Cirris Touch1 LV Installation and operation manual

Touch1 Ultra

Performance Verification Manual

Version 2010.1.4

August 9, 2010

(ISO 9001 Certified)

Touch1 Ultra Performance Verification Manual

Version 2010.1.4

Copyright 2006 by Cirris Systems Corporation

All Rights Reserved

Cirris Systems Corporation

1991 W. Parkway Boulevard

Salt Lake City, Utah 84119

USA

Touch1 Ultra Checkout Manual – Page 1

Table of

Contents

Introduction..........................................................................................................................................2

Set Up ...................................................................................................................................................3

Tester Checkout Tests.....................................................................................................................4

Self Test

Touch Pad Test

Probe Test

Low and High Voltage Threshold Tests

High Voltage Tests

Capacitance and 4-Wire Tests

Scanner Tests

Tester Checkout Summary...........................................................................................................14

Appendix.............................................................................................................................................16

Calibration Certificate.....................................................................................................................18

Touch1 Ultra Checkout Manual – Page 2

Introduction

The Touch1 Ultra Performance Verification Kit allows you to verify calibration and proper

operation of the Touch1 Ultra tester. The Associated Research Hypot Ultra unit has it’s

own calibration procedure found in the Associated Research Hypot Ultra Users Manual.

Each Performance Verification Kit has a lifecycle of two years from the time of purchase.

At the end of two years, the kit can be recalibrated or replaced. All of the components for

this performance verification kit are tested with instruments traceable to the National

Institute of Standards and Technology (NIST).

Calibration should be performed on your Touch1 Ultra tester at least once a year. You

should also check the calibration whenever you suspect the tester may not be operating

properly. If the Touch1 Ultra tester fails any step in the performance verification

procedure, it must be sent back for repair. No external adjustments can be made to fix

the tester.

For information on setting up a calibration system to meet national calibration standards

such as ANSI/NCSL Z540-1, and ISO 10012-1, see the appendix of this manual.

Touch1 Ultra Checkout Manual – Page 3

Set Up

Packing List:

You should have received the following items with your Touch1 Ultra Performance

Verification Kit:

•This manual which includes a copy of a Touch1 Ultra Certificate of Calibration

•0.1% Resistor Leak Adapter

•T1/H+ Capacitance/4-Wire Adapter

•Zero Ohm Adapter

•HVI Block PCHK Adapter

Tester Preparation:

To prepare the tester for calibration, do the following:

•Install any expansion boxes you want to use. For information on how to do this, see

your Touch1 ULtra Users Manual.

•Connect the power cord to the tester. Plug the tester into a grounded power outlet.

•To print Tester Checkout results, connect a printer to the tester using the parallel port.

•Depending on your calibration system requirements, you may need to prepare a form

to record the results of the calibration. At the end of this manual is a Touch1 Ultra

Certificate of Calibration. If you use this form, make a photocopy so you can maintain

the master for the next time you perform the calibration tests.

•Special equipment is required to do the high voltage tests. To do the high voltage

tests, be certain your voltmeter is equipped with a high voltage probe. For

testing above 1000 volts DC, your voltmeter must be equipped with a high voltage

probe which has > 50M ohms of input resistance and be able to safely withstand over

1500 volts DC. Your voltmeter may be damaged if you do not take these

precautions.

Touch1 Ultra Checkout Manual – Page 4

Tester

Checkout

Tests

1. From the Main Menu, press System Setup.

2. At the System Setup screen, press Tester Checkout.

3. The Tester Checkout Selection screen allows you to decide which tests you want to

run for your calibration process. You can select Full Calibration to run all of the tests

or you can select an individual test to run.

Touch here for

full calibration

General Procedures for all Tests

•To switch a test option on, touch the button for that test so a checkmark appears inside

of the box. If there is no checkmark inside the button, the test is turned off.

•To start a test, press Next Test X where X lists the test to be performed. The Touch1

Ultra will perform the test and then show either a Pass or Fail result. You can abort any

test except the Touch Screen Test by pressing the Abort button. The Touch Screen Test

will automatically abort if the screen is not touched for ten seconds.

•To proceed to the next test you have selected, press Next Test X. If all the tests have

finished, press Show Summary.

•If during testing you want to cancel all remaining tests and see a summary of the test

results so far, press Cancel.

•To print the results on a printer, press Print. Some tests have individual summary results

you can also print.

Touch1 Ultra Checkout Manual – Page 5

Self Test

When this test is selected, the Touch1 Ultra will perform ten passes of a series of major

tests. These are the same tests performed automatically on power up. They test the basic

functionality of the tester to see if it can perform reasonable measurements within

specification. Some of the tests include the voltage measurement gain circuitry, the high

voltage circuitry, the high-current source, the negative current clamp, the capacitance

measurement hardware, etc.

1. To start the test, press Next Test: Self-Test.

2. All ten passes must complete without errors for the tester to pass Self Test.

This screen shows the

seventh pass for the group

of self tests being done.

Touch1 Ultra Checkout Manual – Page 6

Touch Pad Test

The Touch Pad Test tests the touch screen to be sure is it working properly.

1. To start the test, press Next Test: Touchpad.

2. A screen with a calibration button in the upper lefthand corner will be displayed.

Press the center of the picture inside the button.

Touch the center of

the button to

calibrate.

3. A screen with a calibration button in the lower righthand corner will be displayed.

Press the center of the picture inside the button.

4. A screen with five buttons will be displayed. Press each button to check the

calibration. You must press a button within ten seconds or the test will fail. A star

should appear where the screen was touched. If the star is not drawn where the

screen was touched, the calibration is not correct. Let the test fail by waiting ten

seconds without touching the screen and perform the Touch Pad test again to

correctly calibrate the touchscreen.

5. To pass the test, all five buttons must be pressed before the timeout.

To check the

calibration, press all

five buttons making

sure a star is drawn

where the screen is

touched.

Touch1 Ultra Checkout Manual – Page 7

Probe Test

The Probe Test tests the ability to correctly identify probed test points. Any one of the

adapters included in the Performance Verification Kit are needed to perform this test.

1. To start the test, press Next Test: Probe.

2. A screen will prompt you to install any adapter in the J1 position on the scanner.

Install the Resistance adapter into the HVI Block Adapter.

3. Install the HVI Block Adapter into the far left hand position (Pin 1) on the scanner

assembly. Once the HVI Block Adapter is in place, press OK.

4. Touch the tip of the probe to the HV test point(s) on the adapter. If the probe is

working correctly, a pop-up window will display the correct point(s) touched by

the probe. If no pop-up window is displayed when the test point(s) are probed,

press No Response. The test will fail and a Failed Probe Test screen will display.

Touch1 Ultra Checkout Manual – Page 8

To display the pop-up

probe window, touch

the probe to any test

point(s) on the

adapter.

5. Release the probe from the test point(s) and a Passed Probe Test screen

will be displayed. If the screen does not change when the probe is

released from the test point(s), press No Response. The test will fail and a

Failed Probe Test screen will be displayed.

LV + HV Meas. (R) Test

The LV/HV Measurement Test checks the low voltage and high voltage measurements. To

pass the test, the Touch1 Ultra must measure the resistor’s value to +- 1% +-0.1 ohm and

the high voltage leakage at 5M ohm +- 10%. The Resistance Adapter included in the

Performance Verification Kit is needed to perform this test.

1. To start the test, press Next Test: LV/HV Meas.

2. A screen will prompt you to install the Resistance Adapter in the J1 position on the

scanner. Install the Resistor Adapter into the HVI Block Adapter. Install the HVI

Block Adapter into the Pin 1 position as shown and then press OK.

Touch1 Ultra Checkout Manual – Page 9

3. The Touch1 Ultra will perform the tests and display either a Pass or Fail result for

each test.

Scroll down to view

the results for all the

tests.

HV Voltages (R + V) Test

The High Voltage Test checks that all the voltages in the high voltage settings of the

Touch1 Ultra are within range. The Associated Research Hypot Ultra voltages are calibrated

separately using the Hypot Ultra Users Manual.

To pass this test, all the voltages must be within 10% of the high voltage setting. The

Resistance Adapter included in the Performance Verification Kit is needed to perform this

test. You will also need a voltmeter with a high voltage probe.

In general, the high voltages on the Touch1 Ultra tester are not considered dangerous

because the current is limited to a safe level. However, touching cable connections when

high voltage is applied causes an unpleasant shock. An operator who has a health condition

that could be aggravated by a startle should not do high voltage tests.

Special Equipment is required:

To do the high voltage tests, be certain your voltmeter is equipped with a high voltage

probe. This is beyond the range for most ordinary voltmeters. For testing above 1000

volts DC, your voltmeter must be equipped with a high voltage probe which must have >

50M ohms of input resistance and be able to safely withstand over 1500 volts DC. Your

voltmeter may be damaged if you do not take these precautions.

Touch1 Ultra Checkout Manual – Page 10

1. To start the test, press Next Test: HV Volts

2. A screen will prompt you to install the Resistance Adapter in the J1 position on the

scanner.

A high voltage probe

is required to perform

the HV Volts test.

3. Install the Resistance adapter into the HVI Block Adapter. Install the HVI Block

Adpater into the Pin 1 position and connect your high voltage probe to the HV test

pins on the adapter as shown. Then press OK.

Attach the high

voltage probe to the

test pins shown here.

4. The Touch1 will apply high voltage during each test so keep your hands clear from

all connections during the test. Press START to begin the test.

Press START to begin

the series of high

voltage tests.

Touch1 Ultra Checkout Manual – Page 11

5. Read the voltage from your voltmeter and press RECORD VOLTAGE to enter the

reading from the voltmeter. Press OK to continue on to the next voltage or press

RETRY x V where xis the voltage the test will retry. Note: The HV Test will timeout if

the Record Voltage button is not pressed.

Enter the voltage

displayed on the

voltmeter here.

6. Repeat steps 4 and 5 until all the voltages have been tested and recorded. After 50

volts, the tests will increment by 100 volts until 1500V. The Touch1 Ultra will perform

the tests and display an overall summary with either a Pass or Fail result for each

test. If any of the the voltages do not pass, the entire HV Test will fail.

Capacitance/4-Wire (C) Test

The Capacitance and 4-Wire Test checks the Touch1 Ultra can accurately measure

capacitance and perform a 4-Wire test. To pass the test, the Touch1 Ultra must measure

the capacitor’s value to ±10% and the 4-Wire resistor to ±1% ±0.001 ohm. The

Capacitance/4-Wire Adapter included in the Performance Verification Kit is needed to

perform this test.

1. To start the test, press Next Test: Cap. & 4W

2. A screen will prompt you to install the Capacitance/4-Wire Adapter in the J1

position on the scanner. Install the Capacitance/4-Wire Adapter into the HVI

Block Adapter. Install the HVI Block Adapter into the Pin 1 position as shown

and then press OK.

Touch1 Ultra Checkout Manual – Page 12

3. The Touch1 Ultra will perform the tests and display either a Pass or Fail

result for each test.

Results will be

displayed for both the

capacitance and

fourwire tests.

Scanner Test

The Scanner Test verifies the analog circuitry and relays inside the scanners are working

properly all the way to each test point. The test checks for loose scanners making sure the

cables are connected properly. Run this test to isolate capacitor measurement errors, high

resistance shorts, and leakage errors by eliminating or identifying contamination on

scanners as the cause of the problem. The Zero Ohm Adapter included in the Performance

Verification Kit is needed to perform this test.

1. To start the test, press Next Test: Scanners

2. A screen will prompt you to install the Zero Ohm Adapter in the J1 position

on the scanner. Install the Zero Ohm Adapter into the HVI Block Adapter

Install the HVI Block Adapter into the Pin 1 position as shown and then press

OK.

Touch1 Ultra Checkout Manual – Page 13

3. The Touch1 Ultra will perform the test and display either a Pass or Fail result

for each portion of the test. A screen will then prompt you to remove the

adapter and install it in the next “J” position on the scanner. Two tests are

done for each scanner. One for each double-high position.

4. The test automatically sequences to the next step if it can detect the removal

of the adapter. If it cannot detect the adapter was removed, you must press

the NO RESPONSE button.

Remove the adapter

to automatically

proceed to the next

test.

5. Remove the HVI Block Adapter and place it into the next Pin 1 position as

shown.

6. If the tester has any expansion boxes installed, continue testing the other

scanners by moving the HVI Block Adapter to each of the “Pin 1” positions

and running the test.

Touch1 Ultra Checkout Manual – Page 14

7. At the end of all the tests, a scanner summary screen will be displayed listing

the results for each test section. If any of the the individual scanner tests do

not pass, the entire ScannerTest will fail.

Results for six

separate tests will be

displayed for each

scanner attached.

Tester

Checkout

Summary

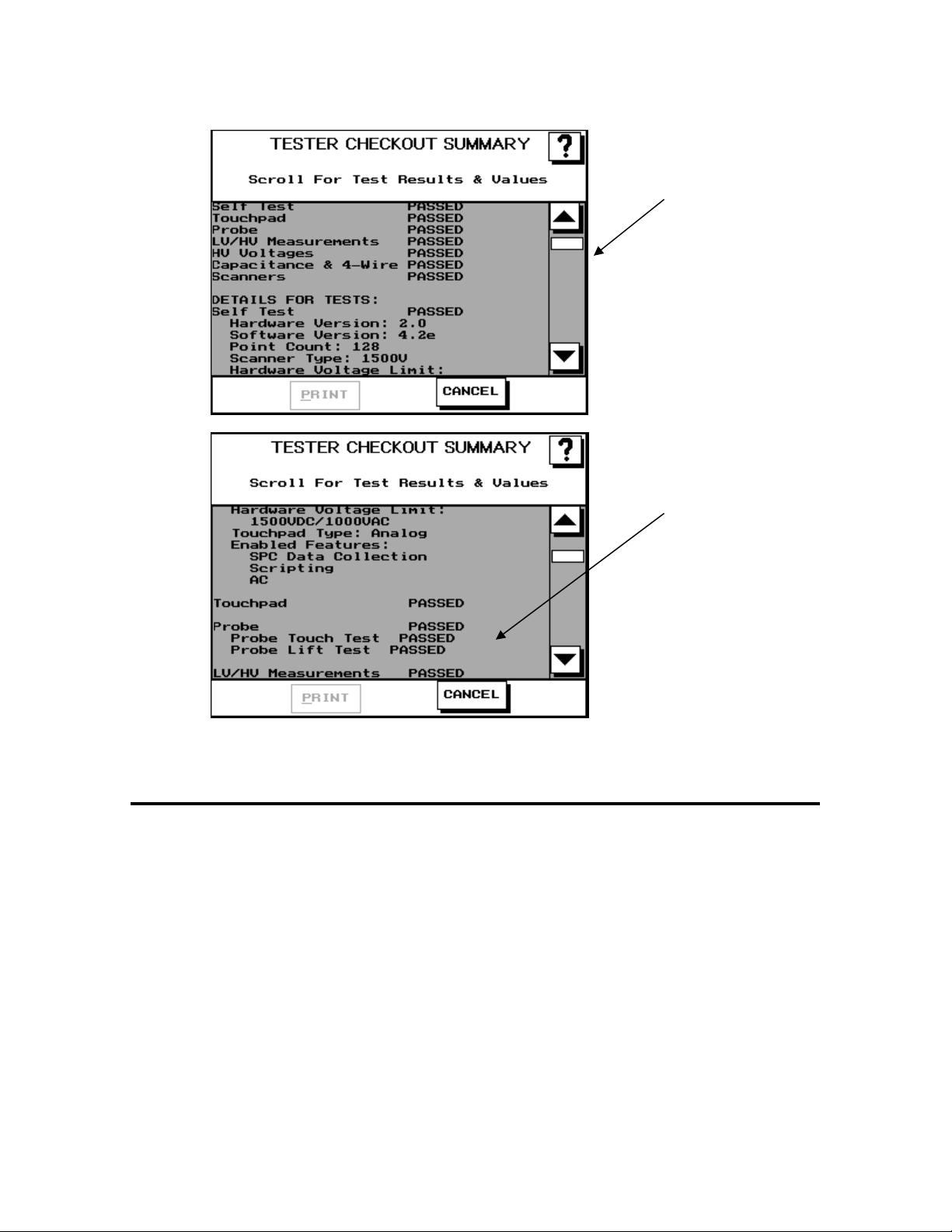

1. To see the TESTER CHECKOUT SUMMARY screen for all the Tester Checkout Tests,

press Show Summary. Use the arrow or scroll buttons to view all the results.

•The summary will display ABORTED for any aborted tests.

•The summary will display SKIPPED for any skipped tests.

•The summary will display FAILED for any failed tests.

2. To save the Test Summary results, you must either print them or copy them to paper

by hand. If you have a printer connected to your Touch1 Ultra, you can print the Test

Summary by pressing PRINT.

Touch1 Ultra Checkout Manual – Page 15

An overall summary

is given for each test

along with the

individual test results.

Scroll down to view

the individual results

for all the tests.

Touch1 Ultra Checkout Manual – Page 16

Appendix

The following information can be used a guide for setting up a formal calibration system in

your organization.

Calibration Standards

Calibration standards refer to written quality system requirements for organizations that

perform calibations and use calibrated equipment. Establishing a quality system according

to calibration standards helps insure calibrations are done competently and lends credibility

to the calibration organization. In the United States, common calibration standards include

ANSI/NCSL Z540-1, ISO/IEC Guide 25, ISO 10012-1, and the former MIL-STD 45662A.

The ANSI/NCSL Z540 standard refered to above, as well as other helpful metrology

information, can be obtained from the National Conference of Standards Laboratories

International (NCSL) at 1-303-440-3339 or www.ncslinternational.org. You can obtain the

ISO standards from the International Standards Organization (ISO) at their web site

www.iso.net/.

The word “standards” is often used in another way in the metrology industry to refer to a

centralized, most accurate unit of measurement regulated by countries. The National

Institute of Standards and Technology (NIST) maintains the national standards for

measurements in the United States.

Good Calibration Practices

The calibration standards, such as ANSI/NCSL Z540-1 and ISO 10012-1, require several

good practices for the calibration industry including the following areas:

Recall System

How do you ensure your company does not forget to send an instrument in for

calibration? Use a recall system which can be a card file or a computerized database,

This system includes calibration dates, due dates, calibration sources, and other

instrument records. The recall system ensures calibrated instruments are recalibrated

in a timely manner.

Calibration Labels

How does someone know if an instrument has been calibrated without looking for the

paperwork in a filing cabinet drawer? When an instrument is calibrated, the calibration

standards require the instrument to be labeled as such. The calibration labels, which

are applied to instruments, have fields for the instrument serial number, calibration

date, calibration due date, and by whom. A good source of inexpensive calibration

labels is United Ad Label at 1-800-992-5755.

Accuracy Ratios

Can you use a ruler to calibrate your digital calipers? Of course not! Wherever

possible calibration standards require an accuracy ratio of at least four to one. In

other words, the insturment being used to measure the calibrated instrument must be

at least four times as accurate as the calibrated instrument.

Touch1 Ultra Checkout Manual – Page 17

Certificate of Calibration

How does everyone know you had an instrument calibrated?The calibration

certificate is the record of who, when, and by what equipment the instrument was

calibrated. A Touch1 Ultra Certificate of Calibration, which you can photocopy for your

calibration, is provided following this section.

Calibration Data Report

So just how accurate is the calibrated test instrument in relation to its published

specifications? Some organizations require the measured values of a calibrated

instrument are written down when an instrument is calibrated. Calibration laboratories

typically charge extra to create a calibration data report. However, when a calibrated

instrument is found to be out-of-tolerance, the calibration standards require the out-of-

tolerance data be recorded in relation to the instruments specifications. A calibration

data report can fill this requirement. The Tester Checkout Summary from the Touch1

Ultra tester can be used as a calibration data report. This report can be printed or

copied to paper by hand.

Traceability

Did qualified personnel perform the calibration procedure under controlled conditions,

using correctly calibrated instruments with the correct test accuracy ratios? To

maintain traceability, the answer to all these questions must be yes. Traceability

refers to each unbroken link of valid calibrations going back to national standards

such as those maintained by the NIST in the United States.

Several years ago NIST numbers (ie. reference numbers issued on NIST reports)

were commonly copied on successive calibration certificates as a means of showing

traceability. This practice has been discontinued. Therefore, if you are writing a

calibration procedure, do not require NIST numbers be copied on reports to show

traceability. NIST numbers are sometimes confused with other numbers that

calibration laboratories create for reference such as “asset numbers”, “NIST trace

numbers”, “ID numbers”, and report numbers. For more information regarding the

discontinued use of NIST numbers, contact Cirris for a copy of the position paper

from the National Conference of Standards Laboratories.

Touch1 Ultra Checkout Manual – Page 18

Touch1 Ultra Certificate of Calibration

Name and Address of Organization Performing the Calibration:

Certificate Number: Calibrated by:

Calibration Date: Due Date:

Applicable Calibration Standard(s): Procedure:

Touch1 Ultra PCHK Version 1.3

Temperature: Relative Humidity:

Tester Serial Number:

Instruments used: Serial Number Cal. Date Due Date

Zero Ohm Adapter

Resistor Leak Adapter

Capacitance/Fourwire Adapter

HV Block PCHK Adapter

Voltmeter

Statement of Traceablility:

Certified by:

Other manuals for Touch1 LV

1

Table of contents

Other Cirris Test Equipment manuals

Cirris

Cirris CH2 User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris Easy-Touch Pro User manual

Cirris

Cirris Touch 1 User manual

Cirris

Cirris Easy-Touch Pro User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris signature 1100R+ User manual

Cirris

Cirris CR User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris CH+ User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris 4200 Series User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris 4200 Series User manual

Cirris

Cirris CR User manual

Cirris

Cirris CR User manual

Cirris

Cirris CH2 User manual

Cirris

Cirris easy-wire CR User manual

Cirris

Cirris Touch1 LV Installation and operation manual

Cirris

Cirris 4200 Series User manual