Helbling & Co Facette Star 500 User manual

Instruction manual

Instruction Manual

Chamfering Machine

500

Technical data, Facette Star 500, Part no. W03.00000

Supply voltage 230 V 50Hz / 110V 60Hz

Motor power Input 500W 650W Output 500W

Speed regulation 1‘200 bis 8‘000 min

-1

stepless

Carriage stroke 500 mm

Table support surface

L: 760mm

B:120 x 43 mm

Chamfer height in one operation 0.1-5 mm stepless (see 3.10)

Workpiece thickness min. 1mm

Workpiece weight max. 20 kg

Machine weight 58 kg

Housing and controller are earthed.

Standard equi ment included

Je 1

Allen key 6 / 8 / 10

2

Keys to Emergency stop button

1

Connection cable available for CH/EU/GB/US

Helbling & Co. AG März 2021

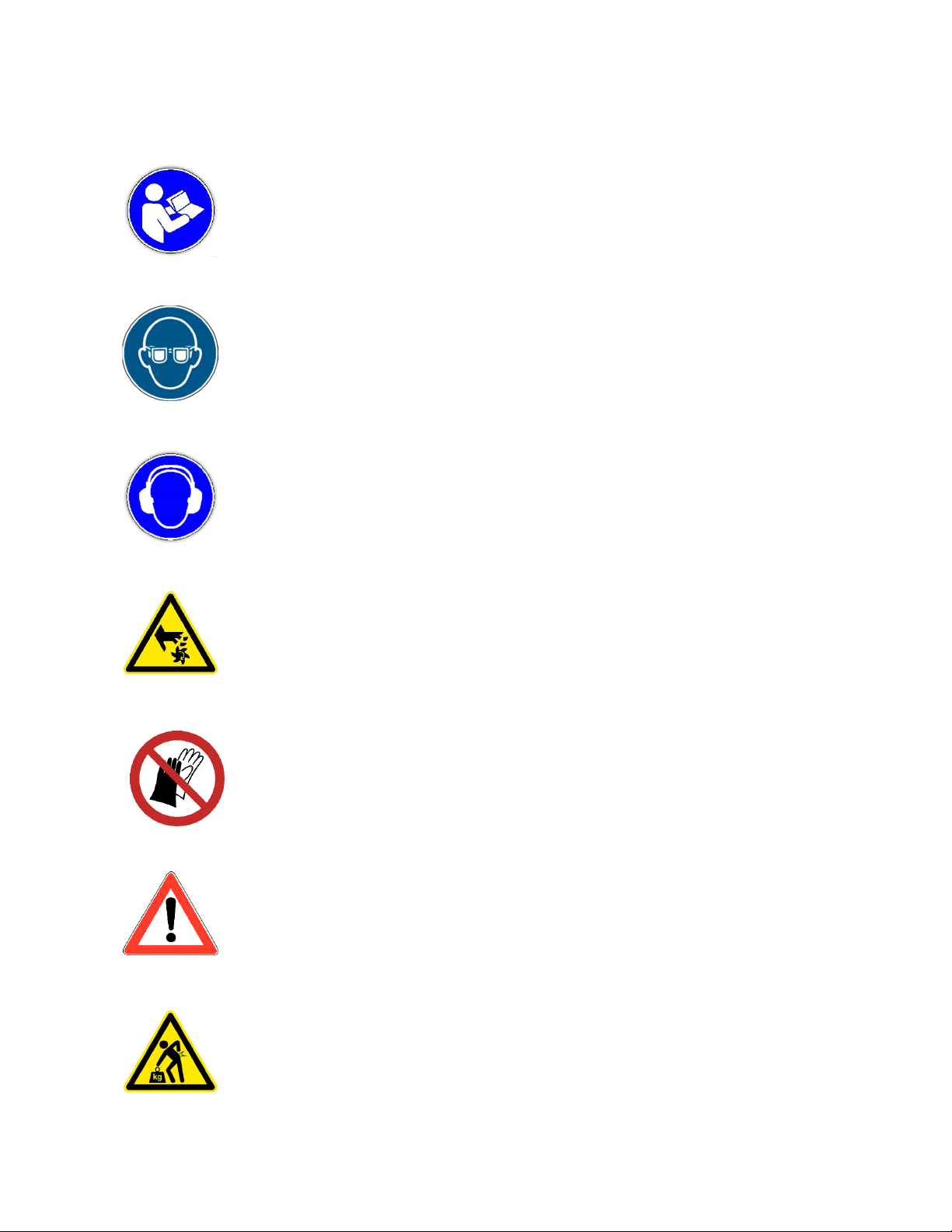

Safety instructions

Read the operating instructions before commissioning.

Wear protective goggles.

Wear hearing protection.

Do not touch the rotating cutter. It may cause injury.

Do not wear gloves when milling.

Attention: If the table is folded up while the machine is

running the machine is automatically switched off by the

inductive limit switch (76). When the table is in the working

position again the machine can be restarted with the start

button (78).

Attention: The weight of the machine is approx. 58 kg.

Helbling & Co. AG März 2021

Intended use

The chamfering machine is intended exclusively for milling bevels and edges. The parts

must not weigh more than 20 kg and can be made of different materials (aluminium

steel stainless steel plastic etc.).

The machine may only be used in accordance with its intended purpose. Any other use

beyond this is prohibited.

Part of the intended use is also the observance of the safety instructions as well as the

commissioning and the mode of operation in the operating instructions.

The manufacturer accepts no liability for damage caused by improper or incorrect use.

Only accessories and spare parts from the manufacturer's range may be used.

Persons who operate the chamfering machine and carry out maintenance work must be

familiar with it and informed about possible dangers. In addition the applicable accident

prevention regulations must be strictly observed.

Bridging of safety elements and modifications to the machine exclude any liability on the

part of the manufacturer and any resulting damage.

All other applications are expressly excluded and are considered as non-intended use.

Esidual risks

As with all machines there are dangers inherent in the operation and handling of this

machine. Attentive operation and correct handling of the machine significantly reduce

possible accident hazards. If the normal precautionary measures are disregarded

accident hazards may arise for the operator.

Behaviour in case of malfunctions and accidents

Immediately press the ON/OFF switch (75) see Fig. 1 and pull out the mains plug.

This deburring machine is built according to

the directives 2006/42/EC + 2014/30 EU and

is spark suppressed.

Helbling & Co. AG März 2021

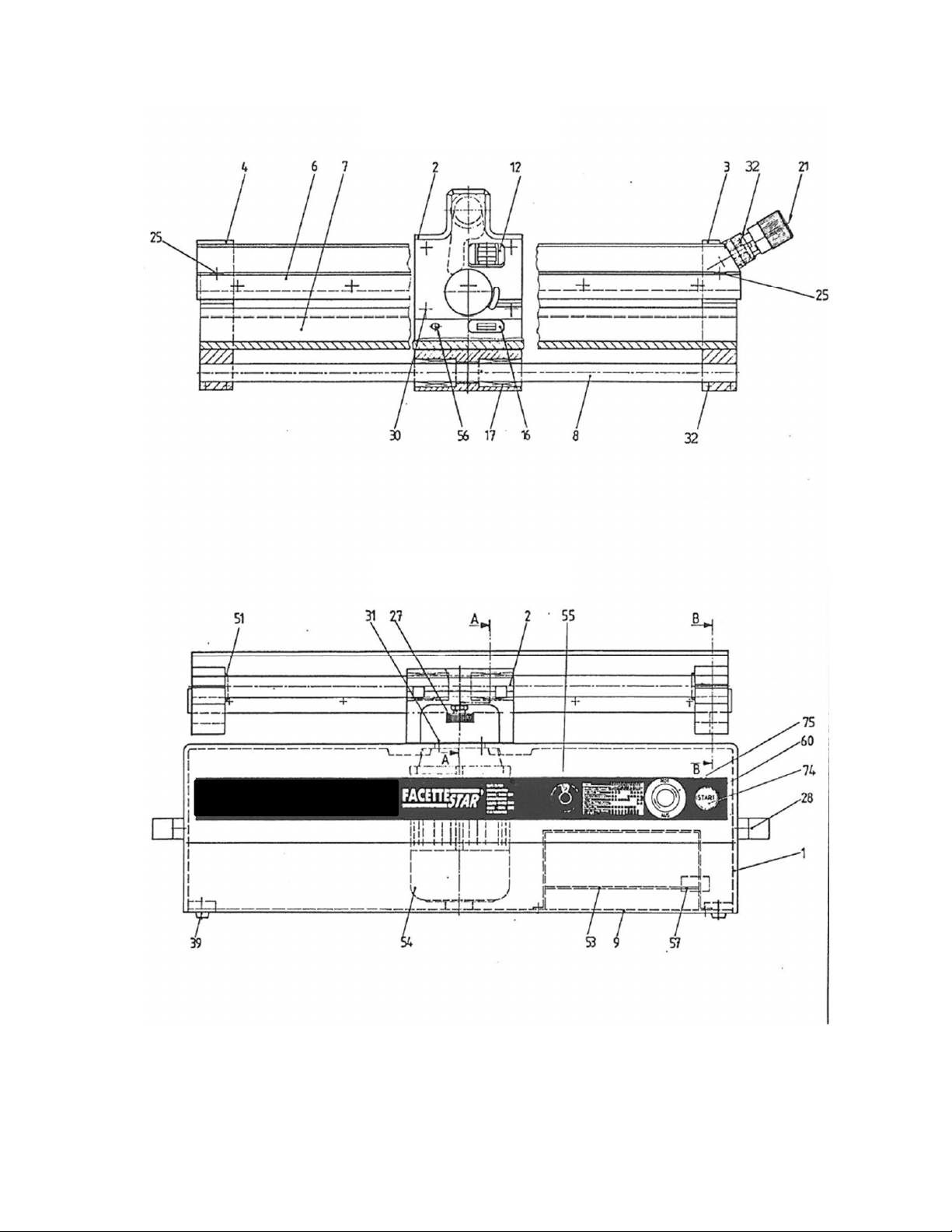

1.

Installation (fig 1)

1.1

The machine weighing approx. 58 kg (110 V model 128 lbs) is easily hand

carried by two people. Reach for the two handles (28) to lift the machine and

place it on a solid table or trolley with lockable cast. Ideal table heigt 75 cm

(30").

1.2

Loosen knurled screw (27) by one quarter of a revolution and lift the sliding

table with both hands until it rests against the support block (2). Remove

protecting covers above supporting ball bearings (12 and 16). Lower sliding

carriage carefully in original position and check if carriage can be moved freely

over full length of stroke from stop to stop.

1.3

The chips are ejected through an opening in the elbow cover (2) at the back of

the machine. Place a box in this area or install a suction device (optional

equipment) to collect the chips and keep the working place clean.

1.4

Connect the cable to single phase power source 230V 650W (USA: 110V

650W)

2.

Safety Instructions

2.1

Read all these instructions before attempting to operate this product and save

these instructions.

2.2

Don't use tools for purposes for which they are not intended.

2.3

Watch what you are doing. Use common sense. Do not operate tool when you

are tired.

2.4

Do not wear loose clothing. They can be caught in moving parts. Wear

protective hair covering to contain long hair.

2.5

Before use of the tool check for physical damage to ensure that it will operate

property and perform its intended function.

2.6

Use safety glasses and earmuff before turning it on "70 dB (A)"

3.

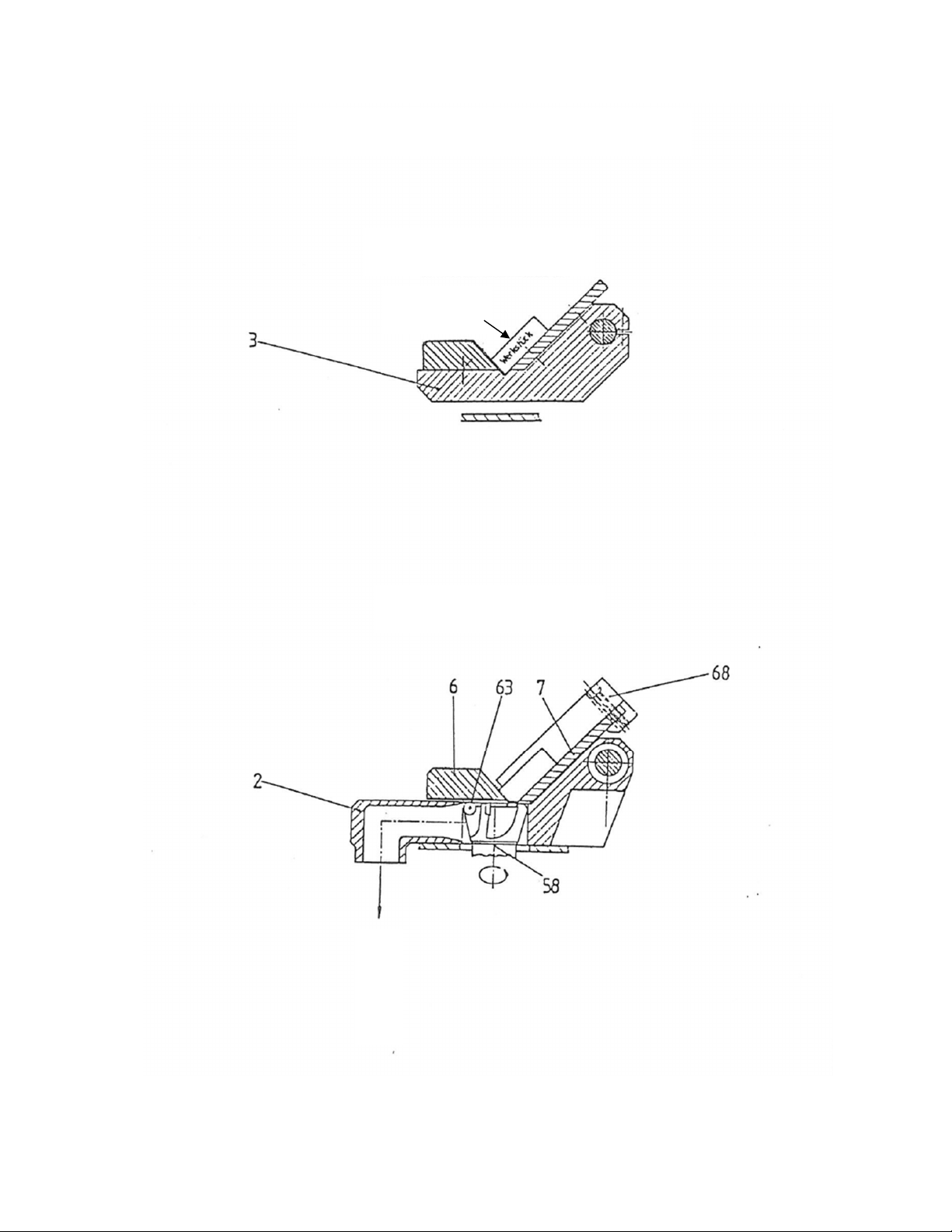

O eration (fig. 1 and 2)

3.1

Move sliding table fully to the ris ht until it contacts the stop.

3.2

Adjust micrometer screw (21) for setting chamber height to the required scale

position (one graduation = .05 mm - 0.002"). E.g. if screw is adjusted to "1 0"

a chamfer of 1 mm (.040") height x 45° will result.

3.3

To check the machine we recommend as follows:

-

Place a block of aluminium size approx. 3" x 3" x 1" on carriage

-

Adjust micrometer screw to "1 0".

-

Unlock danger-stop-button (75) with the key (one quarter of a revolution

on the right). Pull out the key with one quarter of revolution on the left and

place the key in safety. (Attention: Don't push the danger-stop-button!)

-

Turn the speed adjusting knob (55) to the position 8 (6'500 RPM).

-

Push start-button (74)

Helbling & Co. AG März 2021

3.4

Read from plate (60) the recommended position of the speed adjusting knob (55)

for the material used and turn knob to this position.

3.5

Move carriage fully to the right and place the piece to be chambered in the

approximate center of the carriage. Push piece with both hands into the "V"

formed by rail (6) and plate (7) (see fig. 2) and more it together with the sliding

table to the left past the milling cutter. Remove workpiece and check chamfer.

3.6

Move carriage to the right for each new working stroke.

3.7

Small work ieces can easily and precisely be squared with the stop gauge (68

standard equipment). That gauge clamped to the table at any position can also

be used as a pusher bar and retains the workpiece firm in place what-ever the

milling pressure will be.

3.8

Thin work ieces up to 500 mm (approx. 20") long 1 to 5 mm (.04 to 2") thick

can be clamped on overall length during the working procedure with a

holddown unit (optional equipment see leaflet). Min. thickness of workpiece: 1

mm (.040").

3.9

Longer work ieces than 500 mm (20") can be fed along the stationary carriage

"V" past the cutter after having the carriage centered and locked.

3.10

Max. chamfer height in one pass on:

- Mild steel aluminium nonferrous etc.

5 0 mm (.2")

-

Alloyed or stainless steel 2 5 mm (.I ")

-

Heat treated steel with hardness above

57° RC (with CBN grinding head) 0 6 mm (.024")

3.11

The workpiece supporting plates (6 and 7) are made of heat treated steel to avoid

damage to their surfaces.

3.12

Machine turn ON / OFF

Normal case: Off: Stop machine by turning speed knob (55) back to “0”. The

spindle brake stops it immediately.

On: Restart the machine with speed knob (55) to the desired

speed

Danger case: Off: Push stop-button (75) (the danger-stop-button will only

operate

When the key is pulled out) The motor spindle brake stops it

Immediately. Start-button (74) is no longer alighted.

On: To unlock the danger-stop make it possible only with the key

(one quarter of a revolution on the right). Pull out the key with

one

quarter of a revolution on the left and place

the key in safety.

(Attention:

Don't push the danger-stop-

button!)

Push start-button; the motor turn again.

3.13

When lifting the sliding

carriage the electric current is automatically interrupted

by a

proximity switch (56) and the motor will stop immediately. To restart the machine the

sliding carriage has to be brought back into working position. Then the speed

adjusting knob (55) must be reset to "0" before returning to the desired

speed.

3.14

Whenever the sliding table has been lifted check prior to lowering it in working;

position if the bottom side of the carriage and its supporting ball bearings are clean

to prevent chatter or unequal chamfers

3.15

When in trouble see paragraph 7 (trouble Shooting)

Helbling & Co. AG März 2021

4.

Maintenance (fig. 1 and 2)

4.1

The machine does not require any maintenance. We recommend

however to lightly oil the guide bar (8) from time to time.

4.2

When cleaning the machine be careful to avoid allowing chips to fall

between the support ball bearings (12 and 16) and the sliding table

bottom side.

4.3

For spares see paragraph 10.

5.

Trans ort (fig. 1)

5.1

For safety reasons whenever transport is required clamo sliding

carriage in approx. center position with knurled screw (27).

5.2

Place cardboard strip or similar protective material between supporting

ball bearings and sliding table plates to prevent plates from getting

marked.

6.

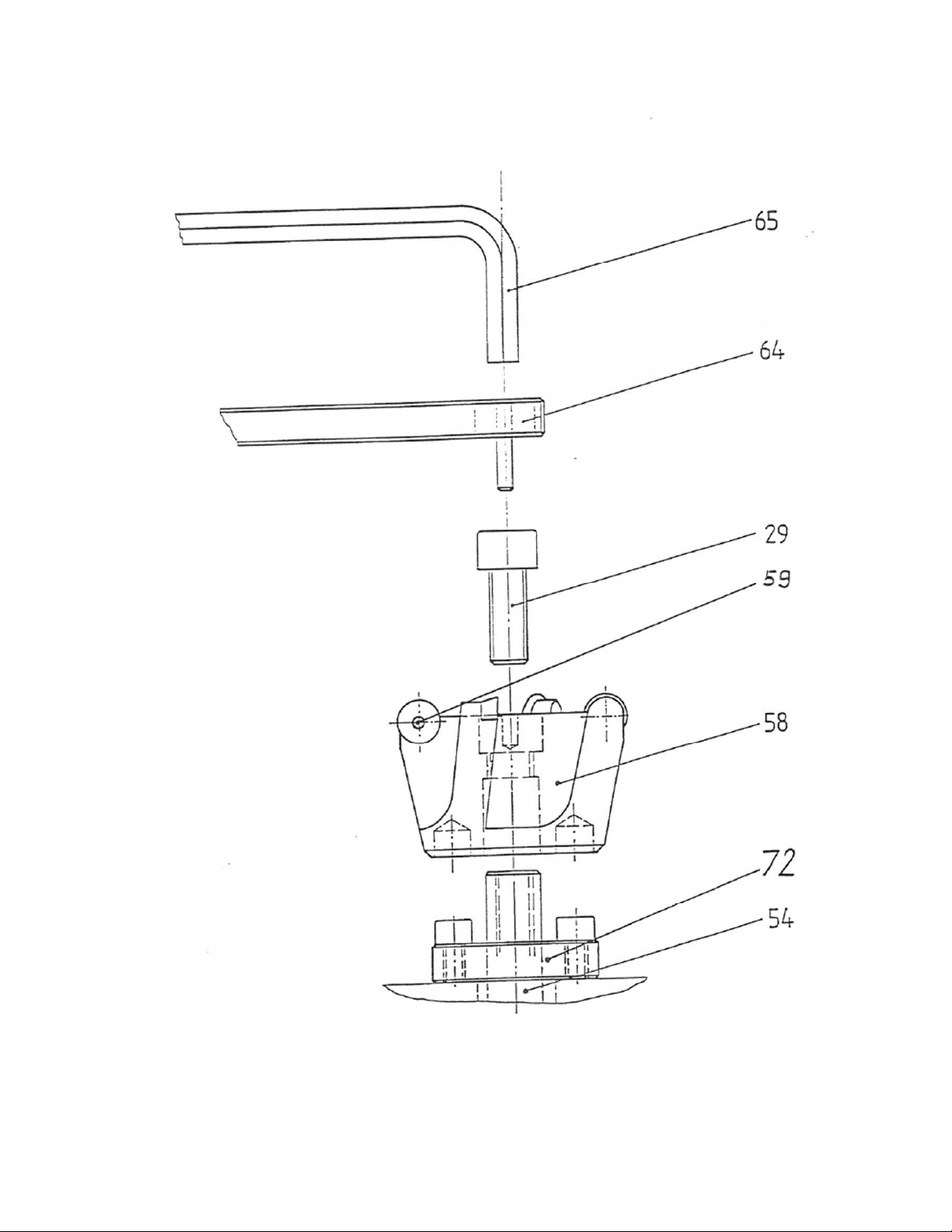

Tool changing (fig. 3 and 4)

6.1

Keep cutter (58) in position with the special pin wrench (64) and remove screw

(29) with hex. wrench (65) - see fig. 3.

6.2

Slide cutter off the spindle (54) by hand. If it sticks pry it loose from motor

spindle by inserting a screw (67) in the tapped hole of the cutter (see fig. 4).

6.3

The milling cutter should be removed when changing or turning the inserts.

6.4

Loosen the screws (59) using the Torx key T20. Remove the inserts and

clean the seats and inserts.

6.5

Rotate inserts 30° compared to the already used section to fully use the

cutting edge all around. Tighten centre screw and make sure that inserts

are well seated.

6.6

Place cutter on motor spindle (54) so that the drive screws (72) are

engaging the drive holes of the cutter (58).

6.7

Hold cutter in position with special pin wrench (64). Insert screw (29) and

tighten it firmly with hex. key (65).

6.8

The assembly and disassembly of other cutters or the grinding head

(optional equipment) is done the same way

Helbling & Co. AG März 2021

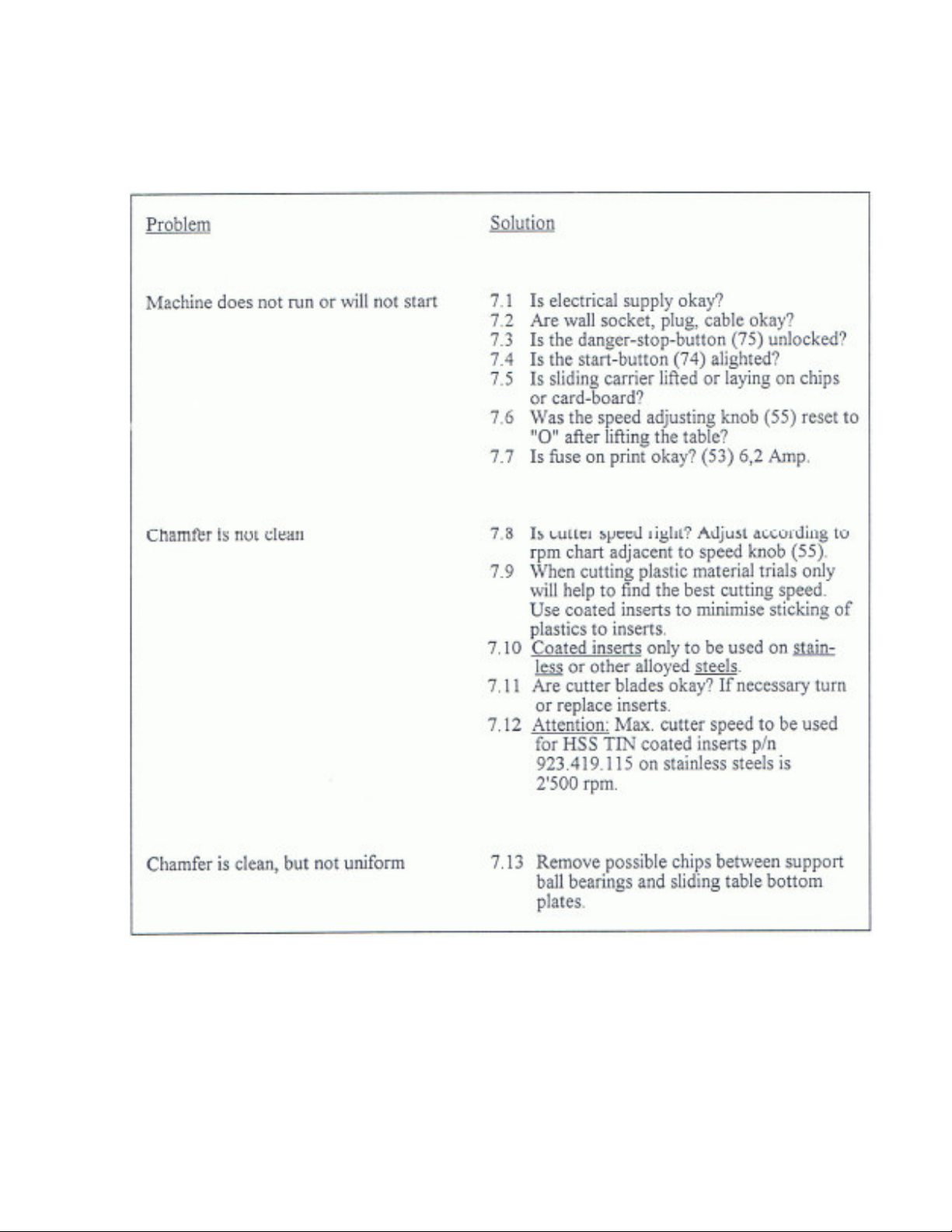

7.

Trouble shooting

Helbling & Co. AG März 2021

8.

Spares (fig. 1 - 4)

Pos. description Article-Number

1

Housing

W03.01001

2

Carriage holder complete

W03.04100

3

Carriage holder right

W03.04501

4

Carriage holder left

W03.04502

6

Chamfer adjustment rail complete

W03.04700

7

Support plate complete

W03.04800

8

Shaft to ball bush

2.0088.00086

9

Base plate

W03.04001

12 Large bearing pedestal complete with felt wiper

W03.04200

16 Small bearing pedestal complete with felt wiper

W03.04300

17 Ball bushings (2 pieces)

2.0088.00087

21 Adjustment complete

W03.04600

25 Sliding blocks complete (2 pieces)

W03.04702

27 Cordell handle complete

W03.04102

28 Bow handle (2 pieces)

2.0088.00088

29 Hexagon socket screw M 10x25

30 Hexagon socket screw M 10x45 (4 Stück)

31 Hexagon socket screw M 6x20 (6 Stück)

32 Hexagon socket screw M 6x20 (6 Stück)

39 Apparatus buffer 2.0088.00089

51 O-rings (2 pieces) 2.0088.00090

53 FU-V2-134Hz 230V / 50Hz

W03.02301

54 MF-V2-134Hz-Motor 230V / 50Hz W03.02500

55 Switch potentiometer complete

W03.02200

55 Speed control knob complete

2.0088.00066

56 Inductive limit switch

W02.02300

57 Mains plug with filter

2.0088.00010

58 Cutter head (see price list)

59 Countersunk screw for cutter head

W10.5001.000/2

60 Front panel complete

W03.03000

63 Inserts (see price list)

64 Pin hole spanner for cutter head with square inserts W10.5001.002

64 Pin hole spanner for cutter head with round inserts W10.5002.002

65 Allen key SW 8 mm

66 Allen key SW 10 mm

67 Hexagon socket screw M12x40

68 Stop

W07.08200

72 Motor flange with mounted screws

74 Start button (illuminated)

W03.02400

75 Emergency stop mushroom button complete with cable

W03.02100

Connection cable CH/EU/GB/US

Helbling & Co. AG März 2021

fig. 1

Details see fig. 2

Details see fig. 2

FRONT VIEW

VIEW ON TOP

Helbling & Co. AG März 2021

fig. 2

fig. 3

SECTIONAL DRAWINGS

RELATING TO FIG. 1

SECTION B - B

Work iece

SECTION A - A

CHIPS

Helbling & Co. AG März 2021

ASSEMBLY AND DISASSEMBLY OF TOOLINGS

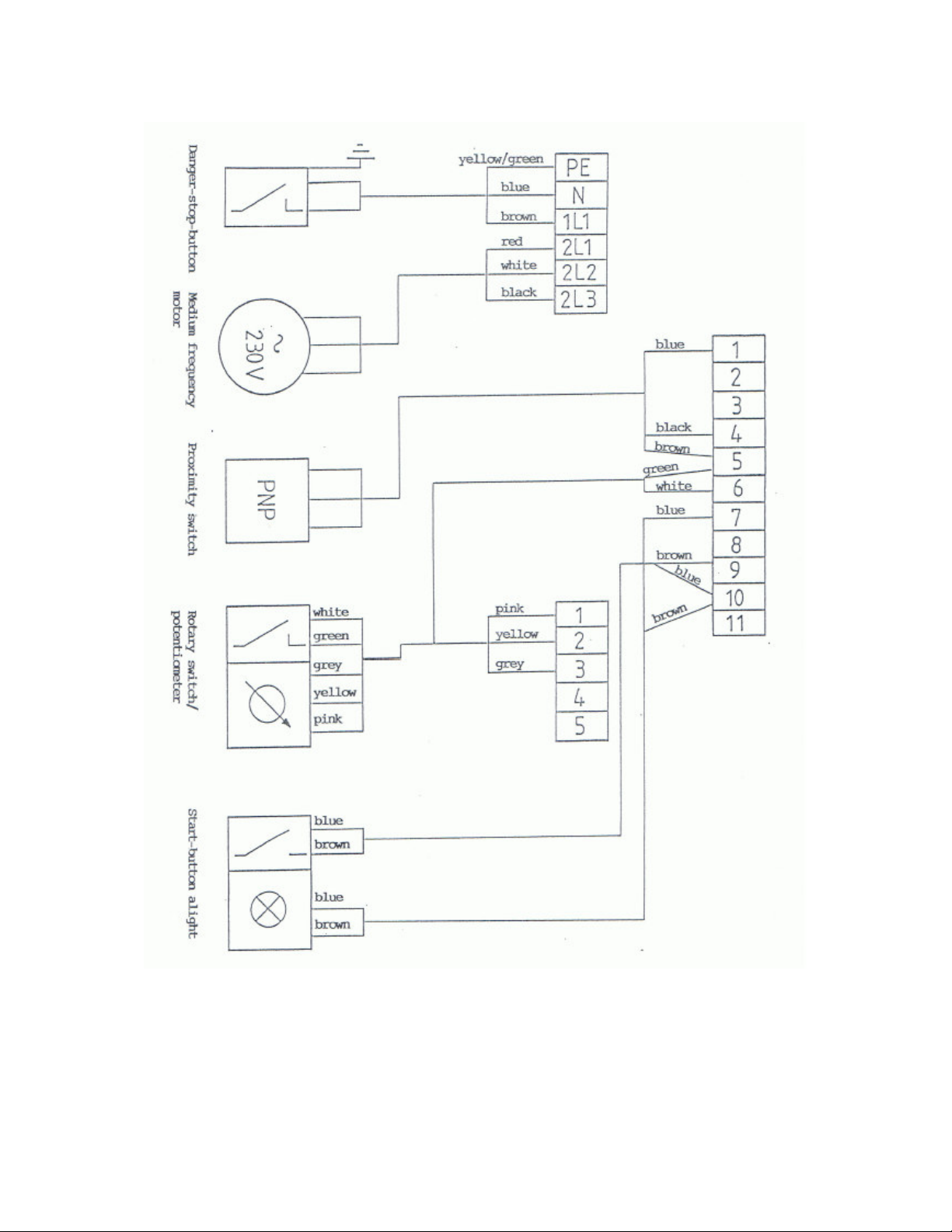

fig. 4 Wiring Diagramm

Helbling & Co. AG März 2021

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

turck

turck RA-SAB-15-36 quick start guide

Neco

Neco STIR-RITE III Owner's/operator's manual

INOXPA

INOXPA KIBER KSF Ex Installation, service and maintenance instructions

WAMGROUP

WAMGROUP VN Instructions for using

Swegon

Swegon COLIBRI Free a Installation, commissioning maintenance

SCHUNK

SCHUNK PWG-plus Series Assembly and operating manual

Samoa

Samoa 391020.270 Parts and technical service guide

EMUGE

EMUGE Speedsynchro Modular/NFC Operating instruction

Apex Digital

Apex Digital A95 OPERATING & SERVICE MANUAL

ensto

ensto EFPLP5 installation instructions

PCB Piezotronics

PCB Piezotronics M352C66 Installation and operating manual

Lenze

Lenze ELN Mounting instructions