Train-Tech RL1 User manual

Instruction manual contents:

• Overview with Connections and Troubleshooting:!! ! ! ! ! ! page 1

• Relay control using Track Sensors or Sensor Signals (can be powered by DCC or DC)!page 2

• Relay control using DCC Accessory Commands (DCC only)!! ! ! ! page 3

• Relay control using Mimic Switches (can be powered by DCC or DC)!! ! ! page 4

•Connecting to the relays – hints and tips on how to connect devices to be controlled !! page 5

•Automatic Train Control for multiple trains using a Sensor Signal or Track Sensor!! page 6

•Automatic Train Control for a single short stop using a Sensor Signal or Track Sensor!! page 7

• ABC Braking for DCC Automatic Train Control!! ! ! ! ! ! page 7

Caution - only ever connect with all power turned off and ensure you never touch any

other connections or components otherwise permanent damage will result.

RL1 Relay Controller

1!

Please handle carefully & read these instructions fully before using!!

Overview

The Train-Tech RL1 Relay Controller incorporates two built in relays to switch high power low voltage

loads controlled by Track Sensors, Sensor Signals, Mimic Switches or DCC Accessory commands.

Please read these instructions carefully.

Document Ref D779766/2 DP300420 ©Train-Tech 2020

Troubleshooting

This product is designed to be easy to connect and use but here are a few tips which may help should you

have problems following installation. Remember only ever wire and install with all power turned OFF.

•If wishing to control Relays using DCC Accessory addresses you must first set your DCC controller to

accessory command mode to set up and use it – refer to your controller manufacturers instructions.

•Use adequate thickness cables to connect Relay outputs to the models it is controlling.

•Please note that it is normal for the base of the Relay Controller to get very warm – do not remove the

foam base which is fitted for protection and allow space for adequate airflow.

•Note that you should include appropriate suppression particularly for trains, motors and solenoids using

capacitors, chokes etc to prevent interference to other train control products and domestic appliances

•

•ABC braking technology is complex and setting up CV commands and wiring Diode modules correctly

varies between DCC decoder manufacturers, so refer to their detailed instructions for specific decoders.

Learn/Set

Button

Sensor Mimic

Control Inputs

Power in

DC/DCC

Mounting Holes

(3mm max)

Connections

Underside – Foam pad

This protects connections

and provides insulation

from circuit board heat.

DO NOT REMOVE PAD!

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

LED

indicator

Channel 1

Relay contacts

Channel 2

Relay contacts

Sensor Mimic

Control Inputs

2

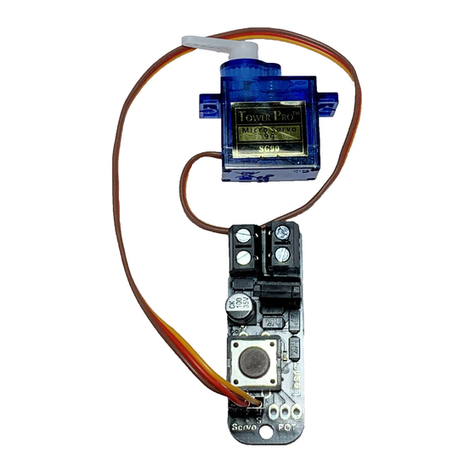

•Relay Control using Track Sensors/Sensor Signals (DC/DCC)

You can use a Track Sensor or Sensor Signal to change a relay when a train passes it.

Just a single wire is needed to link between one of the Sinput of the Relay Controller and the

centre socket of a Track Sensor or Sensor Signal – solid core 1/0.6mm wire is ideal as it just plugs

into the sensor/signal and is as supplied by Train-Tech (WP2/WP3) or model or electrical stores.

The Relay Controller and Track Sensors/Sensor Signals can be powered either by DCC or smooth

DC – see the pictures at the bottom of this page to show how to power the Track Sensors/Signals.

Track Sensors can be used at the same time as Mimic Switch control and DCC accessory control -

priority is the device which sent the most recent control command, ie Track Sensor, Mimic or DCC.

POWER

Power the Track Sensor or Sensor

Signal and the Relay Controller

from the same power supply;

either Track DCC or connect it to

12–16V maximum smooth DC.

Direction

of Trains

SENSOR

POWER

see below

SENSOR

POWER

see below

Optional 2nd

Sensor/Signal

Link wire to optional second Track Sensor or Signal

Track Sensor or Sensor Signal

Power by sliding sensor into track – for DCC

If using DCC you

can power the

sensor from the

track by sliding

these two ‘fingers’

under the rails into

the slots in some

types of track, like

a power clip.

ensure good

connections!

Track Sensor or

Sensor Signal

To power using

DC or DCC solder

2 wires into the

holes shown

Power by wiring to sensor – for DC or DCC

Track Sensor or

Sensor Signal

Cut off the two fingers

with sharp cutters

where marked – – -

Using Track Sensors with N Gauge: The Track sensor is

designed primarily for OO gauge track, however we have

found that it can be used with N gauge if the fingers are

removed, some parts of sleepers trimmed and the sensor is

placed close to (but not touching) the rail.

RL1 Relay

Controller

Power in

DC/DCC

Using one Track Sensor or Sensor Signal the relay will close as soon as the train passes it and

then open again about 7 seconds after the last part of the train has passed the sensor. However if

you use a second Track Sensor/Signal and link it to the first as shown above, then the relay will

close as the train passes the first sensor but not open until the train passes the second sensor, so

in this way you can make something operate while a train is located in a particular section of track.

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

Can be connected to

a Mimic Switch for

simultaneous control

Relay 2 outputs Relay 1 outputs (see page 5)

3

•Relay control using DCC accessory commands (DCC only)

The Relay Controller can be used to switch relatively high power low voltage devices using

standard DCC accessory commands.

The two relay outputs can each be given a unique DCC accessory address so that they can be

turned on or off using a single command from your DCC controller. Accessory commands are

different from the Loco commands used to control the trains, but most DCC controllers can also

control accessories*. Controllers usually have a DCC accessory mode button marked ACC or have

an icon of a point or similar – find out by referring to your particular controllers instruction manual.

Connections

Wiring is easy, with just two wire connections from your standard DCC track output to the DCC/DC

terminals on the RL1. Connect whatever you are controlling to the Relay contact outputs (page 5).

Controlling the relays using DCC Accessory commands

You can control a relay on the Relay Controller by assigning it an Accessory address and sending

a command. Note that unlike loco commands, Accessory commands have just two ‘states’ usually

referred to as on or off (or on some controllers 1 or 2 or left or right direction).

To assign an accessory address to each of your Relays connect the RL1 to the standard DCC

track power output, set your DCC controller to Accessory control mode and turn on DCC power.

To set up the address for Relay channel 1 (CH1):

• Enter the address you want to give to Relay CH1

•Press the Learn button on the relay controller once – the red LED should single flash

•Press your DCC controller on or off button (or 1 or 2, or left or right)

The red LED will then stop flashing and you can control Relay CH1 using that accessory address

To set up the address for Relay channel 2 (CH2):

• Enter the address you want to give to Relay CH2

•Press the Learn button on the relay controller Twice – the red LED should double flash

•Press your DCC controller on or off button (or 1 or 2, or left or right)

The red LED will then stop flashing and you can control Relay CH2 using that accessory address

Note that you can give more than one device the same DCC accessory address, so for example

you can change a relay and a point or signal using one command at a single address.

DCC accessory control can be used at the same time as Mimic Switch and Track Sensor control -

priority is the device which sent the most recent control command, ie Track Sensor, Mimic or DCC.

*NB Note that a few DCC controllers are not able to control DCC accessories, including the basic

Bachmann EZ command controller supplied in some Bachmann train sets and the Gaugemaster

Prodigy Express, both of which can only control DCC Locos. Refer to your controller instructions.

Relay 2 outputs

Power in

DC/DCC

Relay 1 outputs (see page 5)

Learn Button

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

LED

Can be connected to

Track Sensor or

Mimic Switch for

simultaneous control

Can be connected to

Track Sensor or

Mimic Switch for

simultaneous control

RL1 Relay

Controller

4

• Relay control using a Mimic switch (DC or DCC)

•

The relays in the Relay Controller can be controlled using Train-Tech Mimic Switches to manually

control a relay; the dual colour red/green LED (LED A) supplied with each Mimic will also light and

indicate the state of the relay.

Mimic Switches can be used in addition to Track Sensor control and DCC accessory control

previously described and so can be used to manually override a relay. Control priority is given to the

device which sent the most recent control signal, ie Track Sensor, Mimic Switch or DCC command.

Wiring is easy with just a single wire linking the M terminal of the Mimic Switch to the M terminal of

the Relay Controller.

The Mimic Switch should be powered by the same DC or DCC power as the Relay controller.

Mimic Switch

Power supply

DCC or 12–16

volts maximum

smooth DC

Tip

Note that a useful feature is that if a Mimic Switch is connected to an RL1 as well as a Track Sensor

or Sensor Signal to the same relay, then the occupancy LED (LED B) on the Mimic Switch will light

as a Train passes the sensor (see Mimic switch instructions for more details).

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

Relay 2 outputs Relay 1 outputs (see page 5)

Can be connected to

a Track Sensor or

Sensor Signal for

simultaneous control

5

• Connecting to the Relay output contacts

The RL1 contains two relays, each of which has single pole changeover contacts to control

motors, lamps etc. The contacts can be used to switch up to 24 volts AC or DC at up to 3 amps.

They should be connected in the same way as you would connect a switch, so wired in series with

(in between) power and whatever you are controlling. The drawing below shows the internal relay

contacts inside the RL1 so that you can see how they relate to a switch. The common (COM)

terminal is the contact which moves and the other two terminals are Normally Open (NO), which

means it is only connected to the COM terminal when the relay is activated, and Normally Closed

(NC), which means it is connected to COM when the relay is not activated.

These type of relay (or switch) contacts are called changeover contacts.

• How does a relay work?

A relay is an electrically activated switch

and consists of a coil of wire wrapped

around a metal bar which forms an

electro-magnet or solenoid which, when

energised, moves an electrical contact

to make or break connection with other

contacts. The main benefits of a relay

are that you can use relatively low

power to energise the coil to control

much higher amounts of power, and

also the output terminals are not

electrically connected to the coil input

terminals and so are safely isolated.

S M LEARN DCC / DC S M

NO COM NC NO COM NC

CH1

CH2

Relay 2 (shown

not activated)

Relay 1 (shown

not activated)

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

Motor,

Lamp,

Solenoid,

etc

AC or DC power

to suit what is

being controlled

• Simple on-off control using the Relay Controller

Connect

these inputs

to DC or DCC

power and

optionally

also to Mimic

Switches or

Track

Sensors to

control the

relays.

Control this via the relay by DCC

accessory commands, Track

Sensors or Mimic switch

• Reversing a DC Train or motor using the Relay Controller

DC

Motor

Connect

these inputs

to DC or DCC

power and

optionally

also to Mimic

Switches or

Track

Sensors to

control the

relays.

12 volts DC

This example shows how you can use both relays

in an RL1 to control the on-off power & direction

of a DC motor – this could be the motor in a train

on an automatic shuttle line for example.

If both relays are off or both are on then the motor

will not turn, but switching either output on will

make motor run in one direction or the other.

This could be controlled by track sensors or DCC.

Note that you may need to use suppressors particularly on motors and

solenoids to prevent interference (these are usually fitted to loco motors)

Note that you may need to use suppressors particularly on motors and

solenoids to prevent interference (these are usually fitted to loco motors)

eg Loco

Sensor Signal

(or track sensor)

•Automatic Train Control for multiple trains (DCC or DC)

On the real railway train drivers have to drive to signals and stop at red and although that is also

nice to do on model railways, most people operate their layouts by themselves and have too much

to do driving trains, changing points and standing back and enjoy it!

Train-Tech’s Sensor Signals (or the SC100 Signal controller for automating existing signals or N

gauge etc) are Automatic and work just like the real railway’s Block Section signalling, normally

showing green but changing to red as soon as a train goes past it and staying red until the train

clears the following signal after the next section. However a red signal cannot stop the train on its

own, but by making an isolated track section just before the Sensor signal and linking the signal to a

Relay Controller to control the track section, trains approaching a red signal will stop until the signal

displays green and makes it safe for the model train to proceed into the next section. In this way you

can have a completely automatic model railway with several trains ‘chasing’ each other but never

colliding as they will be held at least a section away by Sensor Signals working with Relays.

Although this sounds complex, it is actually relatively easy to wire thanks to the technology already

in the Sensor signals and Layout Link, which is a single wire control system which links the signals

and relays together. The illustration below shows how to wire two Sensor Signals and two stop

sections to an RL1 to stop trains when they come up against a red signal. This shows just two stop

sections, but it can be scaled to many more in the same way, either end to end or continuous ovals.

6

Direction

of Train

To cut the rails use a Dremel type saw, track cutters or use isolating tracks.

You can use plastic isolating fishplates to join cut rails neatly and smoothly.

Stop Section

Rails are cut to make an Isolated track section before

each signal which is long enough to take the longest

locomotive and so stop it before the signal if it is red

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

Sensor Signal

(or track sensor)

A

B

A

B

to other signalsother signals

The Sensor Signals are all powered and linked together as normal (explained in signal instructions)

and a single wire from each Signal goes to the S input of the Relay Controller. A Relay Controller

has two relays, so each can control two track sections and each isolated track section is connected

to the Normally Closed (NC) relay output so that when the relay is not activated by the signal (ie

when signal is red) it connects power to the track section as normal. You can use this system on

either analogue DC or DCC track power layouts, but note that the loco’s will come to a sudden stop

once they are are fully inside an isolated track section unless they are DCC-ABC decoder fitted

locos and optional ABC diode modules are fitted as shown – see page 7 for more on ABC braking.

Manual override

Trains can be released manually from the stop section using either Mimic switches connected to the

‘M’ input of the RL1 (page 4) or DCC commands to override the RL1 (page 3) or Sensor Signal.

Semaphores Although not strictly prototypical to the real railway, it is possible to control Dapol

Semaphore signals using Track Sensors with Train-Tech SC300/400 modules and to stop trains in a

similar way to the colour light signals by also connecting the Track Sensor output to RL1 as above.

POWER

Optional ABC

Diode Module

Interference suppression

Note that you should include

appropriate suppression

particularly for trains, motors

and solenoids using

capacitors and chokes to

prevent interference

Optional ABC

Diode Module

POWER

Power the Sensor Signal or Track

Sensor and the Relay Controller

from the same power supply;

either Track DCC or connect it to

12—16V maximum smooth DC.

See bottom of page 2 for power

connections to Sensor Signals etc

7

• Automatic Train Control for a single short stop (DCC or DC)

This project shows how you can use one Train-Tech Automatic Sensor Signal (or a Track Sensor)

to stop a train for a short time just after a signal at a platform etc, then automatically set off again.

A Sensor signal is normally green until a train goes past it, when it will turn red and stay red until 7

seconds after the last part of the train passes. In this project as the signal turns red the relay will

operate and isolate the stop section from power so that when the locomotive or driving car passes

into the isolated section it will stop* and wait until the signal leaves red when it will start again.

Note that while 7 seconds is quite a short time & is not adjustable (because the time is fixed in the

signal), the stop can also be controlled by an optional Mimic Switch or DCC accessory command

to keep the relay on and the section isolated – on DCC the signal can also be manually overidden.

The project works on DC or DCC layouts, though note that if using DCC Sound locos they will

stop and the sound go off suddenly unless they are fitted with ABC braking chips (see below).

Care should be taken when planning the length of the stop section and its distance from the signal

because the isolated section will only stop the train for 7 seconds after it has passed the signal.

POWER

Power the Sensor Signal or Track

Sensor and the Relay Controller

from the same power supply;

either Track DCC or connect it to

12–16V maximum smooth DC.

See bottom of page 2 for power

connections to Sensor Signals etc

Direction

of Train

Sensor Signal

(or track sensor)

RL1 Relay

Controller

Power in

DC/DCC

S M LEARN DCC/DC S M

NO COM NC NO COM NC

CH1

CH2

Can be

connected to a

Mimic Switch

for control of

stop section

Stop Section

Rails are cut to make an

Isolated track section

To cut the rails use a Dremel type saw, track cutters or use isolating tracks.

You can use plastic isolating fishplates to join cut rails neatly and smoothly.

• Smooth stopping for DCC locos with ABC Braking* (DCC)

Some DCC loco decoders have technology called ‘ABC’ built in which enables locomotives to

slow down gradually and stop when it comes to a section of track with an ABC diode module fitted

in series with the DCC power, and these can be used with the Automatic Train Control projects for

RL1 so that trains slow down instead of suddenly stopping. However note that the ABC diode

modules only work with DCC locos fitted with configured ABC decoders and none-ABC chip fitted

locos will not slow down or stop in isolated sections where ABC diode modules are installed. The

ABC diode modules are made by a number of manufacturers including Train-Tech (part ref ABC1).

Always switch power off

when making connections!

Note that ABC loco decoders

must be configured using the

instructions from the decoder

manufacturer. Some require ABC

diode modules to be connected a

particular way round, so be sure

to carefully follow instructions.

A B

Optional ABC Diode

Module (see below)

A B

The Train-Tech ABC Diode

modules have 2 pairs of terminals,

A and B. They are internally

connected together so either may

be used. Connect the track section

break to A or B terminals and RL1

output to the other terminals.

Other Train-Tech Controllers manuals

Popular Controllers manuals by other brands

JuiceGoose

JuiceGoose CQ Series owner's manual

Global American Inc.

Global American Inc. 3307620 Version 1.0 user manual

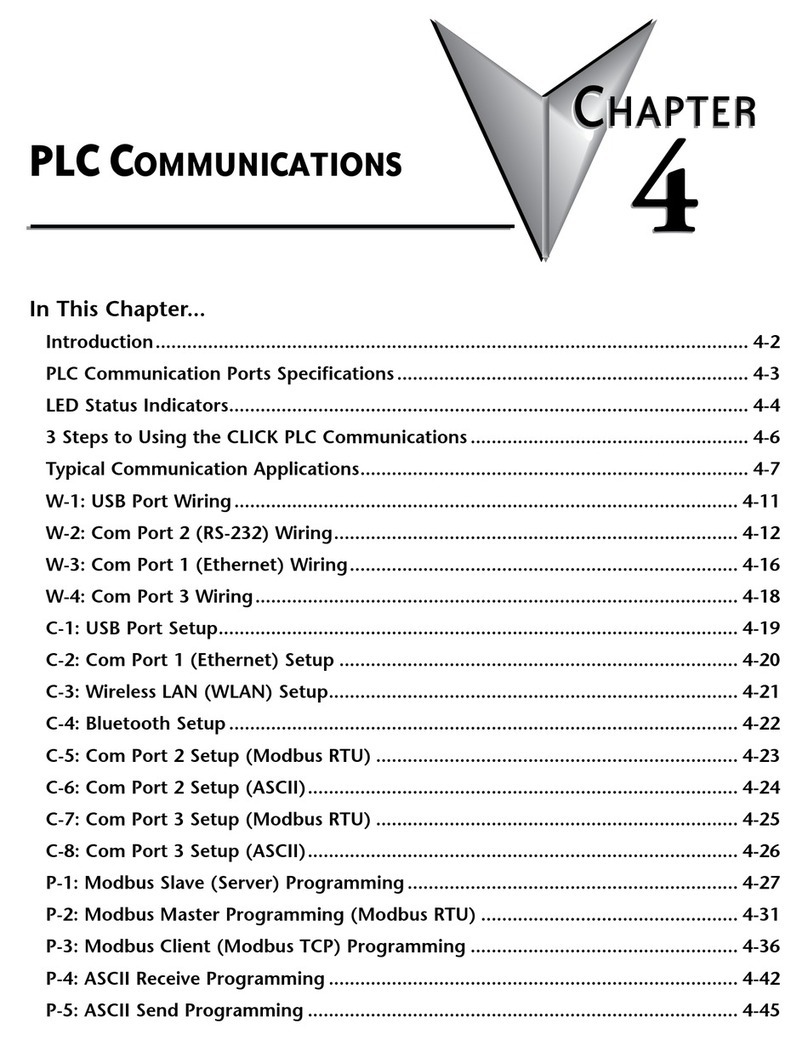

AutomationDirect

AutomationDirect CLICK PLUS PLC manual

Pegasus Astro

Pegasus Astro ULTIMATE POWERBOX V3 product manual

PTZOptics

PTZOptics PT20XSE-PRODUCER-JOY4 user guide

KEBCO

KEBCO COMBIVERT F6 Instructions for use