TA LE OF CONTENTS

1.0 UNIT SPECIFICATIONS.............................................................................................5

2.0 GENERAL DESCRIPTION..........................................................................................6

2.1 Using this Manual.....................................................................................................8

2.2 Conventions.............................................................................................................8

2.3 Scope.......................................................................................................................8

2.4 Terms and Abbreviations.........................................................................................8

3.0 SAFETY INFORMATION............................................................................................9

3.1 Personal Safety........................................................................................................9

3.2 Personal Protective Equipment..............................................................................10

3.3 Modification to the Equipment................................................................................11

4. 0 INSTALLATION........................................................................................................12

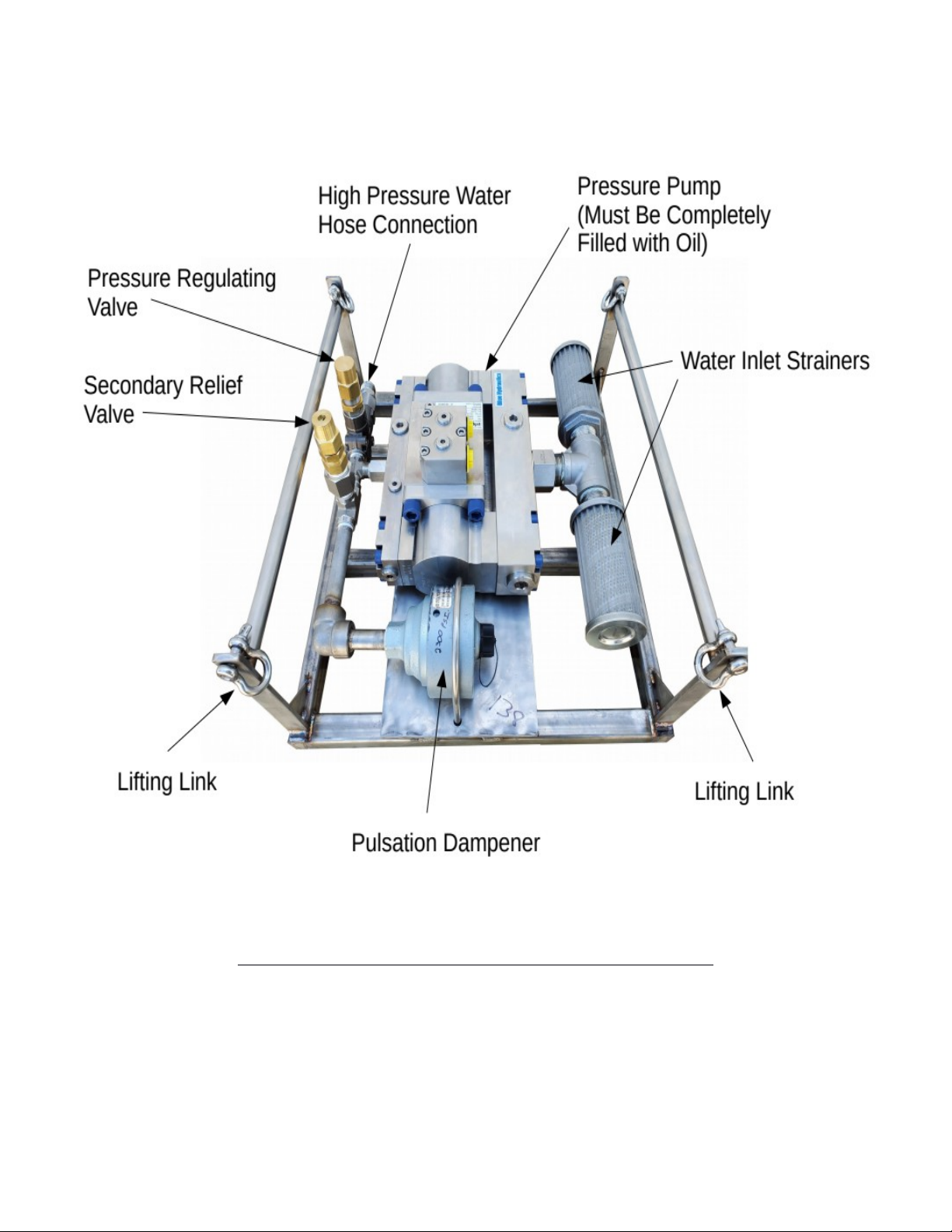

4.1 Uncrating and Lifting..............................................................................................12

4.3 Initial Set-Up...........................................................................................................13

5.0 OPERATION..............................................................................................................14

5.1 Preparing the CaviBlaster for Operation................................................................14

5.2 Startup of the CaviBlaster......................................................................................15

5.3 Normal Operation...................................................................................................15

5.4 Adjusting the CaviBlaster for Maximum Performance...........................................16

5.5 Recommendations for Effective Results................................................................19

6.0 MAINTENANCE........................................................................................................21

6.1 Basic Preventive Maintenance Recommendations...............................................22

6.3 Pump Service.........................................................................................................22

6.4 Inspection / Cleaning of Water Inlet Strainer.........................................................22

7.0 TROU LESHOOTING..............................................................................................23

8.0 REPLACEMENT PARTS..........................................................................................24

APPENDIX - COMPONENT LITERATURE....................................................................25

Page - 3