Det-Tronics U5005 User manual

APPLICATION

The Det-Tronics U5005 Smoke Detector is a sensitive

yet rugged, state-of-the-art protection device that is

designed for classified areas in hazardous industrial

and commercial locations. The detector is designed

to operate effectively with both slow smoldering and

fast burning fires. Typical applications that use the

U5005 include:

• Combustible storage facilities

• Munitions manufacturing

• Volatile chemical storage

• Chemical processing plants

• Petroleum refineries

• Turbine enclosures.

DESCRIPTION

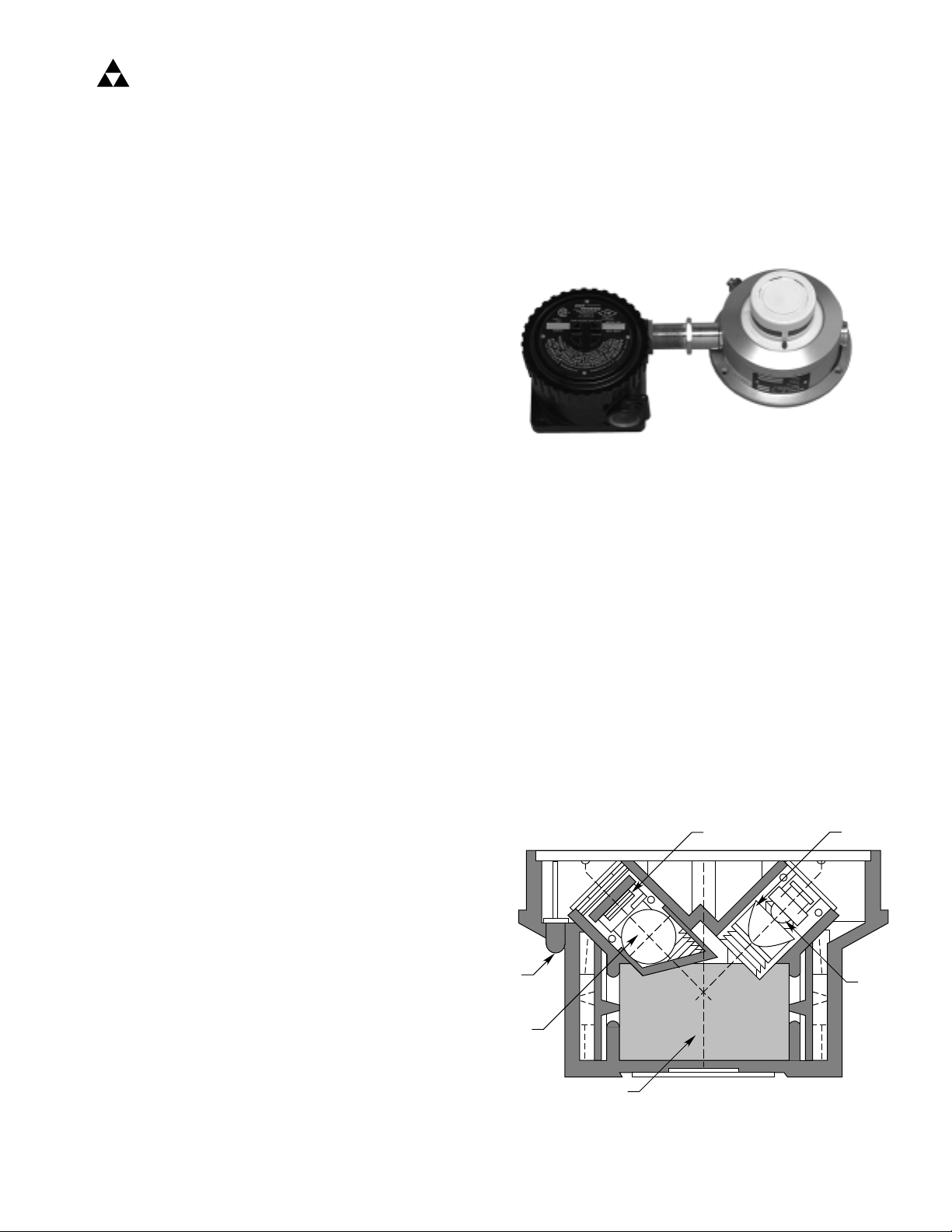

The photoelectric smoke detector uses a solid state

infrared emitting diode (IRED) and a light sensing

photovoltaic cell arranged in a labyrinth assembly.

The labyrinth permits free access to smoke but

restricts external light. Because of its critical function

to the operation of the detector, each IRED is select-

ed with extreme care and is subjected to rigorous

pre-production testing to ensure long-term reliability

and performance.

During normal operation (no smoke), the detector

samples the air approximately every four seconds for

a period of less than one millisecond. The photo-

voltaic smoke cell, which is placed at an angle to the

pulsed invisible light source, is sensitive to the

infrared light in the specified frequency emitted by

the IRED light source and is designed to receive a

signal only when the pulsed IRED source is activat-

ed. See Figure 1.

When smoke enters the chamber, the light from the

IRED reflects off the smoke particles and reaches the

photovoltaic smoke cell. When the amount of light

reflected by smoke reaches the factory set threshold

level, the smoke alarm circuit is actuated.

The detector will respond to a slow smoldering fire

when smoke in the chamber reaches the pre-set sen-

sitivity setting, typically 2.3%.

If a fast burning fire should occur, including fires in

flammable liquids and other materials such as plas-

tics that generate black smoke, the abnormally rapid

movement of smoke into the detection chamber is

sensed by a special rate compensating circuit. An

increase in smoke within the detection chamber that

exceeds a pre-set rate causes the rate compensation

circuit to increase the intensity of the light source,

which increases detector sensitivity. If the smoke

continues to build at this rate, an amplifier circuit is

triggered and the unit generates an alarm. If not, the

detector reverts to normal sensitivity.

INSTRUCTIONS

Smoke Detector

for Classified Areas

U5005

PHOTOVOLTAIC

SENSOR CELL LENS

IRED

LIGHT

SOURCE

ALARM

LED

LENS

SMOKE CHAMBER B1178

Figure 1—Cross Section of Sensing Chamber Assembly

DET-TRONICS®

©Detector Electronics Corporation 2000 8/00 95-8452-01

In normally smoky atmospheres the detector will not

go into alarm as long as the concentration is less

than the fixed sensitivity of the detector. This results

in a sensitive and positive response with the lowest

potential for unwanted alarms.

The main enclosure of the detector contains the elec-

tronic circuitry, alarm relay, and supervision relay.

FAILSAFE OPERATION

To ensure reliable operation, the U5005 is equipped

with self-checking circuitry. A regulation photodiode,

which is matched to the smoke detection circuit, con-

tinuously monitors the output intensity of the IRED

and adjusts it as necessary to compensate for an

accumulation of dust or other contaminants, or any

other variation that can occur with temperature and

time. A power supervision relay in the detector pro-

vides a trouble output signal in the event of an input

power failure.

The detector uses extensive filtering against RF and

transient interference. In addition, there is a 2 sec-

ond time delay before an alarm is generated.

The printed circuit board inside the detector is coat-

ed to minimize the possibility of problems caused by

moisture accumulation.

DETECTOR OUTPUTS

The detector provides a set of Form A (SPST) NO

contacts for connection to the alarm output circuitry

and a set of SPST NC contacts for supervision of

input power. An auxiliary set of Form C (SPDT)

NO/NC alarm relay contacts is also provided for con-

trolling remote annunciation devices.

The alarm output latches on in the event of an alarm

and an LED located on the outer surface of the hous-

ing is illuminated to provide a visual indication that an

alarm condition has occurred. The detector is reset

by momentarily interrupting input power.

SPECIFICATIONS

OPERATING VOLTAGE—

20 to 28 vdc filtered supply, with less than 1.4 vpp at

60 to 120 Hz.

OPERATING CURRENT—

Standby: 10 milliamperes.

Alarm: 35 milliamperes.

TEMPERATURE RANGE—

Operating: –13°F to +140°F (–25°C to +60°C).

Storage: –67°F to +185°F (–55°C to +85°C).

ALARM AND SUPERVISORY RELAY CONTACT

RATING—

1.0 ampere at 30 vdc, SPST.

AUXILIARY ALARM RELAY CONTACT RATING—

2.0 amperes at 30 vdc, Form C, SPDT.

JUNCTION BOX—

Body material: Copper-free aluminum.

Cover: Feraloy.

Conduit Fitting: 25 mm (female).

CERTIFICATIONS—

CSA Certified for use in Class I, Division 2, Groups A,

B, C and D hazardous locations.

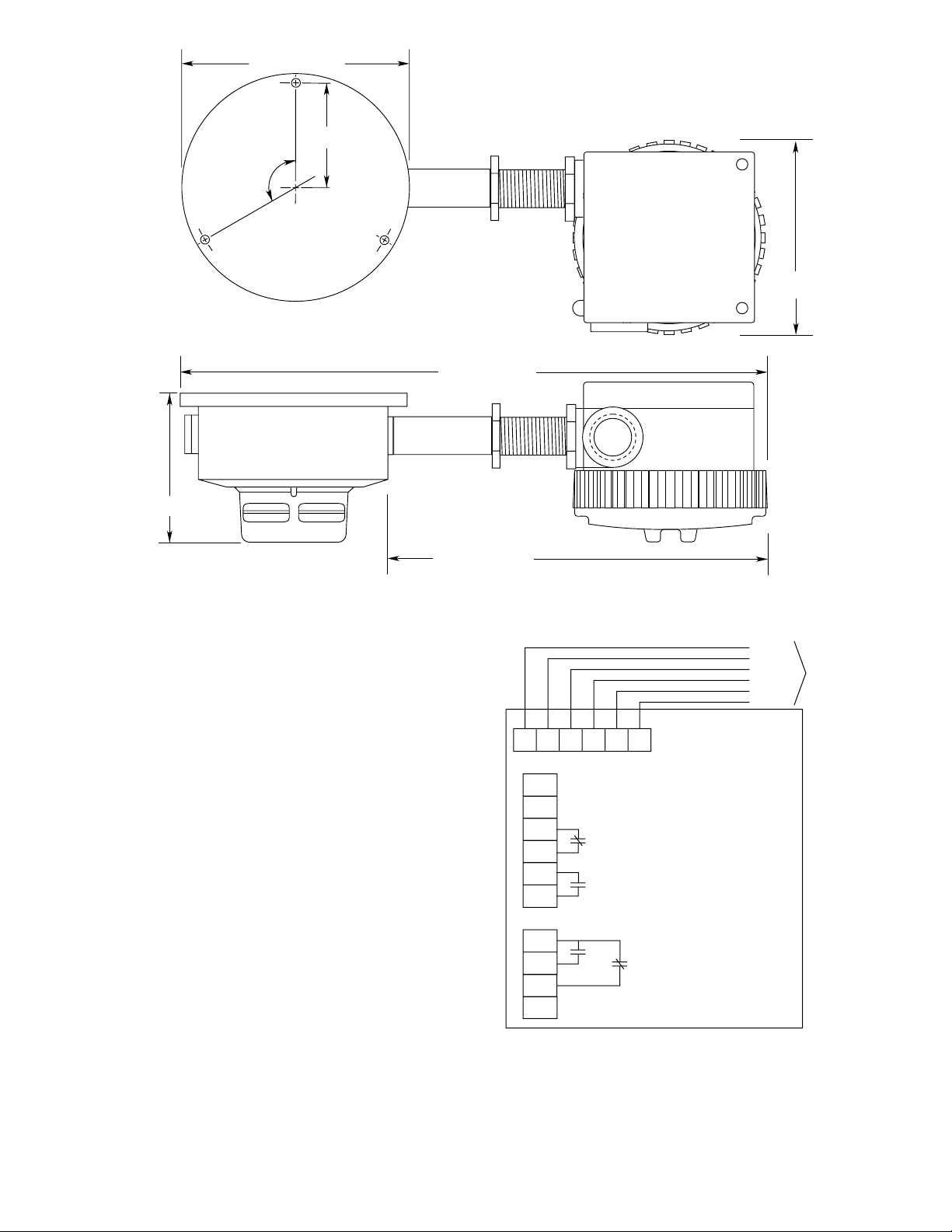

DIMENSIONS—

See Figure 2.

WEIGHT—

2 pounds (0.91 kilogram)

INSTALLATION

The U5005 is intended for surface mounting. See

Figure 2. The mounting screw holes are counter-

bored for No. 8 flat-head screws. Electrical equip-

ment that is used in conjunction with the smoke

detector is connected to the detector using a termi-

nal strip located in the junction box that is furnished

with the unit.

DETECTOR LOCATION

The smoke detector is normally mounted on the ceil-

ing not less than six inches from a side wall. The

exact location of the detector must be determined by

an evaluation based on engineering judgment sup-

plemented, if possible, by field tests.

For additional information on detector location and

spacing, contact the National Fire Protection

Association, Batterymarch Park, Quincy, Mass.

02269, and request a copy of NFPA Number 72, the

Standard on Automatic Fire Detectors.

2

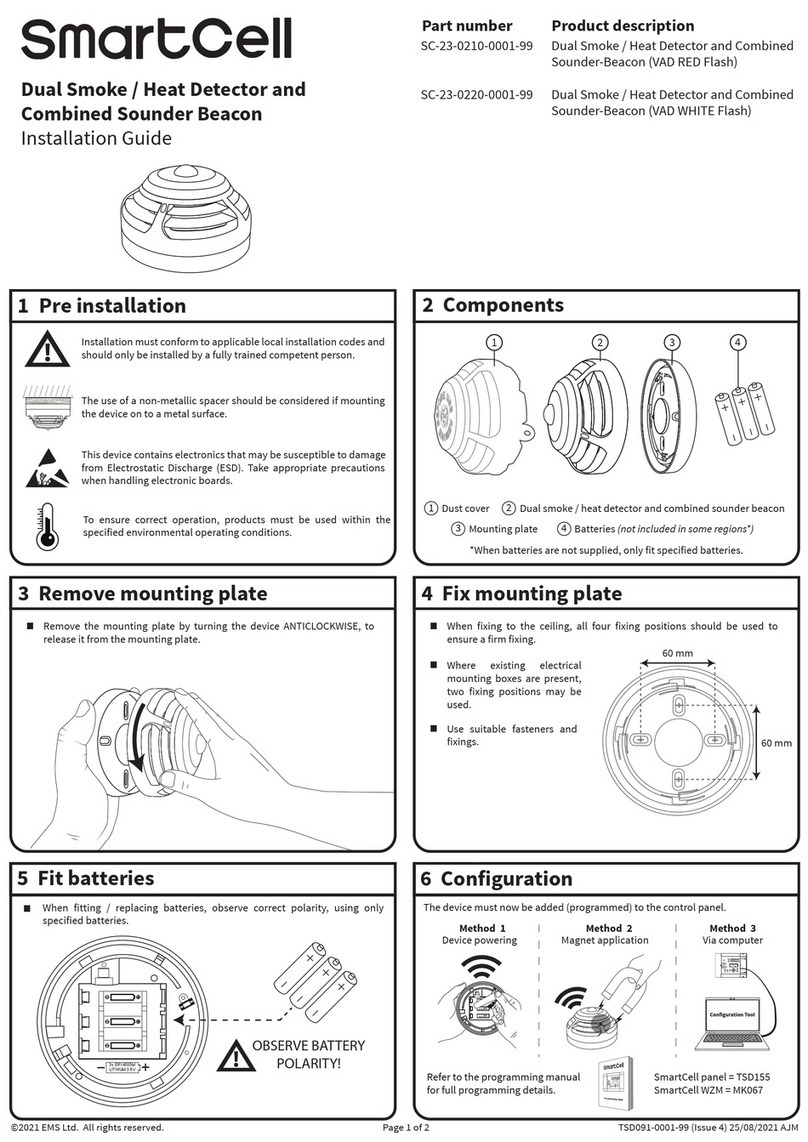

MOUNTING THE DETECTOR

1. Using three No. 8 flat head screws placed through

the counterbored holes in the detector flange,

secure the detector to the surface location. Secure

the junction box if necessary.

2. Remove the cover from the junction box and com-

plete installation of system conduit. Feed the exter-

nal wiring through the remaining junction box entry

or M25 to 3/4 inch adapter. Use care not to dam-

age the wires by twisting them when installing the

junction box.

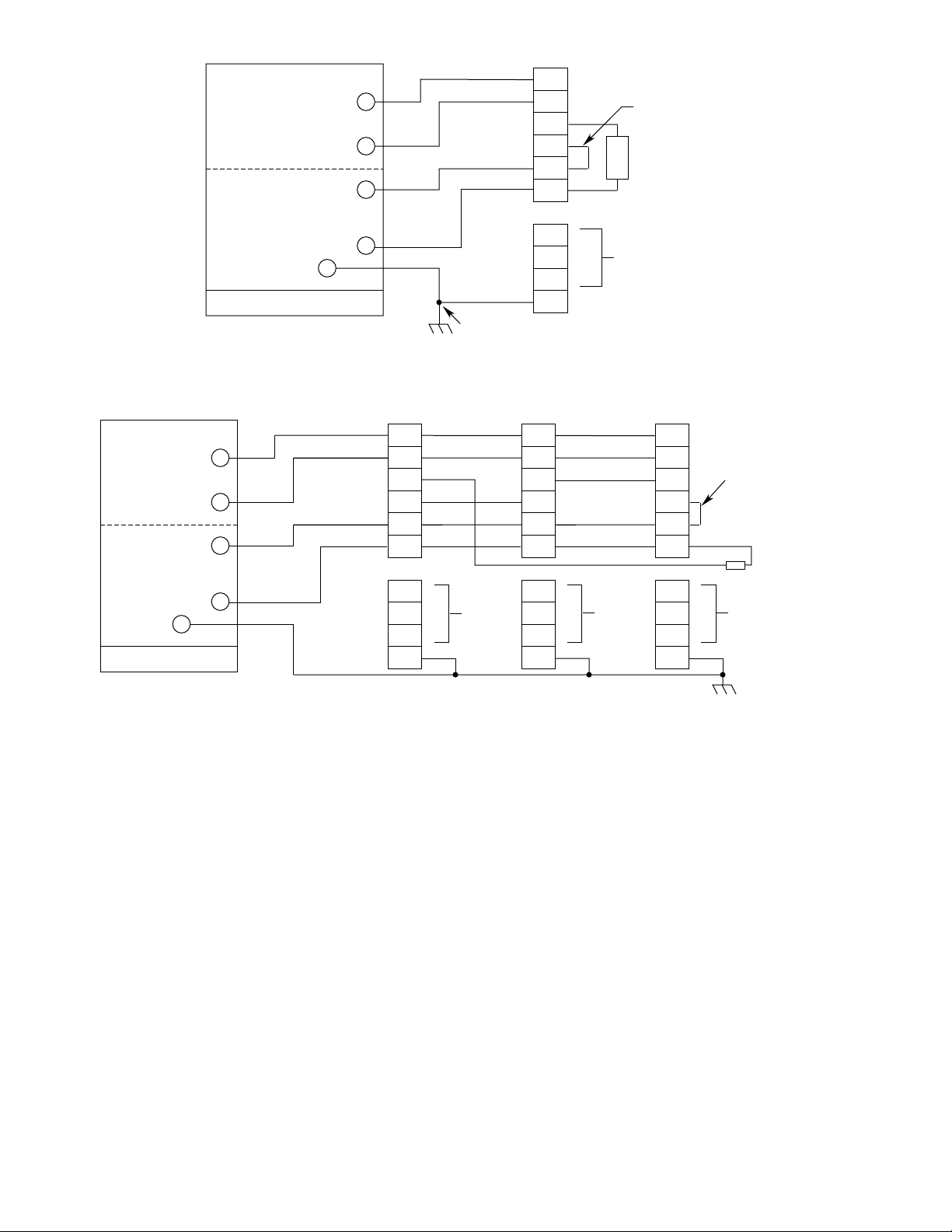

3. Connect the external wiring to the appropriate ter-

minals and re-install the junction box cover. See

Figures 3, 4 and 5 for wiring details.

DETECTOR CONNECTIONS

The U5005 contains two sets of relay contacts:

1. One set of NO Alarm contacts close upon detec-

tion of smoke.

2. One set of NC Trouble contacts close when the

detector is powered.

3 95-8452

12-3/4 INCHES (325 MM)

8-1/16 INCHES (205 MM)

3-1/2 INCHES

(89 MM)

4-1/2 INCHES

(114 MM)

A1967

120°

5/32 INCH DIA. (3)

2-7/16 INCHES

(62 MM)

5-5/16 INCHES (135 MM)

Figure 2—U5005 Dimensions in Inches (MM)

1

2

3

4

5

NORMALLY CLOSED SUPERVISORY CONTACTS

NORMALLY OPEN ALARM CONTACTS

AUXILIARY ALARM CONTACTS

+

–

GROUND

YELLOW

YELLOW

VIOLET

VIOLET

BLACK

RED

TO DETECTOR

1 2 3 4 5 6 TB – 1

TB – 2

TB – 3

NOTE:

CIRCUIT SHOWN IN THE NORMAL STANDBY ENERGIZED MODE

C1192

7

10

8

9

6

Figure 3—Wiring Terminals

MAINTENANCE

Regularly scheduled maintenance is normally not

needed, however, periodic cleaning of the smoke

chamber may be necessary when detectors are

located in abnormally dirty or dusty environments.

Vacuuming around the smoke chamber housing prior

to blowing out the chamber with a “dry air” hose is

recommended.

NOTE

The U5005 is not designed to be serviced or

repaired in the field. Disassembly of the detector

in the field will void the warranty. If service or

repairs are required, return the entire unit to the

factory.

The smoke detector can be tested using the same

methods employed for any photo-electric detector.

Do not use canned aerosol smoke devices to test the

detector, since damage can result.

DEVICE REPAIR AND RETURN

Prior to returning devices or components, contact

Detector Electronics so that a Service Order number

can be assigned. A written statement describing the

malfunction must accompany the returned device or

component to expedite finding the cause of the fail-

ure. Return all equipment transportation prepaid to

the factory in Minneapolis.

1

2

3

4

5

AUXILIARY ALARM CONTACTS

+

–

C

NO

NC

TB –2

TB –3

POWER

2 WIRE

CLASS B

RECEIVING ZONE

CHASSIS

GROUND

LISTED CONTROL PANEL

+

–EOL DEVICE

SUPPLIED BY

PANEL MANUFACTURER

ADD JUMPER

GROUND STUD

B1193

6

7

8

9

10

Figure 4—Single Detector Wiring

Figure 5—Multiple Detector Wiring

FIRST DETECTOR IN LOOP

TB –2 LAST DETECTOR IN LOOP

TB –2

TB –3

POWER

2 WIRE

CLASS B

RECEIVING ZONE

CHASSIS

GROUND

LISTED CONTROL PANEL

+

–

AUXILIARY

ALARM

CONTACTS

C

NO

NC

AUXILIARY

ALARM

CONTACTS

C

NO

NC

AUXILIARY

ALARM

CONTACTS

C

NO

NC

TB –2

TB –3

1

2

3

4

5

TB –3

EOL DEVICE

SUPPLIED BY

PANEL MANUFACTURER

INSTALL JUMPER

C1696

1

2

3

4

5

1

2

3

4

5

666

777

888

999

10 10 10

Detector Electronics Corporation

6901 West 110th Street • Minneapolis, Minnesota 55438 • Operator (952) 941-5665 or (800) 765-FIRE

Customer Service (952) 946-6491 • Fax (952) 829-8750 • www.detronics.com • E-mail: [email protected]

Other Det-Tronics Smoke Alarm manuals