Despatch Watlow 1500 Control User manual

P/N 260786

Rev. 8/96

E-87

U.S. $45.00

Instruction Manual for the

Despatch/Watlow 1500 Control

Copyright © October 24, 2001 by Despatch Industries

Notice

Users of this equipment must comply with operating procedures and training of

operation personnel as required by the Occupational Safety and Health Act (OSHA)

of 1970, Section 6 and relevant safety standards, as well as other safety rules and

regulations of state and local governments. Refer to the relevant safety standards

in OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

Caution

Setup and maintenance of the equipment should be performed by qualified

personnel who are experienced in handling all facets of this type of system.

Improper setup and operation of this equipment could cause an explosion that may

result in equipment damage, personal injury or possible death.

Dear Customer,

Thank you for choosing Despatch Industries. We appreciate the

opportunity to work with you and to meet your heat processing

needs. We believe that you have selected the finest equipment

available in the heat processing industry.

At Despatch, our service does not end after the purchase and

delivery of our equipment. For this reason we have created the

Service Products Division within Despatch. The Service Products

Division features our Response Center for customer service. The

Response Center will direct and track your service call to ensure

satisfaction.

Whenever you need service or replacement parts, contact the

Response Center at 1-800-473-7373: FAX 612-781-5353.

Thank you for choosing Despatch.

Sincerely,

Despatch Industries

Despatch/Watlow 1500 Control Instruction Manual Page i

NOTE:

Read the entire

INTRODUCTION and

THEORY OF OPERATION

before operating the control.

WARNING:

Failure to head warnings in

this instruction manual and

on the oven could result in

death, personal injury or

property damage.

PREFACE

This manual is your guide to the Watlow 1500 control. It is

organized to give you the information you need quickly and

easily.

The INTRODUCTION section provides an overview of the

control.

The THEORY OF OPERATION section details the function

and operation of the control.

The INSTRUCTIONS section provides directions on

unpacking, installing, operating and maintaining the control.

The APPENDIX section contains Special Instructions for

operating the control instrument and a Troubleshooting

Table.

An efficient way to learn about the control would be to

read the manual while working with the control. This will

give you practical hands-on experience with information in

the manual and the control.

While reading this manual, if a term or section of

information is not fully understood, look up that item in the

appropriate section to familiarize yourself with that item.

Then go back and reread that section again. Information

skipped, not understood or misunderstood could create the

possibility of operating the equipment in an unsafe manner.

This can cause damage to the oven or personnel, or reduce

the efficiency of the equipment.

Page ii Despatch/Watlow 1500 Control Instruction Manual

Despatch/Watlow 1500 Control Instruction Manual Page iii

Table of Contents

PREFACE ............................................................i

Table of Contents .................................................iii

List of Figures ....................................................iv

List of Tables .....................................................iv

INTRODUCTION ..................................................... 1

INSTRUCTIONS ...................................................... 3

Operating ........................................................ 3

Watlow 1500 Control ............................................... 4

Manual Set Point Controller ....................................... 6

Guarded Access Programming ..................................... 8

Setting the Clock ............................................. 9

GA0001 and 0002 PID Tuning ................................. 10

GA0000 Alarms ............................................. 10

GA0006 Setting Options ...................................... 11

ECOSPHERE/16000 Series Guarded Access Chart ................ 12

LPB Series Guarded Access Chart .............................. 13

Profile Mode .................................................. 14

Change Data Mode ............................................ 14

Halt Conditions ................................................ 14

Blank Step ................................................... 15

Set Point Step ................................................. 15

Creating Files/Profiles .......................................... 16

Wait Steps ................................................... 20

Next Step .................................................... 21

Recycle Option ................................................ 21

Write Your Program ............................................ 22

WORKSHEETS ..................................................... 23

Programming Work Sheet .......................................... 23

Sample HAST Profile for LPB Chambers ............................ 24

Procedure for Programming HAST Profile ........................... 25

HAST Chamber Programming Instructions and Definitions .............. 31

Ecosphere Sample Program ...................................... 32

Ecosphere Sample Profile Worksheet .............................. 33

Clearing a Program ............................................ 34

Tuning/Programming Worksheet ..................................... 35

Guarded Access Chart .......................................... 35

Warm/Cold Start ................................................. 36

Changing the Position of a Switch ................................. 37

Page iv Despatch/Watlow 1500 Control Instruction Manual

List of Figures

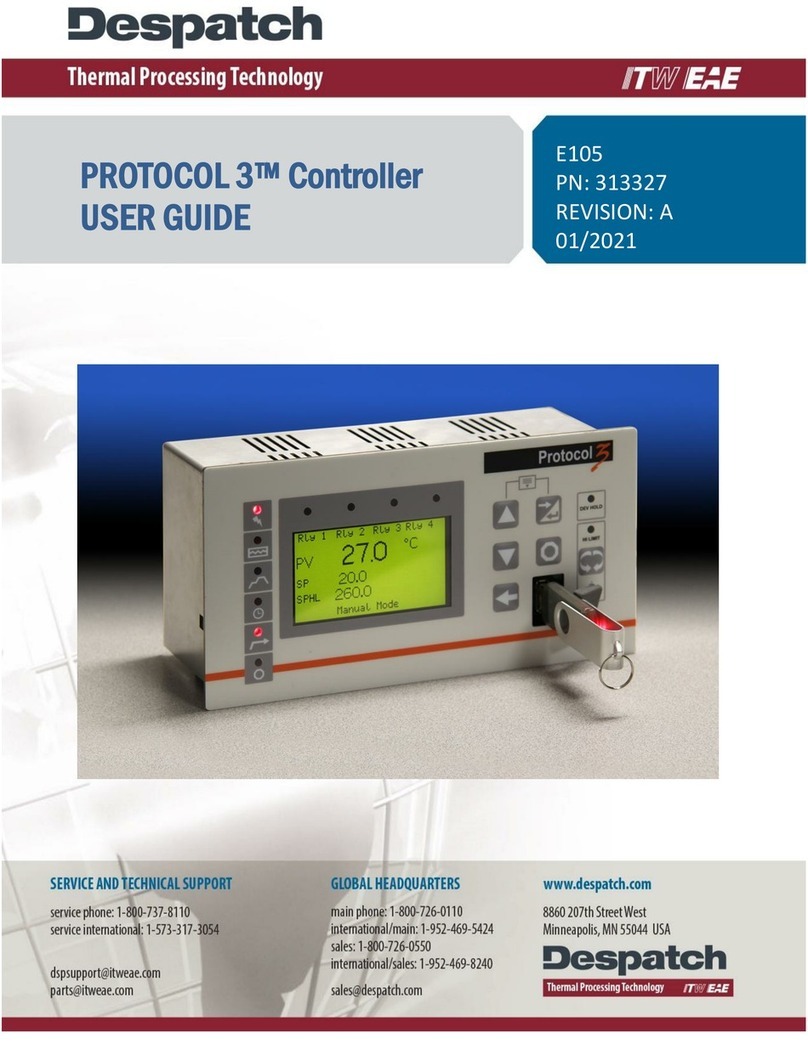

Figure 1 illustrates the Watlow 1500 installed on the Series 16000 environmental

chamber control panel. ............................................. 4

Figure 2 DIP Switch Location and Orientation .............................. 36

List of Tables

Table 1 Watlow 1500 Displays ........................................... 4

Table 2 Watlow 1500 Keys .............................................. 5

Table 3 Watlow 1500 LEDs ............................................. 5

Table 4 GA0001 and 0002 PID Tuning Parameters .......................... 10

Table 5 GA0000 Alarms ............................................... 10

Table 6 Setting Options ............................................... 11

Table 7 Set Point Step Programming Detail ................................ 19

Table 8 Wait Steps ................................................... 20

Table 9 Despatch Sample Program ...................................... 32

Table 10 DIP Switch Selection .......................................... 37

Despatch/Watlow 1500 Control Instruction Manual Page 1

NOTE:

Your control has already

been configured at

Despatch. Use this manual

as a guide to typical settings.

CAUTION:

Before making changes to

your control, consult with

Despatch Industries Product

Service at 1-800-473-7373.

INTRODUCTION

This INTRODUCTION section provides an overview of the

Watlow 1500 controller. The microprocessor based

controller is capable of measuring, displaying and

controlling temperature and humidity from a variety of

inputs.

The controller is easy to use. Control functions, alarm

settings and other parameters are easily entered through

the front keypad. Limited data can be protected from

unauthorized changes with its guarded access mode

security system. Battery back-up protects against data

loss during AC power outages.

In this application the controller has been factory

configured to control temperature and humidity conditions

in your Despatch chamber. Under normal conditions, you

should not have to reprogram this controller. We have,

however, included reprogramming instructions in this

manual to help guide you through that process if it should

become necessary.

Page 2 Despatch/Watlow 1500 Control Instruction Manual

Despatch/Watlow 1500 Control Instruction Manual Page 3

NOTE:

Your control has already

been configured at

Despatch. Use this manual

as a guide to typical settings.

CAUTION:

Before making changes to

your control, consult with

Despatch Industries Product

Service at 1-800-473-7373.

INSTRUCTIONS

Operating

To start the controller, start the oven fans. When you

start the fans the following sequence will automatically

take place.

1. The controller will power up.

2. The controller MNTR DATA LED will light up and the

alarm indicator A1 will be flashing in the FUNCTION

display. Alarm A1 is an indication of power loss.

3. Clear the alarm by pressing the clear button on the

Watlow 1500.

4. The actual temperature and humidity will be shown in

the ACTUAL display located at the top of the control.

Press the SEL key to toggle between temperature

and humidity. Temperature will be displayed on

Channel 1. Humidity will be displayed on Channel 2.

Page 4 Despatch/Watlow 1500 Control Instruction Manual

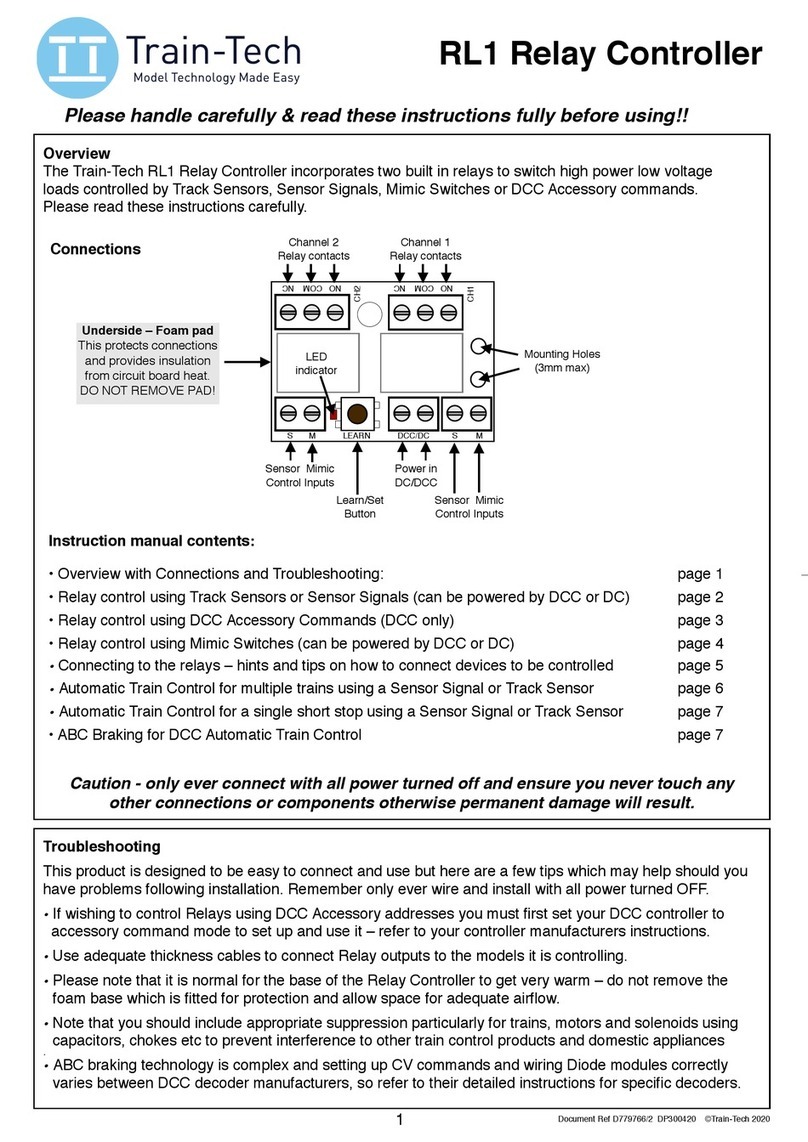

Figure 1 illustrates the Watlow 1500 installed on the Series 16000

environmental chamber control panel.

Display Description

Actual Shows the actual process conditions (dry bulb temp if CH-1 LED is on, RH% if

CH-2 is on.

Event Shows current status of all events. Lowest significant event is left justified

[instead of right justified as when events are shown in data display].

Step Shows which step the programmer is currently pointed to.

Function Describes the function or type of data being displayed in the data display.

Data Shows current value for the function being viewed. This display is effected by

the scroll up and down keys.

Table 1 Watlow 1500 Displays

Watlow 1500 Control

The Watlow Series 1500 is a versatile microprocessor-

based control; powerful, yet simple to learn.

Despatch/Watlow 1500 Control Instruction Manual Page 5

Key Description

CH SEL Selects either channel 1 or channel 2 for the ACTUAL display.

CLEAR Clears alarm codes from the FUNCTION display in the monitor data mode.

Clears the step in the STEP display in the change data mode when the unit

is in the halt condition. Clears all 51 programmed steps when the unit is in

the halt condition, and in the guarded access area of the change parameter

mode.

RE-START Returns the controller to the initial program step only in the program halt

condition.

RUN/HALT Starts or stops the program. The processor will resume a program where it

was interrupted, unless the RESTART key was pressed, or the step number

or set point data at the current step was changed during the halt condition.

MODE Selects either the monitor data, change data or change parameter mode.

FCTN The FUNCTION key steps through the prompts in each of the three modes.

ENTER Enters the selected data or next step operations in the change data and

change parameter modes.

Increases and decreases the value in the DATA display. A light touch

changes the value by one. Holding the key down causes the DATA display

to increase rapidly.

Table 2 Watlow 1500 Keys

LED Description

CH-1 CH-2 Indicates the channel in the ACTUAL display.

EEFIndicates the value in the ACTUAL display is temperature in EF.

EECIndicates the value in the ACTUAL display is temperature in EC.

%RH Indicates the value in the ACTUAL display is per cent relative humidity.

PROG END Indicates that the processor has reached the end of the program.

PROG HALT Indicates that the processor is in the halt condition. This may be caused by

pressing the RUN/HALT key or by a blank step in the program. Flashing

indicates that the processor is in remote-hold condition.

MNTR

DATA Indicates the processor is in the monitor data mode. While in this mode the

Watlow 1500 is used as a set point controller or a process profiler.

CHG DATA Indicates the processor is in the change data mode.

CHG PARA Indicates the processor is in the change parameter mode.

TIME Indicates that the FUNCTION and DATA displays are showing time.

Table 3 Watlow 1500 LEDs

Watlow 1500 Control (Cont.)

Page 6 Despatch/Watlow 1500 Control Instruction Manual

Manual Set Point Controller

Use the following procedure to enter a dry bulb temperature,

RH%, or change auxiliary event status when the MNTR

DATA LED is on.

1. Press the RUN/HALT key so the PROG HALT LED

lights up.

2. Press the RESTART key.

3. Enter the dry bulb temperature.

a. Press the FCTN key until C1 is signaled in the

FUNCTION display.

b. Update the dry bulb temperature by using up/down

arrow keys.

c. Press enter when the desired set point is signaled in

the data display.

Your set point is now in effect.

If the set point shown in the DATA display is higher than

the value shown in the ACTUAL display for CH-1, then

the heat LED near the Watlow 1500 should be on.

If the set point in the DATA display is lower than the

value in the ACTUAL display for CH-1, then the cool

LED should be on.

Despatch/Watlow 1500 Control Instruction Manual Page 7

NOTE:

In the DATA display the right

most character for Event 11

is shown as 0001.

Manual Set Point Controller (Cont.)

4. Enter the %RH. The humidity event must be off when

outside of the range 4EC to 98EC. Humidity beyond

these extremes can result in equipment damage. If a

dry air system and an electronic humidity sensor are

installed in lieu of a wet bulb sensor, the optional dry

air event may be outside the range of 4EC to 98EC.

a. Press the FCTN key. C2 is shown.

b. Update the %RH temperature by using the up/down

keys.

c. Press enter when DATA display shows your desired

set point.

5. Change the auxiliary events.

a. Press the FCTN key. E1 is displayed.

b. Turn the auxiliary event on or off.

1 = on

0 = off

Try varying set points and events and watch how each

effects the output LEDs.

Page 8 Despatch/Watlow 1500 Control Instruction Manual

Guarded Access Programming

The Guarded Access parameters control the process limits.

the three GA parameter loops are restricted to operators by

special codes. The Guarded Access codes prevent

inexperienced or unauthorized operators from changing the

parameters.

You must select one of the following:

GA = 0000 To set CH-1 and CH-2 alarm limits

GA = 0001* To set CH-1 PID tune parameters

GA = 0002* To set CH-2 PID tune parameters

GA = 0006 To set set point scroll limits, optional

lockout and option recycle

*If GA = 0001 and 0002 will not work, try GA code 0005

for both channel parameters.

Use the following sequence to alter the GA prompts:

1. Follow the steps for “SETTING THE CLOCK.”

2. Select a GA code with the >key and the ?key.

3. Press ENTER. The prompt appears in the DATA

display.

4. Press the FCTN key. The next prompt in the loop

appears in the DATA display.

Despatch/Watlow 1500 Control Instruction Manual Page 9

Setting the Clock

1. Press the MODE key to select the Change Parameter

(CHG PARA) mode. The TIME LED will be ON. The

FUNCTION and DATA displays will show the real time

of day.

2. Press FCTN to produce the time prompt, HR, in the

FUNCTION display.

3. Enter the real time of day, beginning with hours. The

CHG PARA programming prompts are listed below in

the order they appear.

a. Enter the real time of day (24 hour basis) by

selecting the hour with the >key and the ?key.

b. Press ENTER to enter the hour into the program.

The prompt MN will appear when you press ENTER.

c. Select correct minutes and seconds.

After setting the real time the FUNCTION prompt should

display a GA. This is guarded access.

Page 10 Despatch/Watlow 1500 Control Instruction Manual

Parameter FUNCTION

Display Description

Proportional

Band Pb

Reset RS

Rate RT

Rate Band Rb Rate band defines where the rate function will occur. The

rate band will occur at one to seven times the proportional

band. With a 0 entry, rate is always in effect.

Cycle Time CT

Dead Band db The dead band defines an area on either side of set point

where no switching action will occur.

Calibration

Offset CA Calibration offset enables you to offset the input value from

-10Eto 10EC or EF.

Table 4 GA0001 and 0002 PID Tuning Parameters

Parameters FUNCTION

Display Description

Upper Process Type Alarm UP If you do not want this alarm, set to highest

value.

Lower Process Type Alarm LP If you do not want this alarm, set to lowest value.

Upper Deviation Type

Alarm Ud If you do not want this alarm, set to highest

value.

Lower Deviation Type

Alarm lD If you do not want this alarm, set to lowest value.

Table 5 GA0000 Alarms

GA0001 and 0002 PID Tuning

Prompts appear for CH-1 with Code 0001, and then repeat

for CH-2 with Code 0002. Except for CA, these parameters

pertain directly to tuning your control to the system.

GA0000 Alarms

Prompts appear for CH-1, then repeat for CH-2. Refer to

the Watlow User's Manual for details.

Sequence repeats for Channel 2 and then leaves the

guarded area, returning to real time.

Despatch/Watlow 1500 Control Instruction Manual Page 11

Parameter FUNCTION

Display Description

CH-1 Upper Set Point Limit U1

CH-1 Lower Set Point Limit L1

CH-2 Upper Set Point Limit U2

CH-2 Low Set Point Limit L2

Front Panel Keyboard

Lockout LC Enter:

C1 to lock the entire front panel,

C0 to unlock it.

Recycle RC Select:

C1 to activate the recycle option (begin

again at Step #1 after completing a

profile),

C0 to deactivate the recycle option.

Temp-Temp, 2-channel

temperature control TT This prompt will not appear on thermocou-

ple units. Select:

C0000 for Temp-RH control

C0001 or Temp-Temp control.

RS-422 Address for the

1500 Ad This prompt appears only on units with data

communications. It applies only for an

RS-422 interface. Each device on the net-

work must have its own address.

Table 6 Setting Options

GA0006 Setting Options

These parameters are high and low display and scroll limits,

and for some units, two channel control type and device

address.

Sequence then leaves the guarded area, returning to real

time.

Page 12 Despatch/Watlow 1500 Control Instruction Manual

ECOSPHERE/16000 Series Guarded Access Chart

Make a copy of this chart to document the Series 1500

Guarded Access for each program you use.

Program #_____ System _______ Programmer ________ Date__________

GA Code Ch Pmpt Parameter Typical ECOSPHERE Setting Your Settings

0000 C1 UP Ch-1 Upper Process Alarm 180

C1 LP Ch-1 Lower Process Alarm -75

C1 Ud Ch-1 Upper Deviation Alarm 538

C1 Ld Ch-1 Lower Deviation Alarm -538

C2 UP Ch-2 Upper Process Alarm 101

C2 LP Ch-2 Lower Process Alarm -001

C2 Ud Ch-2 Upper Deviation Alarm 101

C2 Ld Ch-2 Lower Deviation Alarm -101

0001 1 Pb Ch-1 Prop. Band 0009

1RS Ch-1 Reset 0010

1RT Ch-1 Rate 0000

1Rb Ch-1 Rate Band 0001

1CT Ch-1 Cycle Time 0003

1 db Ch-1 Dead Band 0001

1CA Ch-1 Calibration Adjust. 0000

Dual

PID 1C Pb Ch-1 Prop. Band 0009

1C RS Ch-1 Reset 0002

1C RT Ch-1 Rate 0001

1C Rb Ch-1 Rate Band 0001

1C CT Ch-1 Cycle Time 0007

0002 2 Pb Ch-2 Prop. Band 0020

2RS Ch-2 Reset 0010

2RT Ch-2 Rate 0050

2Rb Ch-2 Rate Band 0003

2CT Ch-2 Cycle Time 0002

2 db Ch-2 Dead Band -0001

2CA Ch-2 Calibration Adjust. 0000

Dual

PID 2C Pb Ch-2 Prop. Band 0020

2C RS Ch-2 Reset 0006

2C RT Ch-2 Rate 0001

2C Rb Ch-2 Rate Band -0001

2C CT Ch-2 Cycle Time 0005

0006 U1 Ch-1 Upper Set Point Limit 177

L1 Ch-1 Lower Set Point Limit -73

U2 Ch-2 Upper Set Point Limit 100

L2 Ch-2 Lower Set Point Limit 000

RC Recycle: ON = 1, OFF = 0 0

TT T-RH = 0000, T-T = 0001 0

Ad Address number RS-422 0

LC Keyboard Lock 0

Despatch/Watlow 1500 Control Instruction Manual Page 13

LPB Series Guarded Access Chart

Make a copy of this chart to document the Series 1500

Guarded Access for each program you use.

Program #_____ System _______ Programmer ________ Date__________

GA Code Ch Pmpt Parameter Typical HASP Settings Your Settings

0000 C1 UP Ch-1 Upper Process Alarm 170

C1 LP Ch-1 Lower Process Alarm 0

C1 Ud Ch-1 Upper Deviation Alarm 538

C1 Ld Ch-1 Lower Deviation Alarm -538

C2 UP Ch-2 Upper Process Alarm 101

C2 LP Ch-2 Lower Process Alarm -001

C2 Ud Ch-2 Upper Deviation Alarm 101

C2 Ld Ch-2 Lower Deviation Alarm -101

0005 RC Recycle 0000

C1 Pb Ch-1 Prop. Band 0003

C1 RS Ch-1 Reset 0005

C1 RT Ch-1 Rate 0001

C1 Rb Ch-1 Rate Band 0001

C1 CT Ch-1 Cycle Time 0001

C1 db Ch-1 Dead Band 0000

C1 CA Ch-1 Calibration Adjust. 0000

C2 Pb Ch-2 Prop. Band 0005

C2 RS Ch-2 Reset 0002

C2 RT Ch-2 Rate 0005

C2 Rb Ch-2 Rate Band 0001

C2 CT Ch-2 Cycle Time 0001

C2 db Ch-2 Dead Band 0000

C2 CA Ch-2 Calibration Adjust. 0000

0006 U1 Ch-1 Upper Set Point Limit 166

L1 Ch-1 Lower Set Point Limit 0

U2 Ch-2 Upper Set Point Limit 100

L2 Ch-2 Lower Set Point Limit 000

RC Recycle: ON = 1, OFF = 0 0

TT T-RH = 0000, T-T = 0001 0

Ad Address number RS-422 0

Page 14 Despatch/Watlow 1500 Control Instruction Manual

Profile Mode

This section of the manual provides details on programming

the Watlow 1500 in the Change Data (CHG DATA) mode,

the Change Parameters (CHG PARA) mode and Guarded

Access. Refer to the Watlow 1500 manual for more details.

Change Data Mode

When the Watlow CHG DATA LED is lit, the processor is in

the change data mode. While in this mode, the

programming steps can be entered into the processor.

There are three step types:

CSet Point (SP)

CJump Loop (JL)

CWait (WT)

Halt Conditions

The Watlow 1500 can HALT in three ways, when the:

Cprocessor encounters a Blank Step in the program,

CRUN/HALT key is pressed while the program is

running,

Cremote hold input is shorted.

While in the HALT condition, the Watlow 1500 actively

maintains set points and event output conditions which

existed at the time the processor was halted.

If you do not want the hot or humid conditions to be retained

at the end of a programmed halt, add a step just before the

Blank Step [End of Program] to establish stand-by set points

near ambient with all Event Outputs OFF.

Table of contents

Other Despatch Controllers manuals

Popular Controllers manuals by other brands

Bray

Bray 92 Series Operation and maintenance manual

Headend Products

Headend Products Remote Kontrol user manual

Titon

Titon aura-t TP539 product manual

Train-Tech

Train-Tech RL1 quick start guide

Castle Creations

Castle Creations CC BEC 010-0004-00 quick start guide

Honeywell

Honeywell Alerton ACM installation instructions

AMX

AMX NX-1200 Hardware reference manual

TECH

TECH ST-431 user manual

Emerson

Emerson Liebert OpenComms EM quick start guide

Long range

Long range MT4300 quick start guide

KROHNE

KROHNE OPTISENS PAC 050 Installation and operating instructions

Homematic IP

Homematic IP HmIP-DRSI4 Installation and operating manual