

TF220s

4

Contents

1 SAFETY

2TECHNICAL INFORMATION

3OPERATION

4MAINTENANCE

5TROUBLESHOOTING

6APPENDIX

7SPARE PARTS

TF220s

5

BLANK PAGE

TF220s

6

SAFETY

TF220s

7

BLANK PAGE

TF220s

8

SAFETY

SAFETY INTRODUCTION

Operators should be trained in the correct and safe use of all equipment.

Before operation the operator(s) must:-

(i) Have read and understood the Operators manual and Safety signs in this

manual and around the machine.

(ii) Be aware of all the moving parts of the machine.

1.2 SAFETY SIGNS

Particular attention should be paid to the following safety signs.

This is the safety alert symbol. When you see this symbol be alert to the

possibility of personal injury or death.

IMPORTANT

Indicates a statement of company policy as the message relates directly or indirectly

to the safety of personnel and protection of property.

FALLING HAZARD

WORKING MACHINERY.

LOCK OUT EQUIPMENT BEFORE SERVICING.

BEWARE OF HYDRAULIC

PRESSURE HYDRAULIC OIL CAN PENETRATE THE

SKIN CAUSING SERIOUS INJURIES. USE A PIECE OF

CARDBOARD TO FIND LEAKS. DO NOT USE BARE

HAND.

OPERATORS MANUAL MUST BE READ AND FULLY

UNDERSTOOD, BEFORE PERFORMING ANY

OPERATION OR MAINT

EYE PROTECTION MUST BE WORN IN THIS AREA

HEAD PROTECTION MUST BE WORN IN THIS AREA

TF220s

9

FALLING HAZARD

–

DO NOT CLIMB ON TO

WORKING MACHINERY.

LOCK OUT EQUIPMENT BEFORE SERVICING.

BEWARE OF HYDRAULIC

OIL LEAKS. HIGH

PRESSURE HYDRAULIC OIL CAN PENETRATE THE

SKIN CAUSING SERIOUS INJURIES. USE A PIECE OF

CARDBOARD TO FIND LEAKS. DO NOT USE BARE

HAND.

OPERATORS MANUAL MUST BE READ AND FULLY

UNDERSTOOD, BEFORE PERFORMING ANY

OPERATION OR MAINT

ENANCE.

EYE PROTECTION MUST BE WORN IN THIS AREA

HEAD PROTECTION MUST BE WORN IN THIS AREA

TF220s

PRESSURE HYDRAULIC OIL CAN PENETRATE THE

SKIN CAUSING SERIOUS INJURIES. USE A PIECE OF

CARDBOARD TO FIND LEAKS. DO NOT USE BARE

OPERATORS MANUAL MUST BE READ AND FULLY

EYE PROTECTION MUST BE WORN IN THIS AREA

HEAD PROTECTION MUST BE WORN IN THIS AREA

EAR PROTECTION MUST BE WORN IN THIS AREA

NIP POINT

TF220s

10

EAR PROTECTION MUST BE WORN IN THIS AREA

NIP POINT

–

KEEP HANDS CLEAR OF MOVING

MACHINERY

TF220s

EAR PROTECTION MUST BE WORN IN THIS AREA

KEEP HANDS CLEAR OF MOVING

TF220s

11

ELECTRICAL AND ENGINE SAFETY

1.

Never work on the electrical system of any equipment unless you are thoroughly

familiar with system details.

2.

Work on the electrical system must only be carried out by a qualified electrician.

3.

The electrical equipment of the machine should be inspected at regular intervals.

Damaged cables or loose connections must be corrected immediately. Use only

original fuses with the specified current rating.

4.

It is recommended that an earth leakage safety switch be fitted in the supply line to

the power point on site. Special care should be taken to ensure that earth wires are

correctly connected.

5.

Disconnect the battery ground leads whenever performing any electrical

maintenance or servicing to your engine.

6.

Battery posts, terminals and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

7.

Never short across the starter terminals of a battery as this can cause a fire and

could also damage the electrical system.

8.

Battery electrolyte contains acid and can cause serious injury. Avoid contact with

skin and eyes. Use gloves and protective glasses.

9.

Diesel engine exhaust emissions contain products of combustion which may be

harmful to your health. Always operate the machine in a well ventilated area and if

operating in an enclosed area, vent the emissions outside.

10.

Do not touch any part of the engine or exhaust system. Allow the engine and

exhaust to cool before performing any repair or maintenance.

11.

Never fill the fuel tank with the engine running, while smoking or when near an

open flame.

12.

Never overfill the tank or spill fuel. If fuel is spilled, clean it up immediately.

TF220s

12

HYDRAULIC SAFETY

1.

Never disconnect any hydraulic circuit without consulting with Dernaseer

Engineering or your local dealer.

2.

Only personnel with expert training and experience in hydraulics are

authorized to perform any maintenance or repair work.

3.

Return controls to neutral position and relieve all pressure in the hydraulic

system, before attempting to disconnect any hydraulic circuit or component.

4.

Do not handle or repair hydraulic equipment with bare hands.

5.

Beware of hydraulic oil leaks. Hydraulic fluid under pressure can penetrate the

skin or damage eyes. Fluid leaks under pressure may not be visible. Use a

piece of cardboard to find leaks but do not use bare hand.

6.

Wear safety goggles for eye protection. If fluid enters skin or eye, get

immediate medical attention.

7.

Ensure that any damaged hoses are replaced with those of the same

specification as the original.

8.

Do not exceed safe limits. Never set a pressure relief valve to a pressure

higher than that set at the factory. 185 Bar (2500 PSI).

TF220s

13

SAFETY BEFORE AND DURING OPERATION

Only qualified and trained personnel should attempt to operate this machinery.

1.

Read and understand the Operators Manual before you start the machine.

Study the DANGER, WARNING, CAUTION and IMPORTANT safety signs on your

machine.

2.

Check your machine and have all systems in good operational condition.

- Check for broken, missing or damaged parts.Replace and make necessary repairs.

- Ensure all safety guards and emergency stops are fitted and in working order.

- See ‘Daily Maintenance’ for more detailed checklist before start-up.

3.

Before starting, walk completely around the machine. Make sure no one is under

it, on it or close to it. Let other workmen and bystanders know you are starting up and

do not start

until everyone is clear of the machine.

4.

During operation, do not climb onto, over or under moving conveyor belts and

rollers.

Always use ladders, steps and walkways when mounting and dismounting.

5.

Hole alignment on mechanical supports must be checked and secured with pins

provided

and in accordance with safety signs.

6.

Never check the tension of ‘V’ belts, drive chains and conveyors when machine is

running.

7.

Never work or stand beneath machinery or attachments as it is raised or lowered.

8.

Never work or stand beneath machinery as they are being loaded with and/or

discharging

material.

9.

Follow safe operating practices. Operate the machine controls smoothly. Avoid

sudden

stops, starts or changes in direction.

10.

Only use emergency stop buttons or emergency stop lines (if fitted) in

emergency situations or during safety drills.

11.

After each day’s operation, always run the machine dry; never leave material in

the beltfeeder on conveyor belts or screenbox. Starting a machine with a full load will

cause strain problems in your machine.

TF220s

14

SAFETY BEFORE AND DURING MAINTENANCE

Maintenance should only be carried out by trained and qualified personnel.

1.

Whenever maintenance or service is being carried out a minimum of two (2)

persons should be present at all times. NEVER WORK ALONE.

2.

Prepare yourself. Wear a hard hat, safety goggles, hearing protection and other

protective equipment as required by job conditions. Do not wear loose clothing or

jewellery that can catch on controls or moving parts. Long hair must be tied back.

3.

Prepare the machine. Move the machine onto a level surface and apply parking

brakes and/or wheel chocks. Shut off the engine and remove the key. Relieve all

hydraulic pressure by returning controls to neutral. Secure all hydraulically operated

attachments with pins provided.

4.

Isolate all electrical supplies to the machine before starting any maintenance work.

5.

Never attempt repairs or adjustments to the machine while it is running. (Exempt to

this rule: Belt tracking adjustments are only possible during working process - see

Belt Tracking).

6.

Remove only guards or covers that provide access. Wipe away excess grease and

oil.

7.

Never leave guards off or access doors open when unattended. Keep bystanders

away if access doors are open.

8.

When working beneath raised equipment, always use blocks, jack-stands or other

rigid and stable supports. Never work under unsupported equipment.

9.

Performing work above 6ft-6” (2m) always use an approved (EN/ANSI) safety

harness. Always use walkways and platforms provided or a safe secure platform

approved by the machine operators management. Do not use any unauthorised or

unsafe platforms.

10.

Never operate any type of engine without proper ventilation – EXHAUST FUMES

CANKILL. (See Electrical and Engine Safety for more detailed checklist).

11.

Checking for hydraulic leaks. Beware hydraulic fluid under pressure can

penetrate the skin or damage eyes. Fluid leaks under pressure may not be visible.

Use a piece of cardboard to find leaks but do not use bare hand.

12.

Wear safety goggles for eye protection. If fluid enters skin or eye, get immediate

medical attention. (See Hydraulic Safety for more detailed checklist).

TF220s

15

13.

Clean or replace damaged, missing or painted over safety signs that cannot be

read.

14.

Rotating and moving parts must be inspected during maintenance and replaced if

cracked or damaged. Excessively worn or damaged parts can fail and cause injury or

death.

15.

After maintenance, tighten all bolts, fittings and connections.

Install all guards, covers and shields. Replace or repair any damaged ones. Refill and

recharge pressure systems with recommended fluids.

Start the engine and check for leaks. Operate all controls and make sure the machine

is

functioning properly. After testing, shut down, check the work you performed (any

missing

cotter pins, washers, locknuts, etc.)?

Recheck all fluid levels before releasing machine for operation.

TF220s

16

TECHNICAL INFORMATION

TF220s

17

BLANK PAGE

TF220s

18

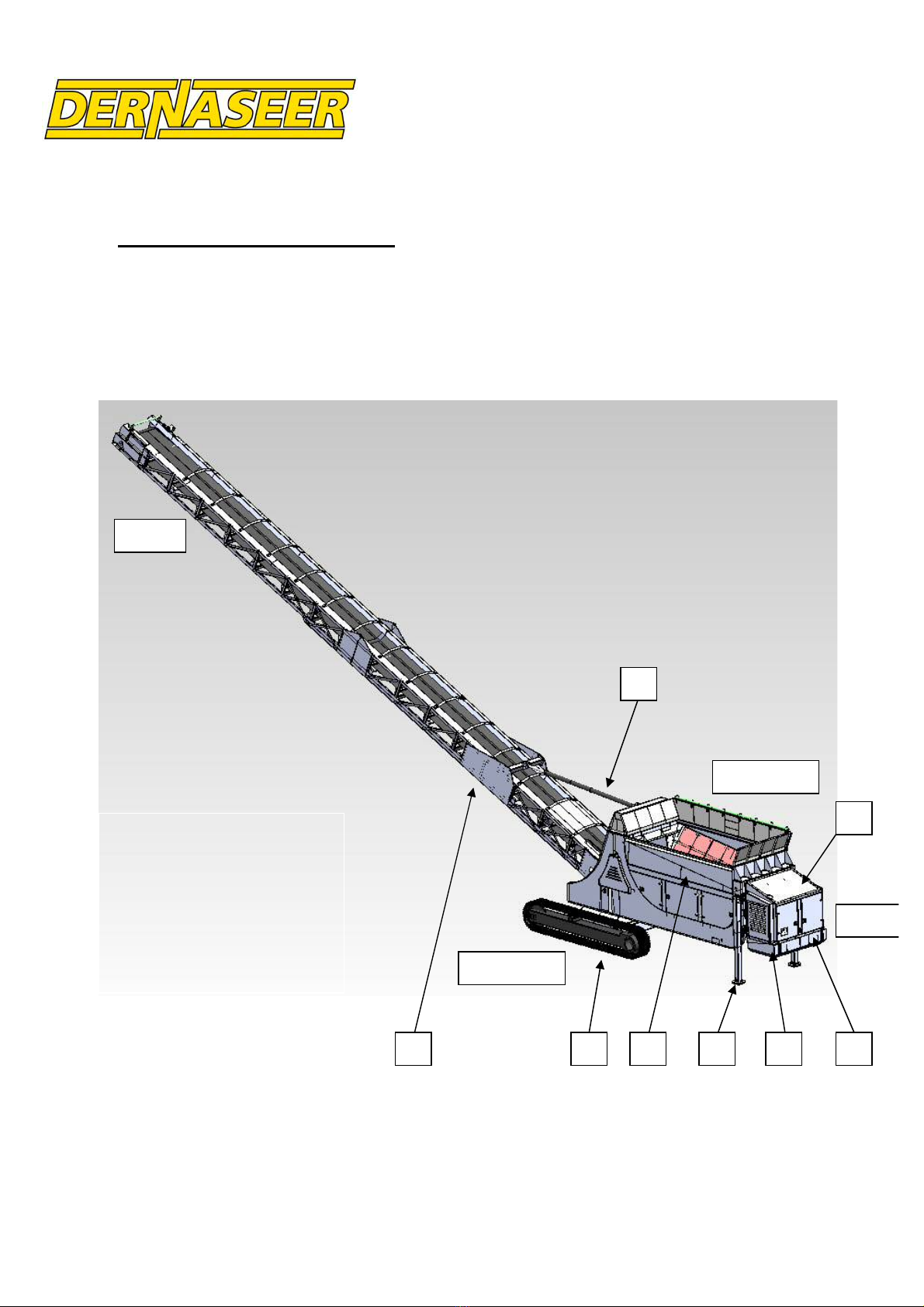

TECHNICAL INFORMATION

GENERAL INFORMATION

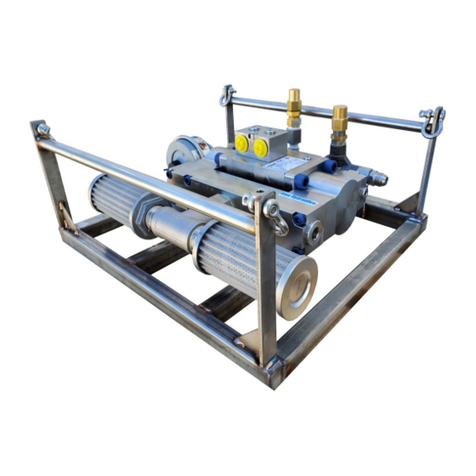

Familiarisation

Front

Rear

Left Side

Right Side

1 3 4 5 62

7

8

1. Main Conveyor

2. Tracks

3. Beltfeeder/Hopper

4. Jacklegs

5. Fuel Tank

6. Hydraulic Tank

7. Main Lifting Ram

8.

Engine Compartment

TF220s

19

GENERAL INFORMATION

Familiarisation

9 Ignition Panel

10 Diesel Fuel Visual Level Gauge

11 Hand Throttle

12 Hydraulic Oil Visual Level Gauge

9

10

11

12

Table of contents

Popular Industrial Equipment manuals by other brands

Panasonic

Panasonic ERJ 2LW Series manual

PCB Piezotronics

PCB Piezotronics ICP 352C67 Installation and operating manual

HyQuest Solutions

HyQuest Solutions TB4 2 Series user manual

NCR

NCR 7702-K100 Kit instructions

CAVIDYNE

CAVIDYNE Caviblaster 2040-ROV-M2 Operation & maintenance manual

Emerson

Emerson ACC/ARTM-7221/FC installation guide

Helbling & Co

Helbling & Co Facette Star 500 instruction manual

Vestil

Vestil HOP-LP manual

SMC Networks

SMC Networks CP96N Series Operation manual

Cyber-Tech

Cyber-Tech mechanical Joysticks JS-2050-HD Series quick start guide

Panduit

Panduit R4PFP Installation Instructions-Mounting

ABB

ABB RELION 650 SERIES Engineering manual