Det-Tronics X3300 User manual

Instructions 95-8502

Protect•ir Multispectrum IR Flame Detector

X3300

Detector Electronics Corporation

6901 West 110th Street •Minneapolis, Minnesota 55438 USA

Tel: 952.941.5665 or 800.765.3473 •Fax: 952.829.8750 9/00 95-8502

IMPORTANT

Be sure to read and understand the entire

instruction manual before installing or operating the

flame detection system.

WARNING

Do not open the detector assembly in a hazardous

area when power is applied. The detector contains

no user serviceable components and should never

be opened. Doing so could disturb critical optical

alignment and calibration parameters, possibly

causing serious damage. This type of damage

could be undetected and could result in failure to

see a fire and/or false alarm.

CAUTION

The wiring procedures in this manual are intended

to ensure proper functioning of the device under

normal conditions. However, because of the many

variations in wiring codes and regulations, total

compliance to these ordinances cannot be

guaranteed. Be certain that all wiring complies

with the NEC as well as all local ordinances. If in

doubt, consult the authority having jurisdiction

before wiring the system. Installation must be

done by a properly trained person.

CAUTION

To prevent unwanted actuation or alarm,

extinguishing devices must be disconnected prior

to performing detection system tests or

maintenance.

ATTENTION

Remove protective cap from front of the detector

before activating the system.

ATTENTION

Observe precautions for handling electrostatic

sensitive devices.

ATTENTION

The X3300 includes the Automatic Optical Integrity

(oi) feature — a calibrated performance test that is

automatically performed once per minute to verify

complete detector operation capabilities. No

testing with an external test lamp is required.

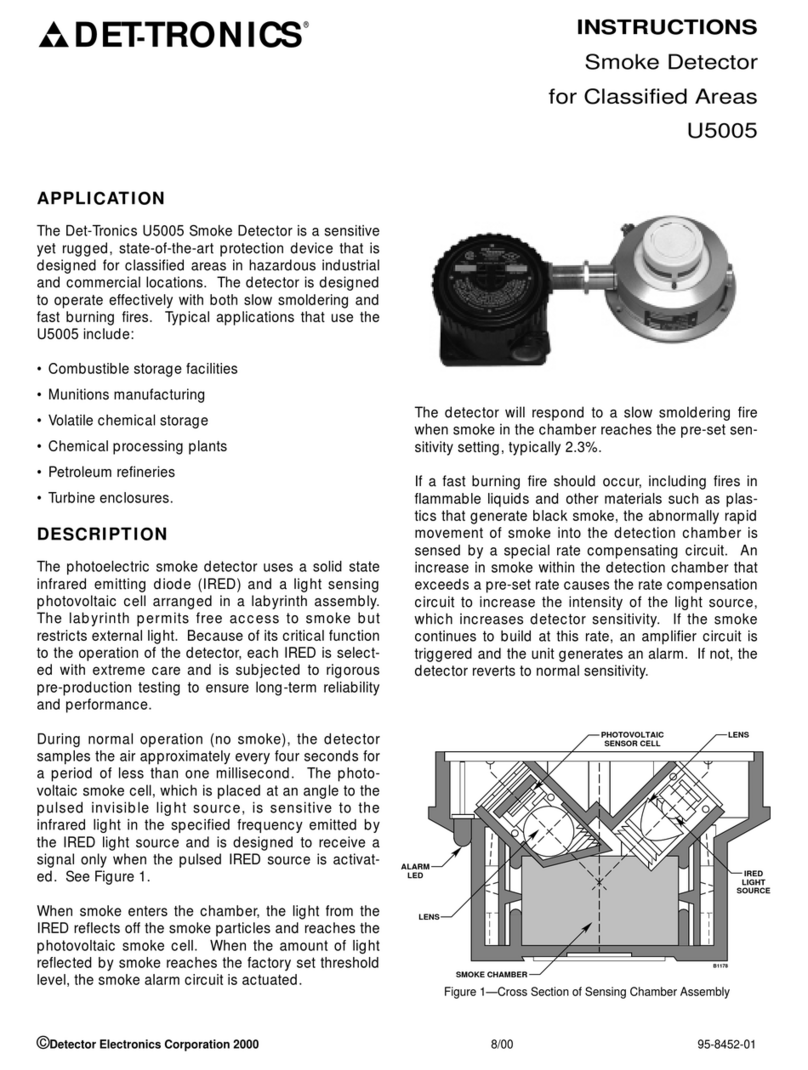

DESCRIPTION

The X3300 Protect•ir is a multispectrum infrared (IR)

flame detector. It provides unsurpassed detection of

fires from light to heavy hydrocarbon fuels combined

with the highest degree of false alarm rejection. The

detector is suitable for use in indoor and outdoor

applications with NEMA 4X/IP66 classifications as well

as EExd/EExe explosion-proof ratings.

The X3300 contains three IR sensors, signal processing

circuitry, and fire and fault relays. A tricolor LED on the

detector faceplate indicates normal, fire alarm, and fault

conditions.

Protect•ir

Multispectrum IR Flame Detector

X3300

©Detector Electronics Corporation 2000 9/00 95-8502

DET-TRONICS®

*oiis Detector Electronics' Trademark for its patented Optical

Integrity Systems, U.S. Patent 3,952,196, United Kingdom Patent

1,534,969, Canada Patent 1,059,598.

INSTRUCTIONS

Factory configurable options include:

• Automatic or Manual Optical Integrity (oi)

• Fire and Fault Relay Operation

– Normally Open (N.O.) or Normally Closed (N.C.)

Contacts

– Normally Energized or Normally De-Energized (Fire

relay)

– Latching or Non-latching.

• 4 to 20 mA output.

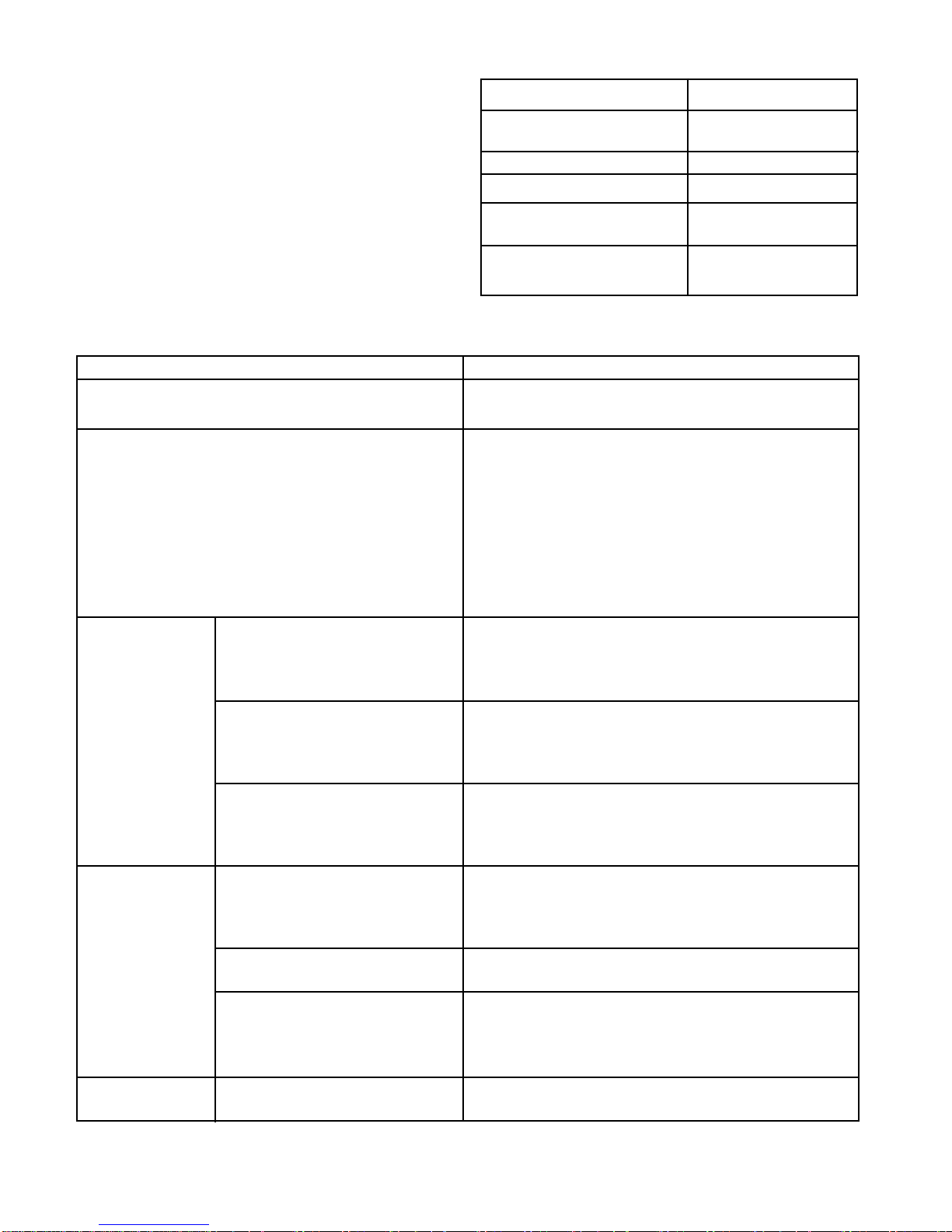

Table 2—Factory Configuration Options (Not Changeable in the Field)

Option Available Configurations

Sensitivity • Detects 1 square foot gasoline fire at 210 feet (very high

sensitivity) or 100 feet (medium sensitivity).

Optical Integrity (oi)*Automatic oi- Automatically checks internal circuitry and

cleanliness of viewing windows to ensure proper operation.

If a fault condition exists, the amber Fault LED lights.

• Manual oi- Cleanliness of viewing windows test can be

manually initiated by closing an external switch that is elec-

trically connected between the oilead and circuit ground.

Warning: Successful Manual oitest results in fire alarm

relay activation and red Alarm LED lights.

• Internal circuitry is automatically tested independent of the

Manual oitest

Fire Relay Latching/Non-Latching • Latching - Relay remains in “Fire” condition after fire has

been detected until X3300 power is cycled.

*Non-latching - Relay remains in “Fire” condition only as long

as a fire is being detected.

Normally Energized/De-Energized • Normally Energized - Fire relay is energized in non-alarm

(no fire) condition.

*Normally De-Energized - Fire relay is de-energized in non-

alarm (no fire) condition.

Contacts Normally Open/Closed *Normally Open - Fire relay contacts are open in non-alarm

(no fire) condition.

• Normally Closed - Fire relay contacts are closed in non-

alarm (no fire) condition.

Fault Relay Latching/Non-Latching • Latching - Relay remains in “Fault” condition after fault has

been detected until X3300 power is cycled.

*Non-latching - Relay remains in “Fault” condition only as

long as a fault is being detected.

Normally Energized *Normally Energized - Fault relay is energized with no fault

present.

Contacts Normally Open/Closed *Normally Open - Fault relay contacts are open when fault is

present.

• Normally Closed - Fault relay contacts are closed when

fault is present.

4 to 20 mA Output • Current output level indicates detector status condition.

* Standard Configuration

2

Detector Status LED Indicator

Power On/Normal Operation Green

(no fault or fire alarm)

Fault Yellow

Fire (Alarm) Red

Medium Sensitivity Two Yellow Flashes

During Power-up

Very High Sensitivity Four Yellow Flashes

During Power-up

Table 1—Detector Status Indicator

Refer to the “Ordering Information“ section for a

complete list of available options and accessories.

Table 1 indicates the condition of the LED for each

detector status. The LED is non-latching. Fire and Fault

relay condition for each detector status varies

according to the factory configuration.

FACTORY CONFIGURATION OPTIONS

The X3300 is configured at the factory to operate as

specified when ordered. Refer to the descriptions in

Table 2 for a functional explanation of each

configuration option.

NOTE

Factory configurable options cannot be changed in

the field.

4 TO 20 MA OUTPUT

This option provides a 4 to 20 mA dc current output for

transmitting detector status information to other devices.

The circuit can be wired in either an isolated or non-

isolated configuration and can drive a maximum loop

resistance of 500 ohms from 18 to 19.9 volts dc and 600

ohms from 20 to 32 volts dc. Table 3 indicates the

detector status conditions represented by the various

current levels. The output is calibrated at the factory,

with no need for field calibration.

NOTE

The output of the 4 to 20 mA current loop is not

monitored by the fault detection circuitry of the

X3300. Therefore, an open circuit on the loop will

not cause the detector status LED to indicate a

fault.

GENERAL APPLICATION

INFORMATION

RESPONSE CHARACTERISTICS

Response is dependent on the type of fuel, the

temperature of the fuel, and the time required for the fire

to come to equilibrium. As with all fire tests, results

must be interpreted according to an individual

application.

See Appendix A for fire test results.

IMPORTANT APPLICATION CONSIDERATIONS

In applying any type of sensing device as a fire

detector, it is important to know of any conditions that

can prevent the device from responding to fire, and also

to know what other sources besides fire can cause the

device to respond.

Welding

Arc welding should not be performed within 40 feet of

the long range detector (10 feet for medium range

detector). It is recommended that the system be

bypassed during welding operations in situations where

the possibility of a false alarm cannot be tolerated. Gas

welding mandates system bypass, since the gas torch

is an actual fire. Arc welding rods can contain organic

binder materials in the flux that burn during the welding

operation and are detectable by the X3300. Welding

rods with clay binders do not burn and will not be

detected by the X3300.

Artificial Lighting

The X3300 should not be located within 3 feet of

artificial lights. Artificial lights should not be positioned

so that they are pointed directly at the detector.

EMI/RFI Interference

The X3300 is resistant to interference by EMI and RFI. It

will not respond to a 5 watt walkie-talkie at distances

greater than 1 foot. Do not operate a walkie-talkie within

1 foot of the X3300.

Non-Carbon Fires

The X3300 is a multiple spectrum IR device with

detection limited to carbonaceous fuels. It should not

be used to detect fires that do not contain carbon, such

as hydrogen, sulfur and burning metals.

3 95-8502

Current Level Detector Status

0 mA Open Circuit

1 mA General Fault

2 mA Oi Fault

3 mA Hi Background IR

4 mA Normal Operation

20 mA Alarm

Table 3—Detector Status Conditions Indicated by Current Level

INSTALLATION

DETECTOR POSITIONING

Detectors should be positioned to provide the best

unobstructed view of the area to be protected. The

following factors should also be taken into consideration:

• Identify all high risk fire ignition sources.

• Be sure that enough detectors are used to adequately

cover the hazardous area.

• Locate and position the detector so that the fire

hazard(s) are within both the field of view and

detection range of the device. Refer to Appendix A

for specific information.

• Be sure that the unit is easily accessible for cleaning

and other periodic servicing.

• For outdoor applications, the detector should be

aimed downward at least 10 to 20 degrees to allow

lens openings to drain. See Figure 1.

• For best performance, the detector should be

mounted on a rigid surface in a low vibration area.

• Dense fog, rain or ice can absorb IR radiation and

reduce the sensitivity of the detector.

• Although IR detectors are less affected by smoke than

other detectors, the X3300 should not be placed

where rising combustion products can obscure its

vision. If smoke is expected before fire, smoke or

other alternative detectors should be used in

conjunction with the X3300. For indoor applications, if

dense smoke is expected to accumulate at the onset

of a fire, mount the detector on a side wall at least a

few feet (approximately 1 meter) down from the

ceiling.

• If possible, fire tests should be conducted to verify

correct detector positioning and coverage.

WIRING REQUIREMENTS

WIRE SIZE AND TYPE

The system should be wired using a 14 to 22 gauge (1.3

to 0.5 mm2) cable. The wire size selected should be

based on the number of detectors connected, the

supply voltage and the cable length. A minimum input

voltage of 18 vdc must be present at the X3300.

The use of shielded cable is recommended to protect

against interference caused by EMI and RFI. When

using cables with shields, terminate the shields as

shown in Figures 6 through 8.

In applications where the wiring cable is installed in

conduit, the conduit should not be used for wiring to

other electrical equipment.

CAUTION

Installation of the detector and wiring should be

performed only by qualified personnel.

PROTECTION AGAINST MOISTURE DAMAGE

It is important to take proper precautions during

installation to ensure that moisture will not come in

contact with the electrical connections or components

of the system. The wiring pigtail for the X3300 is factory

sealed for easy installation onto a junction box where

electrical connections are made. The integrity of the

system regarding moisture protection must be

maintained for proper operation and is the responsibility

of the installer.

If conduit is used, drains must be installed at water

collection points to automatically drain accumulated

moisture. Conduit breathers should be installed at

upper locations to provide ventilation and allow water

vapor to escape. At least one breather should be used

with each drain.

4

Figure 1—Detector Orientation Relative to Horizon

CENTER AXIS

OF DETECTOR

FIELD OFVIEW

CENTER AXIS

OF DETECTOR

FIELD OFVIEW

INCORRECT

CORRECT

NOTE: DETECTOR MUST ALWAYS BE AIMED

DOWNWARD AT LEAST 10 TO 20 DEGREES.

B1974

Conduit raceways should be inclined so that water will

flow to low points for drainage and will not collect inside

enclosures or on conduit seals. If this is not possible,

install conduit drains above the seals to prevent the

collection of water or install a drain loop below the

detector with a conduit drain at the lowest point of the

loop.

The detector is factory sealed. Conduit seals are not

required for compliance with explosion-proof installation

requirements.

MOUNTING AND WIRING PROCEDURE

Refer to the procedure below and the listed figures to

mount and wire the X3300.

Figure 1 – Detector Orientation Relative to Horizon

Figure 2 – Wiring Terminal Identification

Figure 3 – X3300 with Q9003 Swivel Mount

Figure 4 – Front View of the X3300

Figure 5 – X3300 Terminal Block

Figure 6 – A Typical System

Figure 7 – X3300 Detector with 4 to 20 mA Output

oi PLATE ORIENTATION

Refer to Figure 4 and insure that the oi plate will be

oriented as shown when the X3300 is mounted and

sighted. This will ensure proper operation of the oi

system and will also minimize the accumulation of

moisture and contaminants between the oi plate and

the viewing windows. The oi plate includes an arrow,

which should be pointed in the up direction, indicating

that the oi plate and detector are correctly oriented.

IMPORTANT

The oi plate must be securely tightened to ensure

proper operation of the oi system.

INSTALLATION USING Q9003 MOUNTING

BRACKET

1. Install the swivel mounting bracket assembly on the

wall or ceiling. The installation surface should be

free of vibration. Refer to Figure 8 for dimensions of

the Q9003 swivel mount.

2. Make field connections following local ordinances

and guidelines in this manual. Refer to Figures 2

and 6. If the detector is equipped with 4 to 20 mA

output, refer to Figure 7.

NOTE

Connect the shield to power supply minus (circuit

ground) at the detector end. At the fire panel end,

connect the shield and power supply minus to

chassis ground through a 0.47 µF 400 Volt non-

polarized capacitor (not supplied).

3. Check all field wiring to be sure that the proper

connections have been made.

IMPORTANT

Do not test any wiring connected to the detector

with a meg-ohmmeter. Disconnect wiring at the

detector before checking system wiring for

continuity.

4. Make the final sighting adjustments and ensure that

the mounting bracket hardware is tight.

5 95-8502

COLOR FUNCTION

RELAY 4TO 20 MA

WHITE

BLACK

RED

COLOR

WHITE

BLACK

RED

GRAY

PURPLE

BROWN

BLUE

GREEN GREEN

MANUAL Oi

DC –

DC+

FUNCTION

MANUAL Oi

DC –

DC+

FAULT NO

FAULT C

FIRE NO

FIRE C

CHASSIS CHASSIS

WHT/BRN

WHT/RED

4TO 20 (–)

4TO 20 (+)

A1977

1

2

3

4

5

6

7

8

TERMI-

NAL #

Figure 2—Wiring Terminal Identification

Figure 3—X3300 with Q9003 Mounting Bracket

6

Oi ARROW

(MUST BE ORIENTEDWITH ARROW POINTING UP)

VIEWINGWINDOW (3)

Oi PLATE KNOB

Oi PLATE

DETECTOR STATUS INDICATOR

A1984

Figure 4—Front View of the X3300 Detector/Controller

Figure 5—X3300 Terminal Block

7 95-8502

X3300

B1978

FIRE ALARM PANEL

ALARM

24 VDC

+

–

oi

–

+

FAULT RELAY 1

ALARM RELAY 2

WIRING NOTES:

1 FAULT RELAYS SHOWN HAVE BEEN SPECIFIED (WHEN ORDERED)

TO HAVE NORMALLY CLOSED CONTACTS

AND TO BE NORMALLY ENERGIZED WITH NO FAULT PRESENT.

2 ALARM RELAYS SHOWN HAVE BEEN SPECIFIED (WHEN ORDERED)

TO HAVE NORMALLY OPEN CONTACTS

AND TO BE NORMALLY DE-ENERGIZED WITH NO ALARM CONDITION PRESENT.

3 INDIVIDUAL MANUAL oiTEST SWITCHES CAN BE INSTALLED REMOTELY

OR A DETECTOR SELECTOR AND ACTIVATION SWITCH CAN BE INSTALLED AT THE FIRE PANEL.

TEST SWITCHES ARE NOT SUPPLIED.

4 END OF LINE DEVICE SUPPLIED BY PANEL.

END OF

LINE DEVICE 4

oi TEST 3

.47 µF/400 V

FILM CAPACITOR

GREEN

COLOR

RELAY 4TO 20 MA

WHITE

BLACK

RED

GRAY

PURPLE

BROWN

BLUE

GREEN

FUNCTION

MANUAL Oi

DC –

DC+

FAULT NO

FAULT C

FIRE NO

FIRE C

CHASSIS

COLOR

WHITE

BLACK

RED

GREEN

WHT/BRN

WHT/RED

FUNCTION

MANUAL Oi

DC –

DC+

CHASSIS

4TO 20 (–)

4TO 20 (+)

(4)

(1)

(2)

(3)

(5)

(6)

(7)

1

2

3

4

5

6

7

8

TERMI-

NAL #

Figure 6—A Typical System

OPTICAL INTEGRITY (oi)

AUTOMATIC oi

The X3300 includes the Automatic Optical Integrity (oi)

feature — a calibrated performance test that is

automatically performed once per minute to verify

complete detector operation capabilities. No testing

with an external test lamp is required. The detector

automatically performs the same test that a

maintenance person with a test lamp would perform —

once every minute, 60 times per hour. A successful

automatic oi test does not produce an alarm condition.

The Protect•ir signals a fault condition when less than

50% of the detection range remains. This is indicated

by the Fault relay and is evident by the amber color of

the LED on the face of the detector. See the

“Troubleshooting” section for further information.

MANUAL oi

The detector also incorporates a manual oi feature that

provides the same test as the automatic oi, and in

addition actuates the Alarm relay to verify output

operation. The manual oi feature is available in all

models and can be performed at any time. This test

requires bypass of all extinguishing devices to avoid

release resulting from a successful test.

The manual oi test is activated by connecting the white

lead to power supply minus. This places the detector in

a special operating mode. First, the device de-latches

any latching outputs. Next, the IR emitters are activated.

If the resulting signals meet the test criteria, the Alarm

relay changes state and the indicating LED changes to

red. This condition remains until the white lead is

disconnected from dc minus. If the test criteria are not

met, no alarm is produced and no fault is generated.

See the “Troubleshooting” section for further details.

STARTUP PROCEDURE

When installation of the equipment is complete, perform

the “Fire Alarm Test” below.

Allow 20 to 30 minutes for the detector optics to reach

equilibrium. Housing will be warm to the touch.

8

24 VDC

4 TO 20 MA

PLC

–

+

875 MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5+

+

A2005

Figure 7A—X3300 Detector Wired for Non-Isolated 4 to 20 ma

Current Output (Sourcing)

24 VDC

4 TO 20 MA

PLC

–

+

875 MAX

AT 24 VDC –

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5+

+

A2006

Figure 7B—X3300 Detector Wired for Non-Isolated 4 to 20 ma

Current Output (Sinking)

24 VDC

4 TO 20 MA

PLC

–+

24 VDC

–

+

875 MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5+

+

A2007

Figure 7C—X3300 Detector Wired for Isolated 4 to 20 ma

Current Output (Sourcing)

24 VDC

4 TO 20 MA

PLC

–+

24 VDC

–

+

875 MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5+

+

2008A

Figure 7D—X3300 Detector Wired for Isolated 4 to 20 ma

Current Output (Sinking)

FIRE ALARM TEST

1. Disable any extinguishing equipment that is

connected to the system.

2. Apply input power to the system.

3. Connect the oi test line to dc minus for 5 to 10

seconds or perform a pan fire test. The alarm relay

will change states and the red alarm LED will

illuminate when the device goes into an alarm

condition.

4. Disengage the oi test line or extinguish the test fire.

If the Alarm relay is configured for the standard

non-latching operation, it will change states and the

red LED will turn off. If the unit has latching relays,

they can be reset by removing input power (0.1

second minimum).

5. Repeat this test for all detectors in the system. If a

unit fails the test, refer to the “Troubleshooting”

section.

6. Verify that all detectors in the system are properly

aimed at the area to be protected.

7. Enable extinguishing equipment when the test is

complete.

TROUBLESHOOTING

WARNING

The detector contains no user serviceable

components and should never be opened.

1. Disable any extinguishing equipment that is

connected to the unit.

2. Inspect the viewing windows for contamination and

clean as necessary. The detector is relatively

insensitive to airborne contaminants, however, thick

deposits of ice, dirt, or oil will reduce sensitivity.

(Refer to the “Maintenance” section for complete

information regarding cleaning of the detector

viewing window.)

3. Check input power to the unit.

4 If the fire system has a logging function, check the

fire panel log for relay status and/or 4 to 20 mA

output information. See Table 4.

5. Turn off the input power to the detector and check

all wiring for continuity. Important: Disconnect

wiring at the detector before checking system

wiring for continuity.

9 95-8502

10.7 INCHES

(27.2 CM)

7.8 INCHES

(19.8 CM)

3.9 INCHES

(9.9 CM)

3.9 INCHES

(9.9 CM)

3.0 INCHES

(7.6 CM)

3.0 INCHES

(7.6 CM)

0.4 INCH DIA.

(1.0 CM)

A1981

Figure 8—

Q9003 Mounting Bracket Dimensions in Inches (CM)

6. If all wiring checks out and cleaning of the oi

plate/window did not correct the fault condition,

check for high levels of background IR radiation by

covering the detector with the factory supplied

cover or aluminum foil. If the fault condition clears

within 6 minutes or less, extreme background IR is

present. Re-adjust the view of the detector away

from the IR source or relocate the detector.

If none of these actions corrects the problem, return the

detector to the factory for repair.

NOTE

Since the entire unit must be returned to the

factory for repair, it is highly recommended that a

complete spare be kept on hand for field

replacement to ensure continuous protection.

PERIODIC CHECKOUT PROCEDURE

Periodic testing is not required when the detector is

configured for automatic optical integrity testing. If the

X3300 is configured for manual oi operation, a

checkout of the system using the oi feature should be

performed on a regularly scheduled basis to ensure that

the system is operating properly. To test the system,

perform the “Fire Alarm Test” as described in the

“Startup Procedure” section of this manual.

MAINTENANCE

IMPORTANT

Periodic flamepath inspections are not

recommended since the product is not intended to

be serviced and provides proper ingress protection

to eliminate potential deterioration of the flamepaths.

WARNING

The detector contains no user serviceable

components and should never be opened.

To maintain maximum sensitivity, the viewing windows

of the X3300 must be kept relatively clean. Refer to the

procedure below for instructions.

CLEANING PROCEDURE

CAUTION

Disable any extinguishing equipment that is

connected to the unit to prevent unwanted

actuation.

To clean the window and oi plate, use Det-Tronics

window cleaner (part number 001680-001) and a soft

cloth or tissue and refer to the procedure below.

1. Disable any extinguishing equipment that is

connected to the unit.

2. Since the X3300 is less affected by contamination

than other detectors, removal of the oi plate is

needed only under extreme conditions. In addition,

it is not necessary to achieve perfect cleanliness,

because IR is not significantly absorbed by slight

films of oil and/or salt. If a fault condition is still

indicated after cleaning, remove and clean the oi

plate using the procedure below.

3. Clean all three viewing windows and reflector

surfaces thoroughly using a clean cloth, cotton

swab or tissue and Det-Tronics window cleaning

solution. If a stronger solution is needed, isopropyl

alcohol may be used.

OiPLATE REMOVAL

1. Remove the oi plate from the detector by loosening

the oi plate knob.

2. Thoroughly clean the oi plate reflective surfaces,

holding it by its edges to avoid leaving fingerprints

on the inside reflective surface.

3. Re-install the oi plate. Ensure that the plate is flat

on the detector surface. Tighten the oi plate knob

securely (40 oz/inches).

NOTE

If the oi plate is removed, be sure to install the

original oi plate. oi plates are not interchangeable

and should not be mixed with oi plates from other

detectors.

NOTE

If corrosive contaminants in the atmosphere cause

the oi plate surface to deteriorate to the extent that

it is no longer possible to restore it to its original

condition, it must be replaced. Consult factory for

oiplate replacement procedure.

10

Current Level Status Action

0 mA Open Circuit Check wiring

connections.

1 mA General Fault Cycle power.

2 mA Oi Fault Clean windows.

3 mA Hi Background IR Remove IR source or

aim detector away

from IR source.

4 mA Normal Operation

20 mA Alarm

Table 4—Troubleshooting Guide

FEATURES

• Long detection range to carbonaceous fires.

• Maximum false alarm rejection capability.

• Maintains the capability to respond to a fire in the

presence of modulated blackbody radiation without

false alarm.

• Heated optics for increased resistance to moisture

and ice.

• Factory sealed device eliminates need for explosion-

proof conduit seal.

• One-hand oi plate removal for easy maintenance even

in the most difficult locations.

• Automatic and manual optical integrity (oi) testing.

• Fire and fault relays standard.

• Tricolor LED indicates normal operation, fire and fault

conditions.

• Factory available fire and fault relay operation:

latching/non-latching, energized/de-energized (fire

relay only), normally open/normally closed.

• 4 to 20 mA isolated output.

• Other mounting options include mounting directly onto

most junction boxes using a simple adapter, or the

use of a swivel union or swivel mount available from

Det-Tronics.

• Operates under adverse weather conditions and in

dirty environments.

• Flame-proof/increased safety detector housing.

Meets CENELEC and DNV certification requirements.

• Class A wiring per NFPA-72.

• Meets NFPA-33 response requirement for under 0.5

second (available when option selected).

• 5 year warranty.

SPECIFICATIONS

OPERATING VOLTAGE—

24 volts dc nominal (18 vdc minimum, 32 vdc

maximum).

POWER CONSUMPTION—

9.0 watts maximum.

POWER UP TIME—

Fault indication clears after 0.5 second; device is ready

to indicate an alarm condition after 30 seconds.

OUTPUT RELAYS—

Fire Alarm relay, Form C, 5 amperes at 30 vdc:

The Fire Alarm relay is factory configurable for

normally open or normally closed contacts, normally

energized or normally de-energized operation, and

latching or non-latching operation.

Fault relay, Form C, 5 amperes at 30 vdc:

The Fault relay is factory configurable for normally

open or normally closed contacts, normally

energized or normally de-energized operation, and

latching or non-latching operation.

CURRENT OUTPUT (Not available with relays)—

4 to 20 milliampere dc current, with a maximum loop

resistance of 500 ohms from 18 to 19.9 volts dc and 600

ohms from 20 to 32 volts dc.

TEMPERATURE RANGE—

Operating: –40°F to +158°F (–40°C to +70°C).

Storage: –67°F to +185°F (–55°C to +85°C).

HUMIDITY RANGE—

0 to 95% relative humidity, can withstand 100%

condensing humidity for short periods of time.

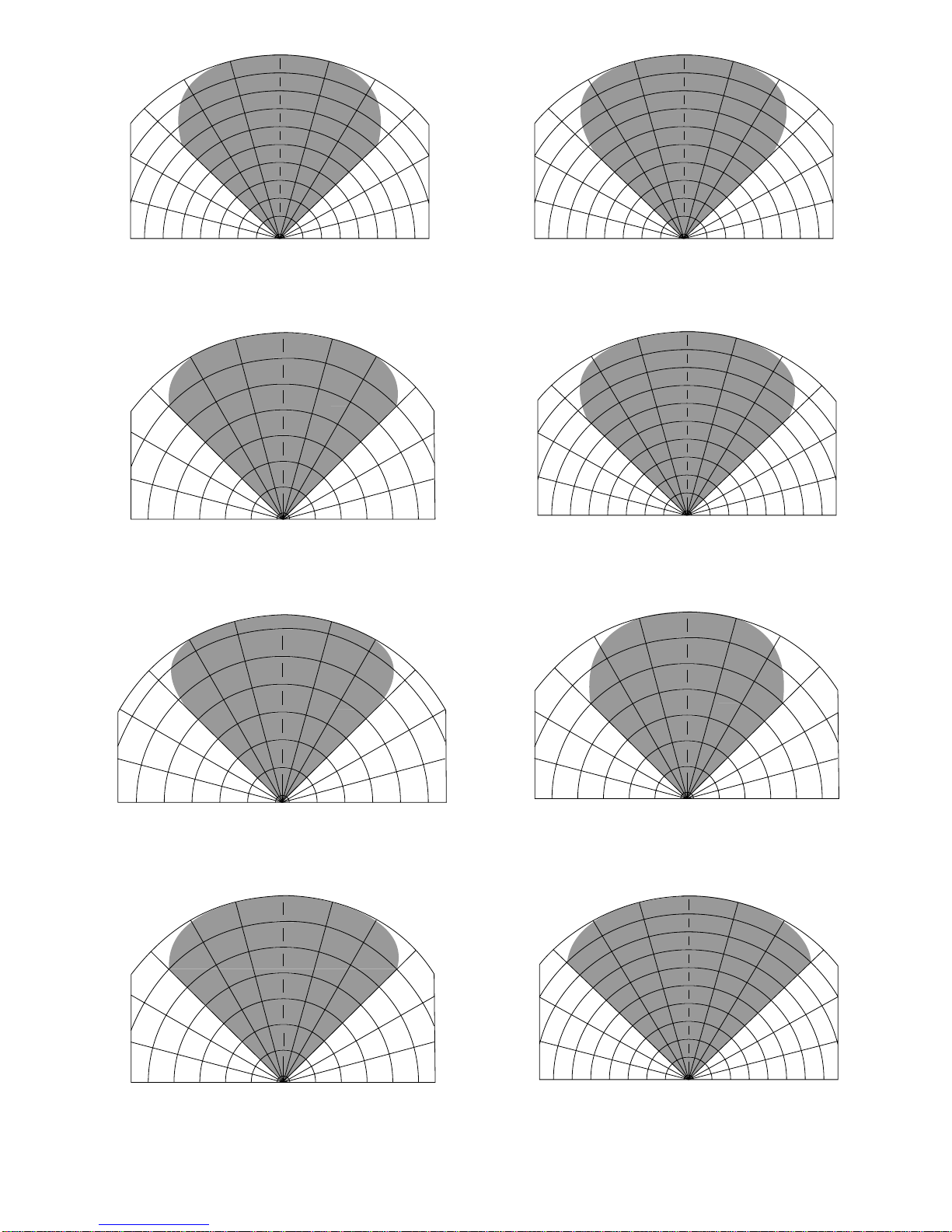

CONE OF VISION—

The detector has a 90° cone of vision (horizontal) with

the highest sensitivity lying along the central axis.

Unlike conventional detectors, the X3300 provides full

coverage at a minimum of 70% of the maximum

detection distance.

Perfect cone of vision for methane fire detection — 100

feet on and off axis. See Figures 9A to 9K.

RESPONSE TIME—

Can respond to fires in under 0.5 second at reduced

distances (50 feet). Response times at maximum

distance are typically under 10 seconds.

ENCLOSURE MATERIAL—

Aluminum (red-painted) or 316 stainless steel.

DIMENSIONS—

See Figure 10.

WIRING—

14 AWG (1.5 mm2) to 22 AWG (0.3 mm2) shielded

cable is recommended.

Important: 18 vdc minimum must be available at the

detector.

MOUNTING THREADS—

Two sizes available: 3/4 inch NPT or M25.

11 95-8502

SHIPPING WEIGHT (Approximate)—

Aluminum: 2.4 pounds (1.1 kilograms).

Stainless Steel: 4.8 pounds (2.2 kilograms).

CERTIFICATION—

CENELEC: EEx d e IIC T6

(T

amb

= –40°C to +60°C).

EEx d e IIC T5

(T

amb

= –40°C to +70°C).

IP66.

DNV: Compliance to DNV Certification Notes No. 2.4.

CE: Conforms to all relevant European norms.

NOTE

Operational performance verified from -40°C to

+70°C.

WARRANTY PERIOD—

5 years, sensor and electronics.

12

4.08 (103.6)

3.23 (82.04)

3.23 (82.04)

7.4 (188)

A1982

Figure 10—X3300 Dimensions in Inches (mm)

0°

15°

45°

15°

30°

30°

DETECTOR VERTICAL FIELD OF VIEW

WITH DETECTOR AT 45°FROM HORIZONTAL.

0°15°

15°

30°

45°

30°

45°

150

ft

150

ft

120

ft

120

ft

90

ft

90

ft

60

ft

60

ft

30

ft

210

ft

210

ft

180 ft

180

ft

Figure 9A—Field of View at Indicated Distance in Feet for Gasoline

at Very High Sensitivity

0°

15°

30°

45°

15°30°

45°

100 ft

90 ft

90 ft

80 ft

80 ft

50 ft

50 ft

40 ft

40 ft

30 ft

20 ft

10 ft

0°

15°

45°

15°

30°

30°

DETECTOR VERTICAL FIELD OF VIEW

WITH DETECTOR AT 45°FROM HORIZONTAL.

70 ft

70 ft

60 ft

60 ft

100 ft

30 ft

20 ft

10 ft

Figure 9B—Field of View at Indicated Distance in Feet for Methane

at Very High Sensitivity

13 95-8502

15°

30°

45°

15°30°

45°

150 ft

135 ft

120 ft

75 ft

60 ft

45 ft

30 ft

15 ft

105 ft

90 ft

Figure 9C—Field of View at Indicated Distance in Feet for

Methanol at Very High Sensitivity

0°15°

15°

30°

45°

30°

45°

150

ft

120

ft

90

ft

60

ft

30

ft

210

ft

180

ft

Figure 9E—Field of View at Indicated Distance in Feet for

JP-5 at Very High Sensitivity

15°

30°

45°

15°30°

45°

150 ft

135 ft

120 ft

75 ft

60 ft

45 ft

30 ft

15 ft

105 ft

90 ft

Figure 9D—Field of View at Indicated Distance in Feet for

Diesel at Very High Sensitivity

0°

15°

30°

45°

15°30°

45°

100 ft

90 ft

80 ft

50 ft

40 ft

30 ft

20 ft

10 ft

70 ft

60 ft

Figure 9F—Field of View at Indicated Distance in Feet for Gasoline

at Medium Sensitivity

0°15°

15°

30°

45°

30°

45°

50

ft

40

ft

30

ft

20

ft

10

ft

70

ft

60

ft

Figure 9J—Field of View at Indicated Distance in Feet for

Diesel at Medium Sensitivity

0°15°

15°

30°

45°

30°

45°

50

ft

40

ft

30

ft

20

ft

10

ft

65 ft

60

ft

Figure 9G—Field of View at Indicated Distance in Feet for Methane

at Medium Sensitivity

0°15°

15°

30°

45°

30°

45°

50

ft

40

ft

30

ft

20

ft

10

ft

70

ft

60

ft

Figure 9H—Field of View at Indicated Distance in Feet for

Methanol at Medium Sensitivity

0°

15°

30°

45°

15°30°

45°

100 ft

90 ft

80 ft

50 ft

40 ft

30 ft

20 ft

10 ft

70 ft

60 ft

Figure 9K—Field of View at Indicated Distance in Feet for

JP-5 at Medium Sensitivity

REPLACEMENT PARTS

The detector is not designed to be repaired in the field.

If a problem should develop, refer to the

Troubleshooting section. If it is determined that the

problem is caused by an electronic defect, the device

must be returned to the factory for repair.

DEVICE REPAIR AND RETURN

Prior to returning devices, contact the nearest local

Detector Electronics office so that a Service Order

number can be assigned. A written statement

describing the malfunction must accompany the

returned device or component to expedite finding the

cause of the failure.

Pack the unit properly. Use sufficient packing material

in addition to an antistatic bag or aluminum-backed

cardboard as protection from electrostatic discharge.

Return all equipment transportation prepaid to the

factory in Minneapolis.

NOTE

Since the entire unit must be returned to the

factory for repair, it is highly recommended that a

complete spare be kept on hand for field

replacement to ensure continuous protection.

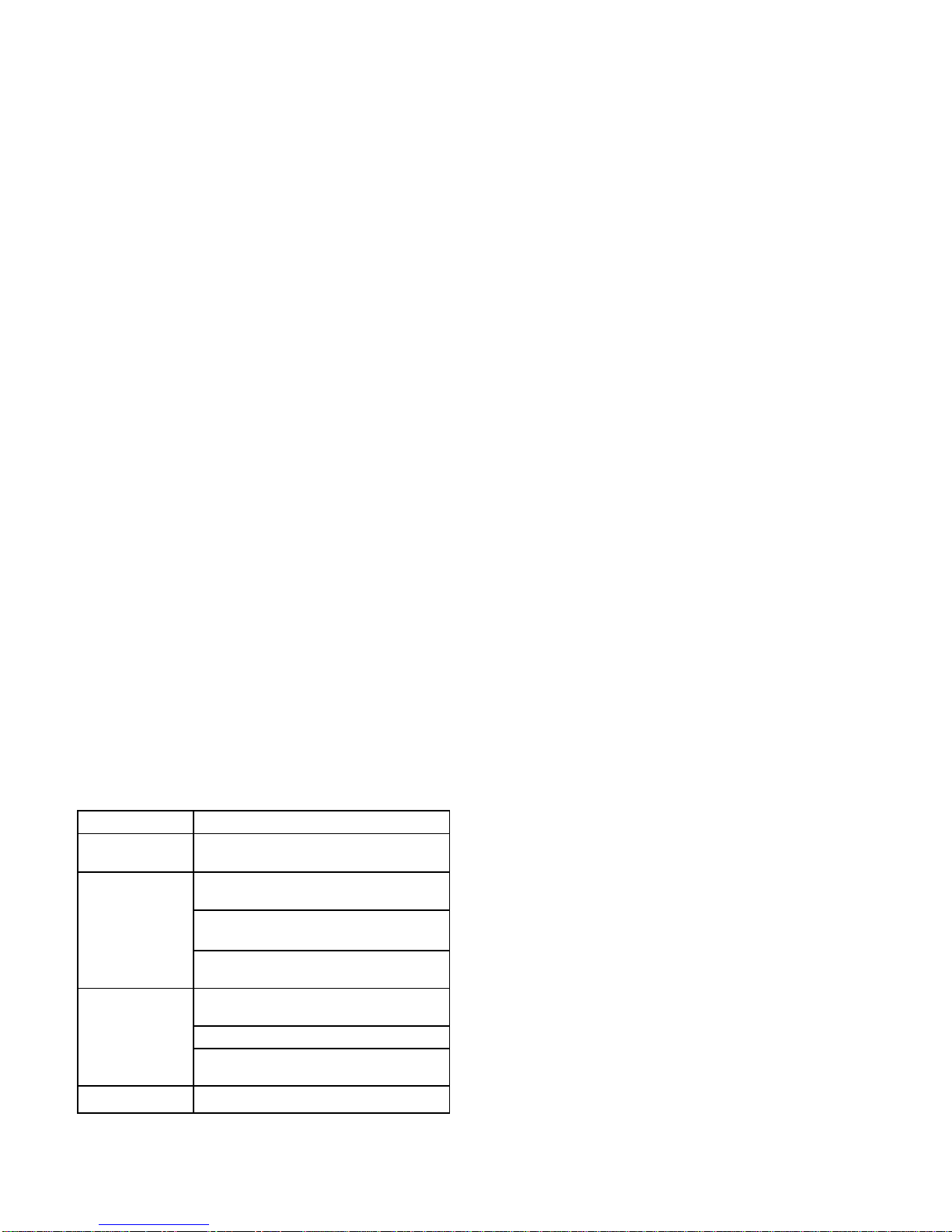

ORDERING INFORMATION

When ordering, refer to Table 5, Ordering Factory

Configuration. For further information on the function of

each configuration option, refer to Table 2.

ACCESSORIES

Q9003 Swivel Mount Assembly is recommended for

mounting the detector when using flexible electrical

conduit.

REPLACEMENT PARTS

Part Number Description

001680-001 Window cleaner squeeze bottle

(package of six bottles)

006918-001 oi plate

107427-049 O-ring

400525-006 Bolts (2)

005143-001 Silicone-free grease

For assistance in ordering a system to fit your

application, please contact:

Detector Electronics Corporation

6901 West 110th Street

Minneapolis, Minnesota 55438 USA

Operator: (952) 941-5665 or (800) 765-FIRE

Customer Service: (952) 946-6491

Fax: (952) 829-8750

Web site: www.detronics.com

E-mail: [email protected]

14

Table 5—Ordering Factory Configuration Options

Option Available Configurations

Optical Integrity (oi) * Automatic oi/manual oi

•Manual oi (only)

Fire Relay •Latching

* Non-latching

•Normally Energized

* Normally De-Energized

* Normally Open

•Normally Closed

Fault Relay •Latching

* Non-latching

* Normally Energized

* Normally Open

•Normally Closed

4 to 20 mA Output •With Fire and Fault Relay

* Standard Configuration

15 95-8502

APPENDIX A

Response Characteristics of the X3300

RESPONSE CHARACTERISTICS:

Fuel Size Distance Average Response Time

(feet) (seconds)

Gasoline 1 x 1 foot 100 6.0

Gasoline 1 x 1 foot 50 3.8

Diesel** 1 x 1 foot 70 7.4

Methanol 1 x 1 foot 70 9.7

Methane 30 inch plume 65 2.4

Methane 30 inch plume 55 0.8

JP-5** 2 x 2 foot 100 5.7

** 10 second pre-burn from ignition.

Medium Sensitivity

Fuel Size Distance Average Response Time

(feet) (seconds)

Gasoline 1 x 1 foot 210* 8.4

Gasoline 1 x 1 foot 100 1.4

Diesel** 1 x 1 foot 150* 9.6

Methanol 1 x 1 foot 150* 5.7

Methane 30 inch plume 100 2.5

JP-5** 2 x 2 foot 210* 8.5

JP-5** 2 x 2 foot 100 2.6

Office 18” x 16” x 10” 100 4.5

Paper 0.5 lb.

Corrugated

18” x 36” 100 15.8

Panel

* Outdoor test condition.

** 10 second pre-burn from ignition.

Very High Sensitivity

16

X3300 Response Characteristics (0.5 Sec. Response Only)

Medium Sensitivity

Fuel Size Distance Ave. Response Time, Sec.

Ft. (M) On Axis (0°) Off Axis (45°)

Methanol Atomized Fuel Fire 50 .39 .40

10 CC Per Sec. (15)

Isopropanol Atomized Fuel Fire 50 .39 .40

10 CC Per Sec. (15)

Acetone Atomized Fuel Fire 50 .36 .38

10 CC Per Sec. (15)

Heptane Atomized Fuel Fire 50 .39 .40

10 CC Per Sec. (15)

RESPONSE CHARACTERISTICS —AUTOMOTIVE APPLICATIONS:

X3300 Response Characteristics

Medium Sensitivity

Fuel Size Distance Ave. Response Time, Sec.

Ft. (M) On Axis (0°) Off Axis (45°)

Methanol 36 Sq. In. 20 6.9 9.9

(0.023 Sq. M.) (6)

Isopropanol 36 Sq. In. 35 3.3 7.3

(0.023 Sq. M.) (10.5)

Heptane 36 Sq. In. 40 2.6 8.6

(0.023 Sq. M.) (12)

NOTE: Atomized fuel fires of methanol, isopropanol, acetone and heptane

are detectable within 0.5 second at a distance of 50 feet. Fuel

flow rate equals 10 cc per second.

OPTICAL FAULT:

The detector generated an optical fault in the presence of contamination on any single or combination of lens

surfaces verifying that the detector performs an optical integrity (oi) test for each sensor. Upon removal of the

contaminant the detector fault was cleared and the detector was verified to detect a fire.

RESPONSE CHARACTERISTICS IN THE PRESENCE OF FALSE ALARM SOURCES:

17 95-8502

False Alarm Source Distance Fire Source Distance Average Response Time

(feet) (feet) (seconds)

Sunlight, direct, modulated, reflected — 6-inch propane 6 < 4

Vibration N/A 6-inch propane 6 < 10

Radio frequency interference 1 6-inch propane 12 < 1

Arc welding 40 1 x 1 foot gasoline 40 3.1

6 kw heater, modulated 100 1 x 1 foot gasoline 100 1.9

6 kw heater, modulated 10 1 x 1 foot gasoline 100 5.3

250 w vapor lamp, modulated 3 1 x 1 foot gasoline 100 2.7

300 w incandescent lamp, modulated 3 1 x 1 foot gasoline 100 3.6

500 w unshielded quartz halogen lamp, modulated 8 1 x 1 foot gasoline 100 2.7

1500 w electric radiant heater, modulated 10 1 x 1 foot gasoline 100 4.2

Two 34 w florescent lamps, modulated 3 1 x 1 foot gasoline 100 1.7

Very High Sensitivity

False Alarm Source Distance Fire Source Distance Average Response Time

(feet) (feet) (seconds)

Sunlight, direct, modulated, reflected — 6-inch propane 6 < 4

Vibration* N/A 6-inch propane 6 < 10

Radio frequency interference 1 6-inch propane 6 < 1

Arc welding 10 1 x 1 foot gasoline 10 0.2

6 kw heater, modulated 100 1 x 1 foot gasoline 100 5.0

6 kw heater, modulated 10 1 x 1 foot gasoline 100 10.7

250 w vapor lamp, modulated 3 1 x 1 foot gasoline 100 7.1

300 w incandescent lamp, modulated 3 1 x 1 foot gasoline 100 9.6

500 w unshielded quartz halogen lamp, modulated 8 1 x 1 foot gasoline 100 6.3

1500 w electric radiant heater, modulated 10 1 x 1 foot gasoline 90 6.4

Two 34 w florescent lamps, modulated 3 1 x 1 foot gasoline 100 4.6

Medium Sensitivity

* Fire was verified with very high sensitivity only.

18

FALSE ALARM IMMUNITY:

False Alarm Source Distance Modulated Response Un-modulated Response

(feet)

Sunlight, direct, modulated, reflected — No alarm No alarm

Vibration N/A No alarm N/A

Radio frequency interference 1 No alarm (keyed) No alarm (steady)

Arc welding 40 No alarm No alarm

6 kw heater, modulated 3 No alarm No alarm

250 w vapor lamp, modulated 3 No alarm No alarm

300 w incandescent lamp, modulated 3 No alarm No alarm

500 w unshielded quartz halogen lamp, modulated 8 No alarm No alarm

1500 w electric radiant heater, modulated 3 No alarm No alarm

Two 34 w florescent lamps, modulated 3 No alarm No alarm

Very High Sensitivity

False Alarm Source Distance Modulated Response Un-modulated Response

(feet)

Sunlight, direct, modulated, reflected — No alarm No alarm

Vibration N/A No alarm N/A

Radio frequency interference 1 No alarm (keyed) No alarm (steady)

Arc welding 10 No alarm No alarm

6 kw heater, modulated 3 No alarm No alarm

250 w vapor lamp, modulated 3 No alarm No alarm

300 w incandescent lamp, modulated 3 No alarm No alarm

500 w unshielded quartz halogen lamp, modulated 8 No alarm No alarm

1500 w electric radiant heater, modulated 3 No alarm No alarm

Two 34 w florescent lamps, modulated 3 No alarm No alarm

Medium Sensitivity

19 95-8502

FIELD OF VIEW:

Fuel Size Distance Horizontal Avg. Horiz. Response Time Vertical Avg. Vert. Response Time

(feet) (degrees) (seconds) (degrees) (seconds)

Gasoline 1 x 1 foot 150 +45 11.9 +45 8.5

–45 9.5 –30 6.0

Gasoline 1 x 1 foot 100 +45 3.5 +45 4.2

–45 4.0 –30 3.2

Diesel** 1 x 1 foot 100 +45 2.2 +45 2.1

–45 4.4 –30 2.8

Methanol 1 x 1 foot 110 +45 8.5 +45 9.5

–45 9.2 –30 4.3

Methane 30 inch plume 100 +45 1.9 +45 3.5

–45 4.3 –30 2.0

JP-5** 2 x 2 feet 180* +45 13.3 +45 10.4

–45 17.3 –30 5.0

JP-5** 2 x 2 feet 90 +45 2.9 +45 1.4

–45 4.1 –30 2.5

Office 18” x 16” x 10” 80 +45 6.4 +45 8.2

Paper 0.5 lb.

–45 9.8 –30 6.0

Corrugated

18” x 36” 80 +45 15.6 +45 14.7

Panel –45 12.2 –30 10.6

Very High Sensitivity

Fuel Size Distance Horizontal Avg. Horiz. Response Time Vertical Avg. Vert. Response Time

(feet) (degrees) (seconds) (degrees) (seconds)

Gasoline 1 x 1 foot 75 +45 9.5 +45 6.4

–45 9.5 –30 5.4

Gasoline 1 x 1 foot 50 +45 3.8 +45 4.1

–45 3.8 –30 3.1

Diesel** 1 x 1 foot 60 +45 4.5 +45 5.5

–45 6.8 –30 2.1

Methanol 1 x 1 foot 45 +45 9.0 +45 9.8

–45 9.7 –30 6.6

Methane 30 inch plume 45 +45 4.4 +45 2.0

–45 0.9 –30 0.5

Methane 30 inch plume 40 +45 1.7 +45 3.4

–45 0.4 –30 1.4

JP-5** 2 x 2 feet 90 +45 2.9 +45 3.4

–45 8.1 –30 2.5

Medium Sensitivity

* Outdoor test condition.

** 10 second flame pre-burn from ignition.

Other manuals for X3300

1

Table of contents

Other Det-Tronics Smoke Alarm manuals