HERKULES OFC6 User manual

Part# 1011189

1/27/2021

OWNERS MANUAL

Made in USA

Website: www.herkules.us

E-mail: [email protected] Herkules Equipment Corporation

2760 Ridgeway Court

Walled Lake, MI 48390-1662 USA

Toll Free: 800-444-4351

Phone: 248-960-7100

Fax:

248 960-7109

This manual contains important information concerning the

installation and operation of the crusher listed below.

Page 1 of 16

Warranty ………………………………………………………………………………………………………………........................................... 3

Warnings ………………………………………………………………………………………………………………....…….................…………. 4

Model Information …………………………………………………………………………………………………………….................………….. 5

Important Instructions …………………………………………………………………………………………………………........……......…...... 6

Installation …………………………………………………………………………………………………………..............…………...………… 7

Schematic …............................................................................................................................................................................................... 8

Operation ………………………………………………………………………………………………………………………………............…......... 9

Maintenance …………………………………………………………………………………………………………………................................. 10

Safety Tips ………………………………………………………………………………………………………………………......……................... 11

Trouble Shooting Chart ........................................................................................................................................................................... 12

Drawings with Part Lists …....................................................................................................................................................................... 13-14

Available Options ..................................................................................................................................................................................... 15

Herkules Equipment Corporation

A U.S.-based manufacturer, Herkules Equipment Corporation offers a diverse line of products that support multiple

industries by improving efficiency, productivity, ergonomics, comfort, and safety in the work environment. The

company consists of the three product lines: Herkules, Enkon and BossLifts.

Since 1985, Herkules has designed, engineered and manufactured quality products at our Walled Lake,

Michigan facility. Our company supports our products after delivery, with U.S. based customer service, and

replacement parts, enabling our customers to proceed with confidence.

questions or concerns.

Thank you for purchasing a Herkules product!

Table of Contents

Page 2 of 16

At Herkules we take great pride in the construction of our American-made products, and we stand behind their reliability.

Our limited liability warranty coverage for Crushers warranties the unit for a period of 12 months from the date of purchase.

This warranty does not apply to equipment damaged from accident, abuse, overload, misuse, negligence, improper

installation, abrasive or corrosive materials, or shipping damage.

In the event of product failure, the defective item must be returned, freight prepaid, to the Herkules manufacturing plant for

repair or replacement. If repairs are required, Herkules will not be liable for these repairs to take place in the field regardless

of the application. Proof of purchase and date of purchase must be confirmed. An RGA* (Returned Goods Authorization) and

written approval from Herkules must be obtained before any goods can be shipped to Herkules. We reserve the right to

Determine whether failure is due to defective material, normal wear, and / or other causes.

*To obtain a RGA, contact Herkules at 1-800-444-4351 and have the item model, serial numbers, and invoice number if applicable.

Upon receipt of your equipment, please write your purchase information below. Please retain this manual for your records.

Serial Number Model Number

Purchase Date Distributor (if applicable)

Warning:

This symbol alerts you to the possibility of serious injury or death if you do not follow

the instructions

Caution:

This symbol alerts you to the possibility of damage to or destruction of equipment if

you do not follow the instructions.

Warranty

There are no warranties which extend beyond the description on the face hereof. Herkules

disclaims any warranty of merchantability or fitness for a particular purpose in connection with

the Buyer's purchase of any Product under this agreement. Damages are limited to the sales

price of the Herkules system. The terms and conditions herein represent the entire agreement

between Herkules and the Buyer. Any prior / future representations do not apply.

IMPORTANT NOTICE: if you have a problem with your Herkules product,

DO NOT RETURN TO PLACE OF PURCHASE

Contact Herkules: by phone 1-800-444-4351; by email, [email protected]; or on the web at herkules.us/contact-us.

Page 3 of 16

1. Herkules will not be held responsible for any personal injury and/or property damaged caused

due to owner/operator failure to follow the warnings and cautions listed in this manual.

2. Read and understand all warnings, cautions and instructions before operating this equipment.

3. It is the owner/operators responsibility to maintain the legibility of all warning and instruction labels.

4. Do not alter or modify any part of this equipment.

5.

DO NOT open the door while the unit is operating. Always wait for the crusher to cycle completely.

6.

7. Always wear safety glasses when operating the crusher.

8. Always wear suitable industrial gloves when handling crushed objects to prevent injury.

9. Check equipment regularly for proper operation, and repair or replace worn or damaged parts immediately.

10. Any crusher that appears to be damaged in any way, is badly worn, or operates abnormally must be removed

from use until repairs are made. Use only manufacture's approved accessories and service parts.

Crush only intended matter for the crusher.

FAILURE TO HEED THE FOLLOWING WARNINGS MAY RESULT

IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

WARNING

Page 4 of 16

Maximum crushing force 8,000 Ibs.

Filter capacity

One heavy duty filter

3.75" dia. X 8" tall

Filter type Automotive

Filter crush size reduction Up to 80%

Residual oil removed from crushed filter 95%

Time to crush filter 45 seconds

Overall width 17"

Overall height (bench mount) 27"

Overall height (with floor mount kit) 57"

Overall depth 17"

Chamber width 15.5"

Chamber height 9"

Chamber depth 15.5"

Required air pressure 90 - 120 p.s.i.

Required air flow 20 cfm

Total weight 150 Ibs.

Filter Specifications:

3.75" maximum filter diameter (single)

8" maximum height

Model OFC6 crusher is capable of crushing one filter under 8" tall per cycle. The crusher is

designed for automotive and light truck shops to crush and dispose of used oil filters in an environmentally correct

manner. The crusher provides the following features:

1.

Powerful 4 ton air bag crushing technology assures the force necessary to

do the job when crushing one filter.

2. Operates with external air only. No electric power is required.

3. Door is equipped with device to prevent unintended crusher

motion when door is open, to protect the operator.

4. Removes 95% of residual oil from oil filter.

5. Easy collection of oil drain off.

6. One oil filter capacity.

Model Information

SPECIFICATIONS

Page 5 of 16

1. Read this manual thoroughly before installing, operating, or maintaining this crusher.

2.

Following the installation of this crusher, this manual is to be delivered to the owner of the crusher.

3. Read the anchor bolt instruction page before drilling and installing the anchor bolts (customer supplied).

4. The troubleshooting and maintenance procedures described in this manual can be done by the user.

Any other procedures should be done only by trained crusher service personnel.

5. Herkules will not be held responsible for any personal injury and/or property damage due to

owner/operator failure to follow the warnings and cautions listed in this manual.

6. Do not operate crusher with defective Control assembly.

Important Instructions

CAUTION

Page 6 of 16

Read this manual thoroughly before installing, operating, or maintaining this crusher.

DO NOT attempt to operate the unit while on a skid. The initial crush of the oil filter will cause

the unit to move or jump if not secured properly. The crusher must be anchored to the floor or bench before operating.

1. Determine where the crusher is to be installed. Make sure there is enough room in front of,

and on the sides of, the crusher.

2. Anchor the unit to the bench (or floor) using 1/2" diameter hardware.

3. Connect external air supply to the unit.

4. Place a waste oil collection receptacle underneath the unit, centered under the drip pan hole.

OWNER/OPERATOR RESPONSIBILITY

It is the owner/operator's responsibility to properly use and maintain this equipment.

The instructions and warnings contained in this manual shall be read and understood by the owner/operator prior

to operating this equipment.

If an owner/operator does not understand English, the contents of this manual shall be explained in the owner/

operator native language to assure the owner/operator comprehends.

It is the owner/operator responsibility to maintain the legibility of all warning and Instruction labels.

The owner/operator shall retain this manual for future reference to important warnings, operating and maintenance

instructions.

Installation

Page 7 of 16

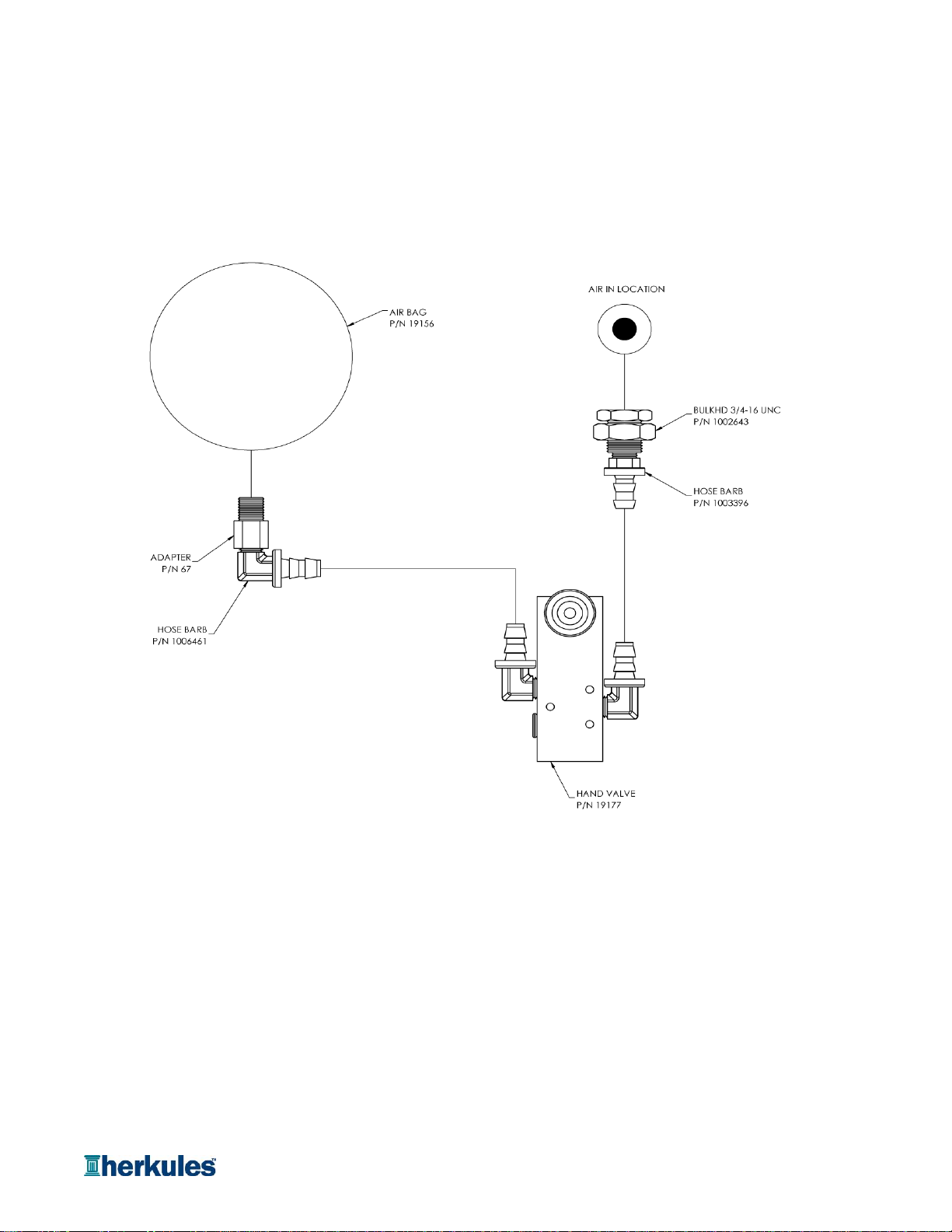

Schematic

Page 8 of 16

1. Connect the external air supply.

2.

Push on Pin Button and swing the door open to gain access to the crushing chamber.

3. Place a single oil filter to be crushed gasket side down on the screen with the filter centered on bolt head.

4Close the door (allowing the pin button to securely latch the door closed).

5. Places the hand valve lever in the UP (Crush) position.

6. Wait until the yellow indicator rod stops.

7. Place the hand valve lever in the DOWN (Return) position.

8. Wait until the yellow indicator rod stops.

9. Depress Pin Button and open door.

10. Remove the crushed oil filter and dispose of it in an environmentally correct manner.

11. Close the door.

Operation

WARNING

WARNING

The crushing ram plate will stop moving when the

door is opened. Wait until the ram plate stops

before placing hand in chamber.

A crushed oil filter may have jagged metal edges.

Use good industrial work gloves to protect the

hands when removing a crushed oil filter.

Page 9 of 16

1. Regularly check the waste oil drain to prevent oil backing up in the crusher cabinet and causing an oil spill.

Clean, repair as required.

2. Regularly clean the crusher chamber to remove any accumulated oil sludge, metal particles or any other debris that

could affect the crusher operation or block the waste oil drain system.

3. Apply 10W oil to door hinges on a regular basis to prevent the door from binding.

4. Check the set screw tightness on the door and hand valve lock-out periodically.

5. Check tightness of the 3/4" nuts located beneath the dome.

Maintenance

Page 10 of 16

Read all instructions.

INSPECT your crusher daily. Never operate if it malfunctions or if it has broken or

damaged parts. Repairs should be made with original equipment parts.

Operating controls are designed to close when released. Do not block open or override them.

NEVER overload your crusher.

ONLY trained and authorized personnel should operate this crusher.

ALWAYS keep crusher area free of obstructions, grease, oil, trash and other debris.

ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact

resistance lenses; they are not safety glasses.

ALWAYS WEAR SUITABLE INDUSTRIAL GLOVES when handling crushed objects to prevent injury.

To reduce the risk of fire, do not operate equipment in the vicinity of open

containers of flammable liquids (gasoline).

Use only as described in this manual. Use only manufacturer’s recommended attachments.

ALWAYS DISCONNECT AIR SUPPLY AND PURGE ALL AIR FROM THE CRUSHER PRIOR TO

PERFORMING ANY MAINTENANCE OF THIS CRUSHER.

POST THESE SAFETY TIPS WHERE THEY WILL BE A CONSTANT REMINDER TO

YOUR CRUSHER OPERATOR. FOR INFORMATION SPECIFIC TO THE CRUSHER, ALWAYS

REFER TO THE CRUSHER MANUFACTURER’S MANUAL.

It is the owner/operators responsibility to maintain the legibility of all warning and instruction labels.

DO NOT alter or modify any part of this equipment.

DO NOT operate crusher while person(s) are on the unit.

Recommendation for mounting this crusher:

To anchored bench: 3/8" hardware (Qty. 3 - hex bolt, washer, & locking nut)

To floor: 1/2" anchor bolts (Qty. 3)

ALWAYS check equipment regularly for proper operation and repair or replace worn or damaged parts immediately.

ALWAYS remove damaged crushers from service until repairs are made to the unit. Use only manufacturer's

approved parts and accessories.

DO NOT REMOVE LABELS. REPLACE IF DAMAGED.

Safety Tips

WARNING

Page 11 of 16

Warning:

There is a danger of personal injury during repair by moving crusher parts.

Warning:

Competent, trained, and instructed staff may perform repair and maintenance work only.

Warning:

Follow all safety instructions during maintenance work.

Troubleshooting Check List

Will not crush as specified No incoming air/low pressure Must supply 90 - 120 psi at intake

fitting

Oil leaking from pan 3/4-10 nuts may be loose Check tightness of 3/4-10 nuts

at top plate

Air leaking sound without crushing Air bag or hose damage Air bag or hose replacement

Consult with manufacturer

Unit jumps while crushing Loose or insufficient anchorage Tighten anchor bolts

Plate nut not retracting enough Internal debris Disconnect air and inspect

interior for debris

Door/air switch interlock not Set screw may be loose Reposition and tighten the set

operating screws in the part

Top plate moving during crusher 3/4-10 nuts may be loose Tighten the 3/4-10 nuts located

operation beneath the dome

Troubleshooting Chart

Possible causes

Kind of trouble

Action Required

Page 12 of 16

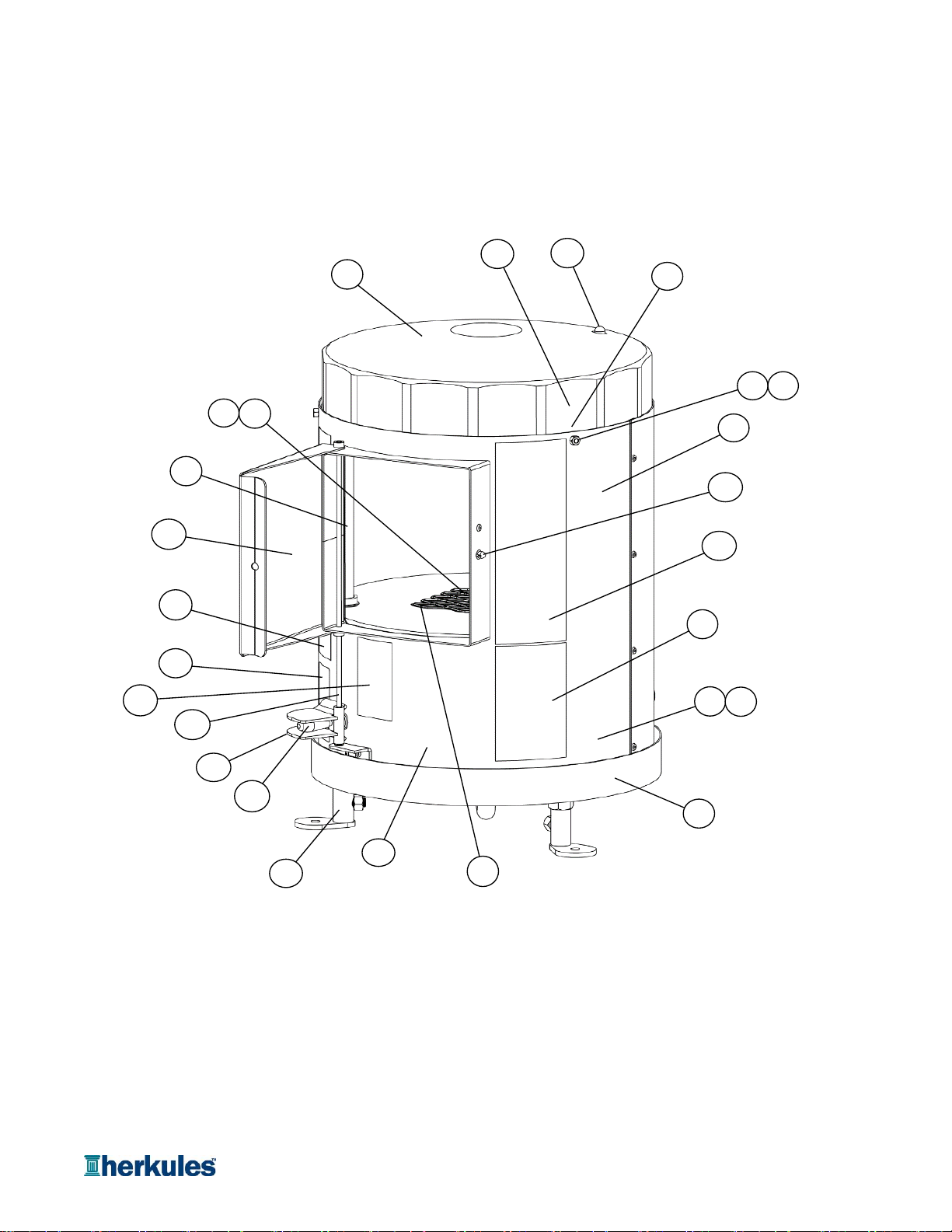

OFC6 Parts Layout

44

6

22

47

45

29

46

43

16

20

21

14

37

25

13

41

31

32

28

38

30

15

2

5

12

4

Page 13 of 16

Part# Description

Qty. Unit

167 (Not Shown) Adapter 1/4 NPT Brass 1EA

284 Nut Hex 1/4-20 Z 3EA

385C (Not Shown) Washer Lock 3/8 Z 2EA

485E (Not Shown) Washer Flat 3/8 USS Z 1EA

5001-702 Bolt Hex 1/4-20 X 1/2 Z 3 EA

6002-172 (Not Shown) Nut Nylock 8-32 Z 3 EA

7008-246 (Not Shown) Screw BHSC 8-32 X 1-1/2 Black 3 EA

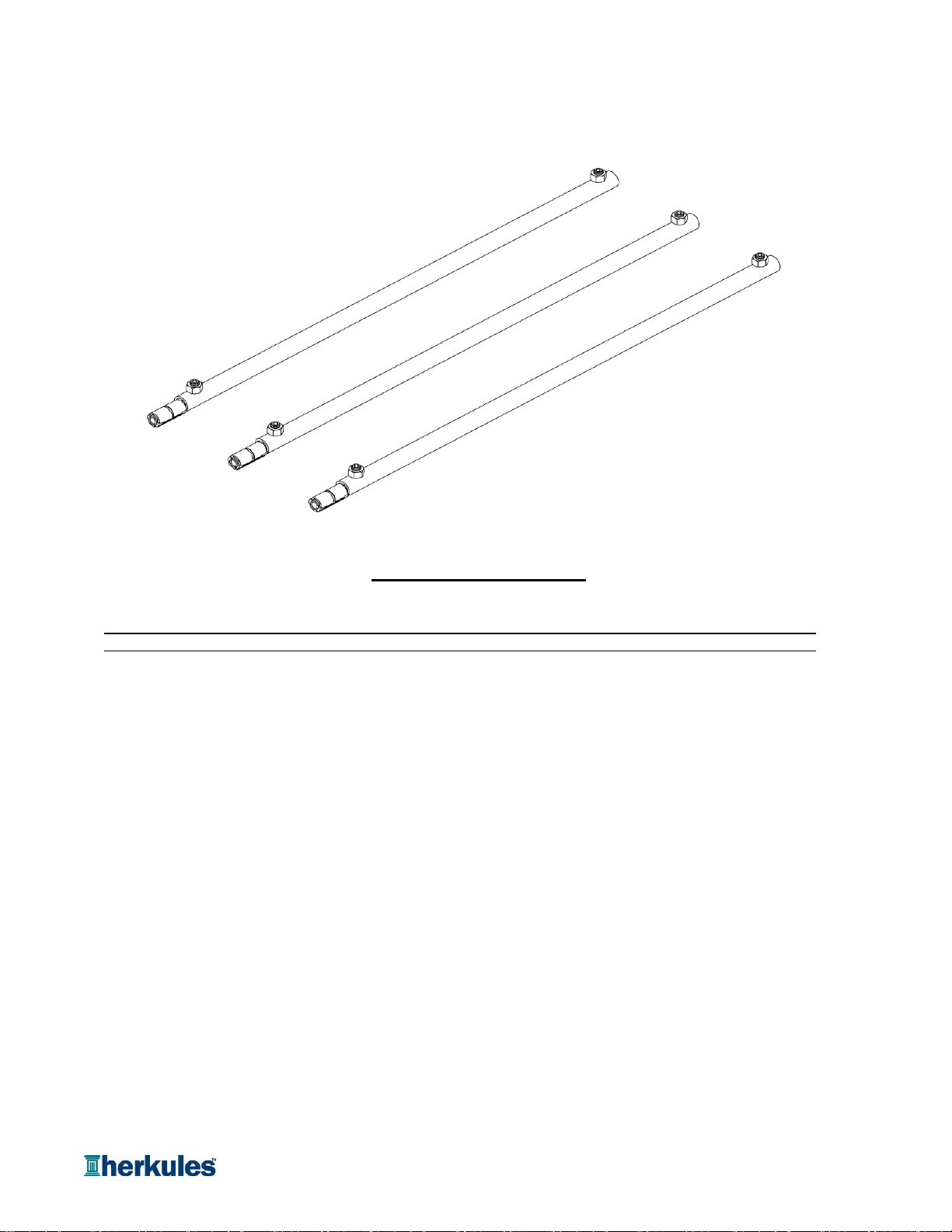

8100-099 (Not Shown) Rod Threaded 3/4-10 x 22.88" LG 3 EA

9100-420 Tube Round 1 x .12 Wall x 13.50" LG 3 EA

10 100-651 (Not Shown) 3 EA

11 18970 (Not Shown) 1 EA

12 18974 Bench Foot Weldment 3 EA

13 18981 Crusher Dome Assembly 1 EA

14 19156 (Not Shown) Air Bag Assembly 1 EA

15 19177 OFC6 Hand Valve 1 EA

16 19197 Drip Pan With Drain Tube 1 EA

17 1000714 (Not Shown) Sticker Serial / Model Number 1 EA

18 1001192 (Not Shown) Bolt Hex 3/8-16 x 1-1/2" LG 2 EA

19 1001229 (Not Shown) Nut Hex 3/4-10 6 EA

20 1001869 (Not Shown) Hose 3/8 ID Rubber 1 EA

21 1001869 (Not Shown) Hose 3/8 ID Rubber 1 EA

22 1002404 Sticker - WARNINGS 1 EA

23 1002643 (Not Shown) Bulkhd 3/4-16UNS 1 EA

24 1003396 (Not Shown) Hose Barb PTL 3/8 1 EA

25 1004822 Bolt SHCS 3/8-16 x 1" LG 1 EA

26 1005082 (Not Shown) Screw Set Cup 1/2-13 X 3/4 3 EA

27 1006461 (Not Shown) Hose Barb PTL 90 1 EA

28 1010053 Pin Button 1 EA

29 1010054 Solid Round 1/4 OD x 16.81" LG 1 EA

30 1010055 Controls Lockout Weldment 1 EA

31 1010063 (Not Shown) Bracket 1-3/4 x 1-1/4 x 1 1 EA

32 1010067 Outer Shell Assembly 1EA

33 1010191 (Not Shown) Guide Yoke Tube 3 EA

34 1010193 (Not Shown) 1 EA

35 1010194 (Not Shown) 1 EA

36 1010196 (Not Shown) 1 EA

37 1010197 Spacer Expanded Metal 5 x 6 1 EA

38 1010201 Indicator Rod 1/2 OD x 15" LG 1 EA

39 1010202 (Not Shown) Ring Retaining External 2 EA

40 1010203 (Not Shown) 6 EA

41 1010207 (Not Shown) Clip - Crusher Dome 3 EA

42 1010208 (Not Shown) Spacer 3/8 OD x 1/4" LG 3 EA

43 1010211 Sticker - Herkules 1 EA

44 1010213 Sticker - OIL FILTER CRUSHER OFC6 1 EA

45 1010214 Sticker - UP / DOWN 1 EA

46 1010216 Sticker - WARNINGS 1 EA

47 1010217 Sticker - CRUSHER Decal 1 EA

48 1010401 (Not Shown) Washer Bonded Sealing 3/4" 3 EA

OFC6 Parts Layout

Tube Round 1-5/16 x 4.256" LG

Plate Round 15.5 OD x 1/2

Plate Round 15.5 OD x 1/2

Plate Round 15.5 OD x 1/2

Ring Retaining External

Yoke Guide Plate Assembly

Page 14 of 16

Part# Description Qty. Unit

18969 Floor Mount Kit 1EA

OFC6 Available Options

Floor Mount Kit #18969

Page 15 of 16

Deliberately Left Blank

Page 16 of 16

Table of contents

Other HERKULES Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB MKey RFID Series product manual

Asyst Technologies

Asyst Technologies VersaPort 2200 Technical manual

ABB

ABB HT590362 Operation manual

Metcalfe

Metcalfe GU4 Installation & operating instructions

Acoustic Signature

Acoustic Signature TA-2000 instruction manual

Conductix-Wampfler

Conductix-Wampfler 0832 operating instructions