595-8723

3.5

IMPORTANT SAFETY NOTES

CAUTION

The wiring procedures in this manual are

intended to ensure proper functioning of the

device under normal conditions. However,

because of the many variations in wiring

codes and regulations, total compliance to

these ordinances cannot be guaranteed.

Be certain that all wiring complies with the

NEC as well as all local codes. If in doubt,

consult the authority having jurisdiction

before wiring the system. Installation must

be done by a properly trained person.

CAUTION

This product has been tested and approved

for use in hazardous areas. However, it must

be properly installed and used only under the

conditions specied within this manual and

the specic approval certicates. Any device

modication, improper installation, or use in a

faulty or incomplete conguration will render

warranty and product certications invalid.

CAUTION

The device contains no user serviceable

components. Service or repair should never be

attempted by the user. Device repair should be

performed only by the manufacturer.

CAUTION

The U5015 is to be installed in locations

where the risk of mechanical damage is low.

LIABILITIES

The manufacturer’s warranty for this product

is void, and all liability for proper function

of the detector is irrevocably transferred to

the owner or operator in the event that the

device is serviced or repaired by personnel

not employed or authorized by Detector

Electronics Corporation, or if the device is used

in a manner not conforming to its intended use.

NOTE

Observe precautions for handling

electrostatic sensitive devices.

NOTE

The U5015 should not be installed in areas

in which ammonia, hydrogen sulfide and

chlorine are normally present.

INSTALLATION

WARNING

All entries must contain appropriately rated

plugs or fittings. It is required that each

plug or fitting be wrench-tightened to an

appropriate installation torque and meet the

minimum thread engagement requirements

per the applicable local standards, codes,

and practices in order to retain the dened

ratings. PTFE sealant or equivalent should

be used on NPT threads.

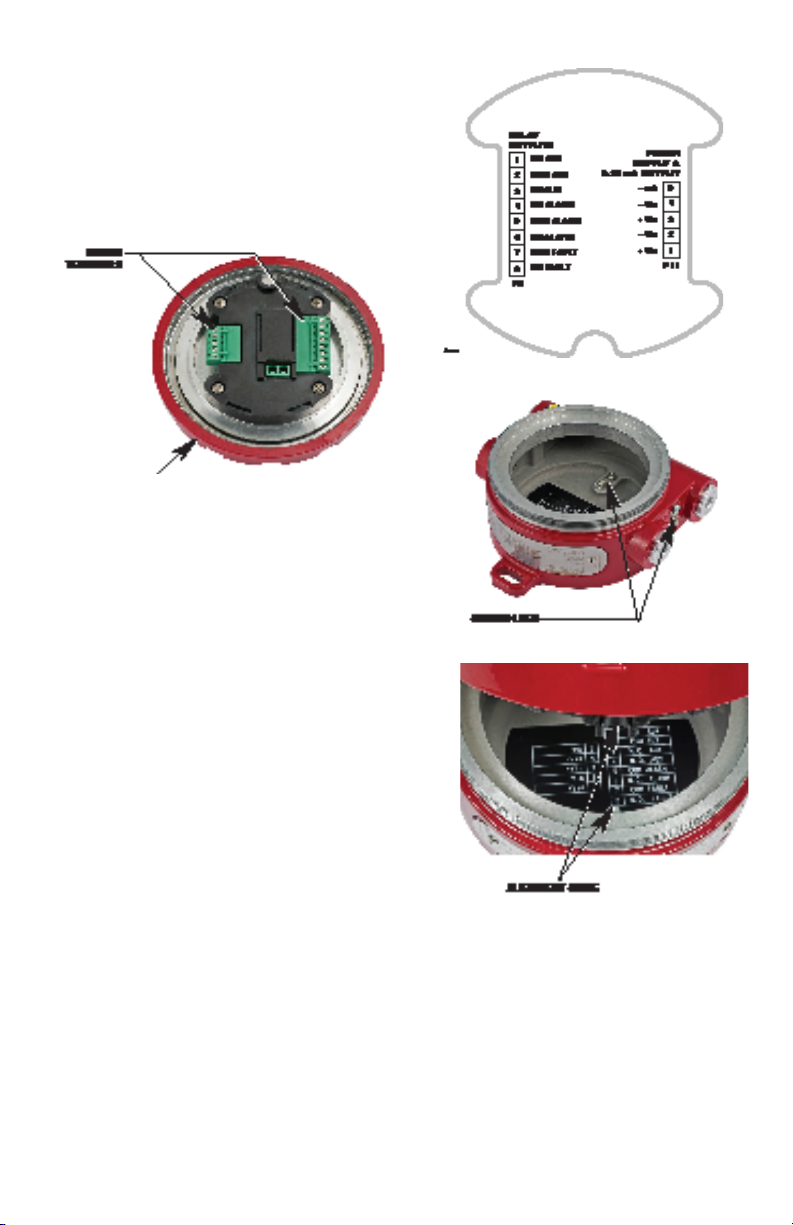

NOTE

Detector housings must be electrically

connected to earth ground. Internal

and external earth ground terminals are

provided. For AEx (United States Zone)

installations the internal ground terminal

shall be used for the equipment grounding

connection. The external terminal can be

used for supplementary bonding where

local codes permit or require.

NOTE

The U5015 detector uses an internal

Intrinsically Safe (I.S.) Barrier. Proper NEC

I.S. grounding must be ensured.

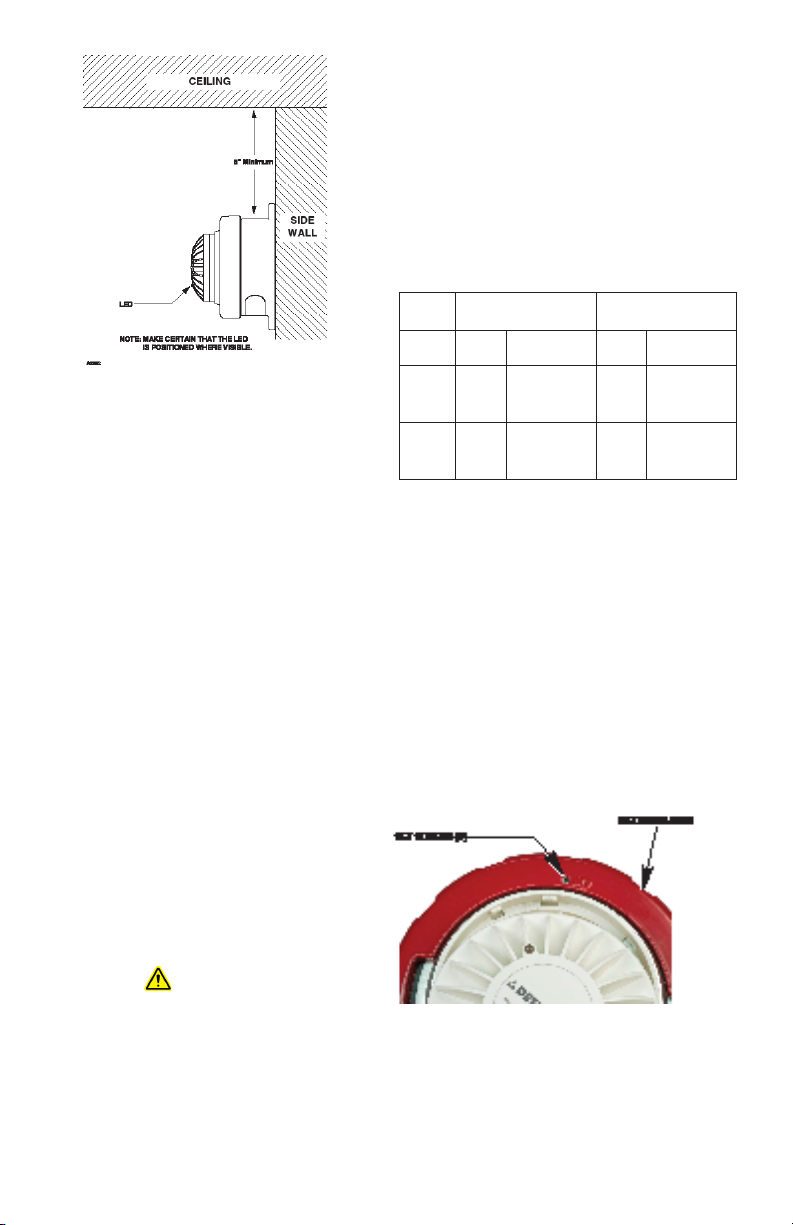

GREASE/LUBRICATION

To ease installation and future removal, all

threaded covers, stopping plugs, and thread

adapters must be installed using thread lubricant.

The recommended lubricant is a silicone-free

grease, available from Det-Tronics.

For devices with NPT threads, Teflon tape or

thread seal lubricant must be used for enhanced

sealing capabilities.

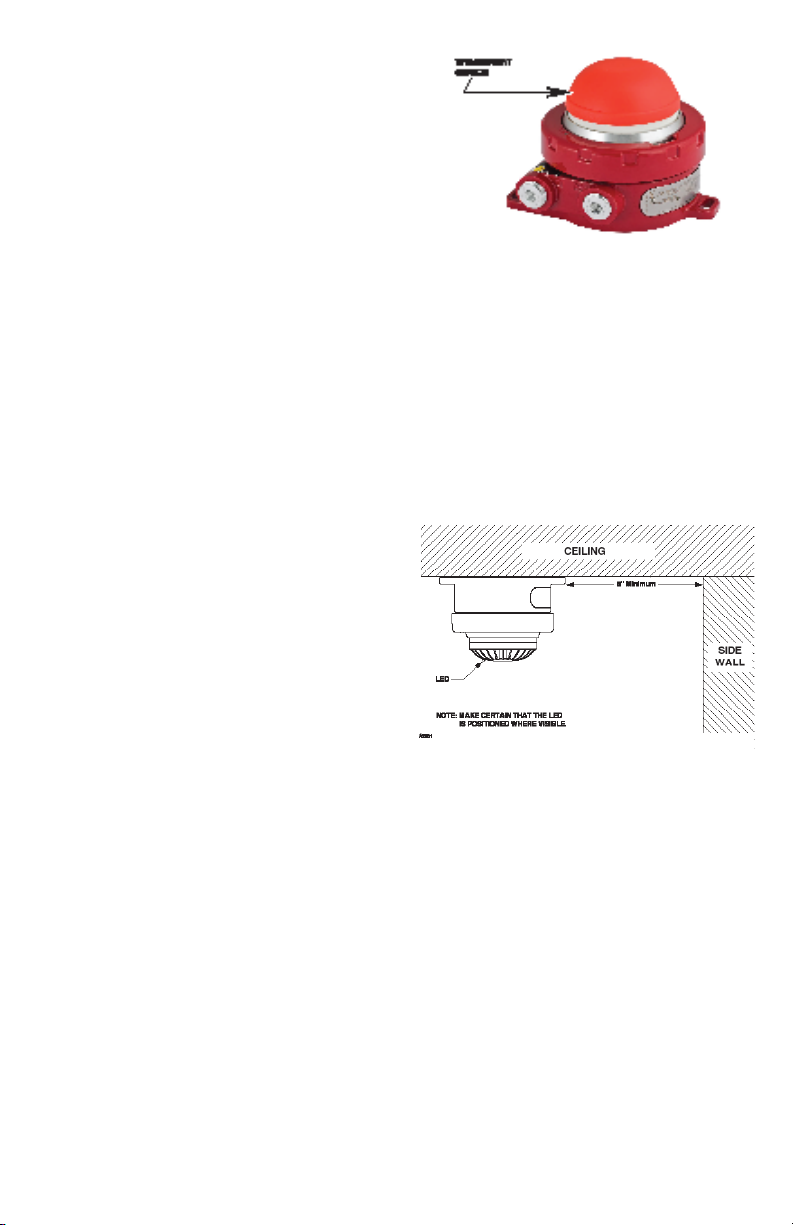

IDENTIFICATION OF DETECTOR MOUNTING

LOCATIONS

The most effective number and placement of

detectors varies depending on the conditions on

site. The individual designing the installation must

often rely on experience and sound judgment to

determine the detector quantity and best locations

to adequately protect the area. Note that it is

typically advantageous to locate detectors where

they are accessible for maintenance.

For additional information on detector location

and spacing, visit the National Fire Protection

Association's website (www.nfpa.org) and refer to

the National Fire Alarm and Signaling Code, NFPA

72, the standard on automatic fire detectors, or

your local codes and standards.