Desay M8 User manual

Document: DS-M8--OPM-1.0M Page 1of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

8mm Pixel Pitch with SMD LEDs

M8

Outdoor LED Display Users Manual

Operation Manual

19-Mar.-2015

Document version 1.0M

Document: DS-M8--OPM-1.0M Page 2of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

Attention

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT OPEN THE PANEL ACCESSIBLE

DOORS WHEN POWER IS ON.

Always ensure that the unit is properly earthed and power connections correctly made.

This equipment must be supplied from apower system providing aPROTECTIVE EARTH

connection and having aneutral connection, which can be reliably identified.

The power outlet supplying power to the unit should be close to the unit and easily accessible.

Always remember to close and lock the panel access doors after servicing and before resuming

the power supply.

Ensure whole system power off before connect or disconnect the net cable.

This pluggable type Aequipment is professional installable.

For pluggable equipment, the socket-outlet shall be installed near the equipment and shall be

easily accessible.

Always remember to dry the panel fully before packing .

Store in adry and airy place .

This is aclass Aproduct. In adomestic environment this product may interference in which case

the user may be required to take adequate measure.

Document: DS-M8--OPM-1.0M Page 3of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

TABLE OF CONTENTS

1General………………….………………....................………………….………………………………......…………….. 4

1.1 M8 LED panel specification …….…………………………………………....….............………………............. 5

2Main Assemblies………………….……….....................………..…………………………………………………...... 6

2.1 Main Composition of display unit …………………………..................……...……………………..........…... 6

2.1.1 Component placement ……………….....................……………….……………………………………......……... 6

2.2 Intelligent modules (IM)………………….........................…………….……………………………………..……... 7

2.3 Hanging Stacker (HB) ………………………………………… ..............…………………...…………………..…... 8

2.4 Stacker &Base……………………….……………………………...…………………............................………….……9

2.4.1 Base ……………………………………………………………..………………............................………………..…….…. 9

2.4.2 Stacker ……………………………………………………………………………..................……………………...….… 10

2.5 Truss ……………………………………………………….....................…………………………………................…... 10

3Installation Guides…………………………………………………………………....................…………..…….…. 11

3.1 Mechanical……………………………………………………………………………………......................……..…...... 11

3.1.1 Rigging/Hanging Installation ……………………………………........……………………………..………….. 12

3.1.2 Stacking Installation ………………………………………………….....……………………………................…….13

3.2 Electrical……………………………………………………..........................……………………………………..……….14

3.2.1 Circuit protection………………………………………………....................………………………………..……....... 14

3.2.2 Earth leakage considerations……………………….............…………………………………………..………….. 14

3.2.3 Inrush-current and over-current considerations……………..…………………………………………..... 14

3.2.4 Earthing………………………………………………………………........................……………………..….………...... 14

3.2.5 MC statement………………………………………………........................…………………………………………….15

3.3 Power Cabling Wiring………………………………………………...............……………………..…….……....…15

3.3.1 AC Power…………………………………………………….........................……………………………………….….... 15

Appendix A : M8 Mechanical Assembly &Wiring Diagram.......................................................... 16

Appendix BProcedure for IM, Power supply& receiving cards Replacement.......................... 17

Appendix CTrouble shooting ………………...……….……………………........................................... 19

Document: DS-M8--OPM-1.0M Page 4of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

1. General

Thank to use DESAY’Sled display screen and the relative devices.

This manual mainly introduces basic parameters and operation method of M8. A Led display screen

involves cabinet, Main controller, Branch controller, HUB, computer and other peripheral.

The M8 is easy to install and operate, with powerful functions, with low requirements on working

environment and high protection rate. And it can realize intelligent power on/off &24 hrs timing

on/off. These above aspects perfect the display function.

Address: Huizhou DESAY Intelligent Technology Co., Ltd. DESAY 3rd Industry Zone, Chenjiang,

Huizhou, Guangdong Province, China

Tel: +86 0752 2617333(Headquarter in Huizhou)

Fax: +86 07522617733 (Shenzhen office)

Website: http://www.desayopto.com

Document: DS-M8--OPM-1.0M Page 5of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

1.1 M8 LED Panel Specifications

M8 Specification

No

.

Specifications

Parameters

1

Model No.

M8

2

Pixel pitch

physical pitch:≥8 mm

3

Brightness

≥6000 nit

4

Pixel configuration

SMD 3in1

5

Pixel density

25600 pixels/sqm

6

Viewing angle (min. 50%

brightness)

Horizontal: 140 degree (+70/-70)

Vertical:120degree (+60/-60)

7

Lifetime (full white –50%

brightness)

≥100,000 Hours

8

Power consumption /sqm

Max.: 450W Avg.: 160W

9

Refresh frequency

≥2000Hz

10

Colors

281trilion

11

Weight/panel

16.6Kg

12

Control system

Nova system

13

Certification

CE

14

Module size

400mm×150mm

15

Panel size

800mm(W)×900mm(H) =0.72sq.m

16

Recommended viewing distance

≥8m

17

Operating environment

Temperature: 10°C~+40°C; Humidity: 10%~95%

18

Input voltage

110~230V/AC(±10%)

19

Input power frequency

50/60Hz

Document: DS-M8--OPM-1.0M Page 6of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2. Main Assemblies

2.1 Main Composition of display unit

Item

Description

Qty(PCS)

1

Intelligent Module (IM) including IM driver /LED PCBA

12 PCS

2

Reception board+ HUB

1

3

5V 300W Switched Mode Power Supply

2

4

Power connector

2

5

signal connector

2

2.1.1 Component Placement

Fast lock

Power/data out

Indicator

light

IM NO.

IM

Handle

Power supply lock

Heat sinks

Label

Lock buckle

Data/power in

Document: DS-M8--OPM-1.0M Page 7of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2.2 Intelligent module (IM)

Module usage: module is avery important part of display unit, it can convert video signal into

optoelectronic signal, finally return to video image.

Failure Analysis: When the display module does not work normally ,they generally will show ablack

screen, full white, flashing, color cast, multi-line black LED lamp dots, etc., and may affects next

module’sworking.

Note: Be sure to turn off the power before replacing the module, pay attention to the method and

strength when pulling out and inserting the power cable and flat cable, dot not damage the

power cable, when plugging the power cable, pay attention to insert to the corresponding place,

cannot misplace or reverse insert, the flat cable insert should choose the right place, do not

reverse insertion.

IM Model

PCB

Data/power supply interface

Document: DS-M8--OPM-1.0M Page 8of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2.3 Hanging Bracket (HB)

(hanging bracket) (double hanging bracket)

The hanging bracket (HB) is alifting device specially designed to lift one or several panels that have

been locked together, and thus form acolumn or astack. When screens are rigged or flown from a

truss, the HB will form the connection between the truss and the column of the screen. Subsequently

the HB holds the complete weight of this column. It is important to keep the HB in good condition and

check it before use.

Mechanism is basically made of the locking rod inside the centre door of the panel. To lock the panel

to the HB, you need to insert the kingpin through the hole in the HB, and then turn the locking rod

(inside the centre door of the panel), so that the kingpin can slide into the locking position on the HB.

When using the hanging brackets, the operator should make sure that the kingpin of the

panel is locked onto the hanging bracket.

Specification of the SHB (size: W x H x D)

Dimensions (hanging bracket including connection piece ): 799.5 x100 x50mm

Weight (hanging bracket): 3.8 Kg

Specification of the DHB (size: W x H x D)

Dimensions (double hanging bracket including connection piece): 1599 x100 x50mm

Weight (double hanging bracket): 8.5Kg

Document: DS-M8--OPM-1.0M Page 9of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2.4 Stacker &Base

(Double stacking +base)(Triple stacking +double base)

2.4.1 Base

The base is used for stacking ascreen. It uses the same locking system as

panels, so the kingpin on the base is locked into the panel. The base has

adjustable feet to level out the screen.

Specification of the Base (size: L x H x W)

Dimensions (base): 1795 x350x 50 mm

Weight (base): 8.0 Kg

Document: DS-M8--OPM-1.0M Page 10 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2.4.2 Stacker

(double stacking)(Triple stacking)

The stacker is an external buttress used when the screen is stacked. These stackers can be locked onto

the back of the panel to give the stacked panels extra support. There are two types of stacker available:

double stacker and triple stacker, which can lock respectively 2or 3panels on the stack. By combing

these, ascreen with uneven rows can be made. The stacker must be locked onto the ski or onto the

stacker underneath using the locking rod and the extra security pin. The stackers are locked onto the

panel using the connection screws. Stackers must be used at all times when screens are stacked. The

stacker should be properly locked to the panel and ski/base.

Specification of the Stacker (size: L x H x W)

Dimensions (double stacker): 1600 x150 x100mm

Weight (double stacker): 22 Kg

Dimensions (triple stacker): 2400 x150x 100mm

Weight (triple stacker): 32 Kg

2.5 Truss

The Truss is an external buttress used when the screen is stacked. These Truss can be

locked onto the back of the panel to give the stacked panels extra support. The truss

can lock respectively 2or 3panels on the stack. By combing these, ascreen with

uneven rows can be made. The Truss must be locked onto the ski. The Truss are

locked onto the panel using the connection screws.

Truss must be used at all times when screens are stacked. The Truss should be

properly locked to the panel and ski/base.

Specification of the Truss (size: H x W)

Dimensions (Short): 1795 x350 mm

Weight: 7Kg

Document: DS-M8--OPM-1.0M Page 11 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

3. Installation Guidelines

Please read the following carefully before installing the panels

3.1 Mechanical

The M8 panels can be installed in two ways: rigging/hanging or stacking/ground support. In either

case, it is important to ensure that the entire screen is correctly aligned both vertically and horizontally,

to ensure there are no visible gaps.

The principle is to build several panels vertically on top of another and horizontally next to another.

The panels are locked together both vertically and horizontally, so that they can form one surface of

screen-configuration.

Locking mechanisms (4 lockers: Up &left )at the panel does the horizontal &vertical locking of the

panels on to each other. Each panel has been tested with aweight of 2.5tons attached to the bottom

locking mechanism. The Top locker is then attached to ahoist and the whole is lifted into suspension.

As panels are locked to one another, each panel forms acritical element of the complete structure.

Especially when screens are rigged or flown, the top panel of each column (or stack) supports its own

weight plus that of the number of panels underneath in the same column. In the stacked screens,

the bottom panel supports the weight of the whole column.

Lock

Loosen

Document: DS-M8--OPM-1.0M Page 12 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

3.1.1 Rigging/Hanging Installation

When ascreen must be rigged, astructure must be placed before the building of the actual screen can

start. The screen engineer makes sure that the structure is correctly built and that it is intended for the

correct weight and size of the screen. The screen engineer must make the same checks for the beam,

beam trolleys, motors or any other devices that form apart of the structure or the lifting devices.

Consult for maximum height of screen in next section.

Notes:

1)A base can never be used without atruss.

2)The motor must always be secured with asteel cable or astrap.

3)Hanging structure verified with TUV strength test 1.8tons

3.1.1a To rig asingle column of ascreen

1Attach the hanging bracket to the hanging motor (with turnbuckle) and hoist it up.

2Lock and secure the panel onto the hanging bracket with the locking system.

3Repeat for all the columns.

4Place the columns next to each other and lock the panels horizontally.

5Bring the next panel straight under the row that is already hanging on the motor.

6Lock and secure the panel on the hanging panel. Repeat for other columns and lock

horizontal. Finally hoist up the 2rows of panels. Continue this process until the screen column

is finished.

3.1.1b To rig the screen in row direction

The side lock is used to lock the columns of panels next together to form the rows.

Safety while in use:

When the installation is finished, steel cables or straps can secure the columns.Cables or straps

must be attached to the screen so that it can rock back and forth, but cannot move to far to the front

or to the back. Make sure everything is locked &secured.

double stacking

Document: DS-M8--OPM-1.0M Page 13 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

3.1.2 Stacking Installation

Before starting make sure that the surface, on which the screen

is to be build, is strong enough to hold all the weight, including

counterweights. Consult for maximum height of screen in

next section.

Procedure for stacking installation:

1Place the base with the one or two short skis. If

necessary you can place an extension ski locked onto ashort ski.

Lock the connection screws of the skis onto the bases and level

out with the adjustable feet. Do this for all bases and lock these

together and level out.

2Place the first row of panel onto the base and lock.

3Lock the panels horizontally together.

4Place and lock the next row(s) onto the panels and also

lock horizontally.

5Depending on the height of the total screen you now lock

adouble (two panels high) or triple stacker (three panels high)

onto the panels.

6Continue this procedure for all the rows. Make sure to

lock firmly and the stackers must be lock onto each other.

Safety while in use:

When dismounting the screen care must be taken that the

horizontal locking is undone before attempting to hoist the

panels.

Truss

Stacking

Base

Document: DS-M8--OPM-1.0M Page 14 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

3.2 Electrical

The power distribution system used must provide adequate protection against excess line current and

leakage currents to earth.

Electrical Characteristics for ONE M8

For large installations, athree-phase supply is recommended and the power from each phase should

be distributed evenly to the single-phase appliance coupler on each panel. The screen may be

conveniently split into sections (e.g. rows or columns), each powered from asingle phase.

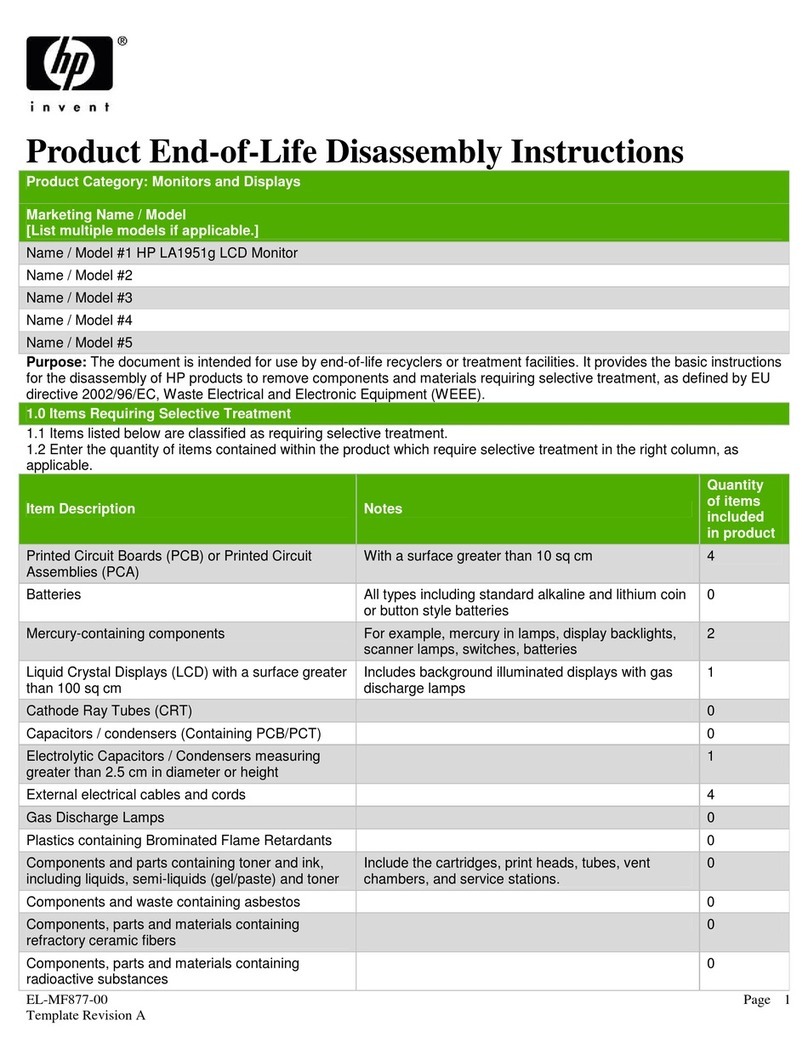

3.2.1 Circuit Protection

Each section of the screen should be protected by aCircuit Breaker to protect against high fault

currents, and aResidual Current Device (RCD) to detect earth leakage currents.

3.2.2 Earth Leakage Considerations

To reliably operate aLED video screen, the leakage value figure per panel must be known, or if the

leakage value is close to the breaker trip value, the breaker may trip at avery inopportune time.

Ensure that the total leakage current value per earth leakage breaker is at least 10% (preferably 20%)

below the value earth leakage breaker trip point to ensure that nuisance tripping does not occur. Earth

leakage current is normally aconstant value, but can increase in wet or humid weather, so this margin

is suggested.

Each panel of the system has earth leakage current contributions from two switched-mode power

supplies and one RFI filter. The total earth leakage current per panel can be up to 3mA at 240V. If a

24mA RCD is used, then the maximum number of panels per section should be safely limited to 8.

3.2.3 Inrush-current and over-current considerations

Video screen panels draw avery high in-rush or surge current at the moment of switch-on. This

current can be twenty times the maximum operating current of the panel, but occurs only for avery

short time –typically less than half an AC power cycle –less than 10 ms.

On each M8 panel the in-rush current is 180A at 230V. However, maximum current in the steady-state

for apanel is considerably less: 2 A at 240 volts. This high in-rush current needs to be considered when

selecting asuitable circuit breaker to feed the panels. In choosing the circuit breaker, both the

maximum operating current and the in-rush (surge) current need to be considered.

Document: DS-M8--OPM-1.0M Page 15 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

3.2.4 Earthing

Each panel is separately connected to the ac power distribution system’searth though the appliance

coupler’sgreen/yellow wire connection. All exposed panel metalwork (main frame and doors) is also

connected to this earth.

If the framework is earthed only through each panel (i.e. through the panel’smounting bolts), there is

apossibility of electrical damage if awiring fault occurs, or if an electrical discharge, such as lightning

strike, hits the panels. Under these circumstances, the current discharge path will be through the panel

to earth rather than through the framework to earth. When permanently installed on ametal

framework, the framework itself should be directly connected to earth.

3.2.5 FCC Statement

This equipment has been tested and found to comply with the limits for aClass Adigital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in acommercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in aresidential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. (in order to realize this one

product must be in conformity with the EMC standard screen, common case is not suitable )

*Note: Modifications not authorized by the manufacturer may void users authority to operate this

device. The above Electrical data subject to Ming Wei power supply with CE certification

3.3 Power Cable Wiring

3.3.1 AC Power

An approved three-pole appliance coupler inside the center door connects to the AC supply. The AC

power cable is then connected to the EMI filter and distributes to the power supply units on left and

right doors. Each door has an earth point for grounding.

DC power from each power supply unit provides low voltage power to the assigned electronics

components, for example, driver board, and fans, the responding color of the wire represents the

relevant component´s power connection, please note the list below for aclear cabling configuration.

Document: DS-M8--OPM-1.0M Page 16 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

Appendix A: M8 Mechanical Assembly &Wiring Diagram

1. Mechanical Assembly

Document: DS-M8--OPM-1.0M Page 17 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

2. Wiring Diagram

①handle

②Receive card

③PCB

④Reticle

⑤cable

⑥power supply

⑦The power supply box lock

⑧Black MYLAR sheet

Appendix B: Procedure for IM Replacement,Power Supply, Receiving Card

Procedure for IM Replacement :

1. Power off the panel.

2. Open the relevant panel door and locate the problem IM.

3. Remove all the cabling (from the power connector and data connector) of the problem IM

and take the IM off from the panel; (totally 5screws need to be remove, see the following pictures.)

4. Take out the replacement IM.

①

②

③

④

⑤

⑥

⑦

⑧

Document: DS-M8--OPM-1.0M Page 18 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

Procedure for Receiving Card replacement:

1. Power off the panel.

2. Find the receiving cards. (see the following picture)

3. Disconnect the four screws.

4. cut off the cable tie fixed the black MYLAR sheet.

5. Replace it with new receiving cards.

Procedure for Power Supply replacement:

1. Power off the panel;

2. Open the relevant panel door and locate the problem Power supply;

3. Disconnect the four screws by M3 sleeve;

4. Disconnect the power supply line of the input and output;

5. Replace it with new power supply.

Cable tie

Document: DS-M8--OPM-1.0M Page 19 of 19 ©DESAY INTELLIGENT CO. LTD.

T+752 2617 333 led@desay.com WWW.DESAYOPTO.COM

Appendix C: Trouble shooting

Failure phenomena

Failure cause

Treatment

LED lamp in IM

(intellectual LED

module)dead, dark,

and long lighting.

Dead and dark Lights 50

are generally the problem of LED lamp; LED long

bright may be caused by IC empty soldering or

internal short circuit.

Replace the IM

Four LEDs in arow are

dark or long bright

IC short soldering or bad pin inserting

Replace the module

Entire IM and the IM

next to it doesn’t

display or display

white

1.The IM with bad circuit

2. Bad Flat signal cable

3. Bad power supply plug on the IM

1.Replace the bad

module

2.Replaced the bad flat

signal cable

3.Replace power supply

plug

Many IMS don’t

display

1.No voltage output for the power supply

2.Bad branch controller

1.Replace the bad

power supply

2.Replace the branch

controller

The whole screen is

blank

1.Main control card is damaged

2. The first branch card has been damaged.

3.IPC don’thave DVI output

4Multifunction card has been damaged

1.Replace the main

controller card

2.Replace the branch

controller

3.Set the DVI output or

replace the bad display

card in the PC;

4.Replace bad

multi-function card

picture is not

consistent in multiple

area of the screen

Wrong Panel address setting or wrong wire

connecting in the Control software

Reset the Panel address

and wire connecting in

the software

exchanged displaying

for multi -IMs

Exchang the connection of the first flat module of

data line

Exchange date line

The screen can not

automatically control

the brightness

1.Multifunction card has been damaged;

2Light sensors have been damaged;

3Control software does not start the automatic

brightness control;

1.Replace the

multifunction board;

2.Replace the light

sensors;

3. Reset to automatic

brightness control in

the software.

Table of contents