TB-2039 Page 3 of 4

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - 90 Hudson Road, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

Step 2: Connect the second test lead to the 675K jack

labeled “A” on the 07010. Touch the opposite end of

test lead to the test plate. Observe the LED’s for the

proper response as indicated below. Be sure to hold

the cord at an insulated point, so that the resistance

value is not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low - hazard)

Green jack “B” - 825K: Green (OK - in limits)

Green jack “C” - 8.5M: Green (OK - in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown for the 19350. If the tester does not

meet calibration specifications, contact factory for

calibration, or ask for Technical Bulletin TB-2004.

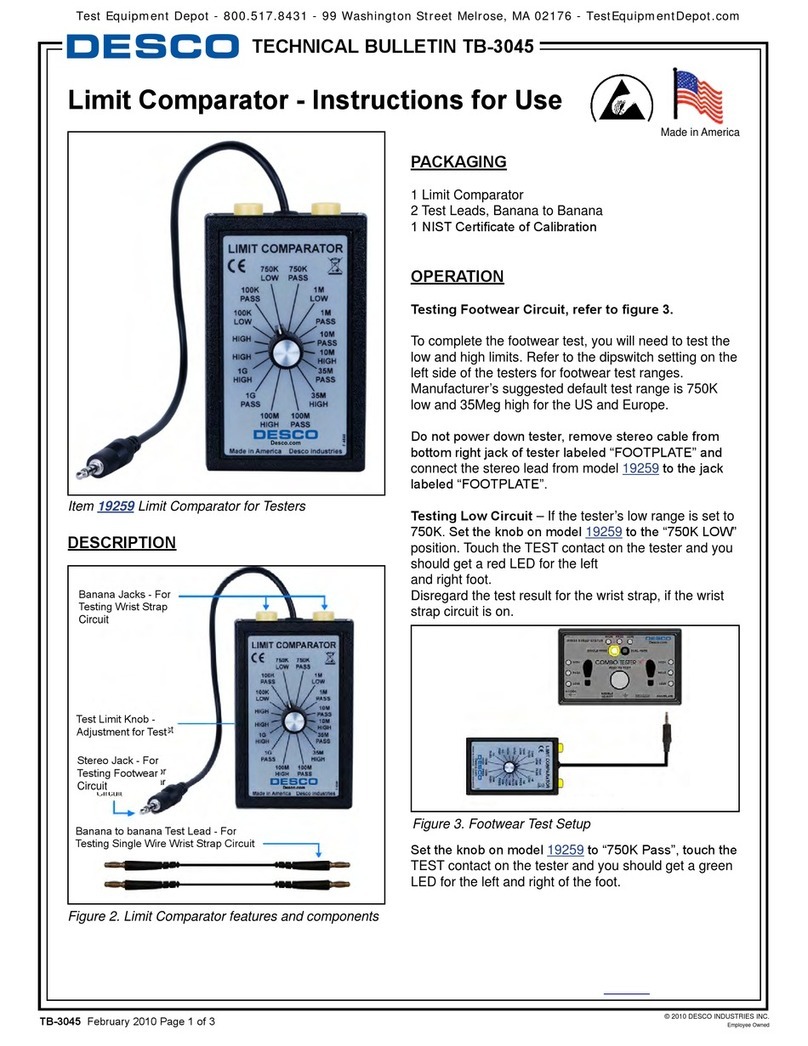

Figure 7. Testing 19350 for “PASS” and “FAIL” ranges

as indicated on calibration unit.

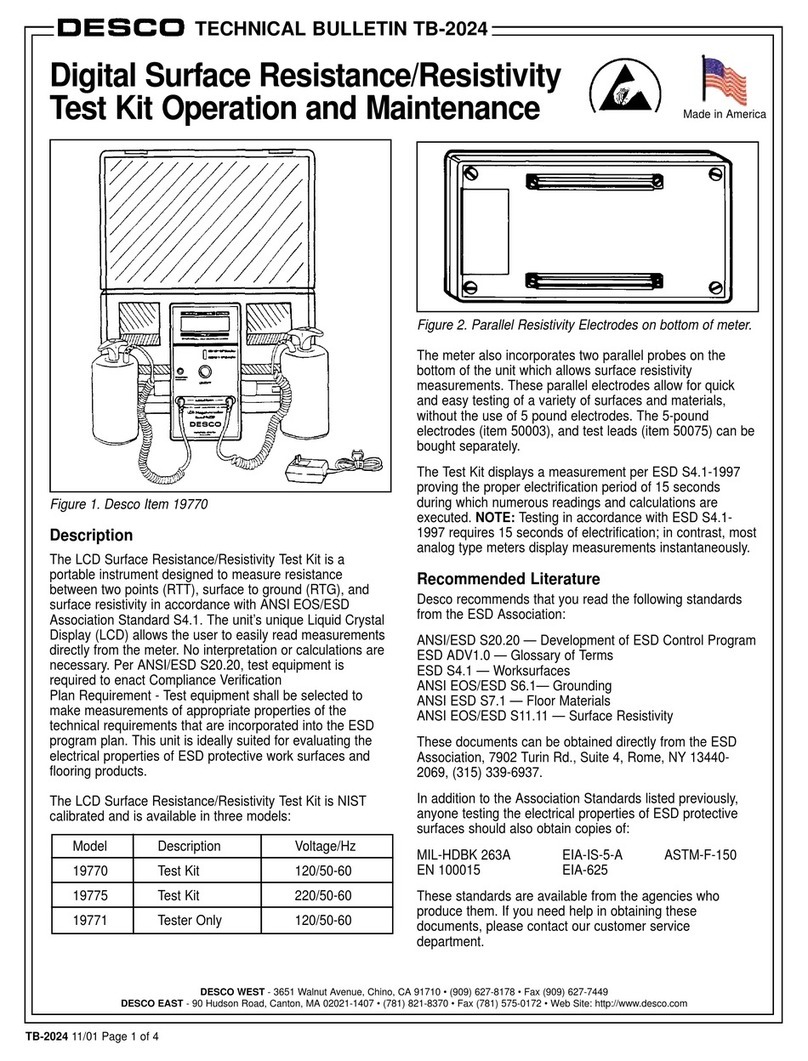

CALIBRATION OF THE MODELS

19250, 19251 AND 19252

The models 19250, 19251 and 19252 testers utilize the

identical test unit. The difference between the three

models is the hardware that is included with each unit.

The model 19250 includes only the tester, model

19251 includes the tester and a metal foot plate, while

the 19252 is the tester and metal test stand assembly.

This test unit is designed with two separate test circuits

with distinct pass fail ranges. The wrist strap test

circuit incorporates a 750K - 10M pass range while the

footwear test circuit is set to pass at 750K - 100M.

Each test circuit needs to be tested individually. For

detailed information on these testers please ask for

Technical Bulletin TB-2040.

Wrist Strap Test Circuit

Step 1: Connect one of the test leads to common

point banana jack labeled “E” on 07010. Connect the

opposite end of test lead to the 19250’s wrist cord jack

located on the face of the unit.

Step 2: Connect the second test lead to the 675K jack

labeled “A” on 07010. Touch the opposite end of test

lead to tester’s test plate and press down with enough

pressure to activate the test circuit. Observe the LED’s

for the proper response as indicated below. Be sure to

hold the cord at an insulated point, so that the

resistance value is not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675K: Red (Low - hazard)

Green jack “B” - 825K: Green (OK - in limits)

Green jack “C” - 8.5M: Green (OK - in limits)

Yellow jack “D” - 11.5M: Red (High resistance)

Step 3: Repeat the procedure testing across jacks B,

C, and D. The different resistance ranges should give

the display shown above. If the tester does not meet

calibration specifications, contact factory for calibration,

or ask for Technical Bulletin TB-2040.

Figure 8. Testing 19250 for “PASS” and “FAIL”, wrist

strap test circuit.

Footwear Test Circuit

Step 1: Connect one of the test leads to common

point banana jack labeled “E” on 07010. Connect the

opposite end of test lead to the 19250’s foot plate

ground jack located on the side of the unit.

Step 2: Connect the second test lead to the 675K jack

labeled “A” on the 07010. Touch the opposite end of

test lead to tester’s test plate and press down with

enough pressure to activate the test circuit. Observe

the LED’s for the proper response as indicated below.

Be sure to hold the cord at an insulated point, so that

the resistance value is not affected by the body.

© 2003 DESCO INDUSTRIES INC.

Employee Owned